An electronic device pick-up tooling

A technology for electronic devices and tooling, applied in the field of electronic device pick-up and tooling, can solve the problems of wasting labor, low efficiency, and increase production costs of enterprises, and achieve the effects of convenient use, improved production efficiency, and reduced labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

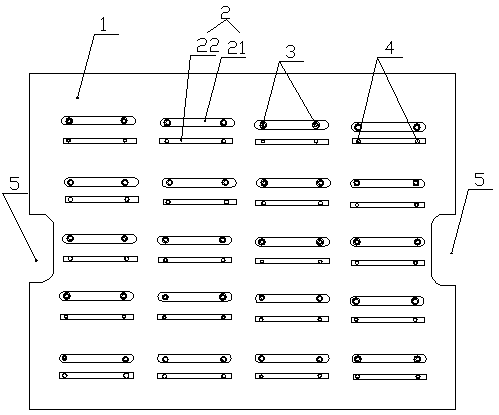

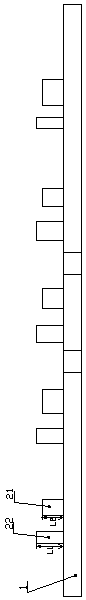

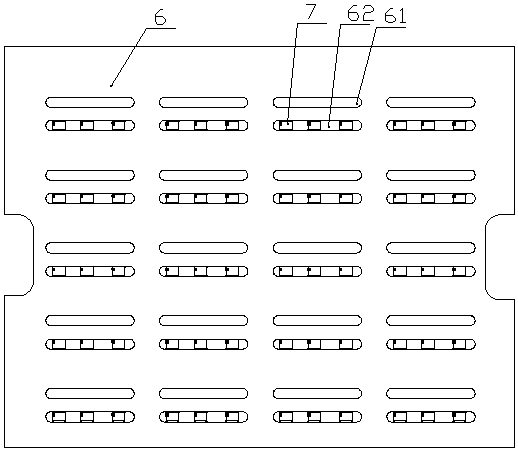

[0017] A pick-up tool for electronic devices, which includes a board body 1, on which a take-out part 2 is arranged, and the number of the take-out parts 2 is 20; There are 5 rows, and each row is horizontally distributed with 4 take-out parts 2; The fixed protrusion 21 is a strip-shaped protrusion, and its two ends are arc-shaped structures. The fixed protrusion 21 is provided with a fixed screw hole 3, and the fixed protrusion 31 is fixed on the fixed screw hole 3 and a bolt. on the board body 1; the device ejection portion 22 has a cuboid structure, and the height L1 of the device ejection portion 22 is higher than the height L2 of the fixed raised portion 21; the device ejection portion 22 is provided with a positioning Screw hole 4, the device ejection part 22 realizes the connection with the plate body 1 through the positioning screw hole 4 and the bolt; the two sides of the plate body 1 are provided with positioning grooves 5, and the positioning grooves 5 are left and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com