Rapid steam turbine coupling bolt disassembling tool and using method

A steam turbine and wheel bolt technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of small gap spacing, high technical requirements of construction personnel, and many precision thermal control measuring probes, etc. The effect of shortening dismantling steps and improving dismantling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0027] It is worth noting that the orientation words such as "up" and "down" involved in this article are all determined relative to the perspective of the drawings, and are only for the convenience of description, and cannot be understood as limitations on the technical solution.

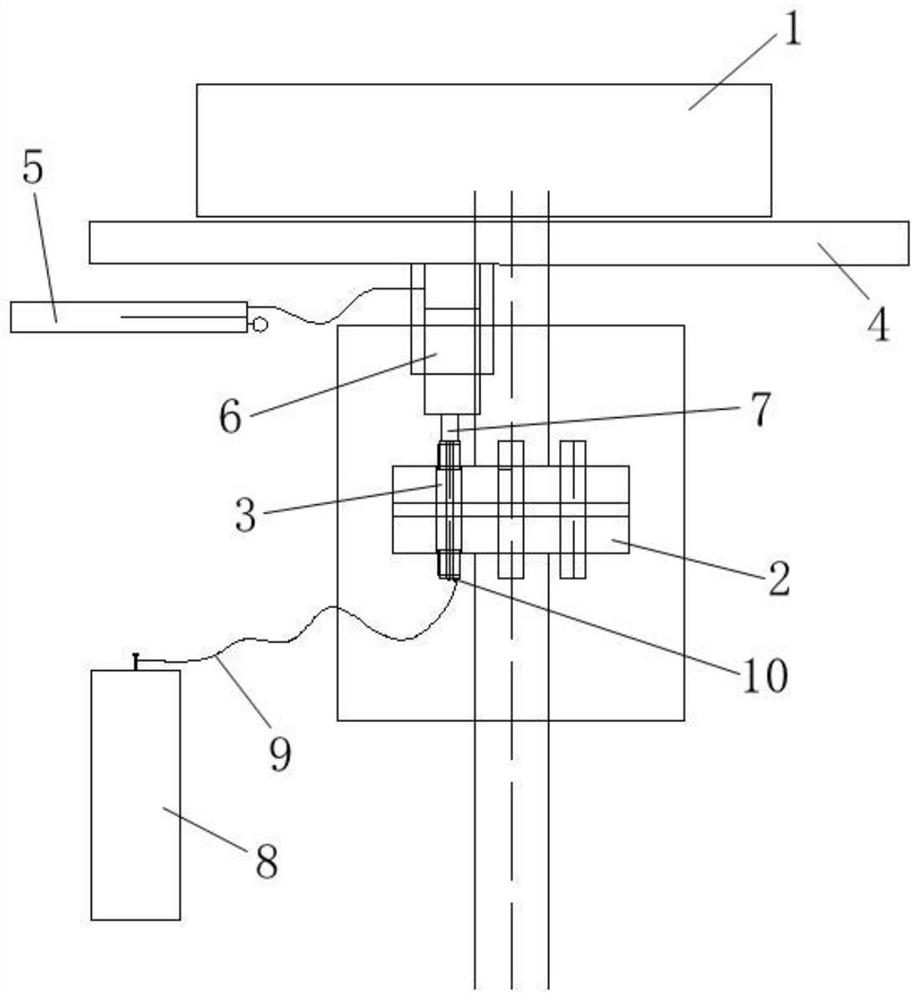

[0028] Such as figure 1 As shown, the present invention provides a fast steam turbine counter-wheel bolt dismantling tool, including a ejection mechanism and a cooling mechanism. The ejection mechanism is arranged between the counter-wheel 2 and the steam turbine 1, and the ejection mechanism and the counter-wheel One end of the pin bolt 3 of 2 is in contact; the cooling device is in contact with the other end of the pin bolt 3 .

[0029] The steam turbine 1 has been in a high-speed rotation state of 3000r / min for a long time during operation. In order to transmit the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com