Spray pipe for ejector, ejection unit and air ejector

A technology of ejectors and nozzles, applied in the field of wind tunnels, can solve the problems of difficult popularization and application of differential ejectors, energy loss of the ejected airflow, difficulty in design and processing, etc., and achieve easy installation and debugging, and low processing difficulty , overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

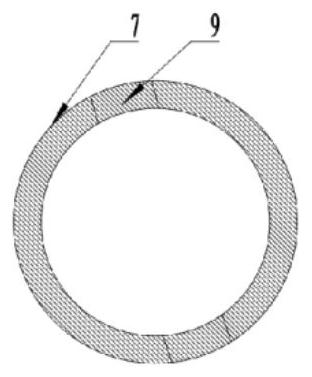

[0063] This embodiment provides a nozzle for the ejector, such as figure 2 , 3A with Figure 3B As shown in , the nozzle 3 is trumpet-shaped, including a large-diameter end and a small-diameter end, and at the large-diameter end of the nozzle 3, a connecting plate 14 is integrally formed along the circumference of the nozzle 3;

[0064] In the tube wall of the nozzle 3, an annular airflow chamber 17 is provided along the circumference of the nozzle 3, and the side of the annular airflow chamber 17 toward the small diameter end is provided with an annular opening, corresponding to the annular airflow chamber 17, and the opening The axial section includes a throat section 19 and an expansion section 18 connected in sequence. The throat section 19 is connected to the annular air flow chamber 17. The expansion section 18 is wedge-shaped, and its tip is connected to the throat section 19, and the other end extends to the end surface of the small diameter end. ;

[0065] On the ...

Embodiment 2

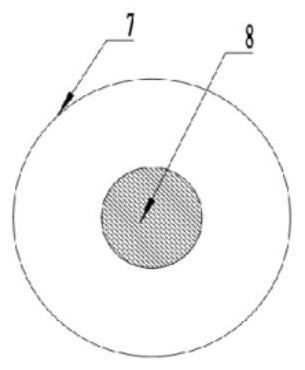

[0071] This embodiment provides an injection unit, such as Figure 3A with Figure 3B Shown, comprise the nozzle pipe 3 that is used for ejector in sleeve 4 and embodiment 1, one end of sleeve 4 is sleeved on nozzle pipe 3 by the small diameter end of nozzle pipe 3 and with the large diameter end of nozzle pipe 3 The connecting plate 14 is connected by a flange and a sealing gasket, the end surface of the small diameter end of the nozzle 3 is located in the sleeve 4, and the area distribution ratio of the two sides of the small diameter end of the nozzle 3 is F, F=1:1.

[0072] The ejector unit of this embodiment can make the ejected air flow sprayed into the sleeve from the small-diameter end of the nozzle pipe, the ejected air flow flows through the nozzle pipe and the air hole, and is ejected by the ejected air flow, and the ejected air flow contacts Large area, high mixing efficiency, and small airflow pressure loss.

Embodiment 3

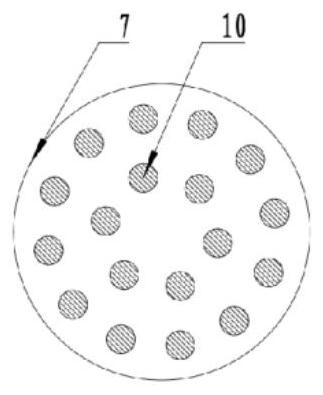

[0074] This embodiment discloses an air injector, such as figure 2 As shown, it includes an intake pipe 1, a mixing chamber, and a diffuser pipe 5 connected in sequence, wherein the mixing chamber includes five injection units in Embodiment 2, and the five injection units are coaxially connected in series, and each injection unit The small-diameter ends of the nozzle pipes 3 are all facing the diffuser pipe 5, and the sleeve 4 of the upstream injection unit is connected to the connecting plate 14 of the large-diameter end of the nozzle pipe 3 of the downstream injection unit through a flange 6 and a sealing ring. ;

[0075] The front end of the intake pipe 1 is used to connect the supersonic diffuser, where the supersonic airflow has been decelerated and pressurized to a subsonic state, and the intake pipe accepts the subsonic airflow, which is the ejected airflow; the rear end of the intake pipe passes through the flange and The sealing ring is connected to the connecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com