Patents

Literature

62results about How to "Improve marking quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

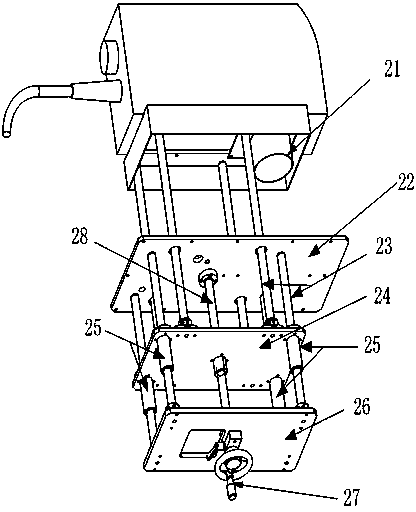

Automatic marking production line of bearing

InactiveCN1712221AReduce labor intensityStrong reliabilityRotary pressesProduction lineManufacturing engineering

An automatic marking production line for bearings is composed of an automatic feeder consisting of feeding tray and automatic single bearing feeder, a marking unit consisting of control panel, bearing driving cylinder, bearing track, bearing cleaner, marking unit, template and template locator, and an automatic collecting unit consisting of bearing driving unit, control panel and bearing collector.

Owner:鞍山市庆隆机电有限公司

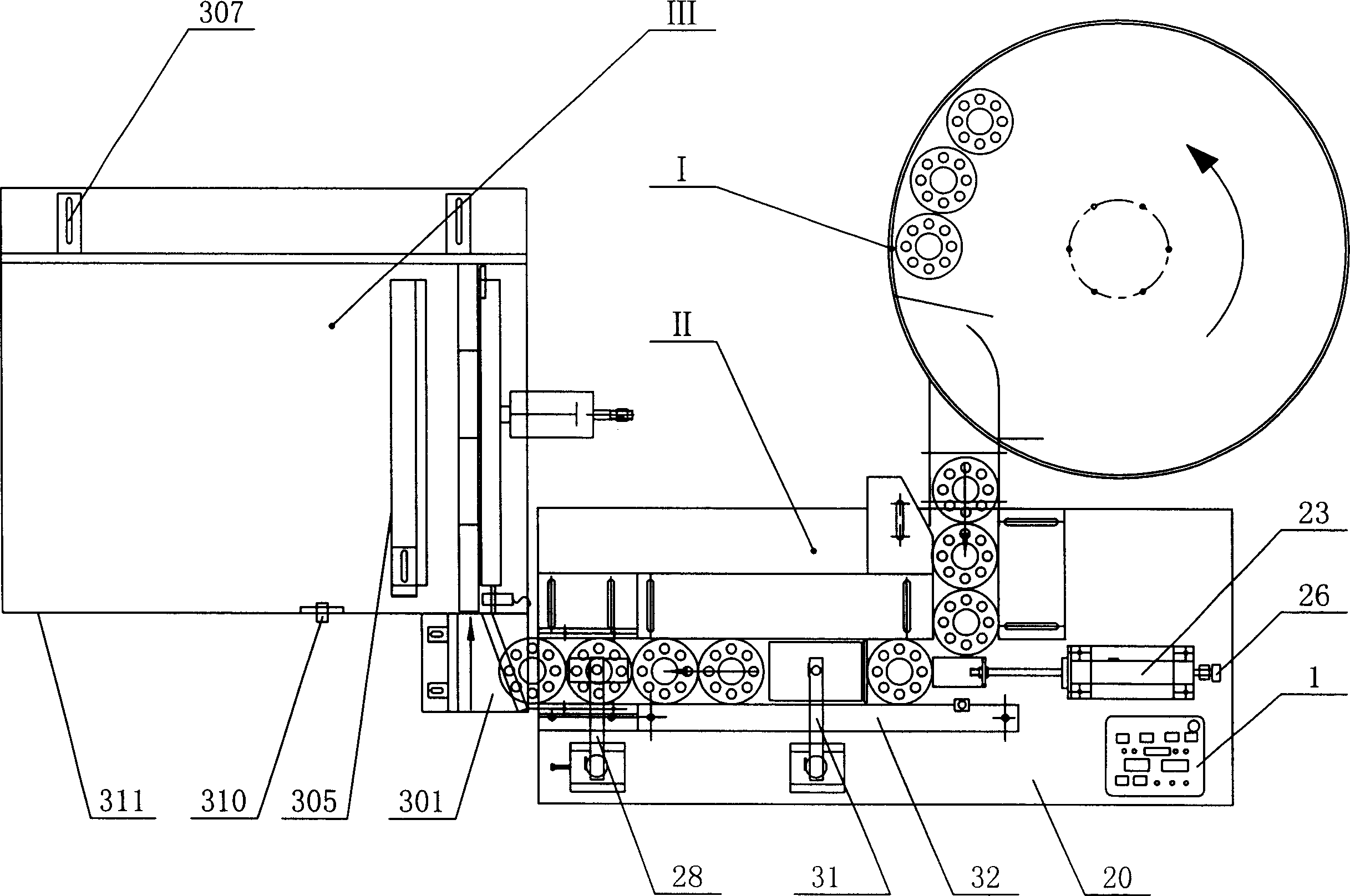

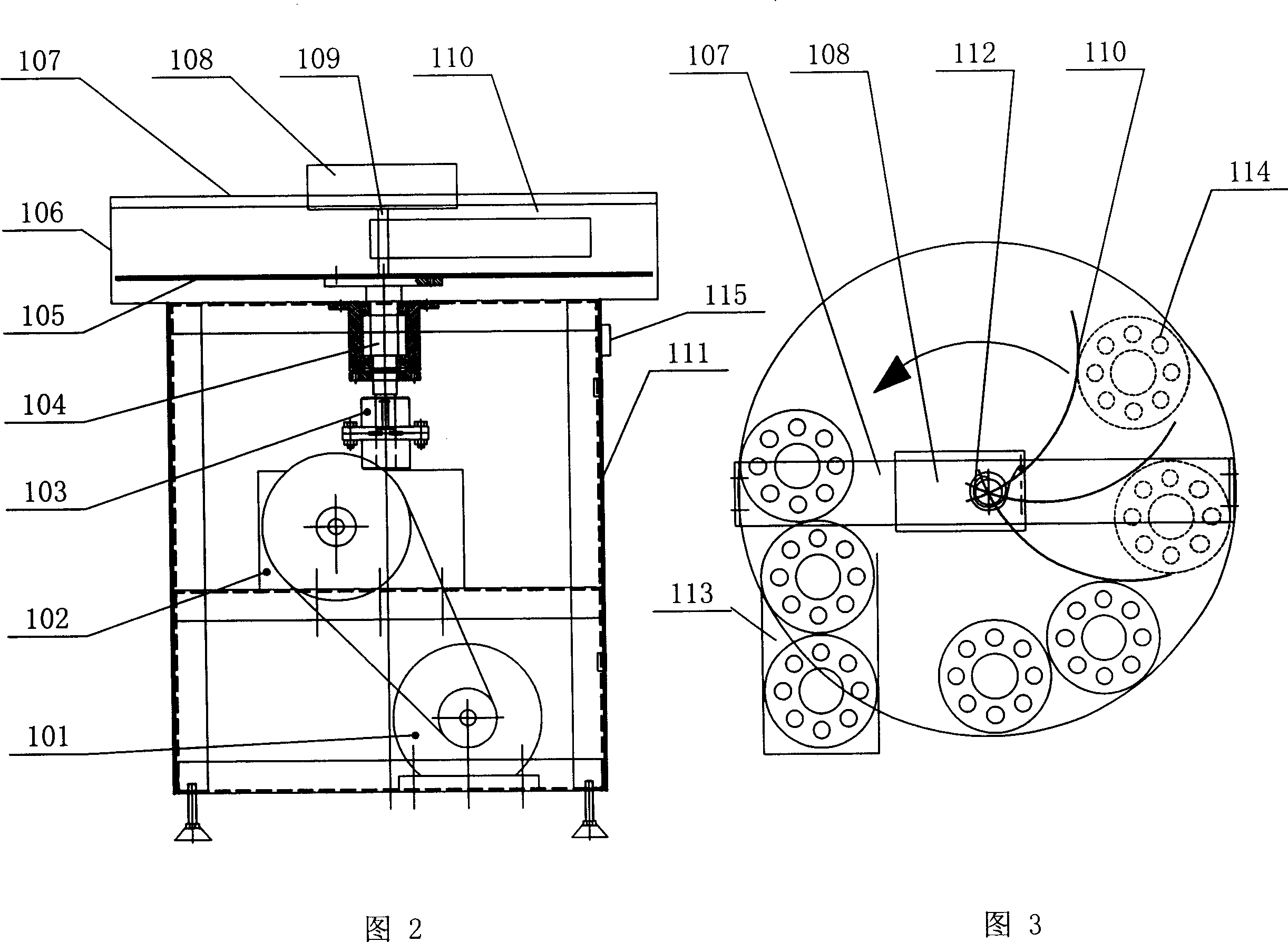

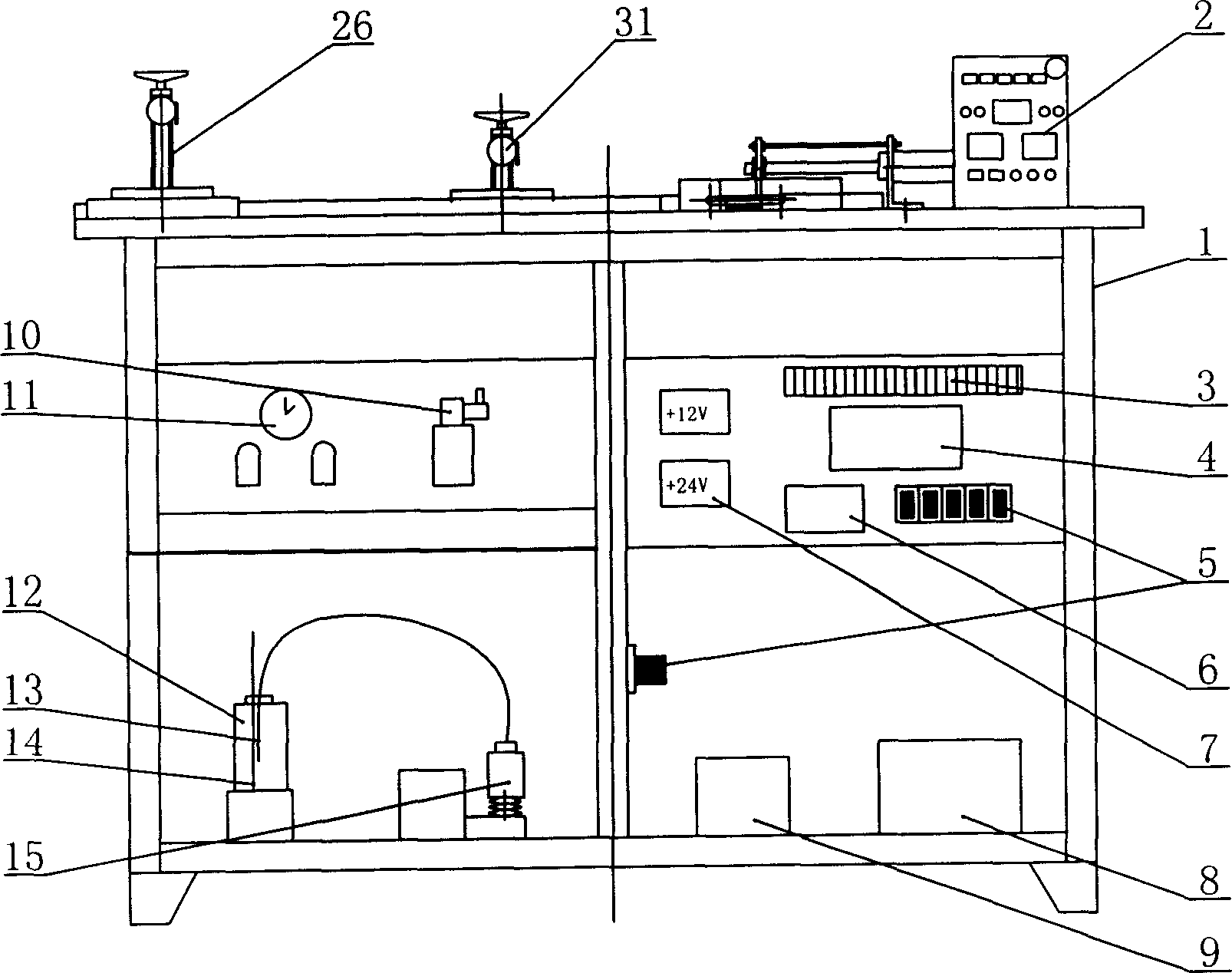

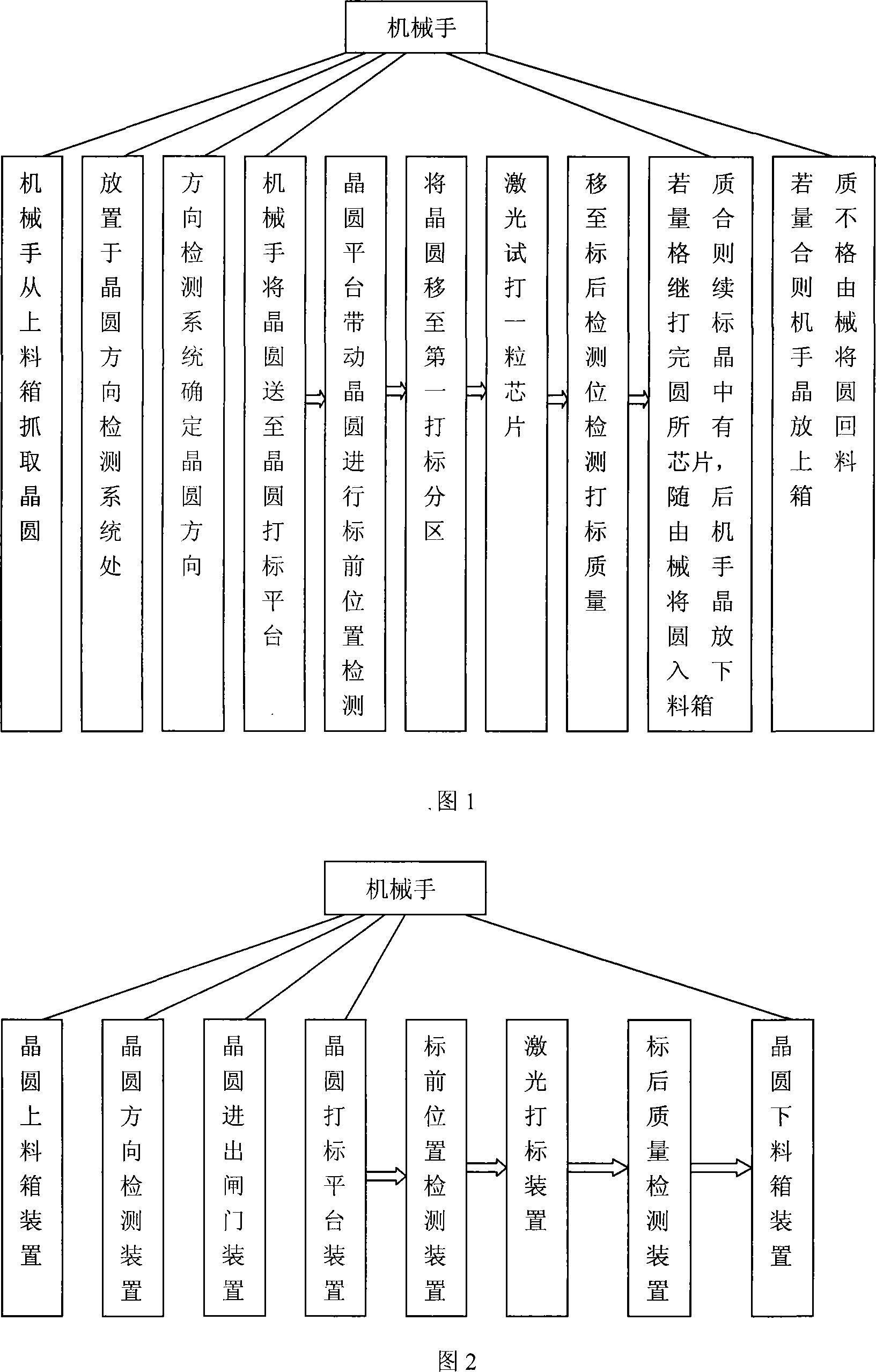

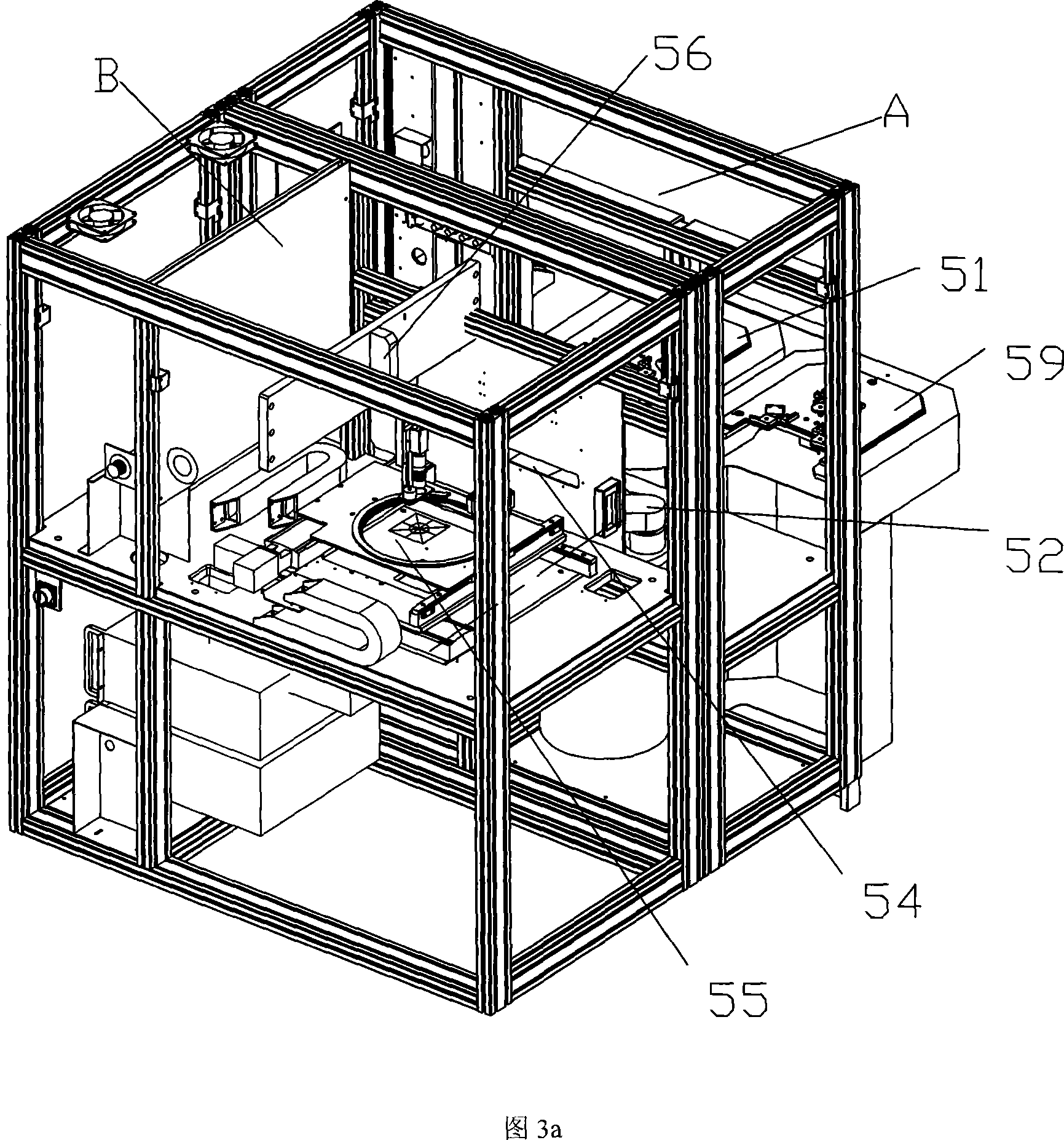

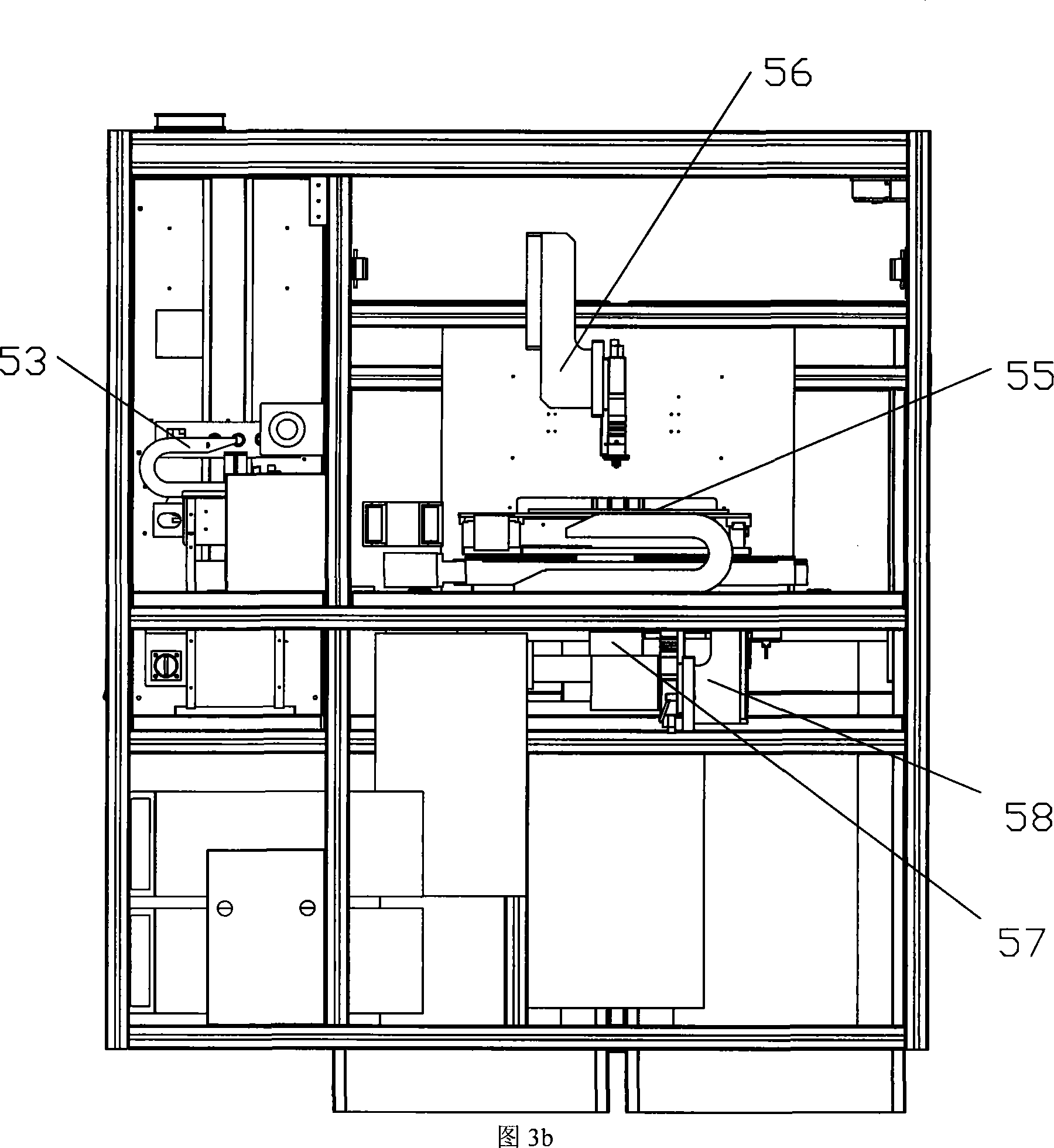

Full-automatic wafer rear marking machine

InactiveCN101097848AWill not deformMeet deformationSemiconductor/solid-state device manufacturingConveyor partsEngineeringManipulator

The invention relates to a novel device for marking IC crystal, in particular to a full-automatic crystal back marking machine, which uses a mechanical hand to take out crystal from a material feeding box to be sent to a crystal direction checker, a crystal marking platform or the like, to be marked and checked to be taken off by a mechanical hand to be put into a material outputting box. The invention is composed of a front area and a back area, wherein the front area is arranged with an electric controller and a PC, a baffle plate is arranged between the front and back areas, the baffle plate is arranged with a gate entrance, the outer side of the front area is arranged with a material feeding box and a material discharging device, the front area is arranged with a mechanical hand and a crystal direction checker inside, the back area is arranged with a crystal marking platform inside, the marking platform is respectively arranged with a before-marking checker and an after-marking checker above and under.

Owner:GRAND TECH SHENZHEN

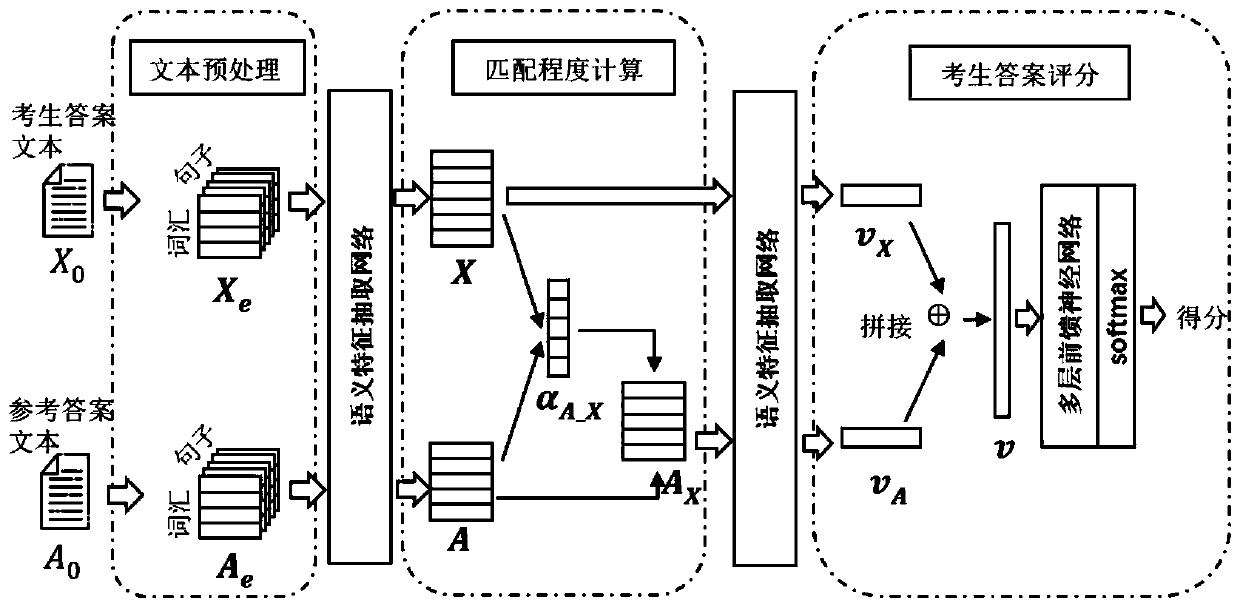

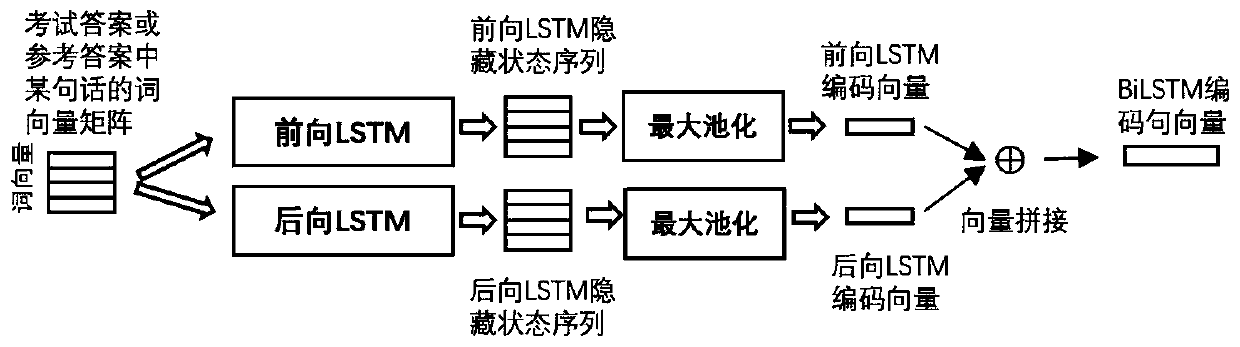

Intelligent paper marking method for subjective questions

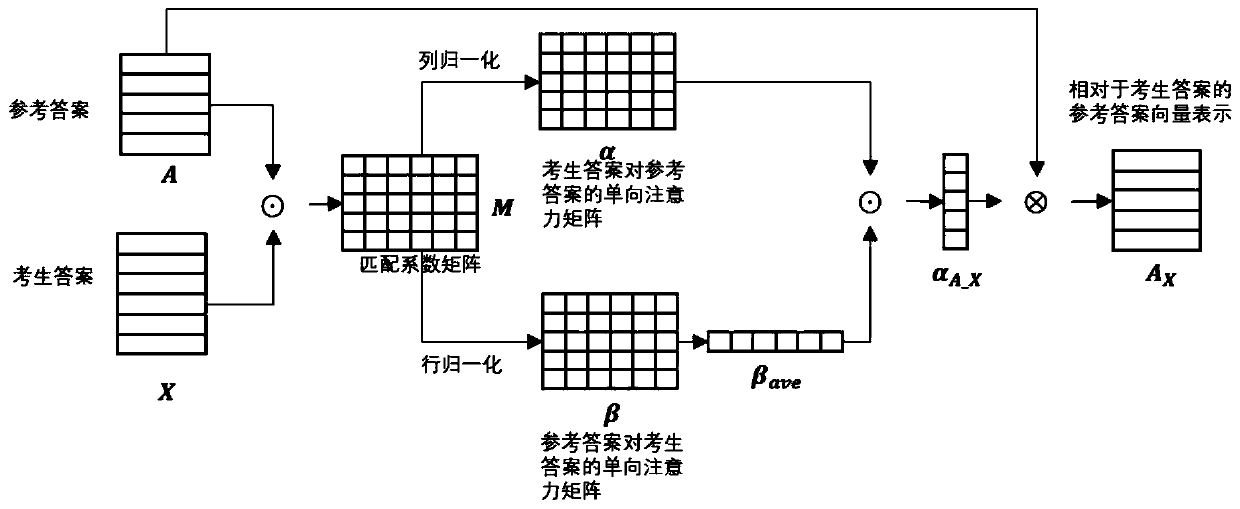

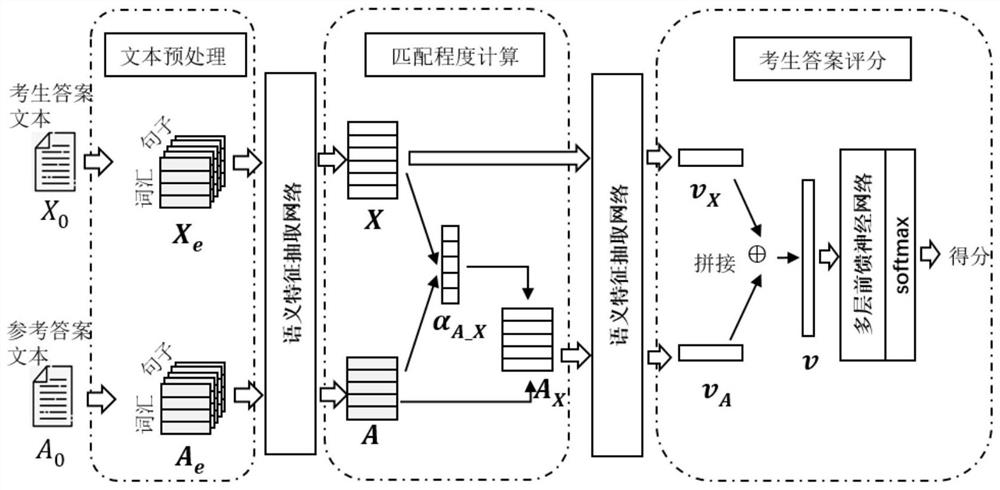

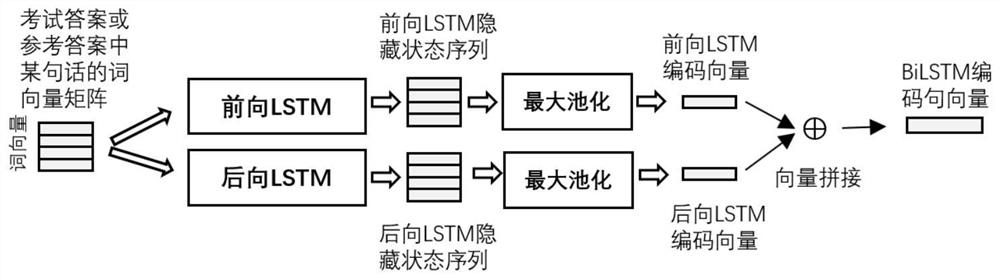

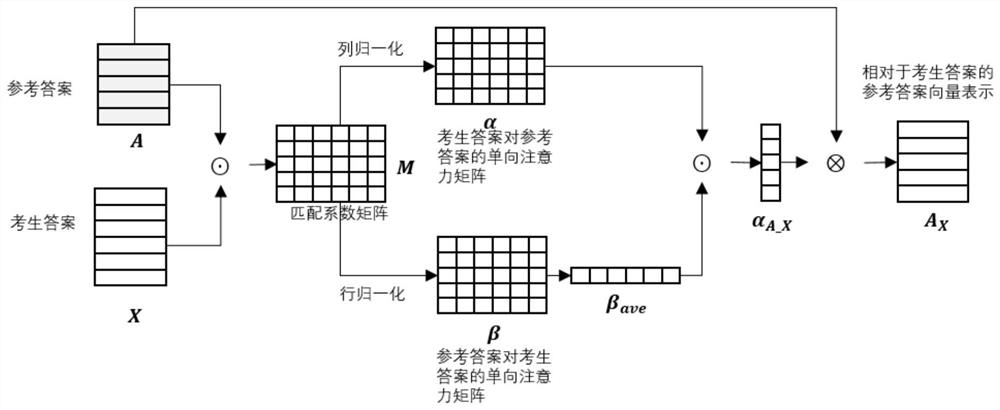

ActiveCN110413741ASolving inefficienciesSolve the problem of uneven marking qualityNeural architecturesText database queryingSemantic vectorTwo-vector

The invention provides an intelligent paper marking method for subjective questions. The method comprises the steps of respectively preprocessing an examinee answer text and a reference answer text toobtain word vector sequence representations corresponding to the examinee answer text and the reference answer text; extracting semantic vectors of sentences in the examinee answers and the referenceanswers by utilizing a semantic feature extraction network; calculating semantic matching degrees of sentence vectors of the examinee answers and the reference answers by utilizing a fusion attentionmechanism; calculating an examinee answer weighted sentence vector by utilizing the matching result; aiming at the sentence vector sequence of the answers of the complete examinees and a weighted sentence vector sequence based on a fusion attention mechanism; utilizing a semantic feature extraction network to calculate semantic vectors of the complete answers and semantic vectors based on attention of the reference answers; and bonding the two vectors to form a final vector representation of the examinee answer; scoring the final vector representation of the examinee answer by using a multi-layer feedforward neural network. According to the invention, automatic examination paper marking of subjective questions can be realized, and examination paper marking efficiency is greatly improved.

Owner:山东山大鸥玛软件股份有限公司

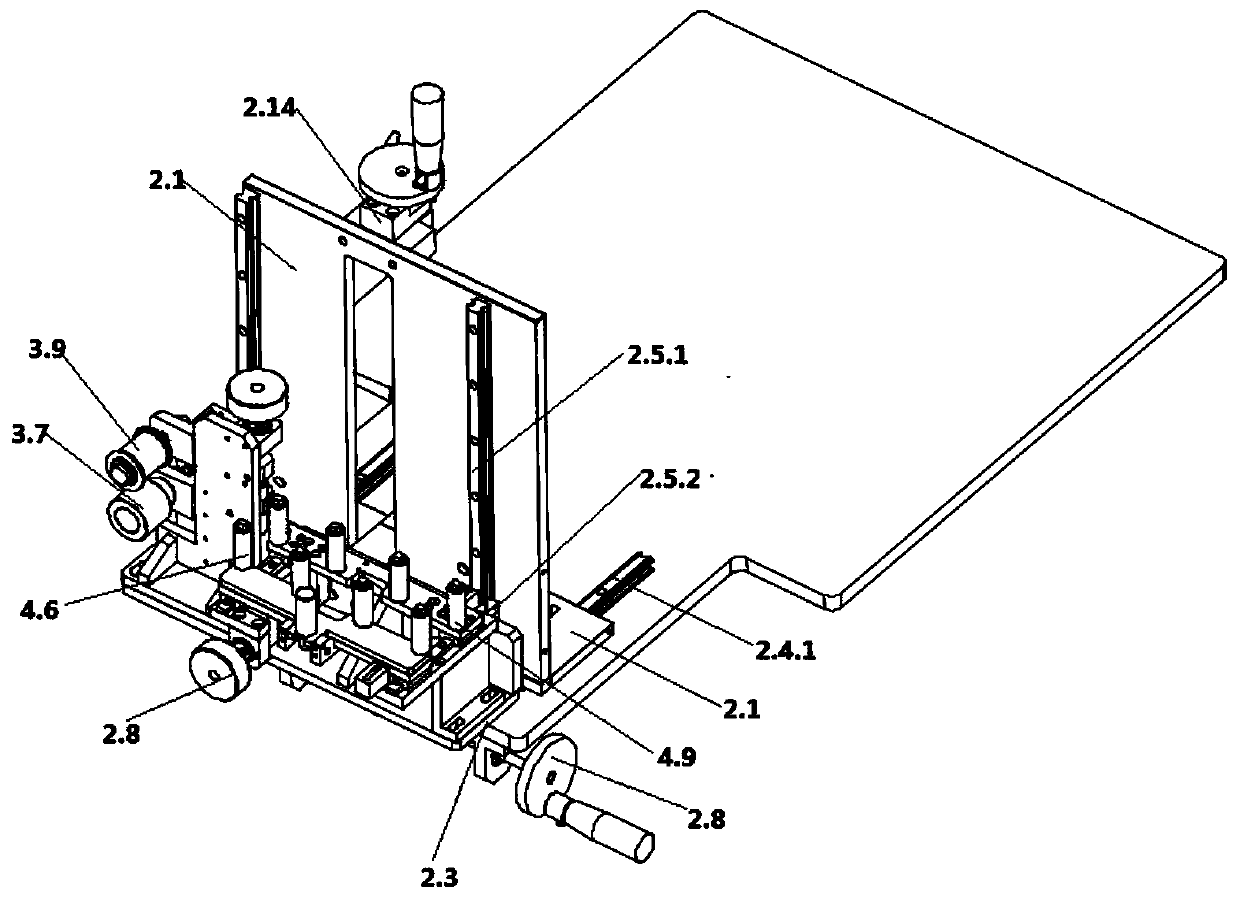

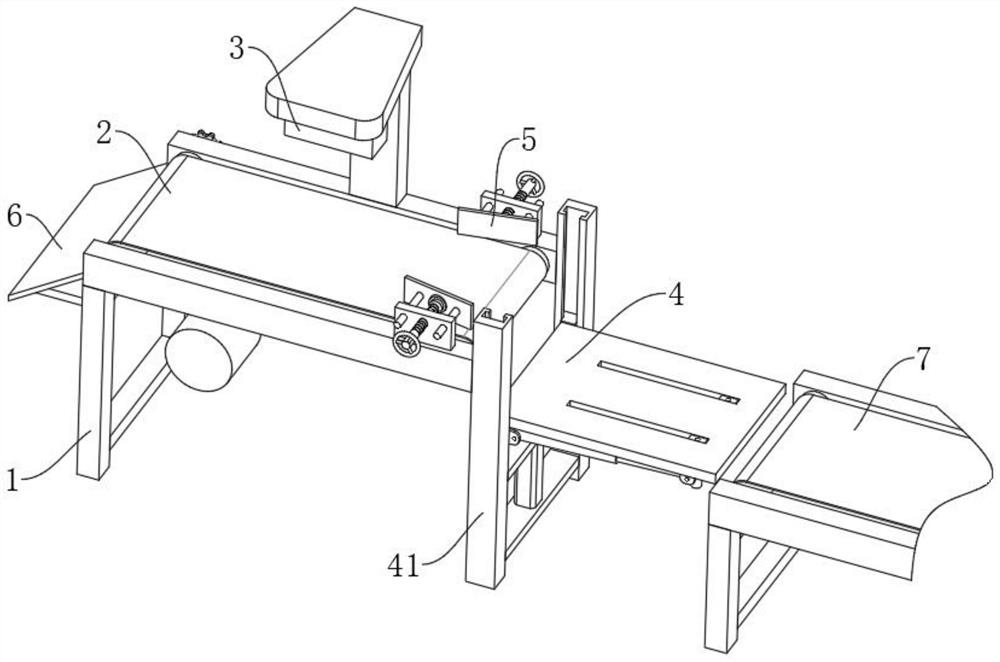

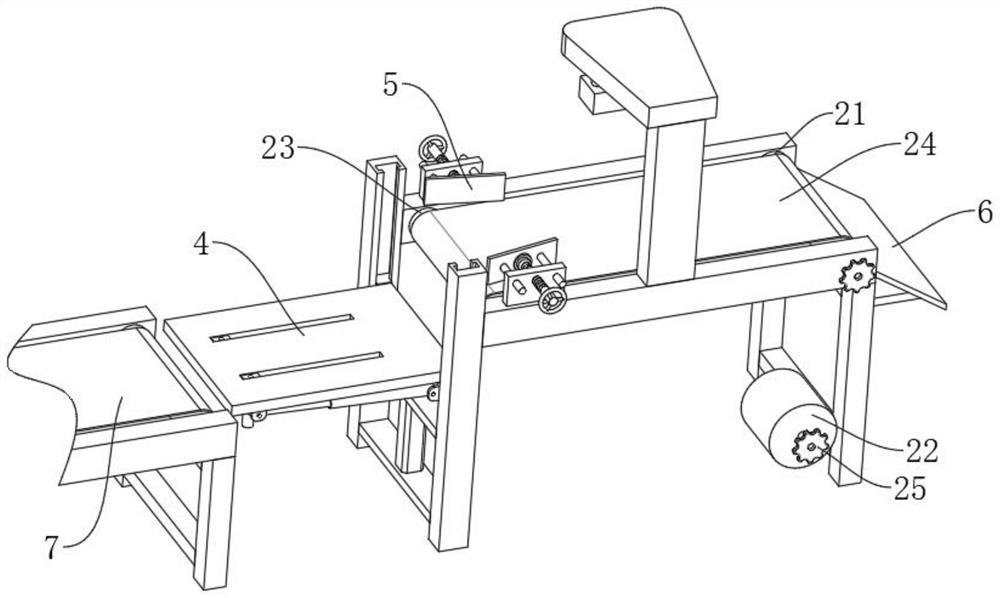

Marking device with automatic clamping and positioning function

ActiveCN104015498AWith automatic clamping and positioning functionAutomatic clamping and positioning are accurateTypewritersOther printing apparatusTransmission beltAirbag

The invention discloses a marking device with an automatic clamping and positioning function, which is accurate in positioning and can effectively improve the marking efficiency. The marking device with an automatic clamping and positioning function comprises a printing device, a transmission device is arranged right below the printing device, the transmission device comprises a transmission belt and an automatic clamping and positioning device, the automatic clamping and positioning device comprises inflatable airbags arranged at intervals at sides of the transmission belt, one inflatable airbag located at one side and the corresponding other inflatable airbag located at the other side form a clamp, one inflatable airbag of each clamp is provided with a starting end position sensor, the other inflatable airbag of each clamp is provided with an ending end position sensor, each inflatable airbag is internally provided with a sensing device used for sensing a workpiece, the inflatable airbag is connected with a pneumatic pump, the pneumatic pump is arranged at the side part of the support of the transmission device, and the starting end position sensors, the ending end position sensors and the sensing devices are connected with the controller of the pneumatic pump.

Owner:ABO BUILDING MATERIAL KUNSHAN CO LTD

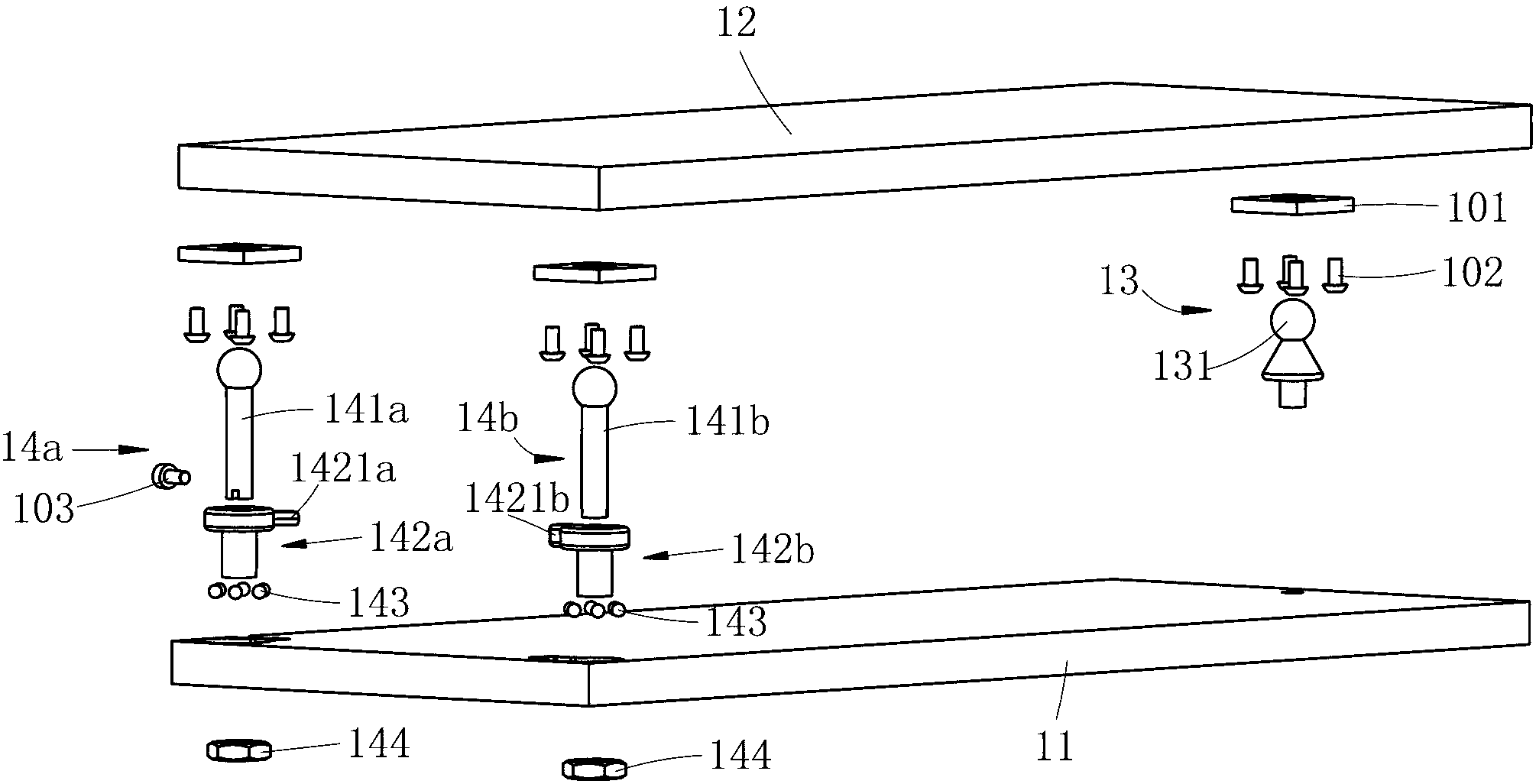

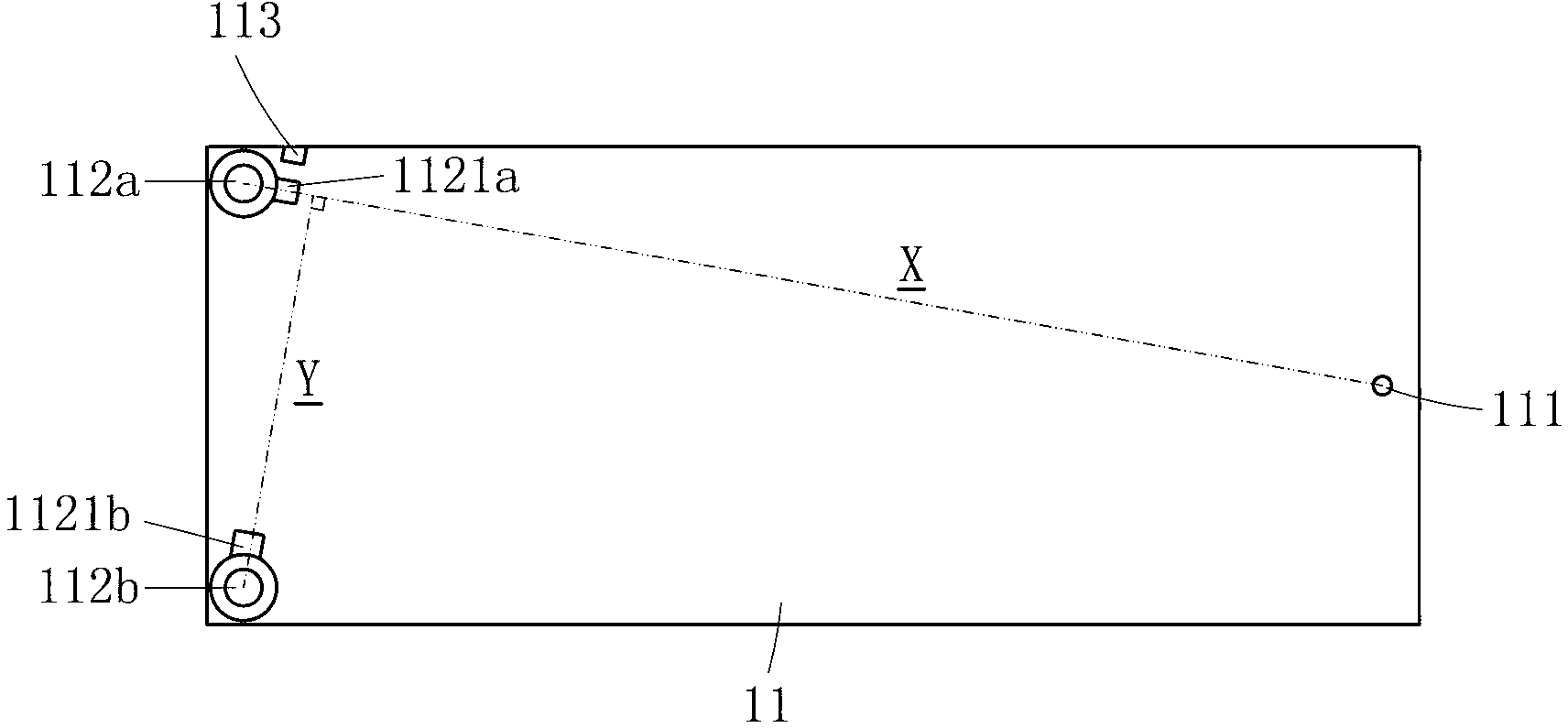

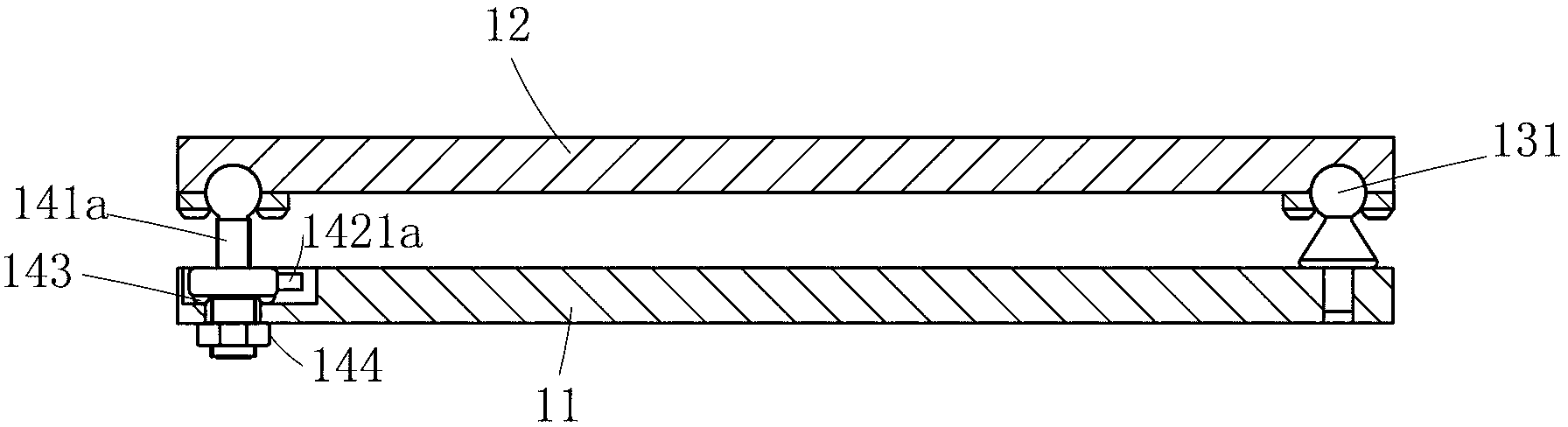

Plane trimming device and laser marking machine using plane trimming device

The invention discloses a plane trimming device and a laser marking machine using the plane trimming device, and relates to the technical field of plane adjusting equipment of precision machinery. The plane trimming device comprises an adjusting plate and a fixing plate, wherein the fixing plate and the adjusting plate are vertically connected together by three groups of support assemblies, the three groups of support assemblies are arranged in a triangle way, one of three groups of support assemblies is fixed support assemblies, and the other two groups of support assemblies are adjusting support assemblies. The plane trimming device has the advantages that the structure is simple, and the cost is low; a principle of using three points not in a common line to form a plane is utilized, so the precise adjusting of the parallel degree or the inclination degree between the two planes is realized, and easiness, convenience and easy implementation are realized; and the plane trimming device is applied to the laser marking machine, and on the premise of slight increase of the cost, the marking precision and the marking quality are greatly improved, and further the price-performance ratio of a product and the market competitiveness are improved.

Owner:WEIFANG LOKOMO PRECISION IND

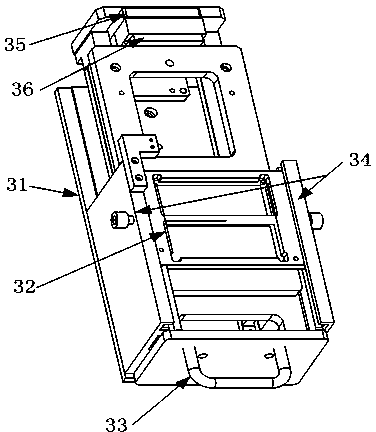

Automatic lithium battery laser marking machine

InactiveCN107350630AImprove marking efficiencyImprove marking qualityMetal working apparatusLaser beam welding apparatusEngineeringLaser

The invention is aimed at providing an automatic lithium battery laser marking machine high in efficiency and quality. The automatic lithium battery laser marking machine can automatically conduct laser making on lithium batteries through a laser marking device and meanwhile can automatically sort out unqualified products from qualified products after laser marking.

Owner:张浩洋

Municipal road marking device

ActiveCN106087690AUniform widthUniform thicknessRoads maintainenceRoad surfaceMechanical engineering

The invention provides a municipal road marking device and belongs to the technical field of municipal road equipment. The municipal road marking device solves the problem that the municipal road marking quality is low. The municipal road marking device comprises a guide frame. The guide frame comprises two guide rails. Each guide rail is connected with a movable board in a sliding manner. Each movable board is connected with a separation board in a sliding manner and provided with a compression spring. A material spraying pipe and a material grinding pipe are fixedly connected between the two separation boards. A grinding screw is arranged in the material grinding pipe. A roller shaft is further rotationally connected between the two separation boards. When the movable boards move, the roller shaft can roll marking paint on a road surface. Material return suction pipes are further arranged on the two separation boards. The movable boards are provided with drive pieces capable of driving the movable boards to move in a reciprocating manner. The municipal road marking device is good in marking quality.

Owner:临沂临港经济开发区市政工程有限公司

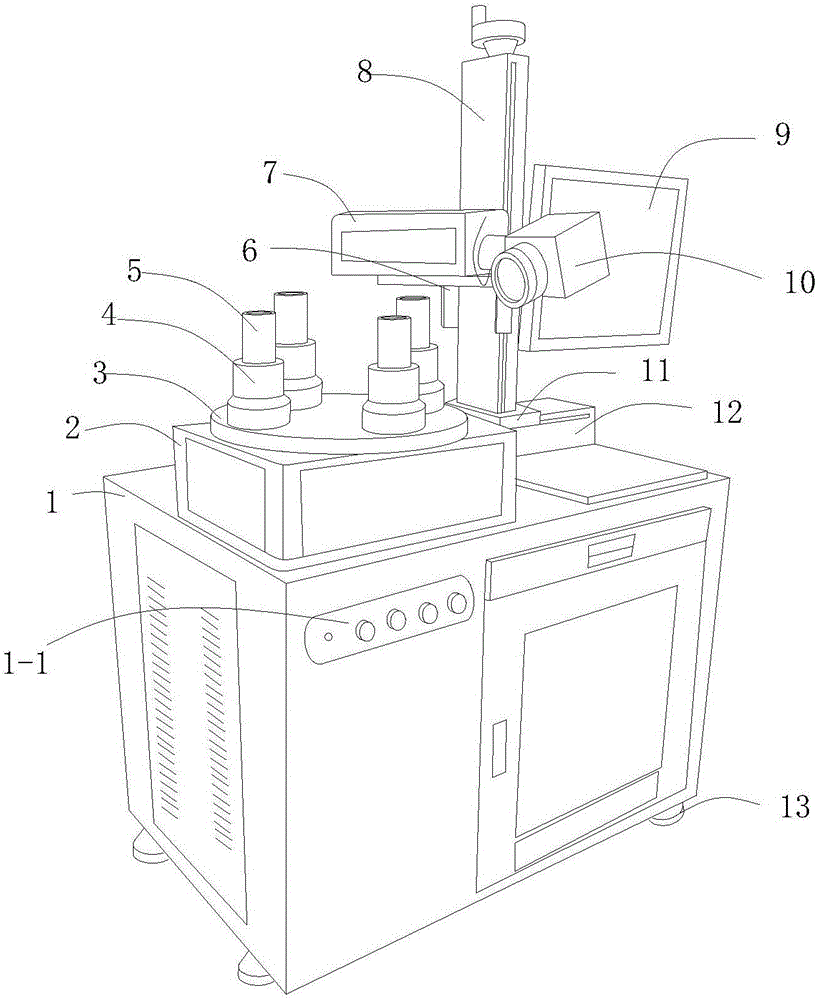

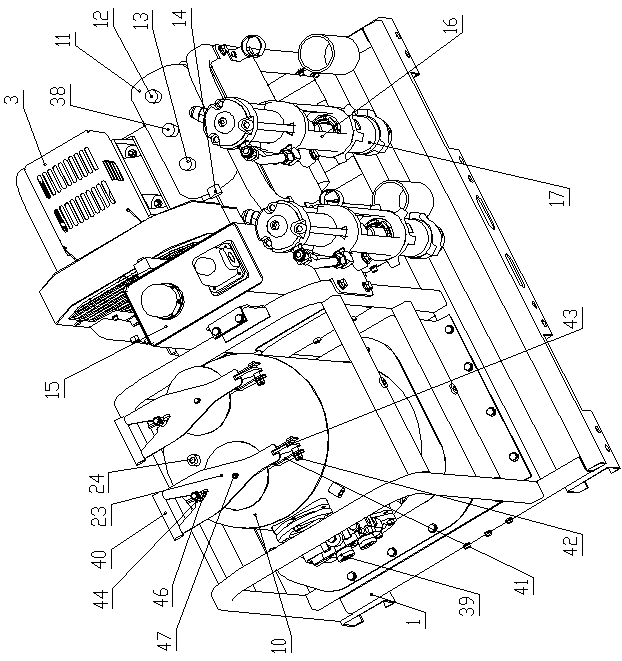

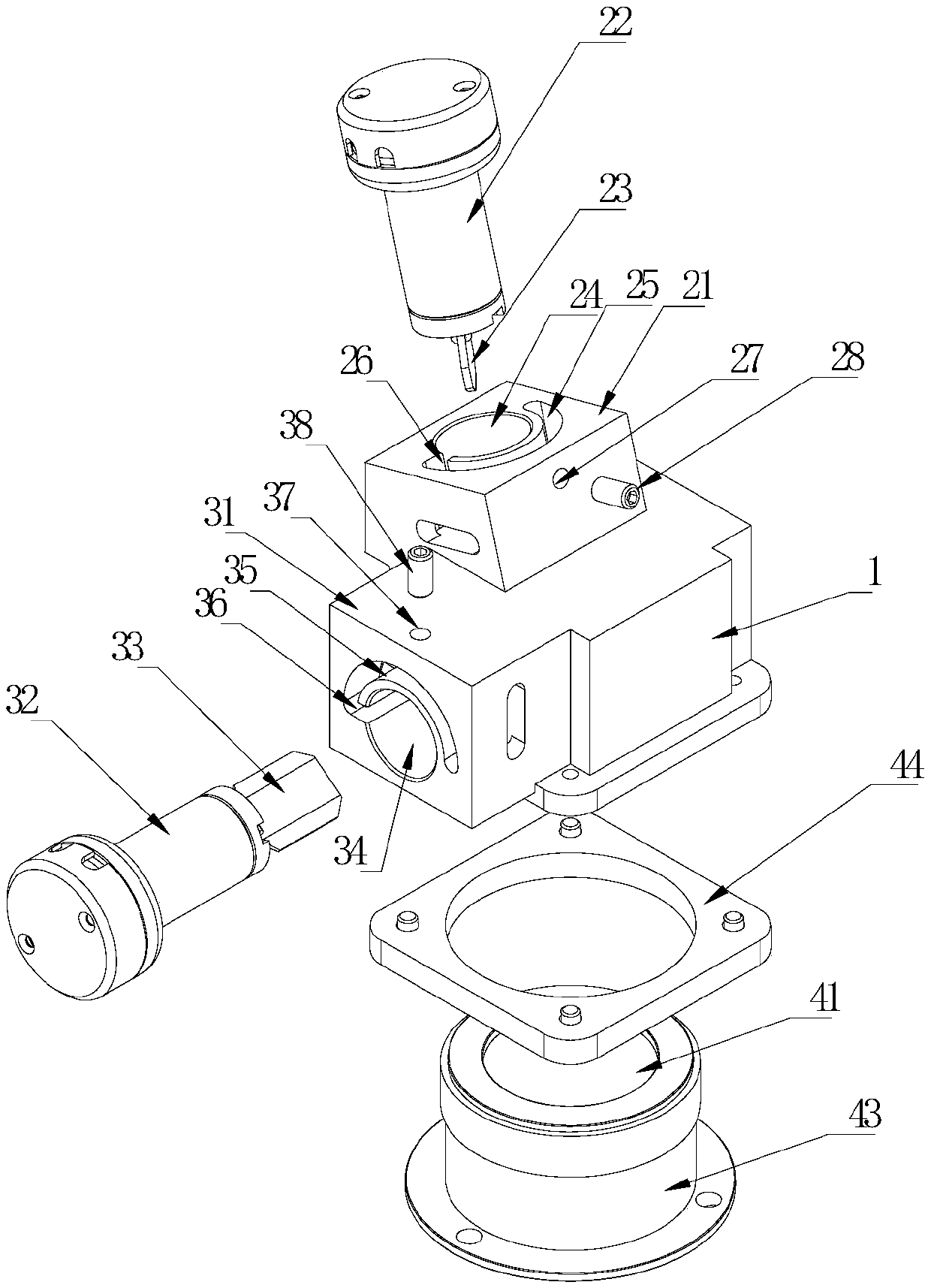

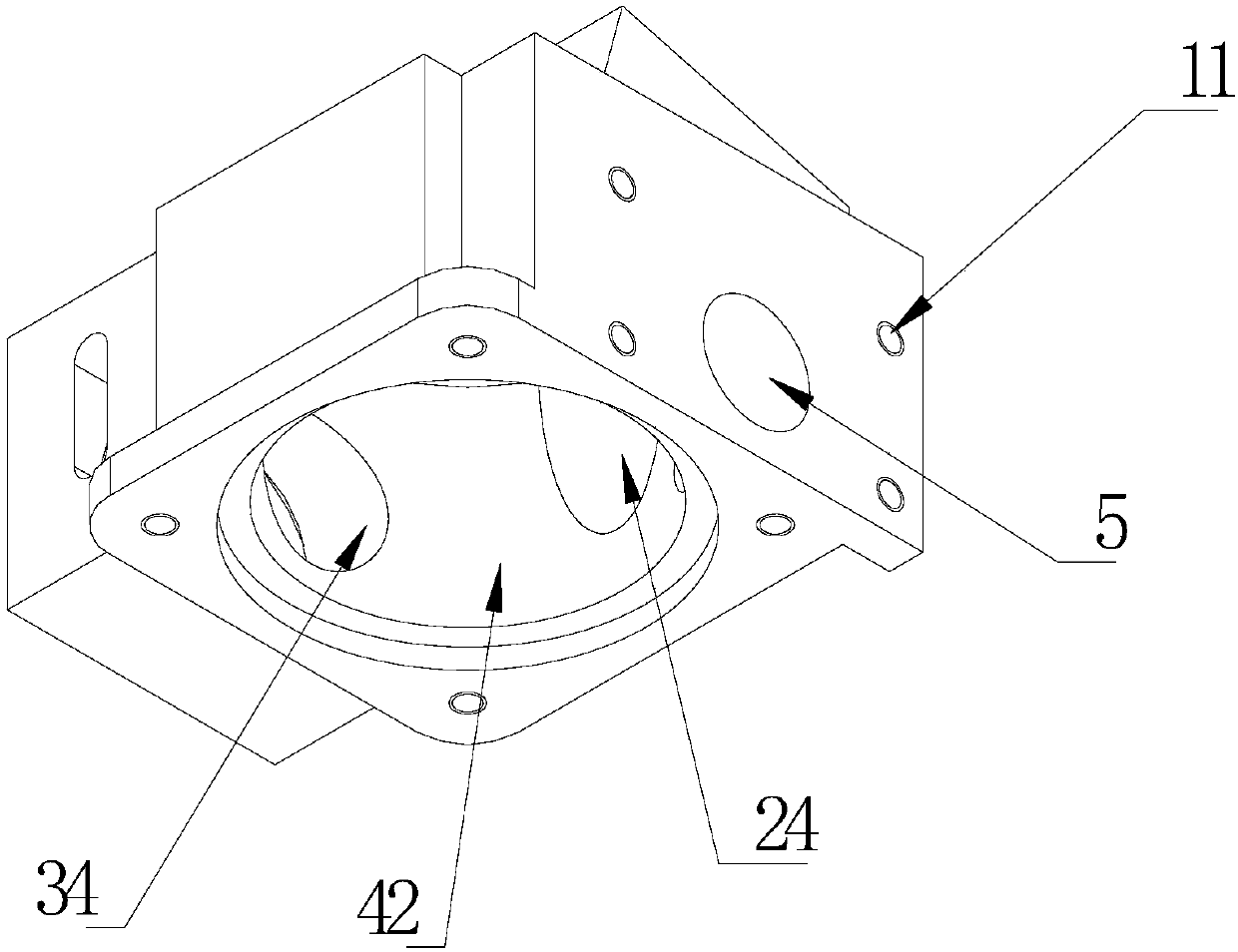

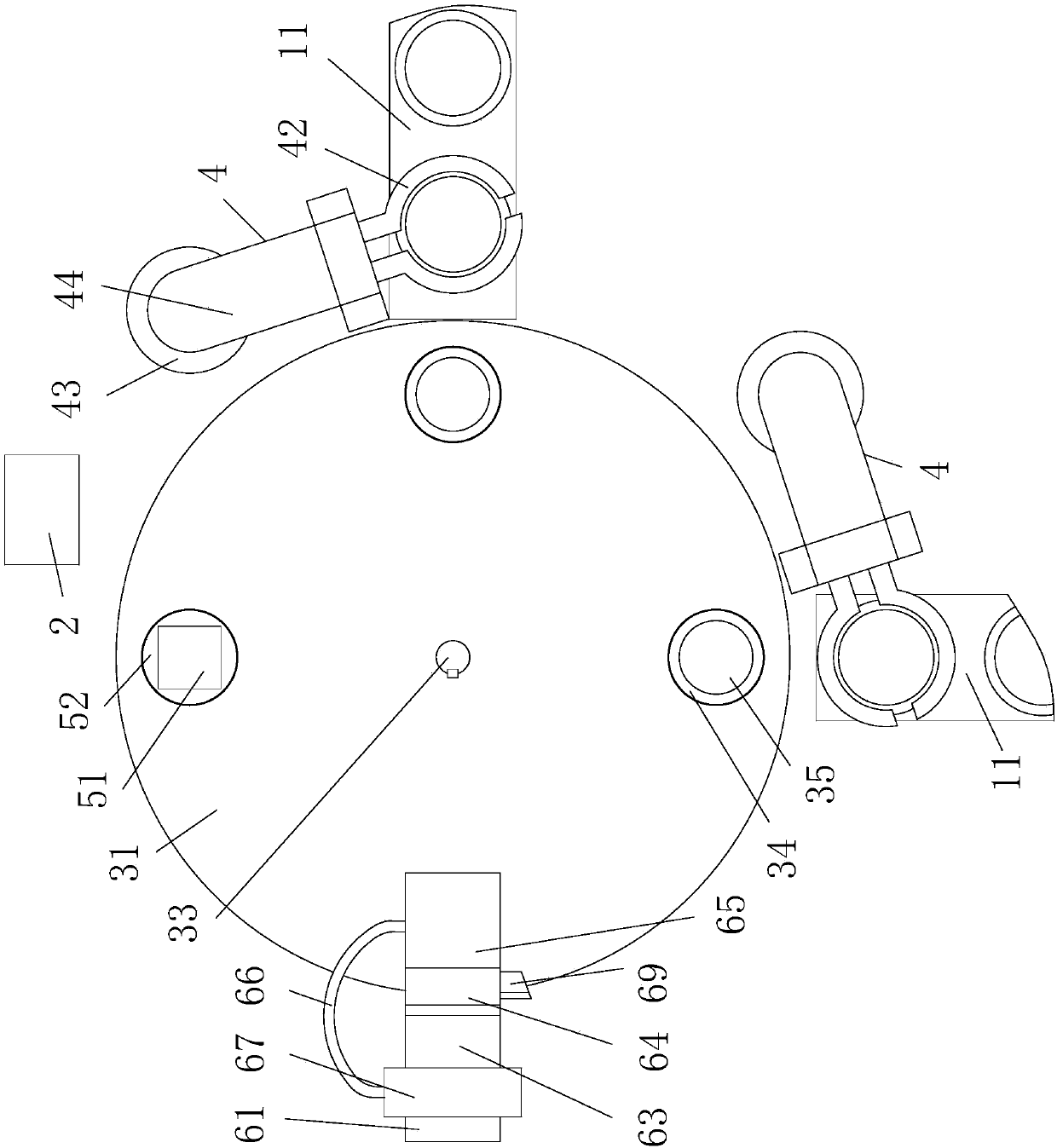

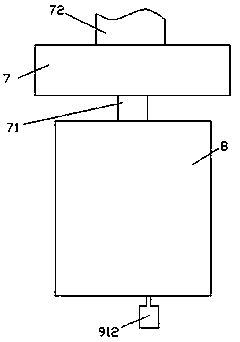

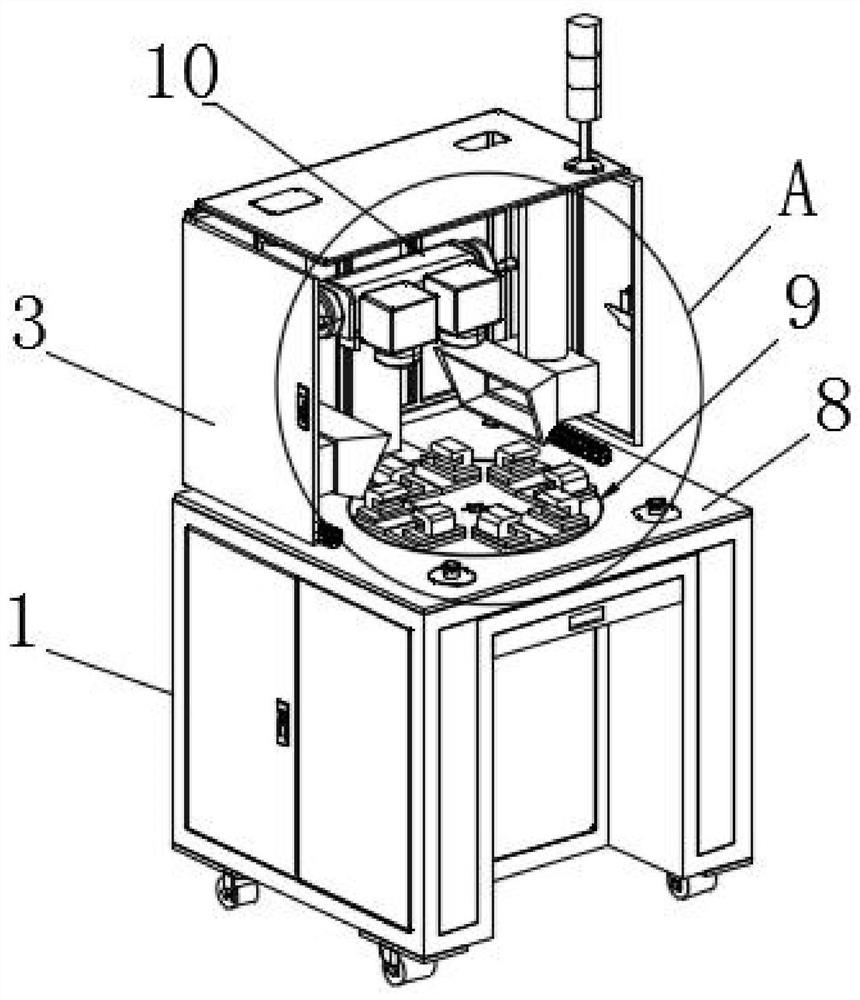

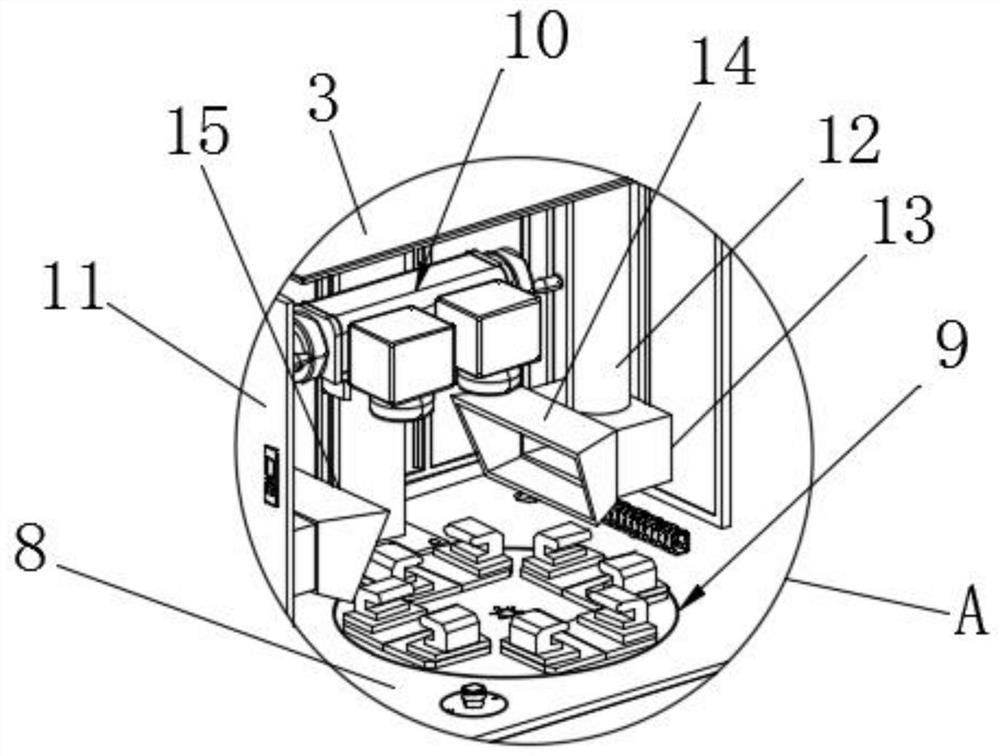

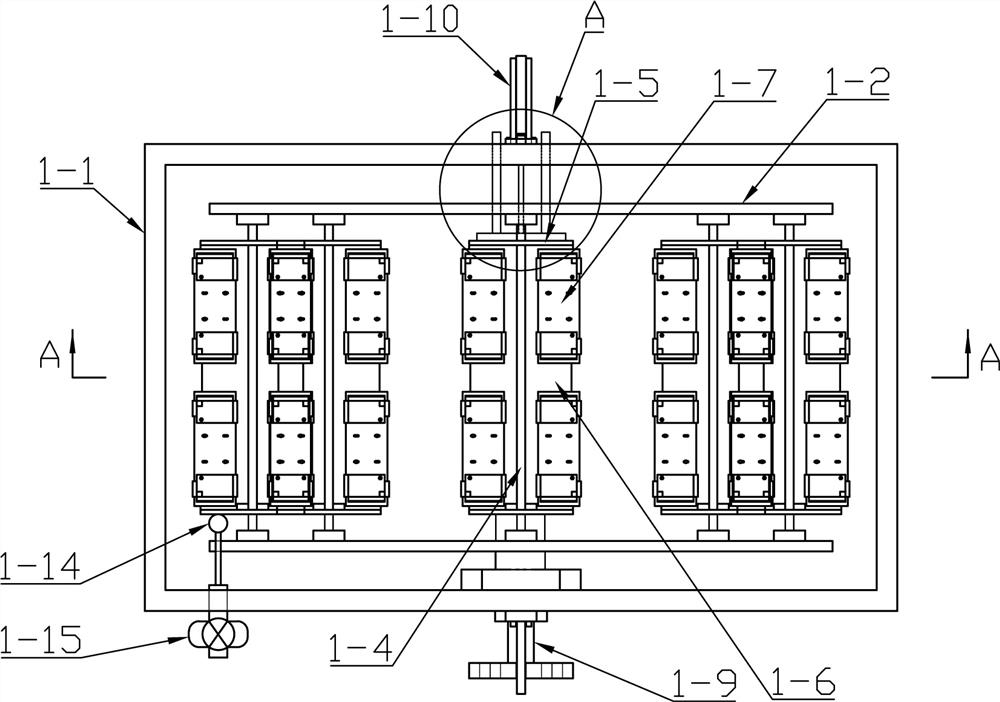

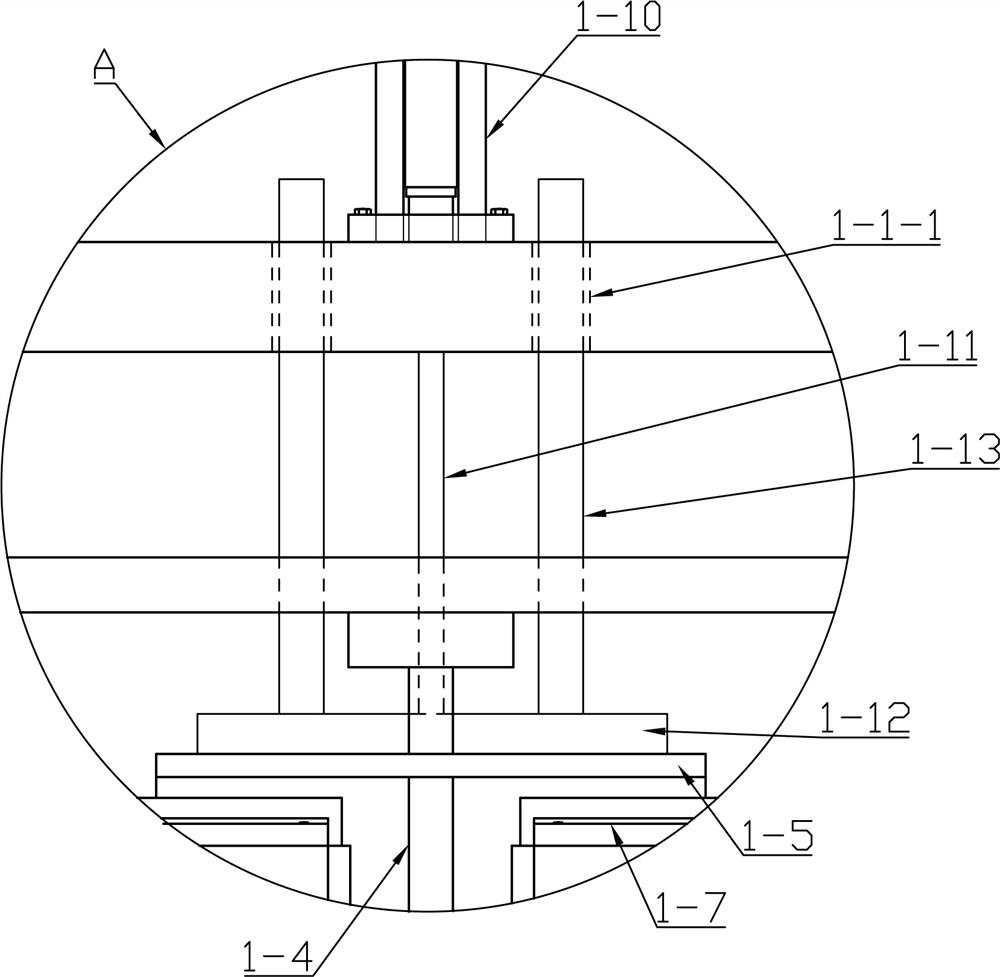

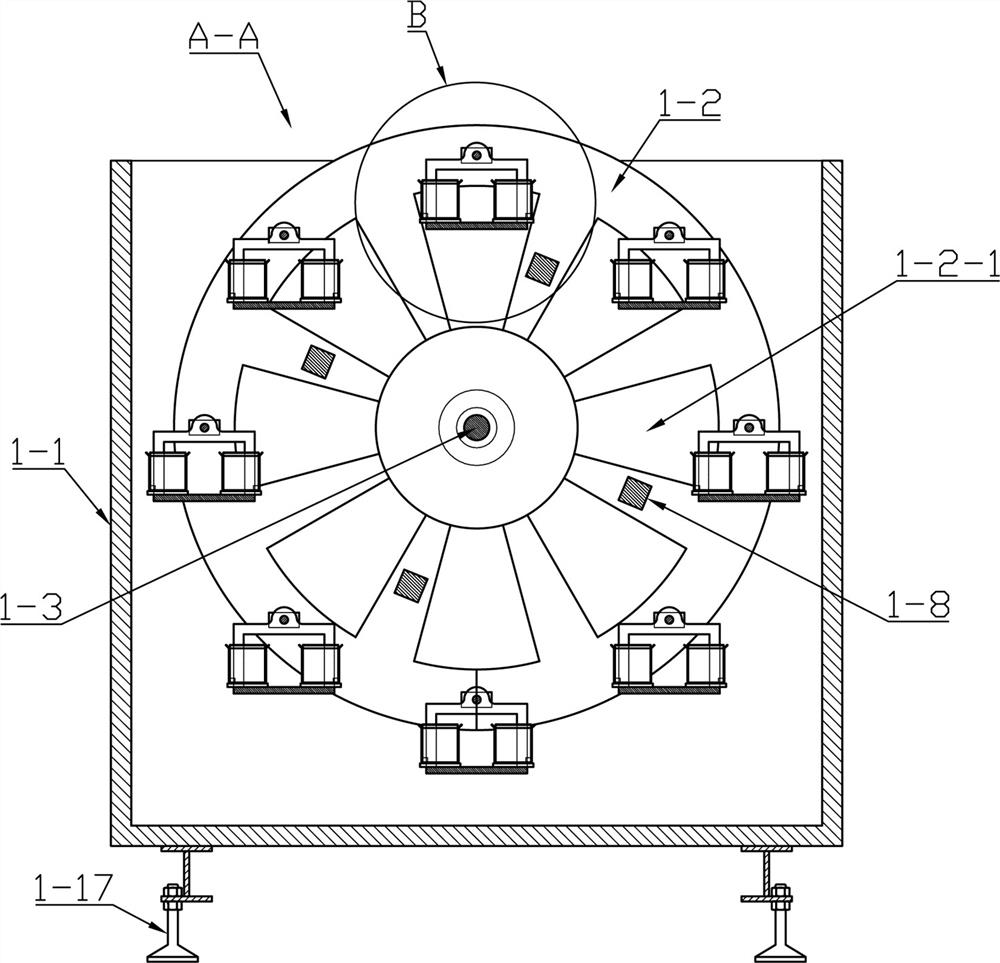

Inner hole laser marking equipment used for sucker rod coupling and marking method thereof

The invention discloses inner hole laser marking equipment used for a sucker rod coupling and a marking method thereof, and relates to the technical field of laser marking. The inner hole laser marking equipment comprises an electric control cabinet and a laser. An indexing separator is arranged on the electric control cabinet. A rotary plate is connected to the indexing separator. A plurality of adapting sleeves used for mounting the marking coupling are evenly distributed on the rotary plate. A rotary laser head is movably connected to the laser. The inner hole laser marking equipment has the advantages that the structure is simple, the working efficiency is high, the labor intensity is low, inner hole marking of the to-be-marked coupling is facilitated, and marking characters are not liable to be abraded; during operation, the to-be-marked coupling is mounted on the adapting sleeves of the rotary plate, the position of the laser is adjusted, required marking parameters are input into a computer, the focal distance of the laser beamon the inner wall of the coupling is adjusted, then marking is started, the focal distance of the laser beams is adjusted, deep marking and carbonizing marking can be achieved, after marking of a product is completed, the rotary plate rotates automatically to another product for marking, and thus uninterrupted marking operation can be achieved.

Owner:重庆亮科激光科技有限公司 +1

Laser marking machine and marking machine

InactiveCN107598384AImprove marking qualityImprove reliabilityLaser beam welding apparatusEngineeringWorkbench

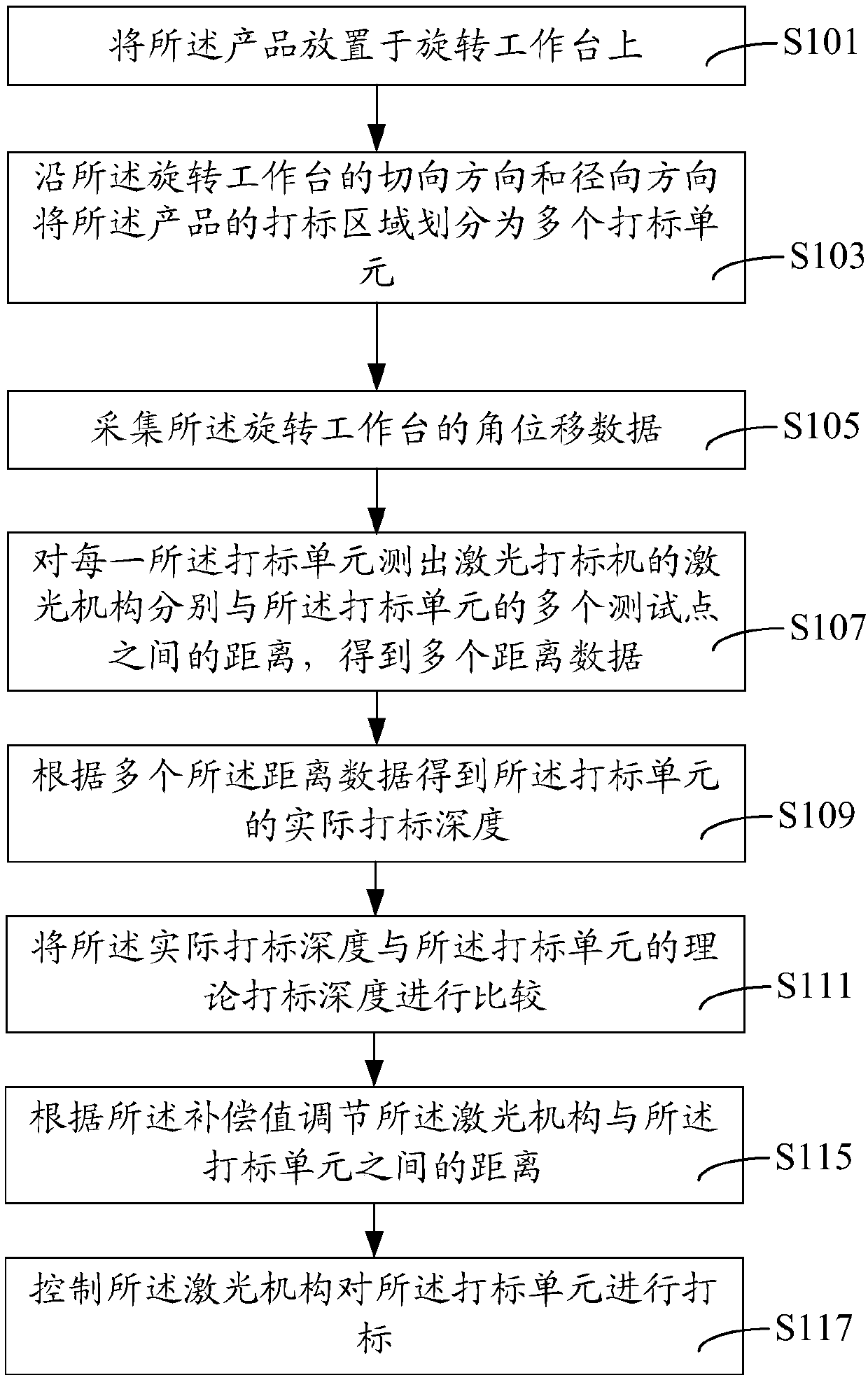

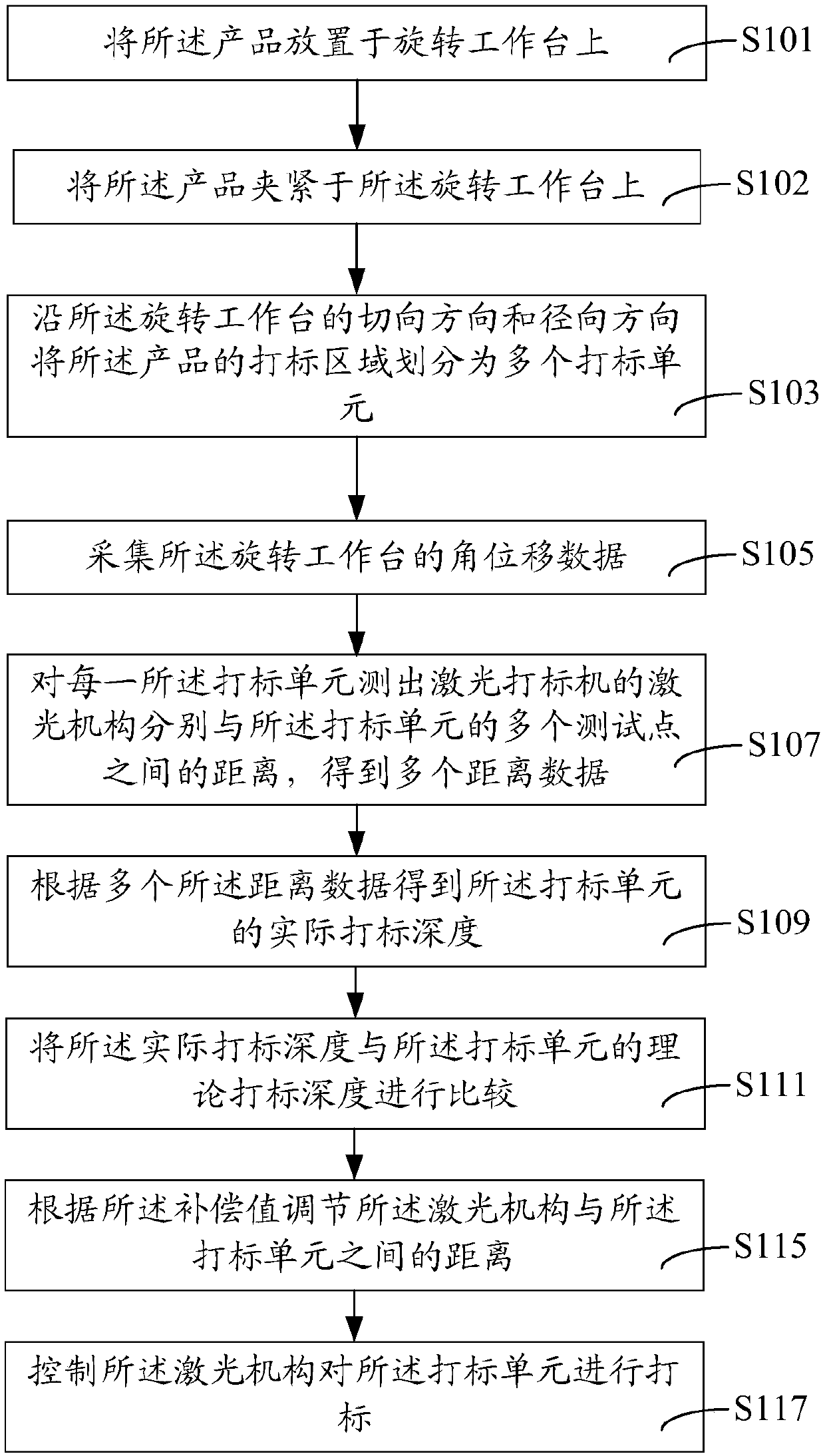

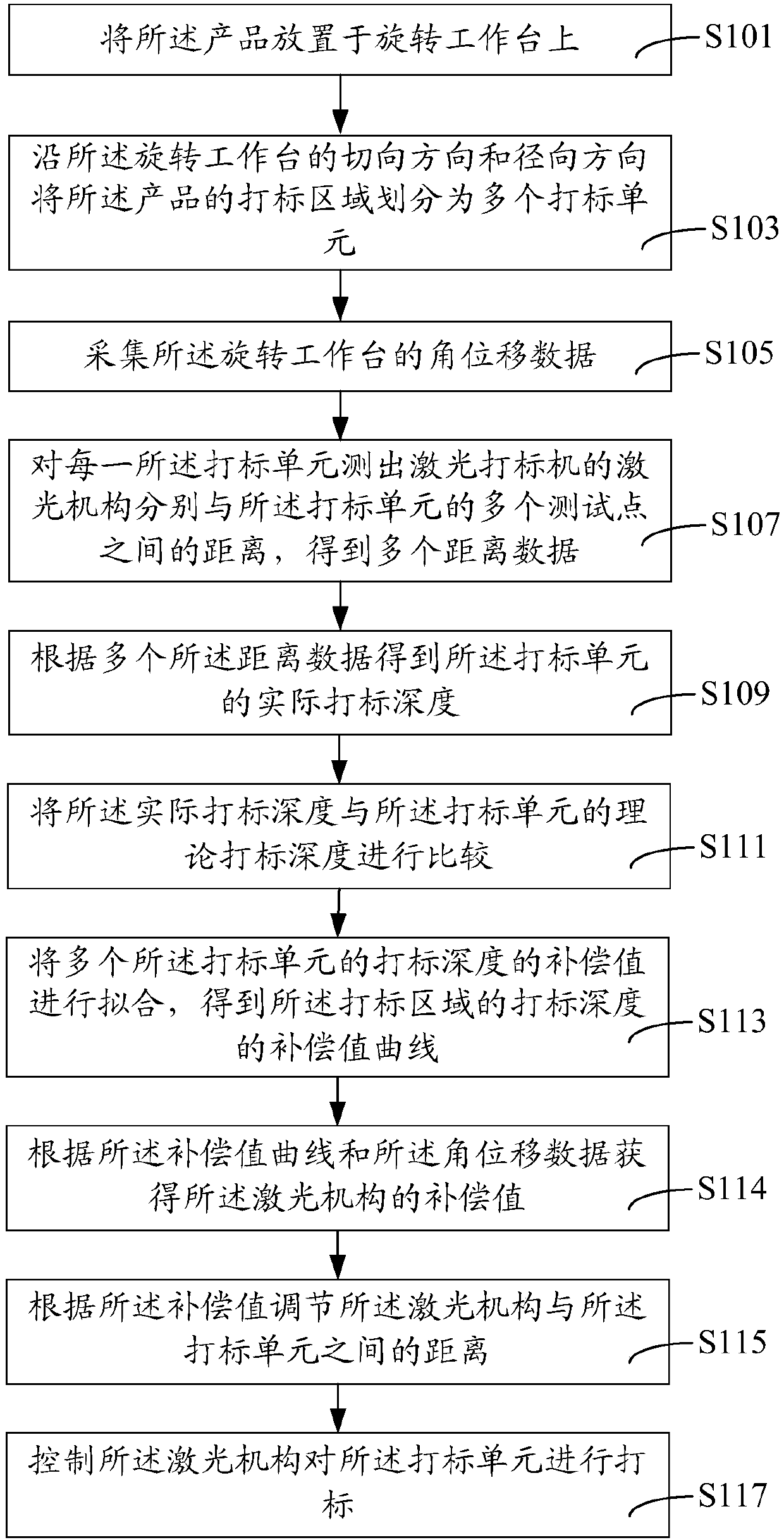

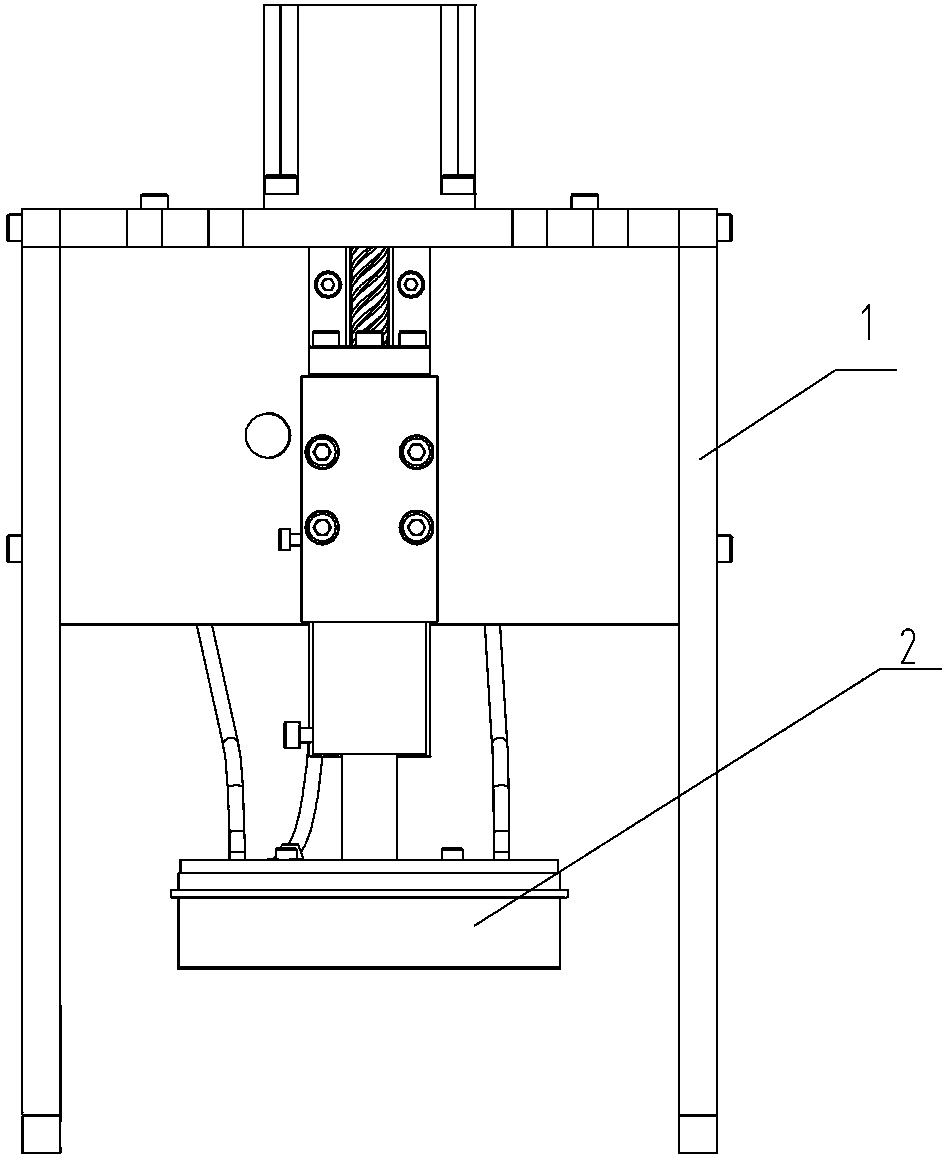

The invention relates to a laser marking machine and a marking method. The marking method is used for marking products. The marking method comprises the steps of placing a product on a rotating workbench, and making the product rotate along with the rotating workbench; dividing the marking area of the product into more than one marking unit in the tangential direction and the radial direction of the rotating workbench; acquiring the angular displacement data of the rotating workbench; measuring the distance between the laser mechanism of the laser marking machine and the multiple test points of the marking units to obtain multiple distance data; obtaining the actual marking depths of the marking units according to the multiple distance data; comparing the actual marking depths and the theoretical marking depths of the marking units to obtain the compensation values of the marking depths of the marking units; adjusting the distances between the marking mechanism and the marking units according to the compensation values; and controlling the laser mechanism to mark the marking units. According to the marking method, the marking quality of the marking units is improved, and therefore,the reliability of marking of the laser marking machine on the marking area of a product is good.

Owner:惠州市洛玛科技有限公司

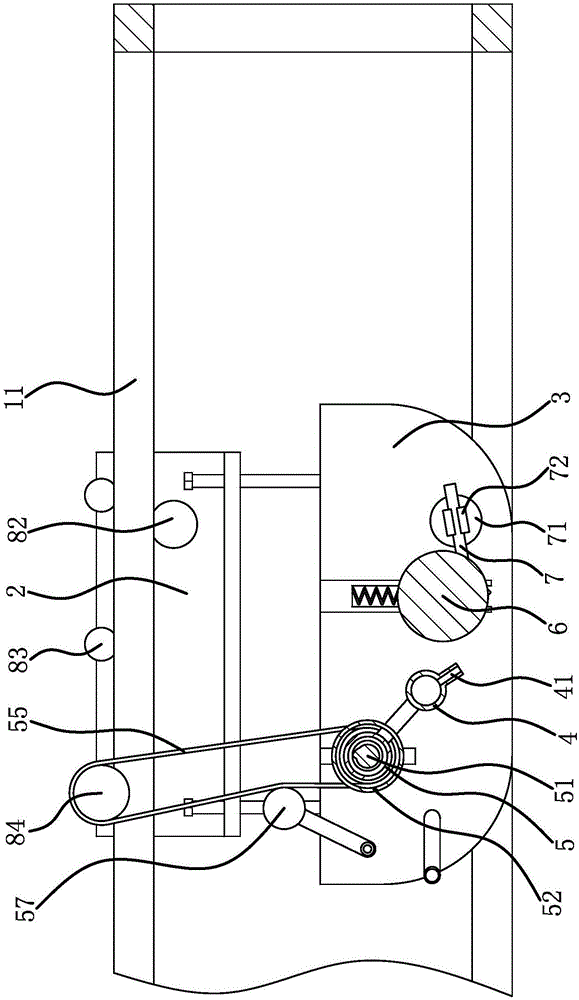

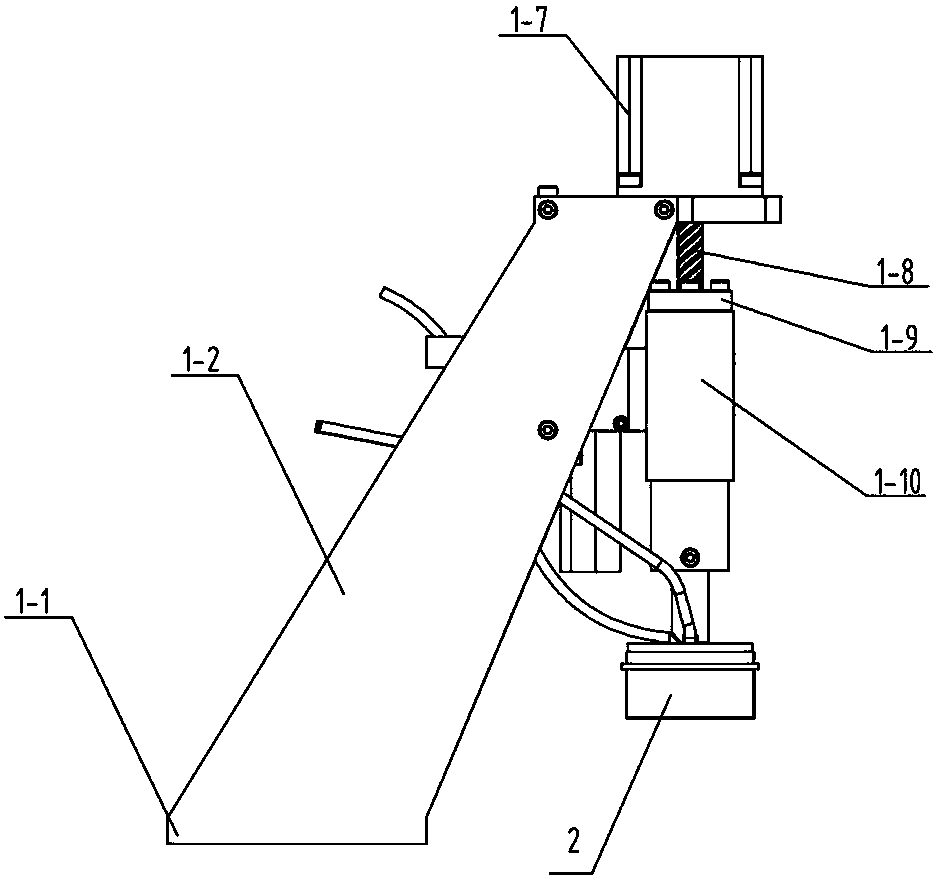

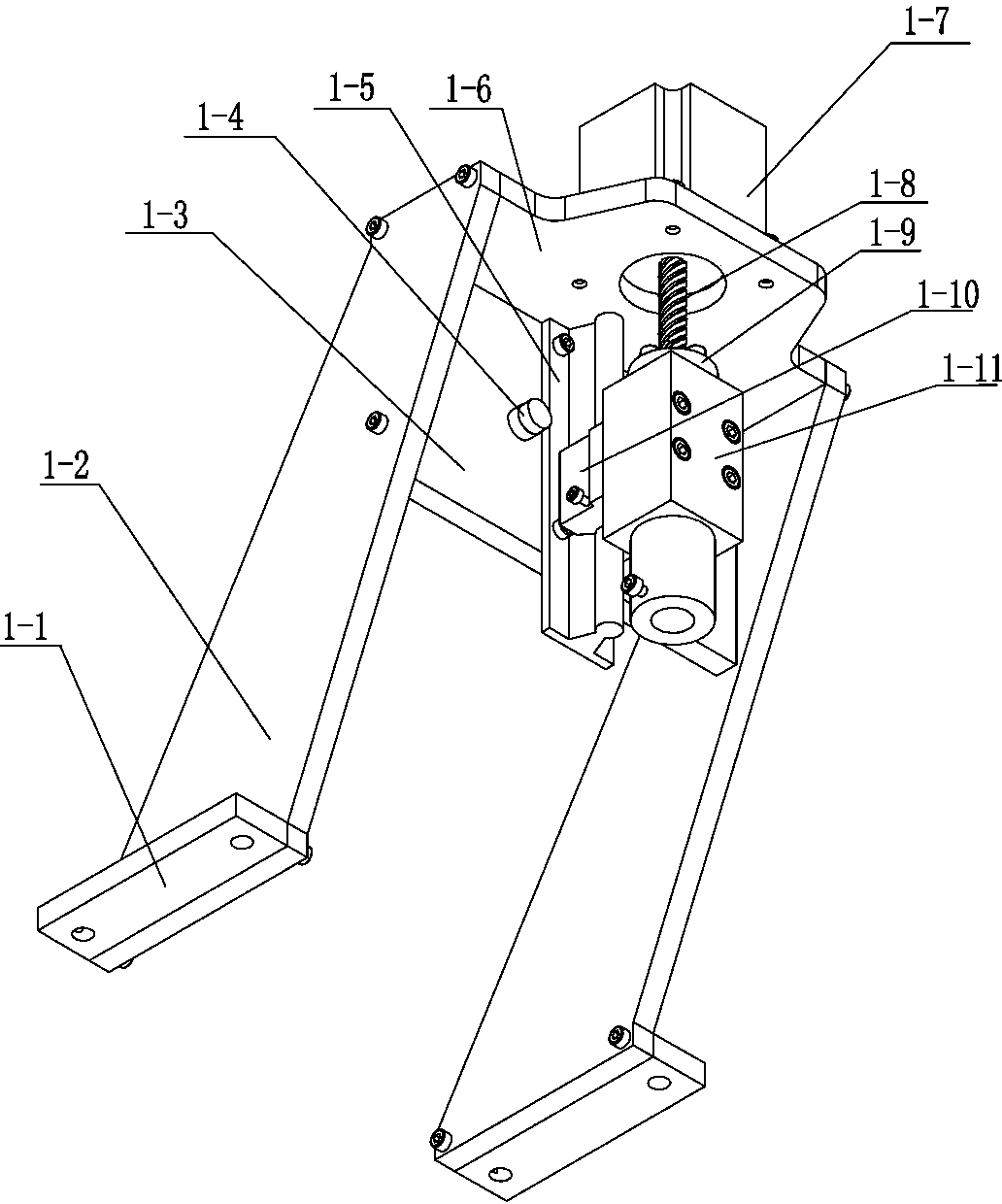

Electric control marking system for electrocorrosion marking production line

ActiveCN103862893AUniform markingMarking marks are clearTypewritersOther printing apparatusPeristaltic pumpCarbon felt

The invention relates to an electric control marking system for an electrocorrosion marking production line. The electric control marking system comprises a marking executing mechanism and a marking head connected with the marking executing mechanism. The marking executing mechanism comprises a fixing frame and a marking driving device arranged on the fixing frame. The electric control marking system is characterized in that the fixing frame is an oblique-pulling type fixing frame, the marking driving device comprises a stepping motor, a lead screw, a sliding sleeve, a straight line bearing and a sliding track, and the marking head comprises an organic glass lining plate, a fixing frame, a graphite block, carbon felt, a conducting net, an electrode piece, a marking head locating sleeve, a lead wire connected with a pole piece with electricity, a marking liquid injection pipe, a marking liquid sucking pipe, a filter and a marking liquid storage and peristaltic pump. The electric control marking system has the advantages that stroke is accurate, pressure is constant, the structure is stable, locating is accurate, operation is convenient, model changing is convenient, speed is high, production efficiency is high, worker operation labor intensity is low, liquid providing is even, circulating using is achieved, liquid sucking force is strong, liquid flowing is avoided, energy is saved, and environment is protected.

Owner:鞍山市庆龙机电有限公司

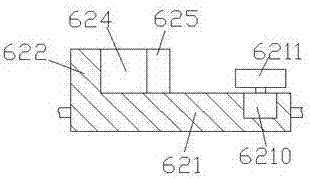

Axial pneumatic clamping tool for steel bottle circumferential marking

InactiveCN107571653AReduce labor costsImprove positioning and clamping efficiencyWork holdersStampingBottleUltimate tensile strength

An axial pneumatic clamping tool for steel bottle circumferential marking is provided. A support is arranged in the middle of the upper end of a frame body, a telescopic cylinder is fixed to the leftside wall of an installation seat, and a piston rod of the telescopic cylinder penetrates through the left side wall of the installation seat to be fixedly connected with a sliding clamping rotary device arranged on the right side of the installation seat; and a positioning device corresponding to the sliding clamping rotary device in height is arranged on a fixing seat, a steel bottle is arrangedbetween the sliding clamping rotary device and the positioning device, and after the steel bottle is supported and positioned through the positioning device and a supporting device arranged on the support, the sliding clamping rotary device is driven by the telescopic cylinder to move rightwards to achieve clamping and rotation of the steel bottle. According to the axial pneumatic clamping tool for steel bottle circumferential marking, the steel bottle is positioned and then rotates through the sliding clamping rotary device and the positioning device arranged on the frame body, the middle ofthe steel bottle is supported through the supporting device, and the reliability and marking precision of the steel bottle during marking are ensured. The marking quality is improved, the finished product rate is increased, the labor intensity of a worker is greatly reduced, the labor cost is low, and the high use value is achieved.

Owner:SHAANXI LAIFU TECH DEV CO LTD

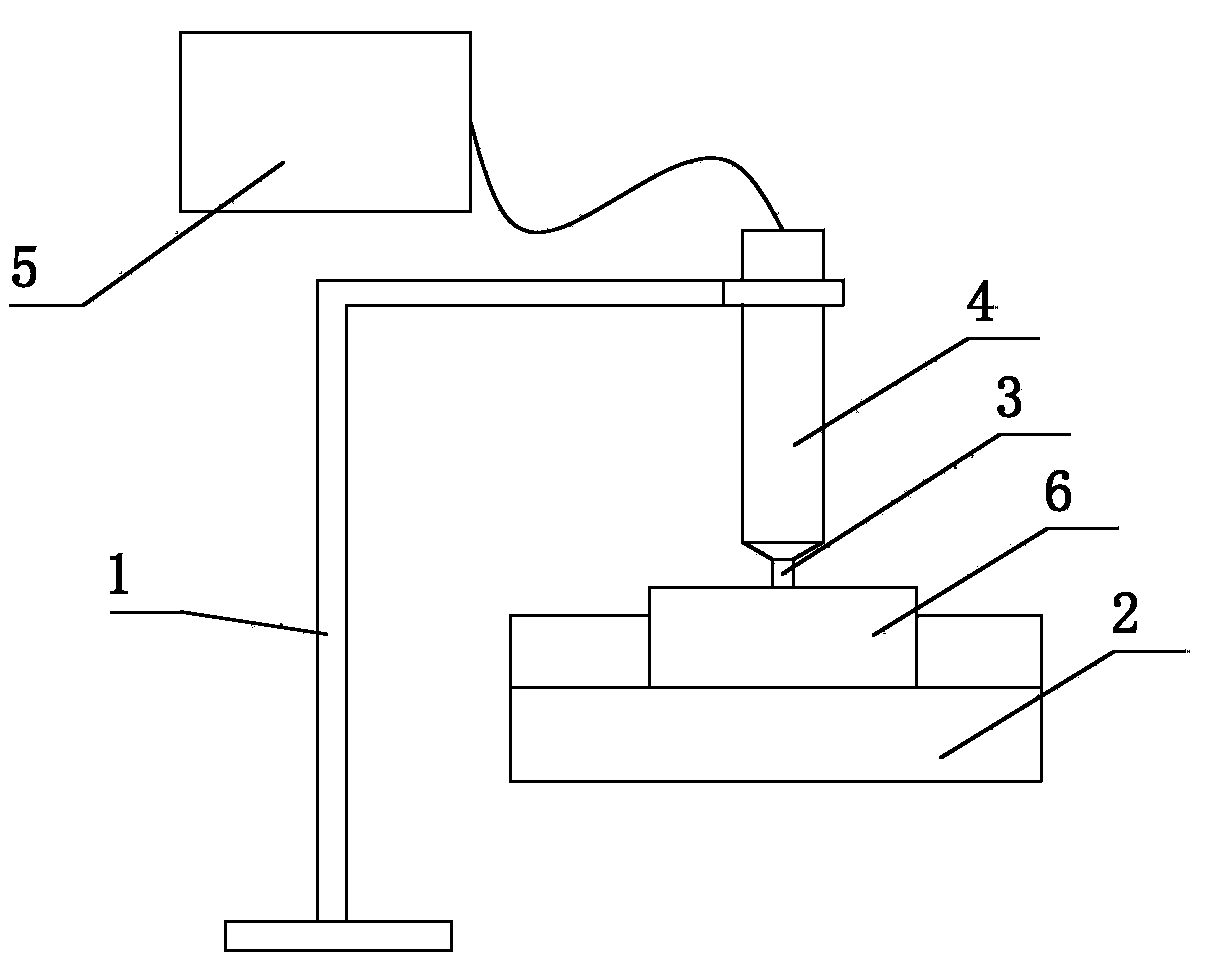

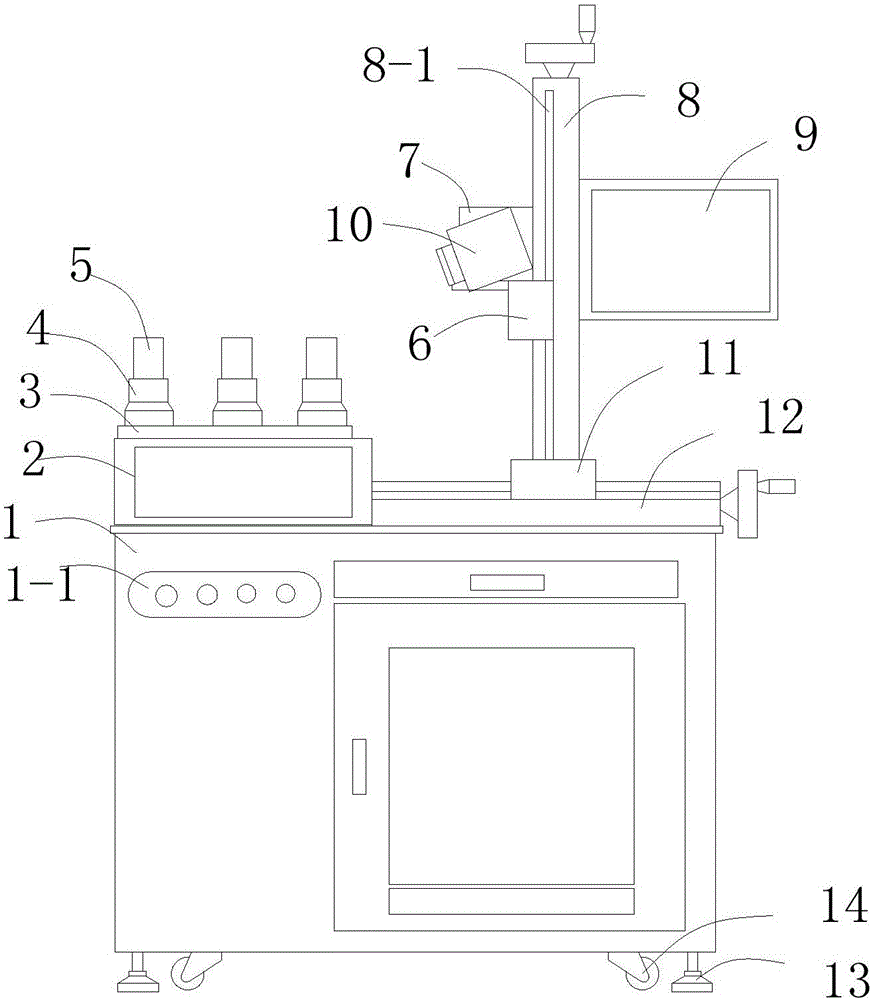

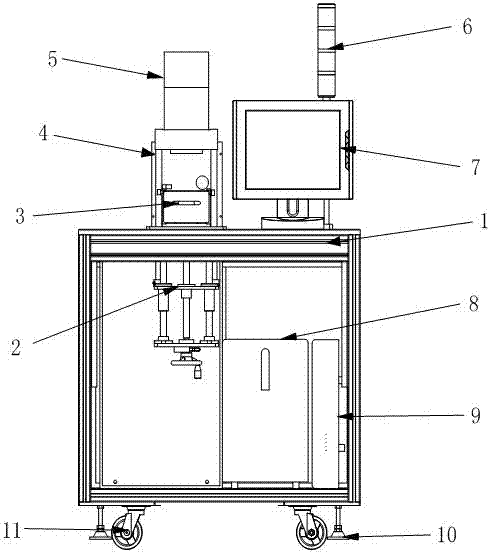

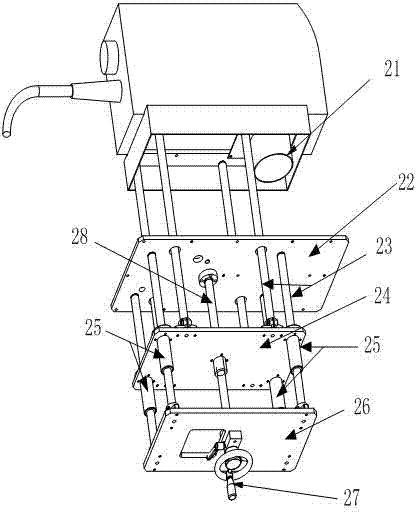

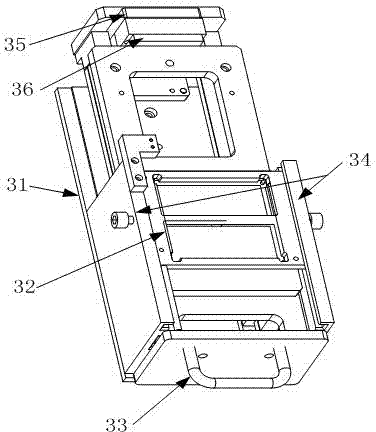

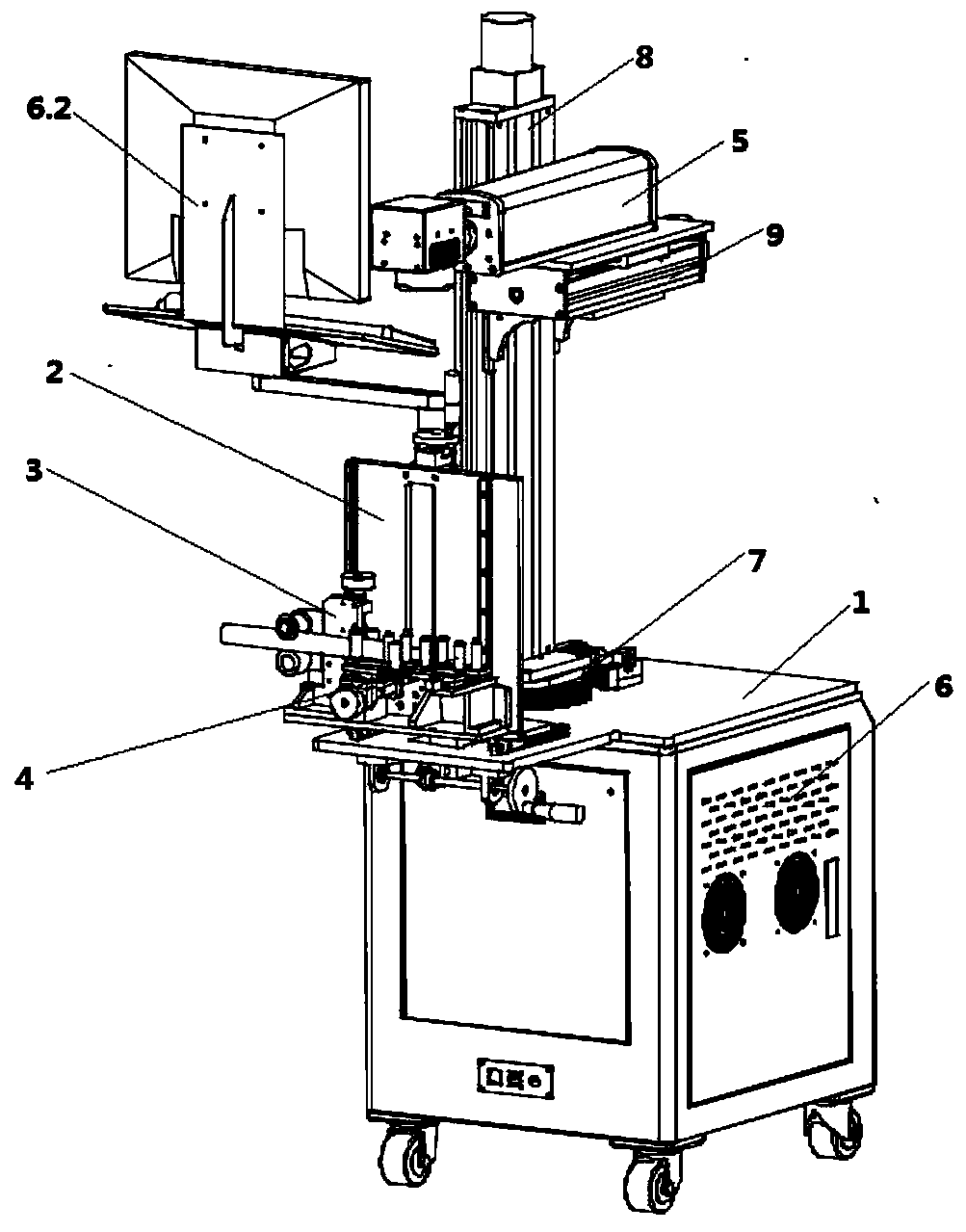

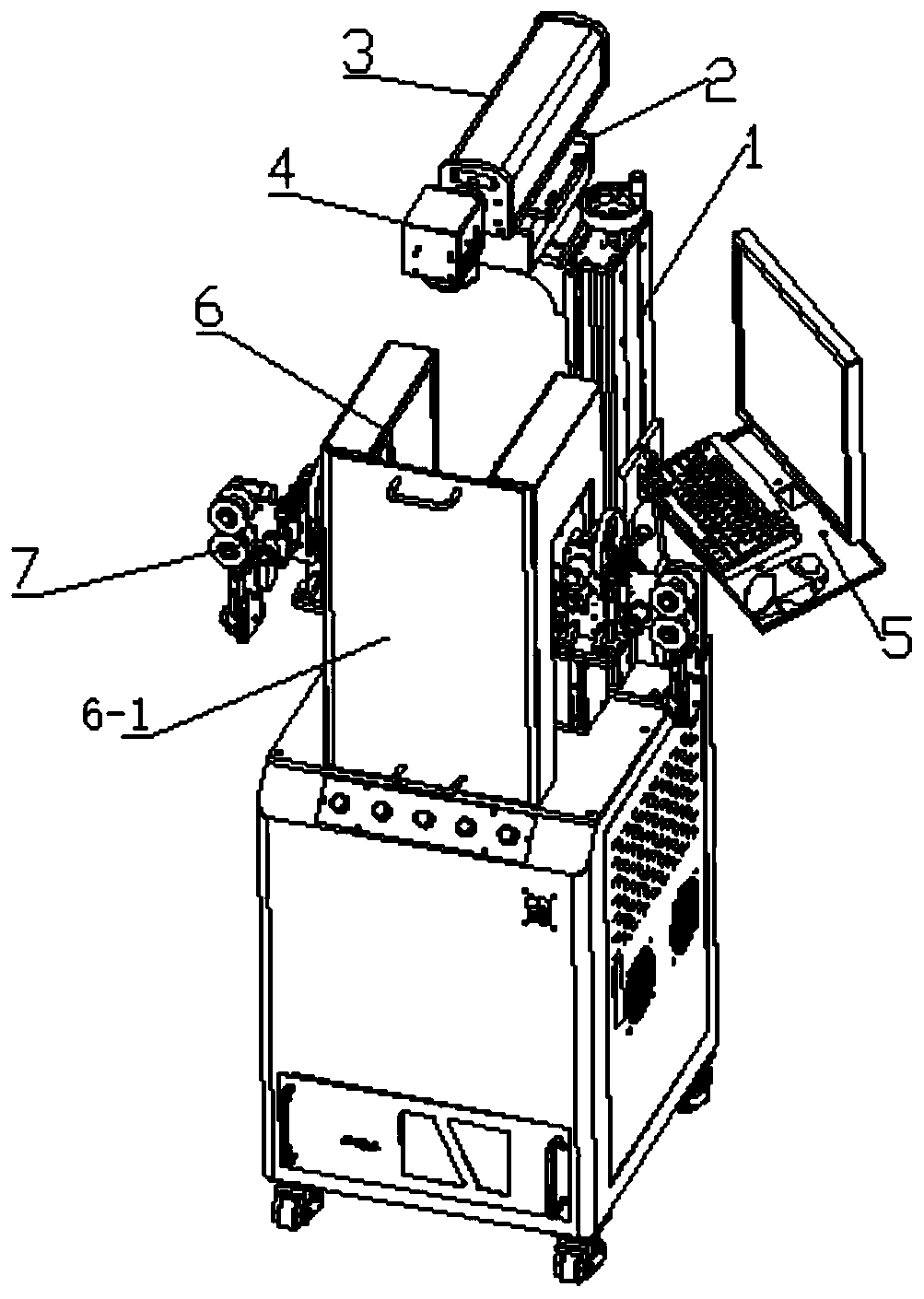

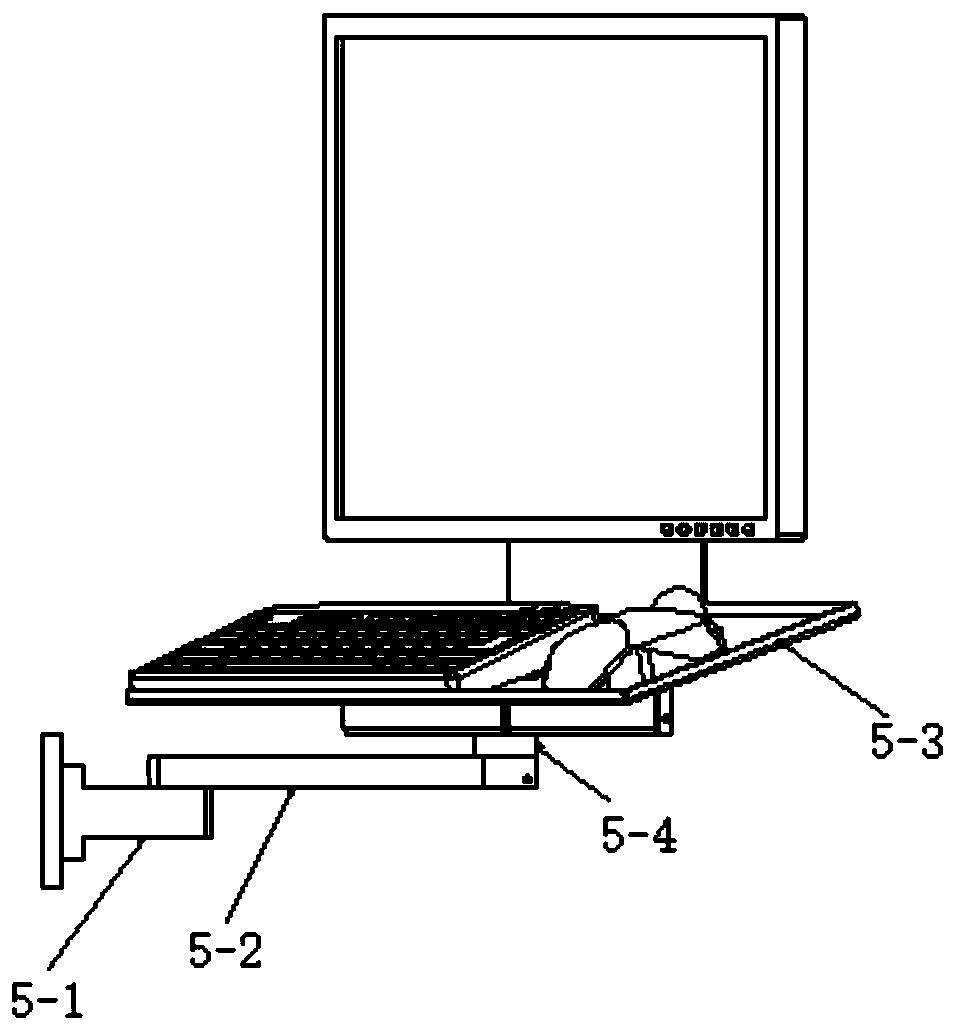

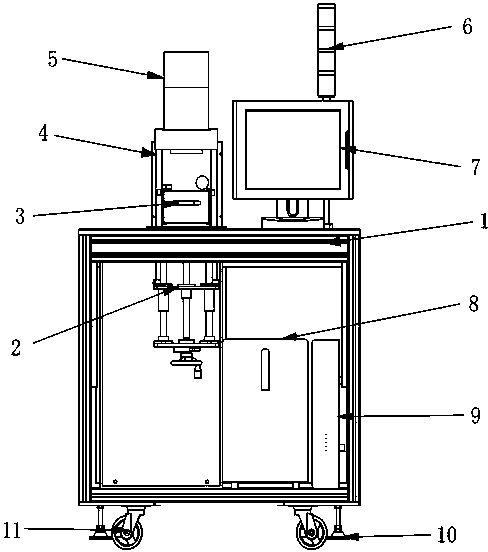

Laser marking machine

The invention provides a laser marking machine, which comprises a rack, wherein the rack is a workbench; the workbench is a cube made of section bars; the middle of the workbench is hollow; one side of the workbench is fixedly provided with a transmission device by a transmission fixing board; the transmission device is divided into a laser component and a transmission part by the table board of the workbench; the laser component is positioned above the table board of the workbench; the transmission component is positioned below the table board of the workbench and is positioned in the hollow part of the workbench; the transmission component is cooperated with the laser component by a transmission pair; the top of the laser component is provided with a laser head device; the transmission fixing board of the transmission device is fixedly provided with a sliding table mechanism; the sliding table mechanism is positioned in the laser component; the sliding table mechanism is mutually cooperated with the laser head device; the other side of the workbench is provided with a PC (personal computer) display; and the PC display is provided with an indicating lamp device. The cooperation of a movable product placement table on the sliding table mechanism and the transmission pair in the transmission component can be controlled by a PC host to realize marking, so that the yield of the laser marking machine is improved, the laser marking machine is simple to operate, and the production efficiency is improved.

Owner:SUZHOU LOCUS TECH

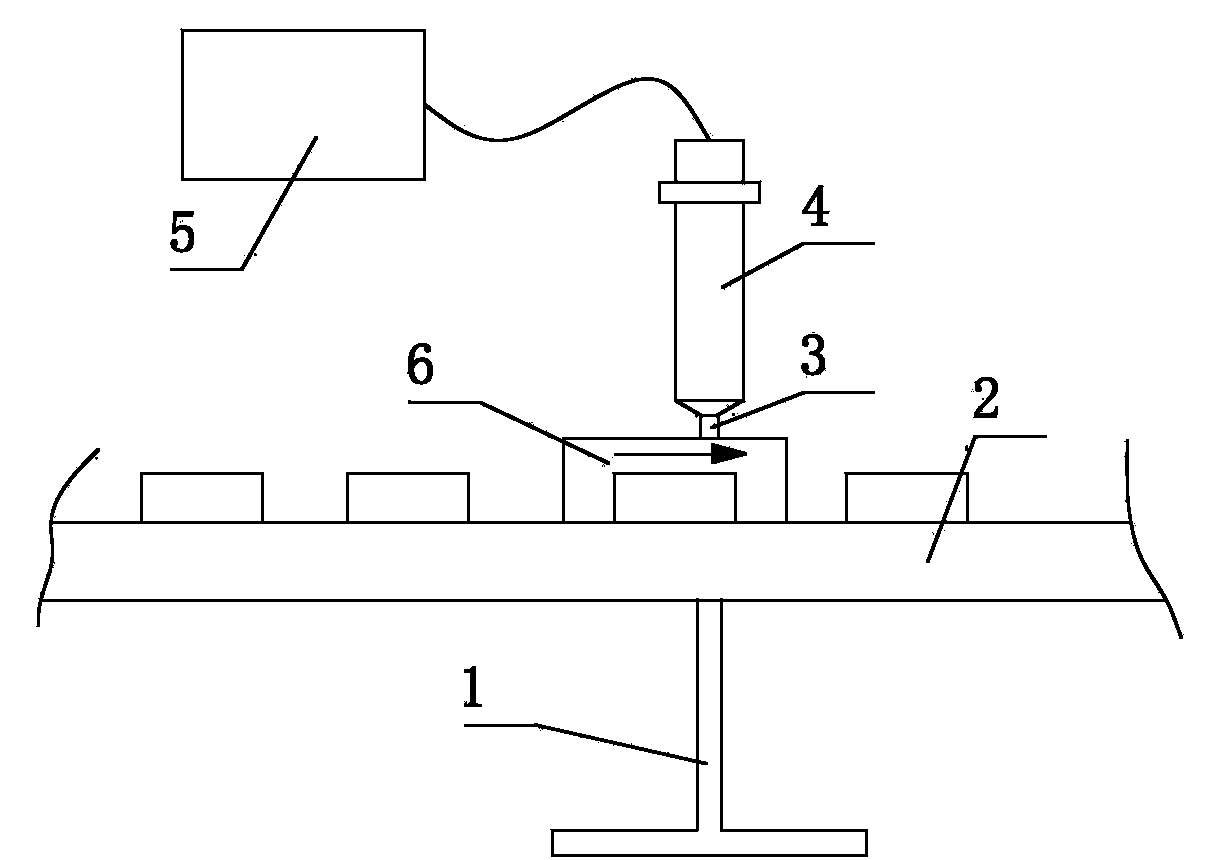

Assembly line flight marking equipment and marking method

PendingCN110340535AAvoid shaking or jumpingImprove stabilityOther printing apparatusLaser beam welding apparatusAssembly lineLaser

The invention provides assembly line flight marking equipment and a marking method, and relates to the technical field of laser marking. The assembly line flight marking equipment comprises a controlmechanism as well as a laser coding optical mechanism, a positioning tool and a movable module mechanismwhich are separately connected to the control mechanism, wherein the positioning tool is equipped with a marking station for marking a product on an assembly line, and is used for clamping and fixing the product on the assembly line, and regulating the position of the marking station according to different product assembly lines; and the movable module mechanism is used for regulating the position, above the marking station, of the laser marking optical mechanism under control of the controlmechanism. The positioning tool is adopted for positioning the product on the assembly line, so that the product on the assembly line is prevented from shaking or jumping during product marking, andtherefore, stability ofthe equipment marking quality and marking effect is improved. The control mechanism is connected to an MES, so that a marking process of the assembly line flight marking equipment is favorably always in a process control state, and therefore, marking efficiency of the assembly line flight marking equipment is improved.

Owner:苏州市长峰激光技术有限公司

Vehicle-mounted normal temperature type striping machine

A vehicle-mounted normal temperature type striping machine is provided. The vehicle-mounted normal temperature type striping machine comprises a rack, the rack is provided with a power transmission system, a pneumatic control system and a paint spraying system, and the power transmission system comprises an engine, an air compressor and a hydraulic gear pump; the pneumatic control system comprisesa glass bead tank and a high-pressure bag, the paint spraying system comprises a hydraulic oil tank, automatic reciprocating oil cylinders and high-pressure plunger pumps, and two sets of automatic reciprocating oil cylinder and high-pressure plunger pumps are correspondingly arranged; the glass bead tank comprises a tank body, pressing devices and a glass viewing window, the tank body is internally provided with a separating plate which divides the tank body into an upper material cavity and a lower material cavity, the top of the tank body is provided with an upper cavity feeding port and alower cavity feeding port, and the bottom of the tank body is provided with an upper cavity discharging port and a lower cavity discharging port; and an upper cavity feeding port cover and a lower cavity feeding port cover are correspondingly pressed by the two pressing devices. According to the vehicle-mounted normal temperature type striping machine, a complicated electric control system and ahydraulic system are canceled, the structure is simple and compact, operation is simple, the striping machine system is stable, and the fact that shutdown for feeding is not required during long-distance striping working of the glass bead tank.

Owner:WELL ROAD MACHINERY CO LTD

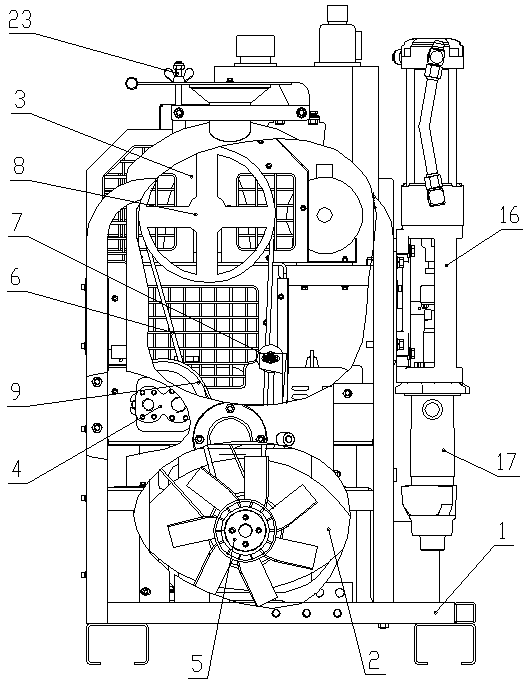

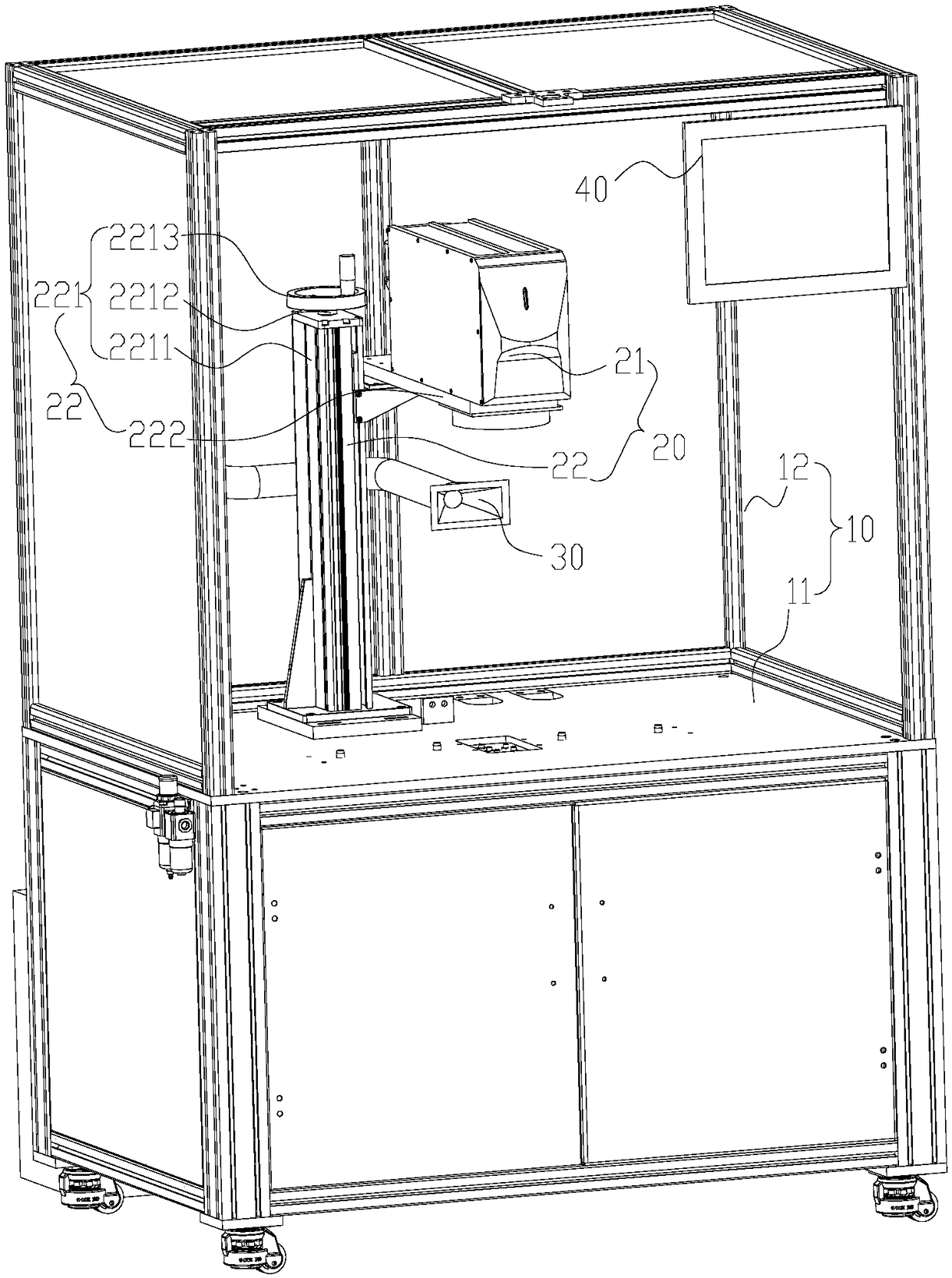

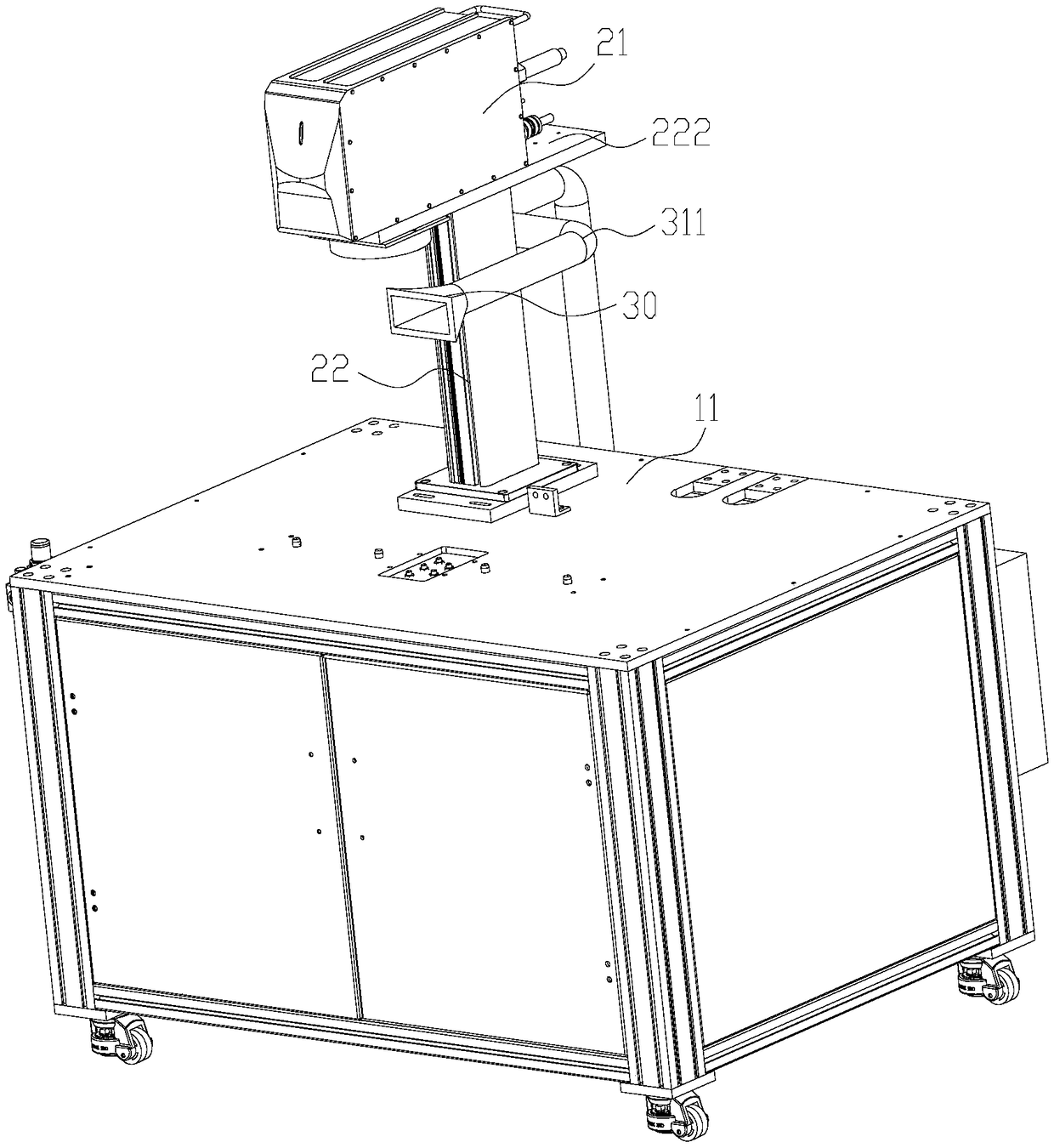

Laser marking machine

PendingCN109332907AStable operationImprove marking qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a laser marking machine. The laser marking machine comprises a rack, a control assembly, a temperature adjusting assembly, a laser marking device and a clamp assembly, whereinthe control assembly and the temperature adjusting assembly are mounted on the rack, and the laser marking device and the clamp assembly are assembled in the rack; the control assembly is electricallyconnected with the laser marking device and the clamp assembly, and the rack comprises a worktable and a machining cover assembled to the worktable; and the machining cover is provided with a closedmachining space, and the laser marking device and the clamp assembly are mounted on the worktable and both located in the machining space. When the laser marking device machines a workpiece assembledto the clamp assembly, the temperature adjusting assembly is used for adjusting the temperature of the machining space to enable the temperature in the machining space to be within the preset range; the laser marking machine is equipped with the temperature adjusting assembly, so that the laser marking device is within the preset temperature range; and the clamp assembly clamps the preset positionof the workpiece so that the laser marking device can accurately conduct marking, the workpiece can be quickly replaced, and thus the machining efficiency is high.

Owner:IKD CO LTD

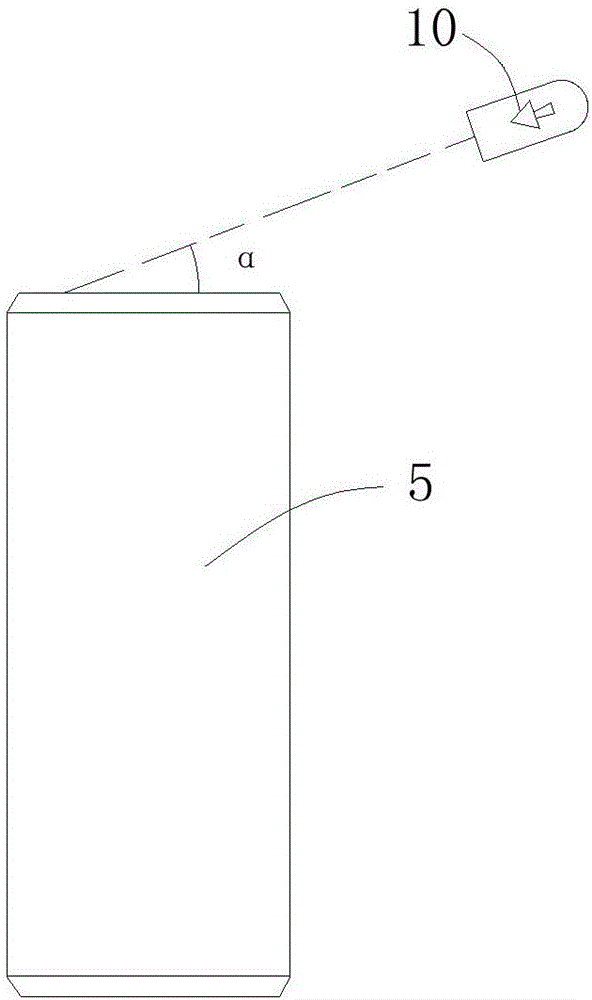

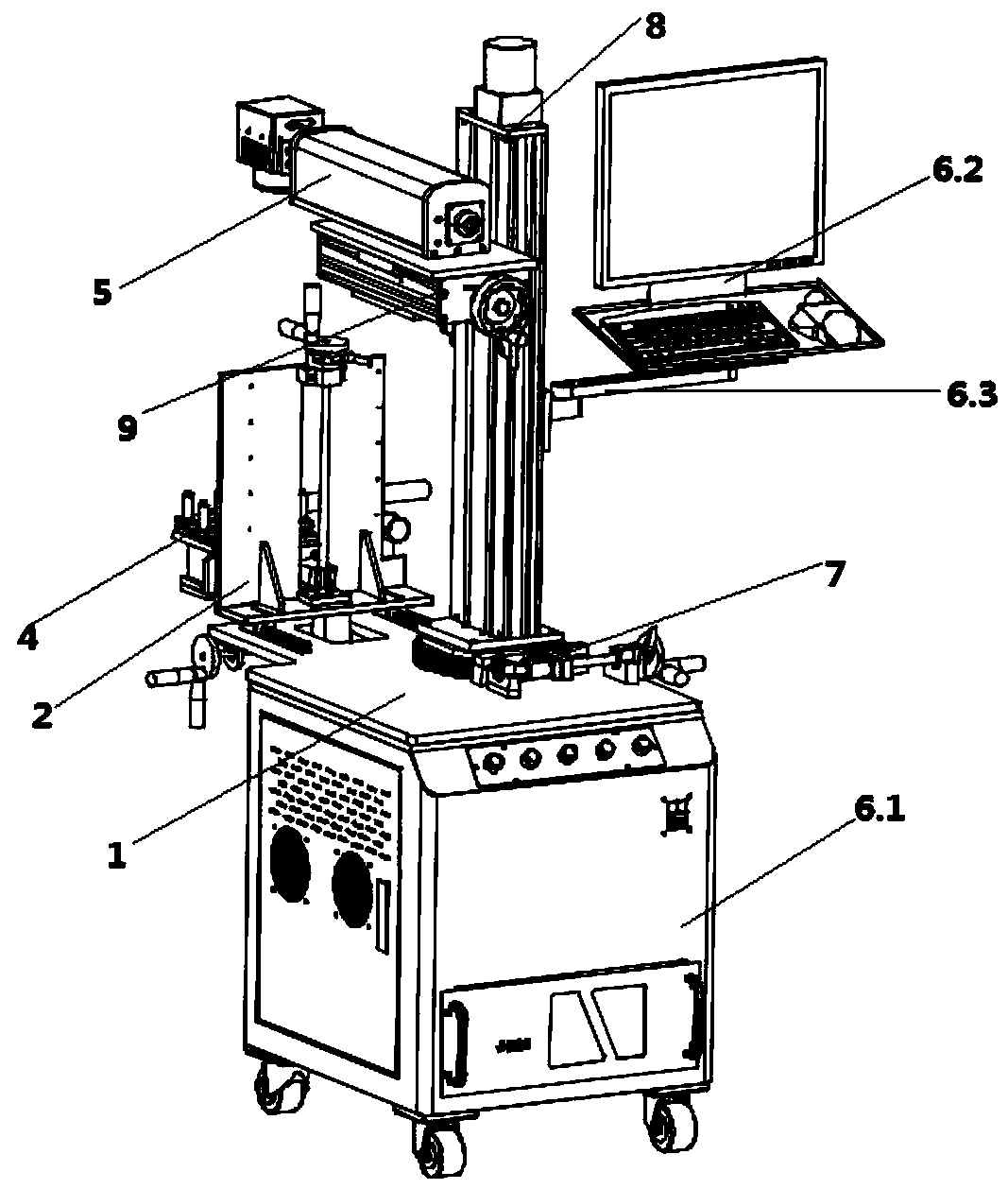

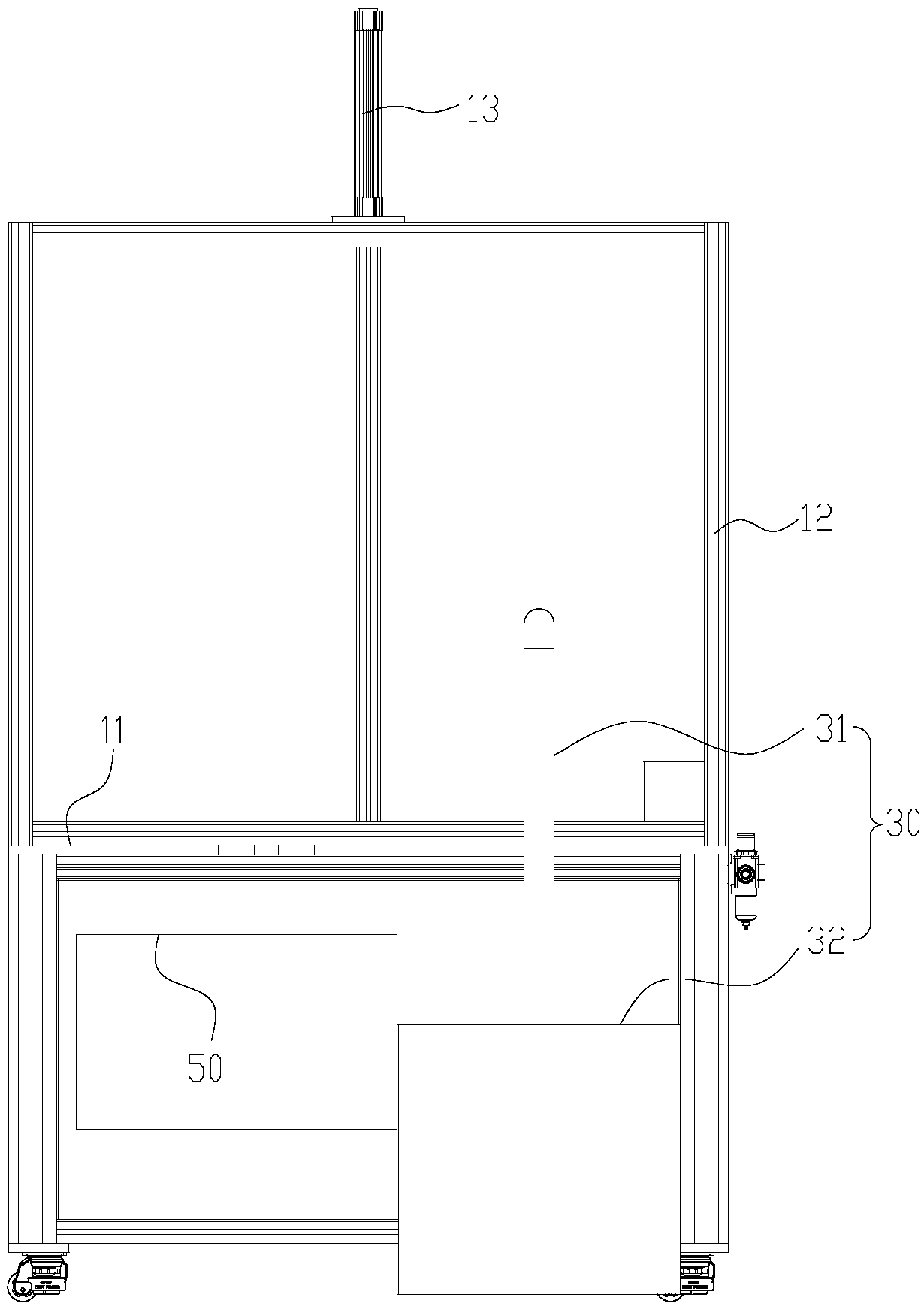

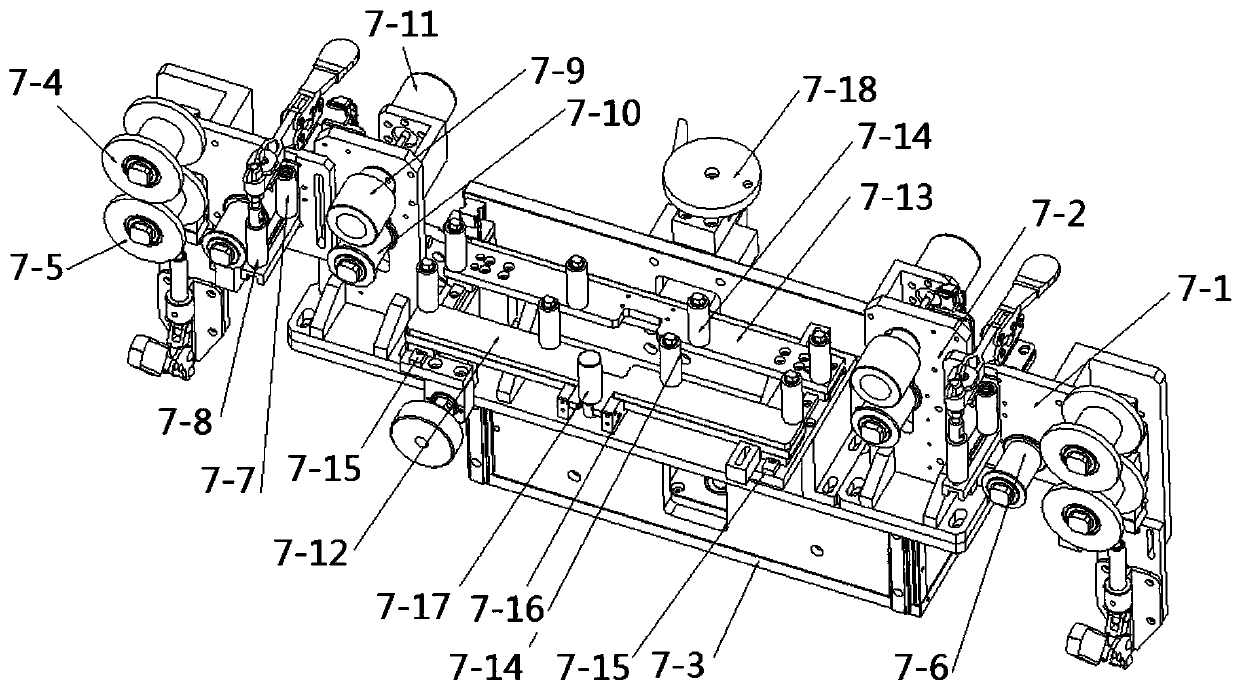

Linear product clamping and guiding tool and high-speed marking equipment

PendingCN110369877AReduce jumpingStable marking positionLaser beam welding apparatusWire rodEngineering

The invention discloses a linear product clamping and guiding tool and high-speed marking equipment. The linear product clamping and guiding tool comprises a support mechanism, preliminary vertical positioning and guiding wheel sets, a vertical guide wheel, a transverse positioning rotary column group and a vertical tightening wheel set, wherein the preliminary vertical positioning and guiding wheel sets are arranged in a bilateral symmetry manner; and the preliminary vertical positioning and guiding wheel sets, the vertical guide wheel, the transverse positioning rotary column group, the vertical tightening wheel set and a width adjustable routing mechanism are arranged in sequence from the end to the interior. The high-speed marking equipment comprises an equipment cabinet, a light source up and down lifting device, a front and rear moving platform, a laser light source, a laser head and the product clamping and guiding tool. The high-speed marking equipment can improve the stabilityof the running track of flight assembly lines such as pipe bodies and wire rods during laser marking, improves the quality of the high-speed laser marking, and can realize the online editing of the marking content.

Owner:苏州市长峰激光技术有限公司

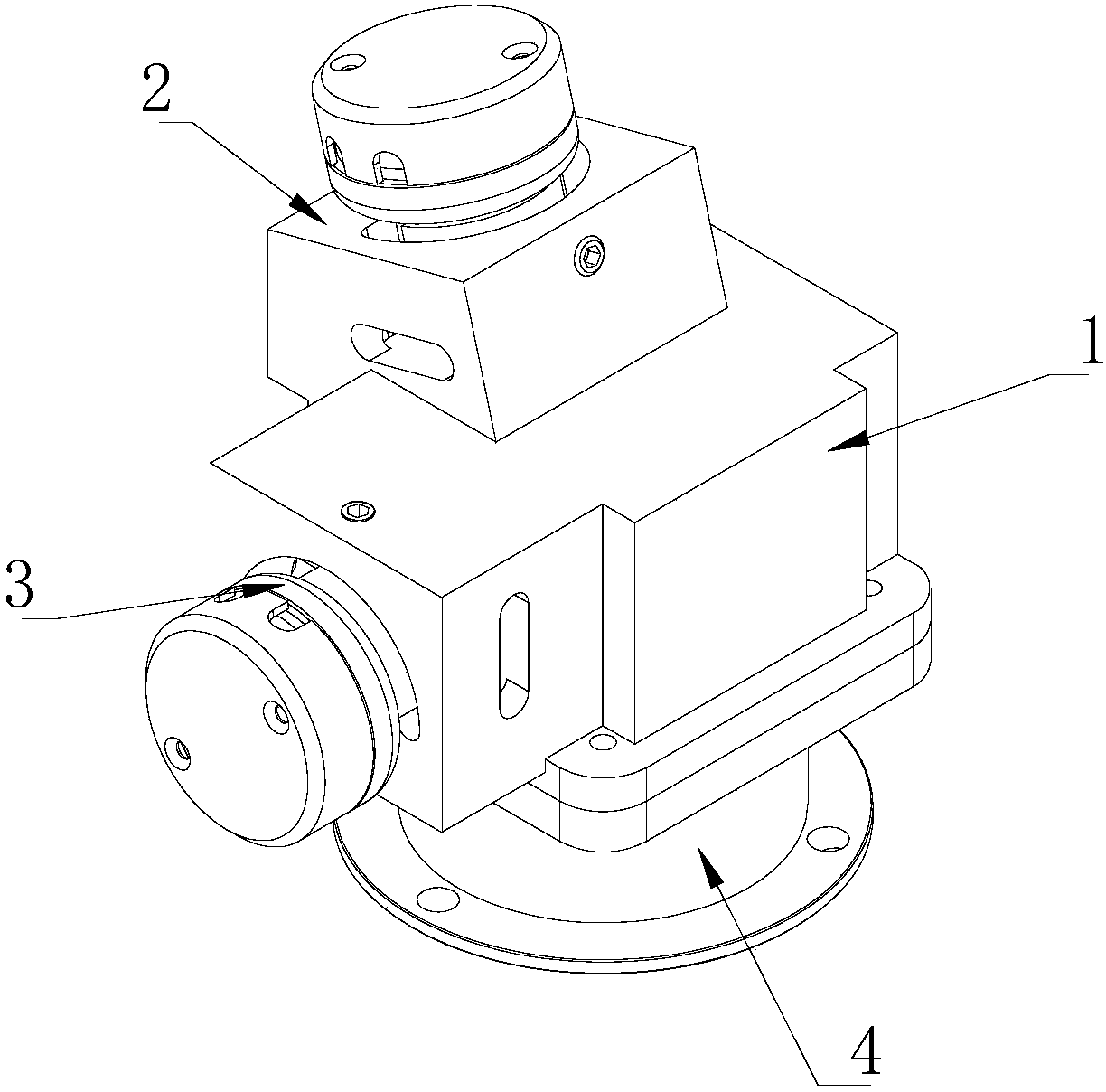

Closed scanning galvanometer device for laser machine

PendingCN107790892AReduce distractionsStable positionLaser beam welding apparatusOptical elementsGalvanometerLaser beams

The invention provides a closed scanning galvanometer device for a laser machine. The device comprises a base, an X galvanometer mechanism, a Y galvanometer mechanism and a field lens mechanism. The Xgalvanometer mechanism comprises an X galvanometer motor, an X galvanometer lens and an X galvanometer base which is provided with an X positioning hole, the Y galvanometer mechanism comprises a Y galvanometer motor, a Y galvanometer lens and a Y galvanometer base which is provided with a Y positioning hole, the field lens mechanism comprises a field lens, the front end of the base is provided with a laser incidence hole, the bottom of the base is provided with a field lens installation hole, the field lens is installed in the field lens installation hole, the X positioning hole, the Y positioning hole, the field lens installation hole and the laser incidence hole are mutually connected in a cavity, and the cavity is provided with no other through hole except for the X positioning hole, the Y positioning hole, the field lens installation hole and the laser incidence hole. The scanning galvanometer device fixes the Y galvanometer motor, the X galvanometer motor and the field lens, therelative positions are more stable, the closed cavity is formed in the base after fixing, and dust pollution is small when a laser beam passes.

Owner:广东铭钰科技股份有限公司

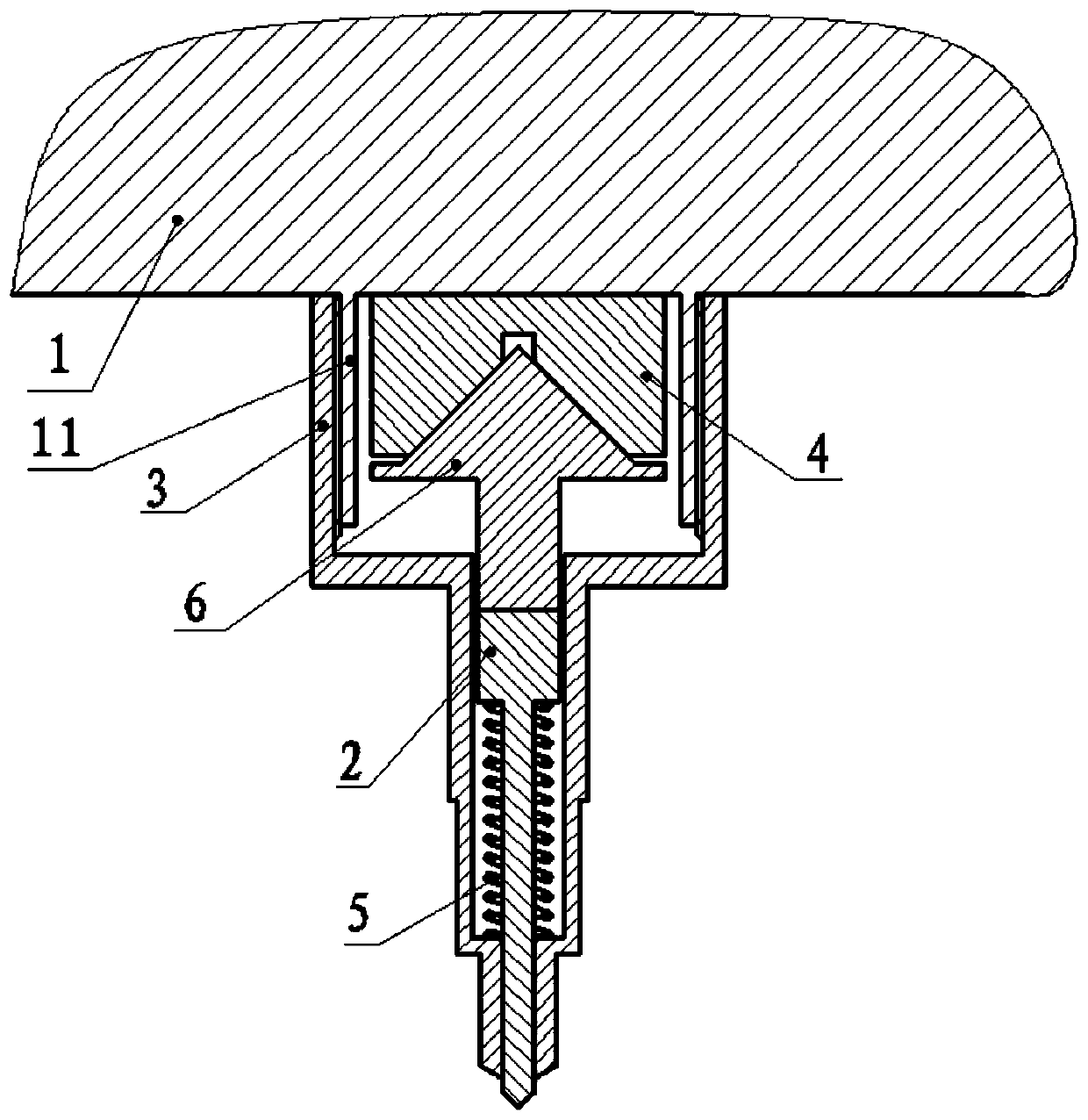

Marking machine two-dimensional code marking head and two-dimensional code marking method

InactiveCN110774775AReduce manufacturing costImprove marking qualityPattern printingTypewritersCode pointMagnetic poles

The invention provides a marking machine two-dimensional code marking head and a two-dimensional code marking method. The marking machine two-dimensional code marking head comprises a supporting seat,a marking needle and a needle shell. A protruding ring is arranged on the supporting seat. A high-frequency pulse electromagnet is installed in the protruding ring. The marking needle is connected with an end opening of one end of the needle shell in a sliding fit manner. The marking needle is further sleeved with a spring, and the two ends of the spring make contact with the inner wall of the marking needle and the inner wall of the end opening of the needle shell. The tail end of the marking needle is further fixedly connected with a permanent magnet. An end opening of the other end of theneedle shell is fixedly connected with the protruding ring through a threaded pair, and in addition, the permanent magnet and the high-frequency pulse electromagnet are oppositely arranged with opposite magnetic poles. The two-dimensional code marking method includes the step of using the marking head to print a two-dimensional code. By the adoption of the technical scheme, due to the cooperativeconnecting structure of the permanent magnet and the high-frequency pulse electromagnet, the code point marking consistency of the two-dimensional code is improved, the marking quality of the two-dimensional code is improved, and the requirement for the manufacturing precision of related composition structure parts of the marking head is lowered.

Owner:GUIZHOU LIYANG INT MFG

Inner pot cover marking device and marking method

ActiveCN107717232AImprove marking efficiencySimple structureLaser beam welding apparatusEngineeringLaser

The invention aims to provide an inner pot cover marking device and a marking method. The inner pot cover marking device comprises two stepping conveyors with conveying belts, a controller with a display screen, a rotary device with a rotary plate, four inner pot cover accommodating holes uniformly distributed along the circumference of an axis of the rotary plate and communicating with the upperend and the lower end of the rotary plate, two inner pot cover moving devices distributed along a side wall of the rotary plate and in one-to-one correspondence to the inner pot cover accommodating holes, and a position levelling device and a laser marking device located between the two inner pot cover moving devices. The two stepping conveyors are in one-to-one correspondence to the two inner potcover moving devices. The inner pot cover marking device is used for marking an inner pot cover of an electric pressure cooker, and has higher marking efficiency and stable marking quality.

Owner:HANGZHOU LIFUHAO MECHANICAL & ELECTRICAL EQUIP

Device for producing and machining mailboxes

InactiveCN107738532ARealize automatic up and down translation workSimple structureEmbossing decorationsSurface mountingExpansion chamber

The invention discloses a device for producing and processing mailboxes, which comprises a hanger and a work frame installed on the lower side of the hanger. A hanger is installed directly above the top of the hanger. The left and right chambers are equipped with connecting columns that expand downwards in translation. The screws in the connecting columns are equipped with screw shafts that expand left and right. The end of the part is installed with the main motor. The outer surface of the main motor is installed in the left end wall of the left and right chambers and fixedly connected. The bottom end surface of the connecting column is fixedly installed with the position directly above the work frame. The side and the tail are slightly connected with a guide groove that is extended upwards, and the inner wall of the work frame on the upper side of the guide groove is provided with a running chamber that is extended to the left; the invention has simple structure, convenient operation, high safety, improved marking speed and quality.

Owner:PUJIANG ANHENG IMPORT & EXPORT

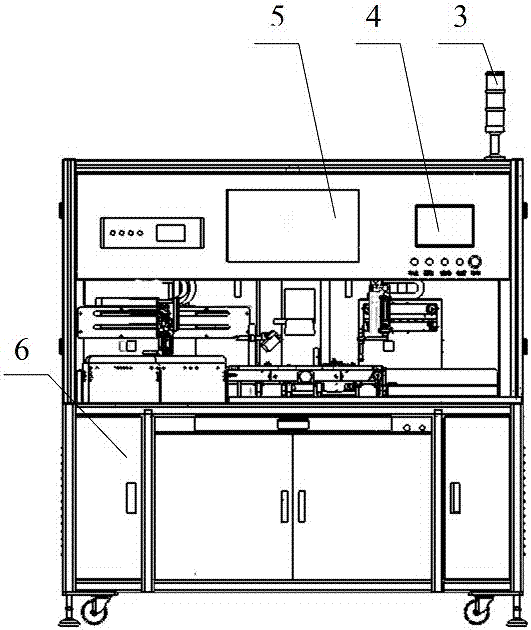

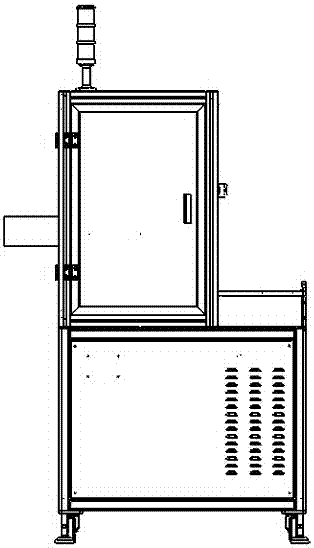

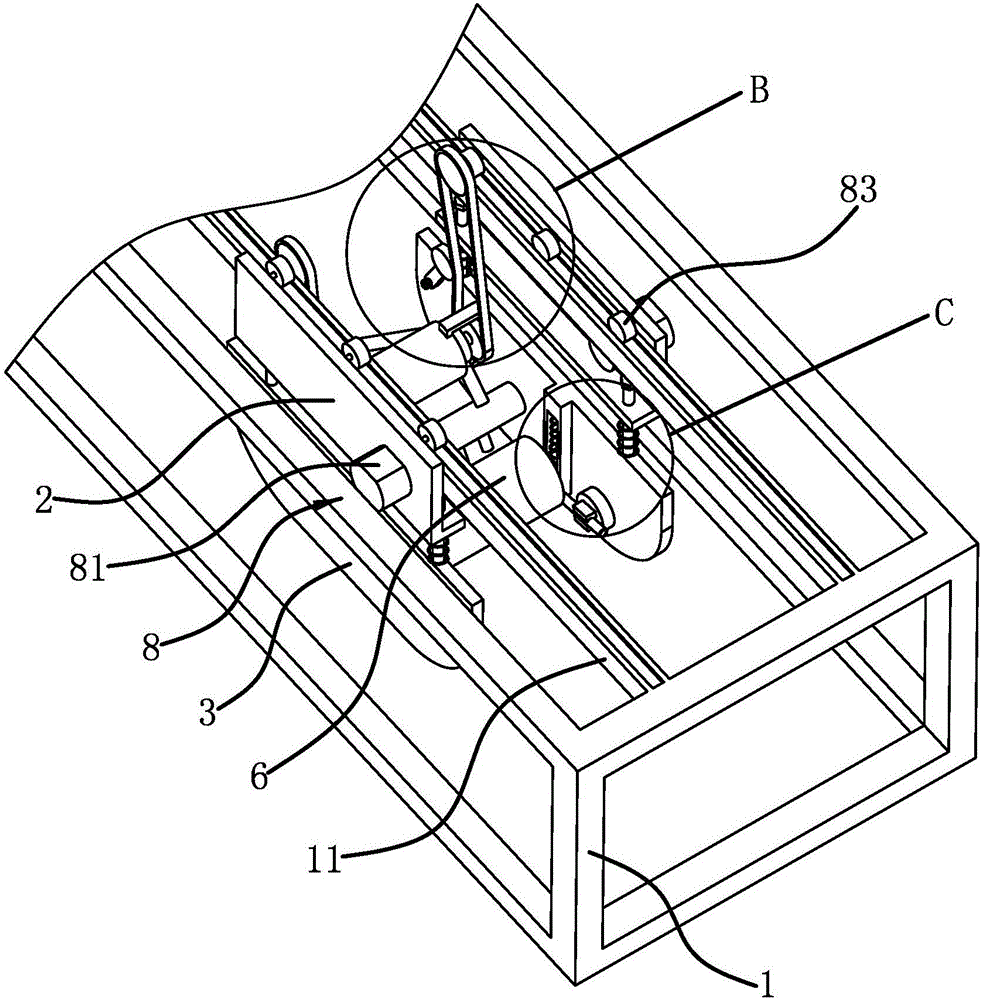

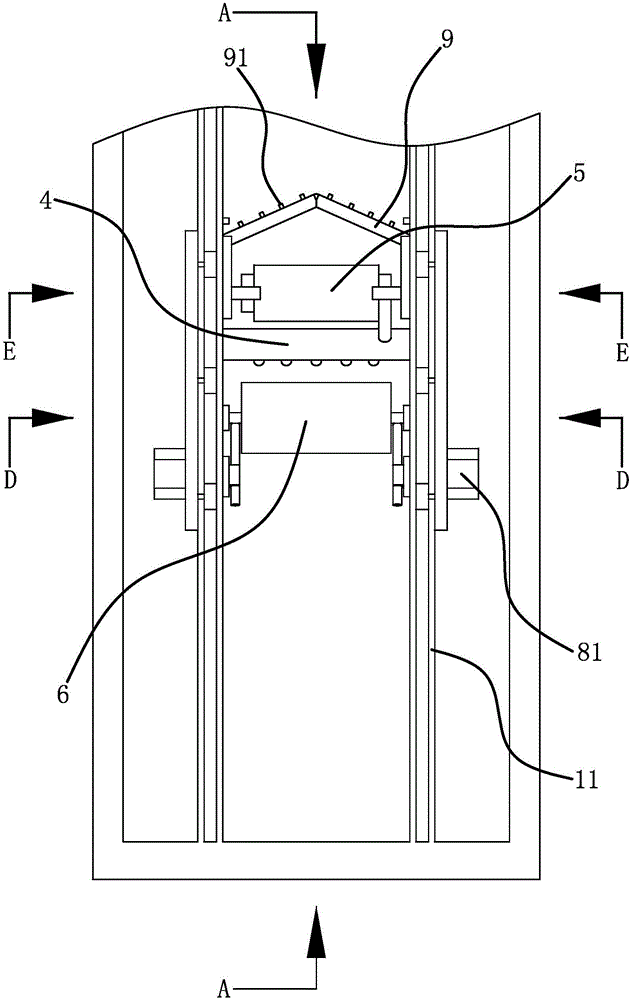

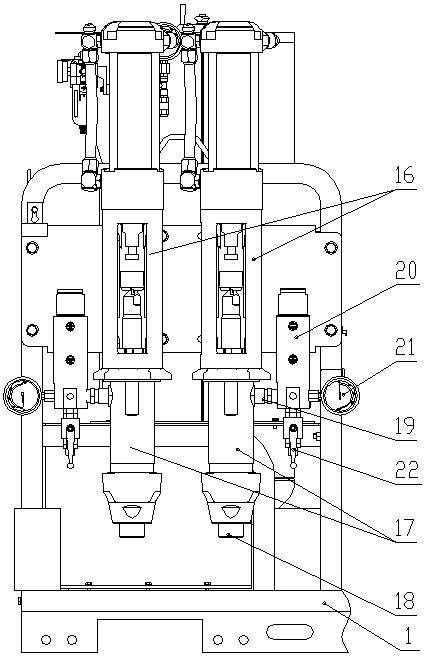

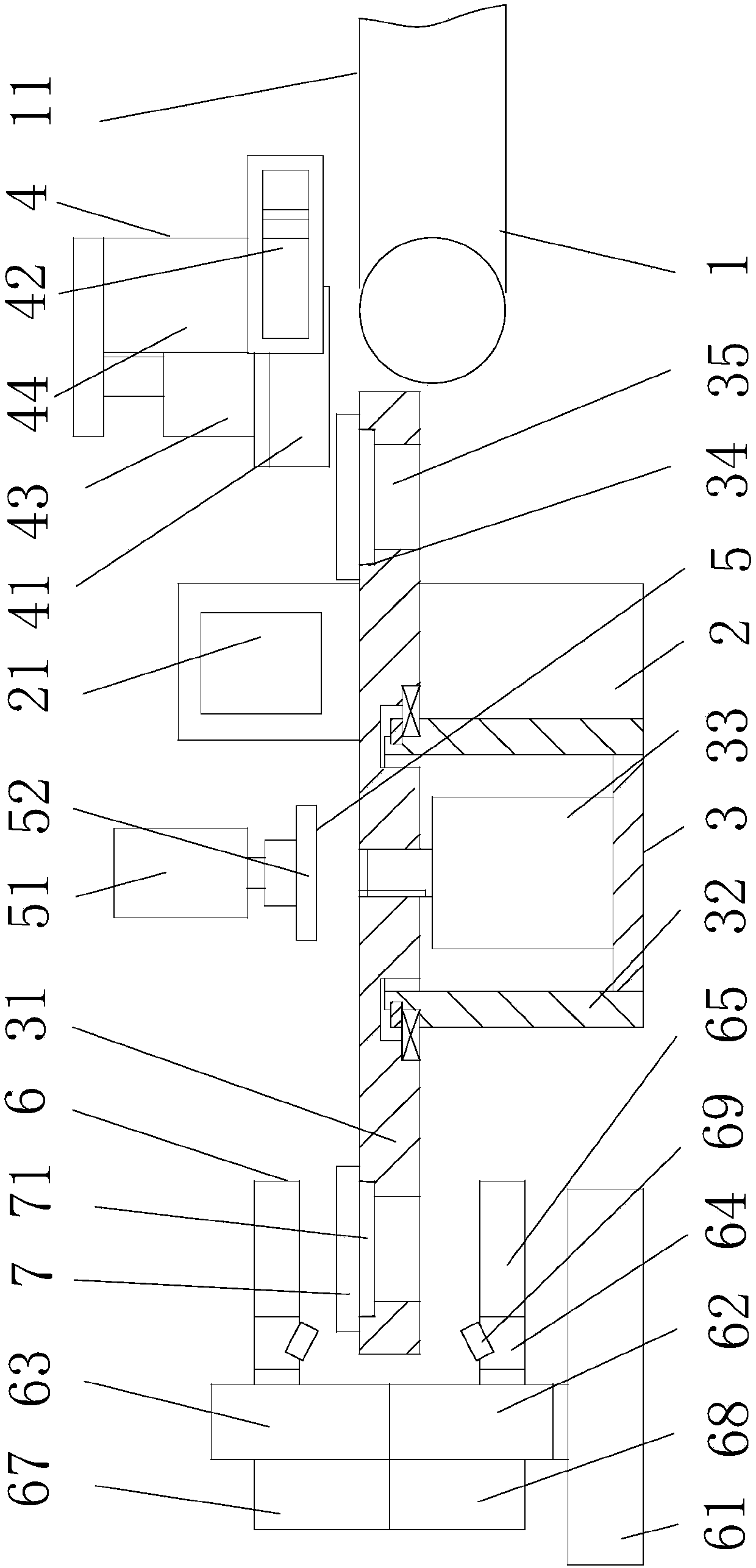

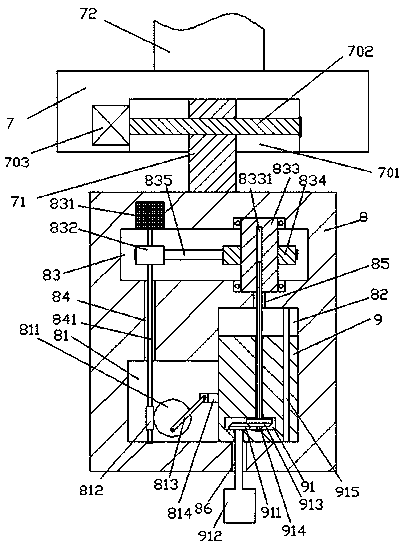

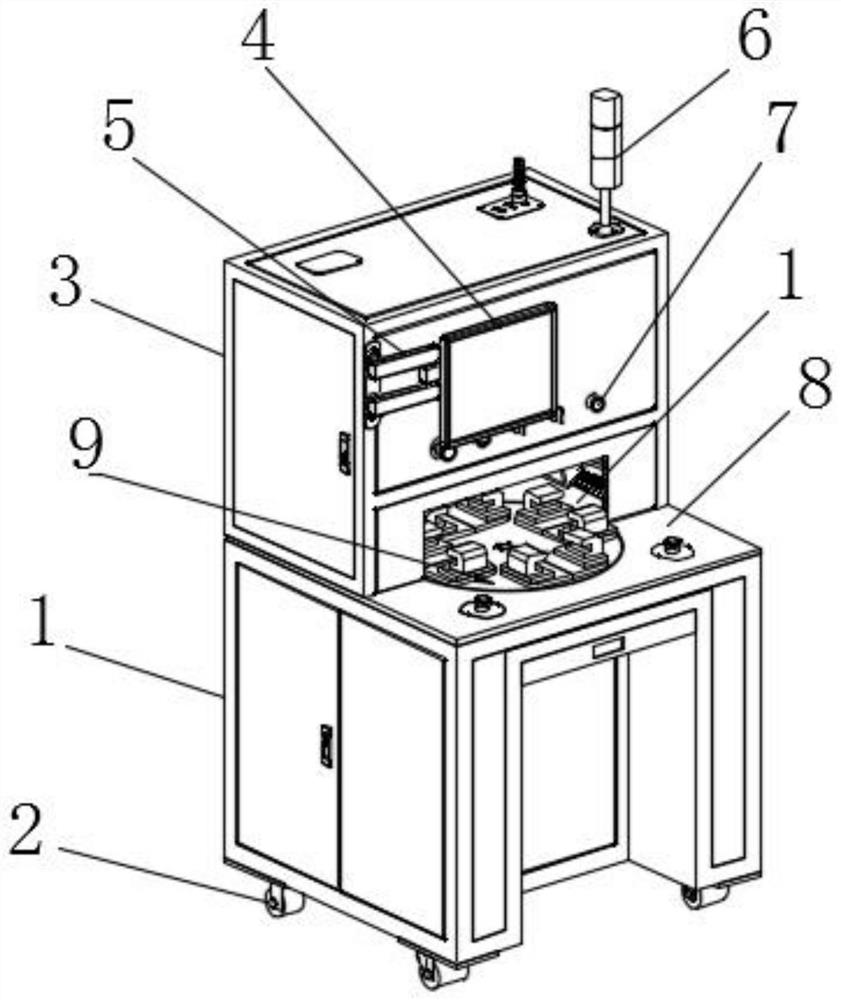

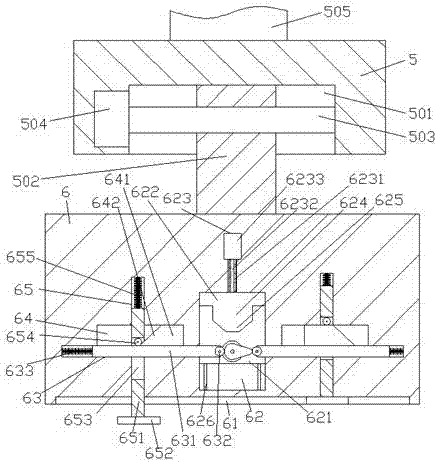

A multi-directional and precise four-station double-head laser marking machine

ActiveCN109648208BMark accuratelyImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesMarking outEngineering

The invention discloses a multidirectional accurate type four-station double-head laser marking machine which comprises a bearing table and a supporting outer frame. The supporting outer frame is fixedly installed at the upper end of the bearing table. An illumination lamp is installed at the corner position of the upper end of the supporting outer frame. A scram button is arranged at the position, close to the bottom end, of the supporting outer frame. The surface of the upper end of the bearing table is covered with a worktable. A clamping station mechanism is installed at the middle position of the surface of the upper end of the worktable. A marking mechanism is installed over the clamping station mechanism. By means of the multidirectional accurate type four-station double-head lasermarking machine, multidirectional marking can be conducted on a to-be-marked workpiece, meanwhile, four sets of stations are used for limiting and fixing the to-be-marked workpiece in four different directions, due to double laser heads, the marking rate can be increased, the production cost is reduced, effective damping can be conducted on a station circular truncated cone, the marking accuracy is ensured, in addition, heat generated by marking can be dissipated, air drying can be conducted on the marked mark, and the marking quality is ensured.

Owner:BINZHOU UNIV

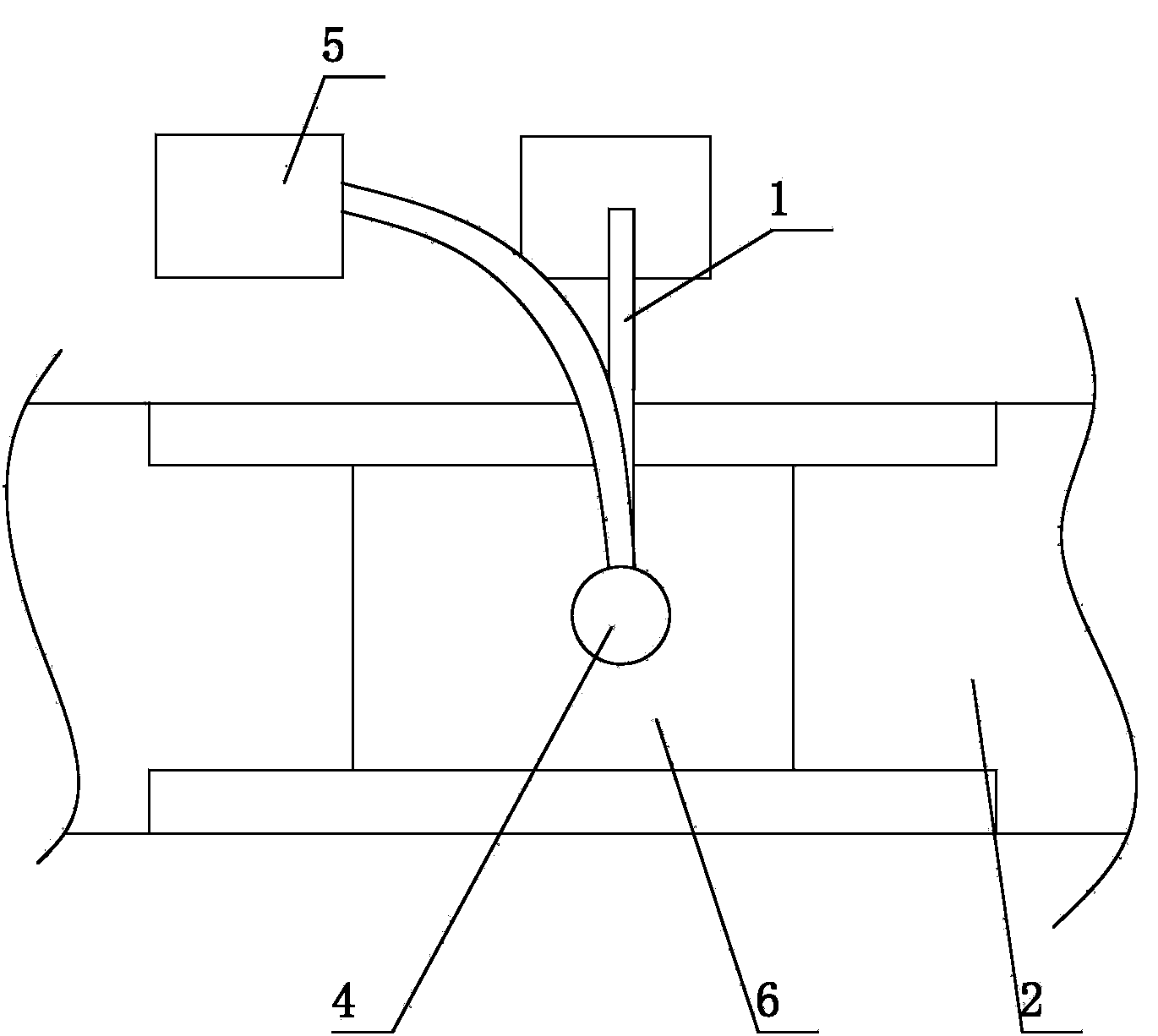

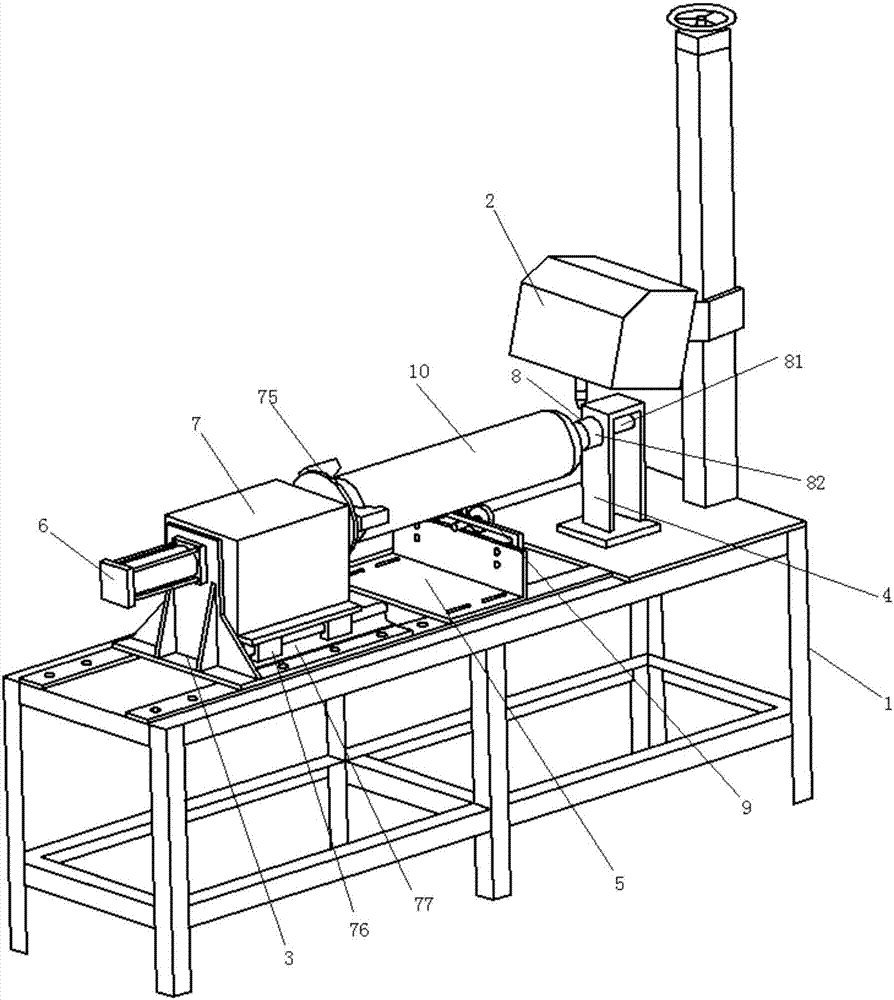

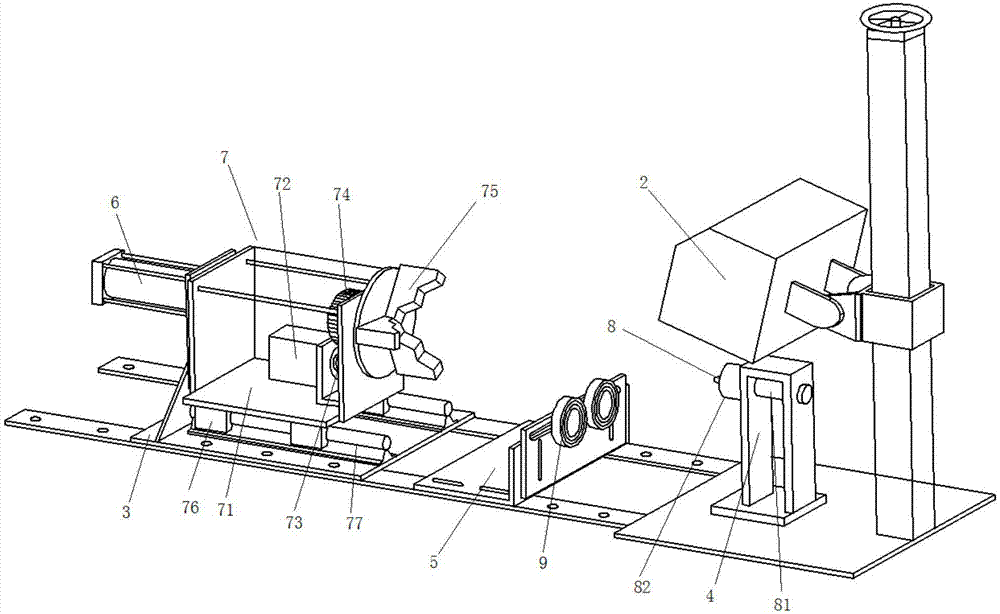

Tooling for pipeline flying marking

The invention provides a tooling for pipeline flying marking, and relates to the technical field of laser marking. The tooling comprises a mounting bottom plate, a two-way mobile platform arranged onthe mounting bottom plate, a first positioning part and a second positioning part, wherein the first positioning part and the second positioning part are mounted on the two-way mobile platform, and the two-way mobile platform is used for driving the first positioning part and the second positioning part to move in the direction parallel to the surface of the mounting bottom plate and / or vertical to the surface of the mounting bottom plate; the first positioning part is used for primarily positioning flowing products, the second positioning part is used for secondarily positioning the flowing products, the product positioning center of the first positioning part and the product positioning center of the second positioning part are located in the same horizontal height, and the connecting line of the product positioning centers is parallel to the transmission direction of an assembly line. By means of clamp positioning for the products in the assembly line in two different directions, the products on the assembly line are effectively prevented from shaking or jumping during marking, and marking quality and marking effect stability are effectively improved.

Owner:苏州市长峰激光技术有限公司

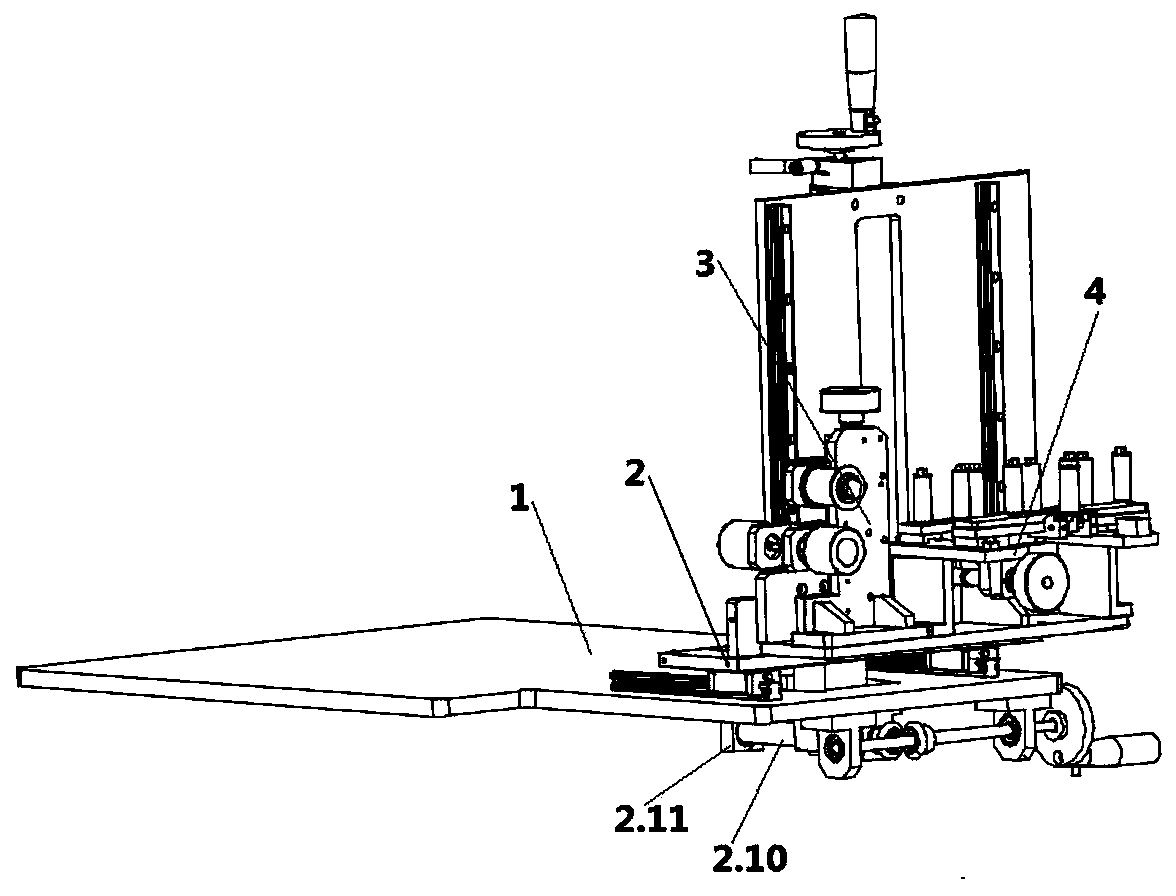

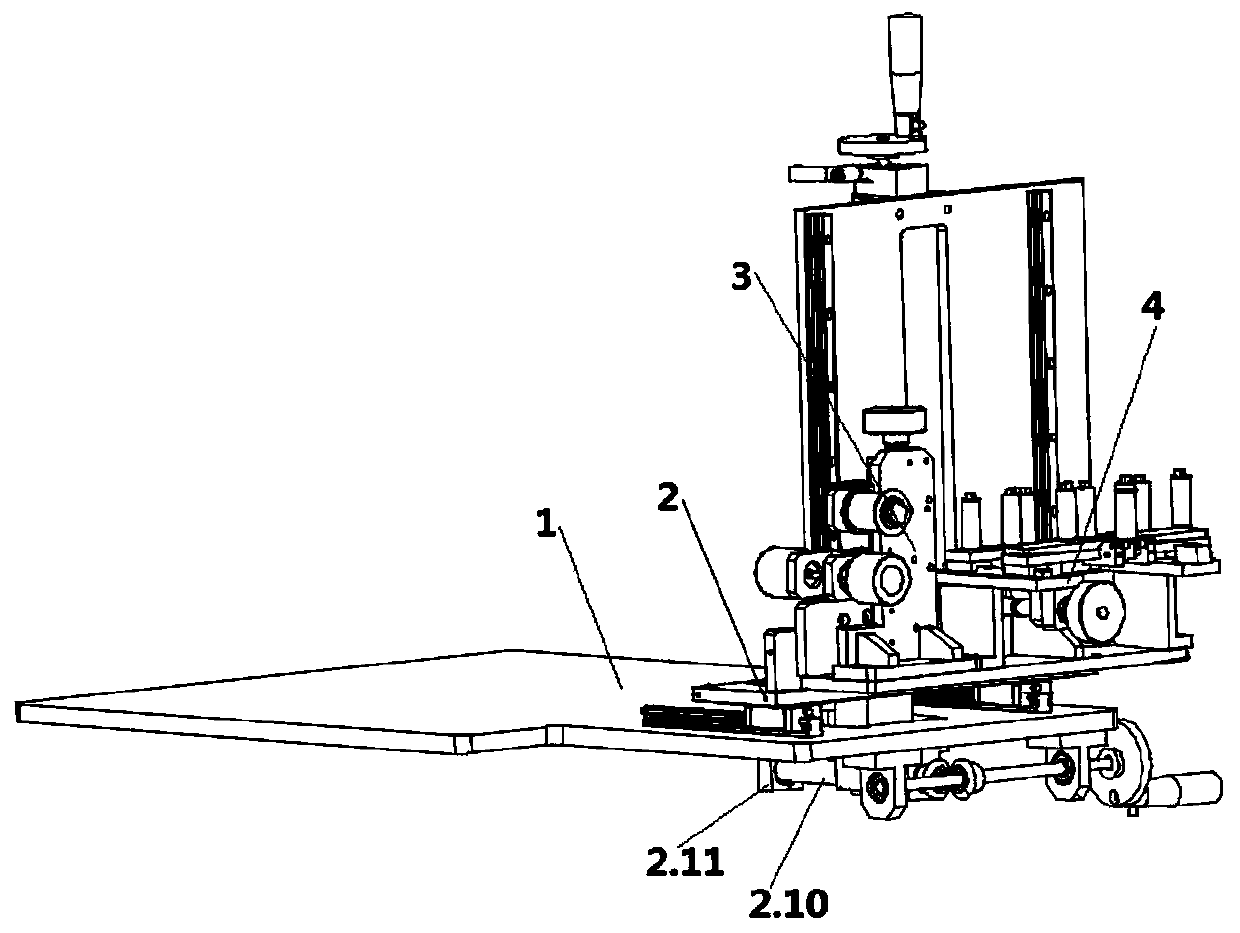

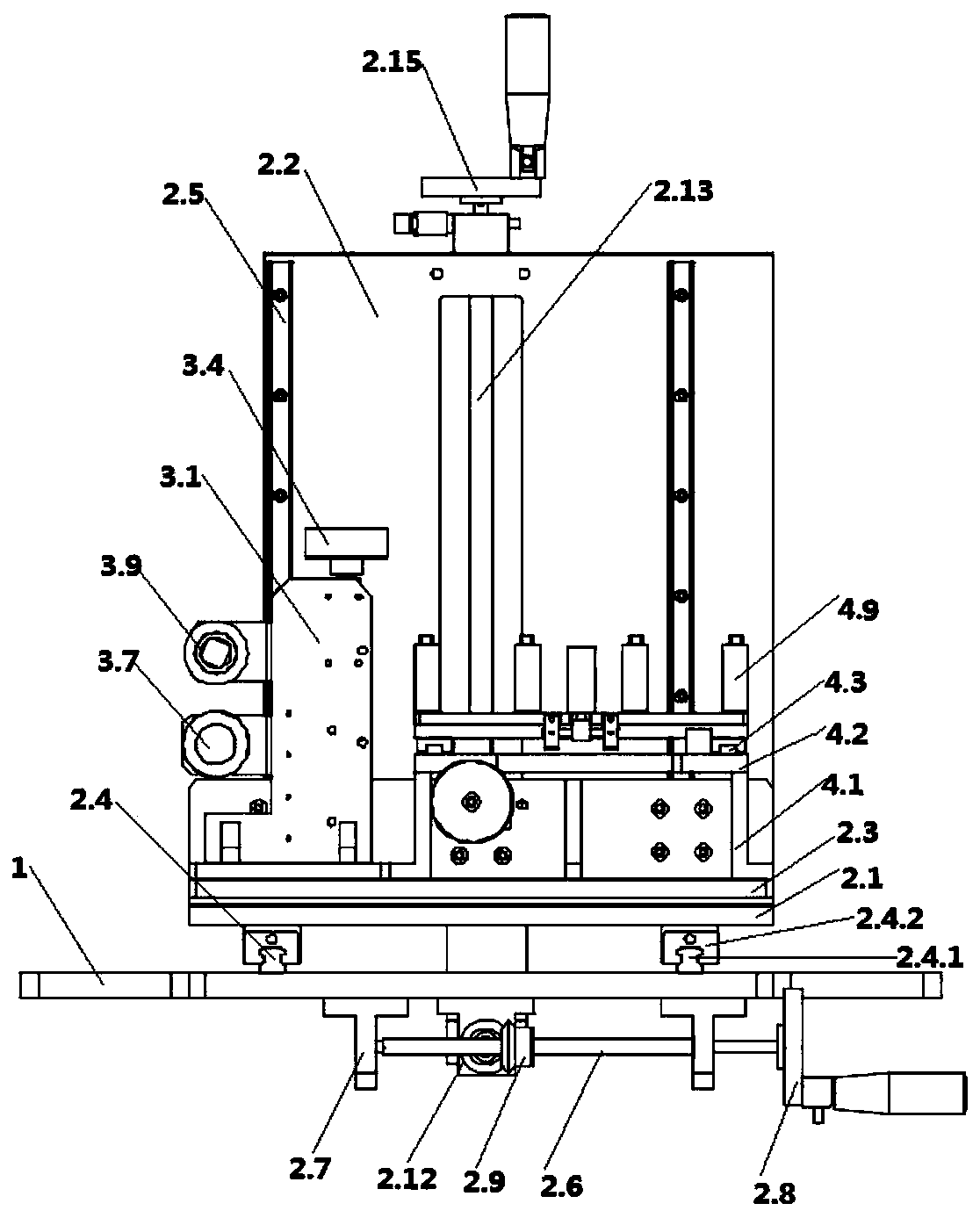

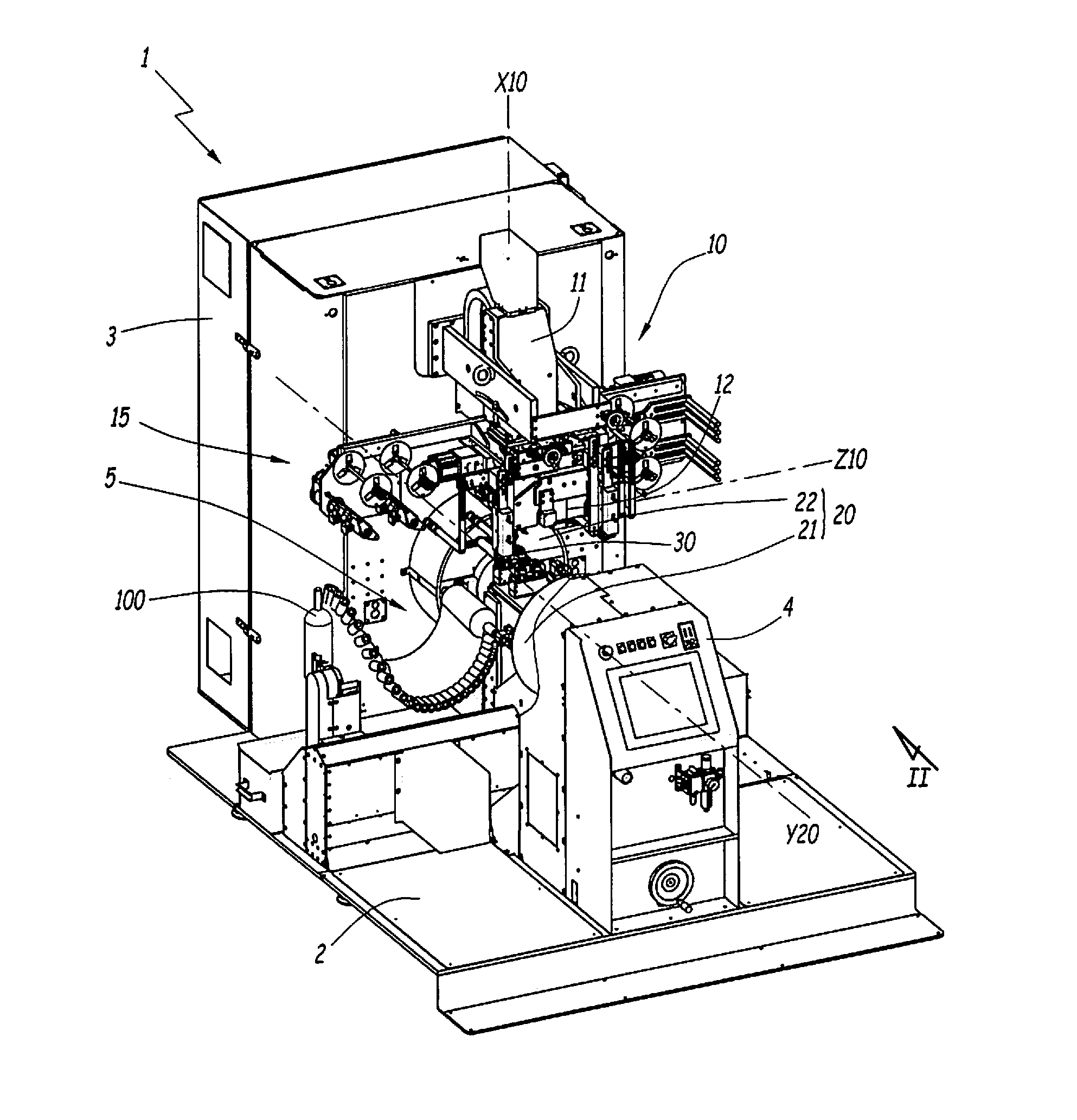

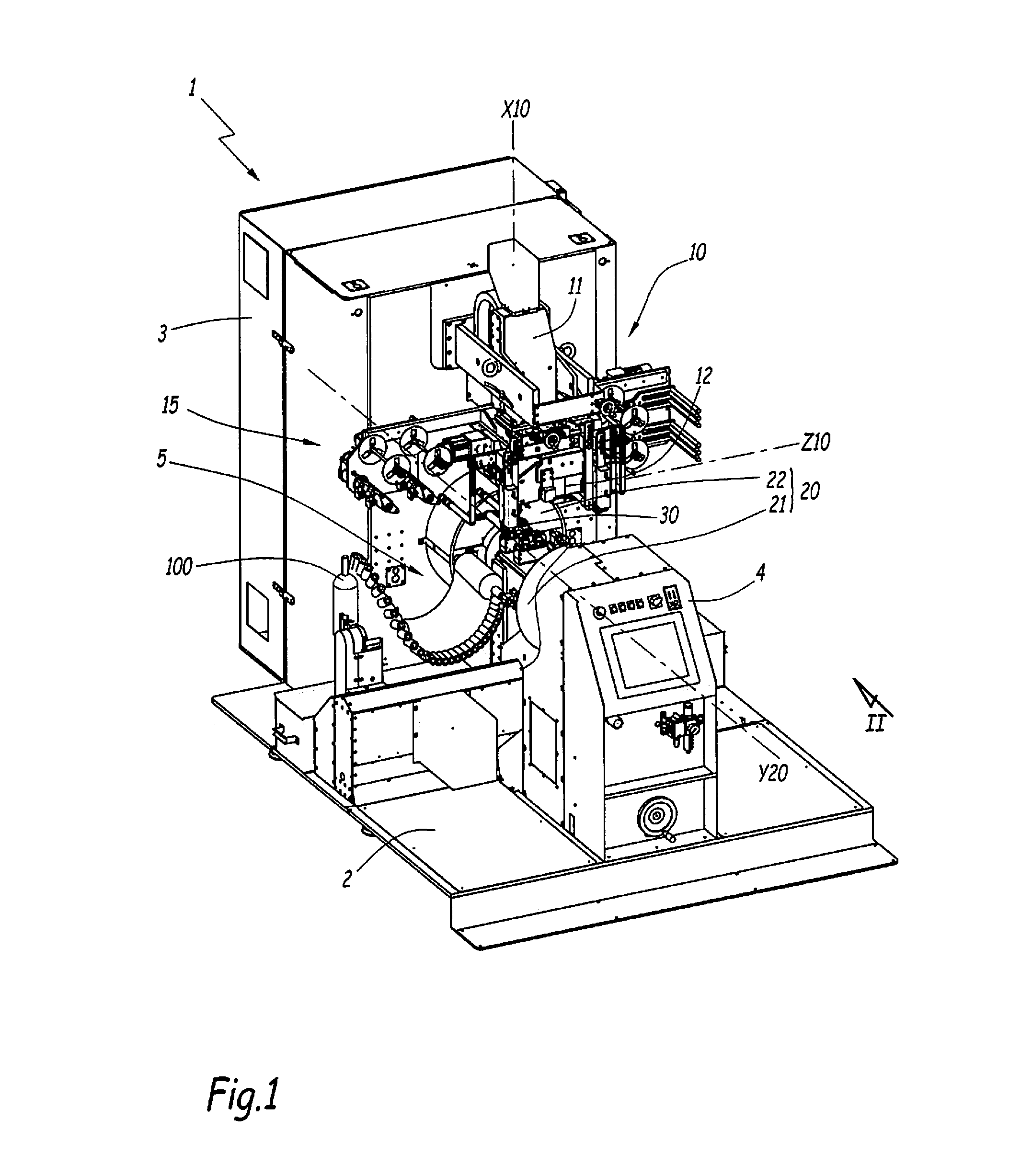

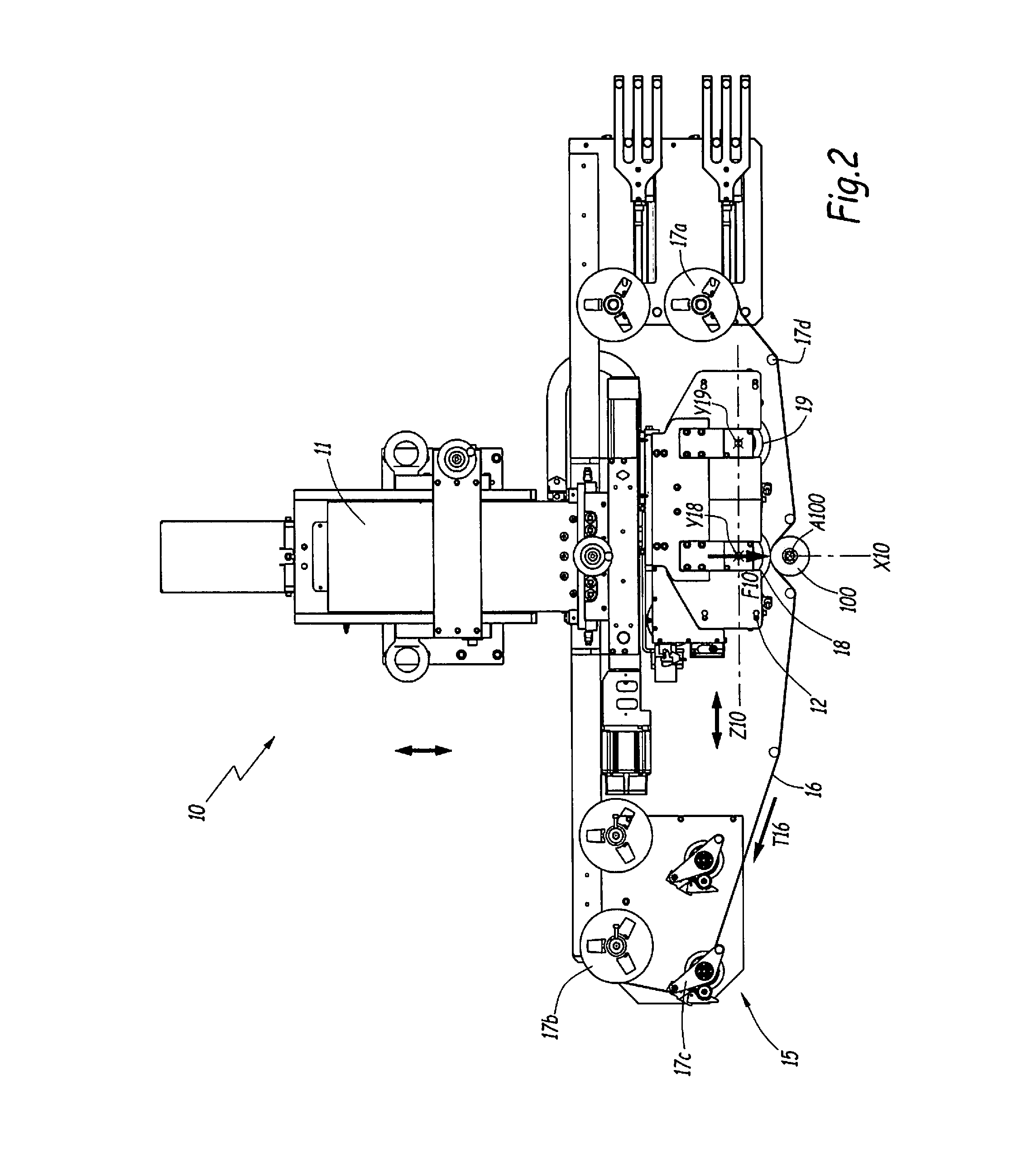

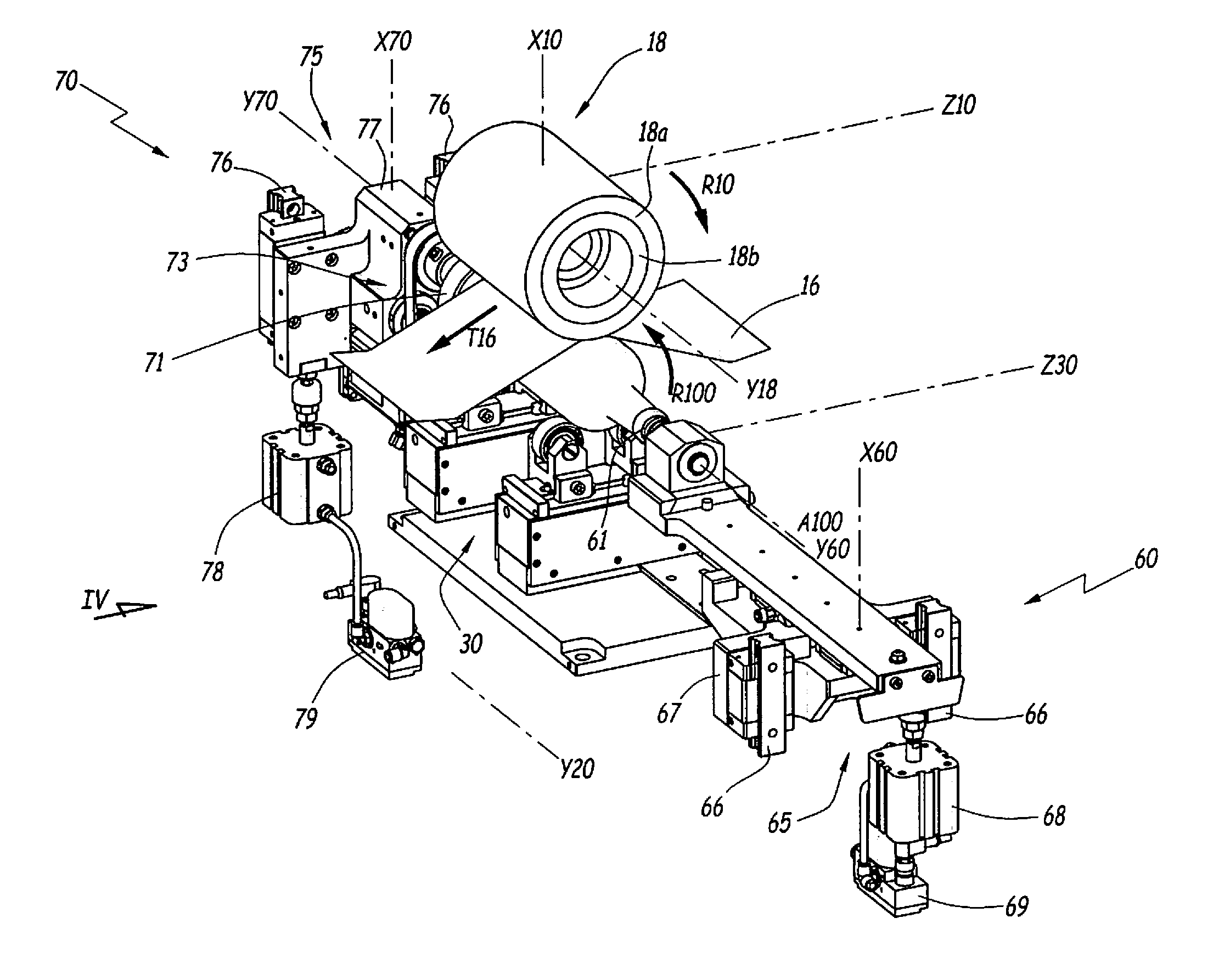

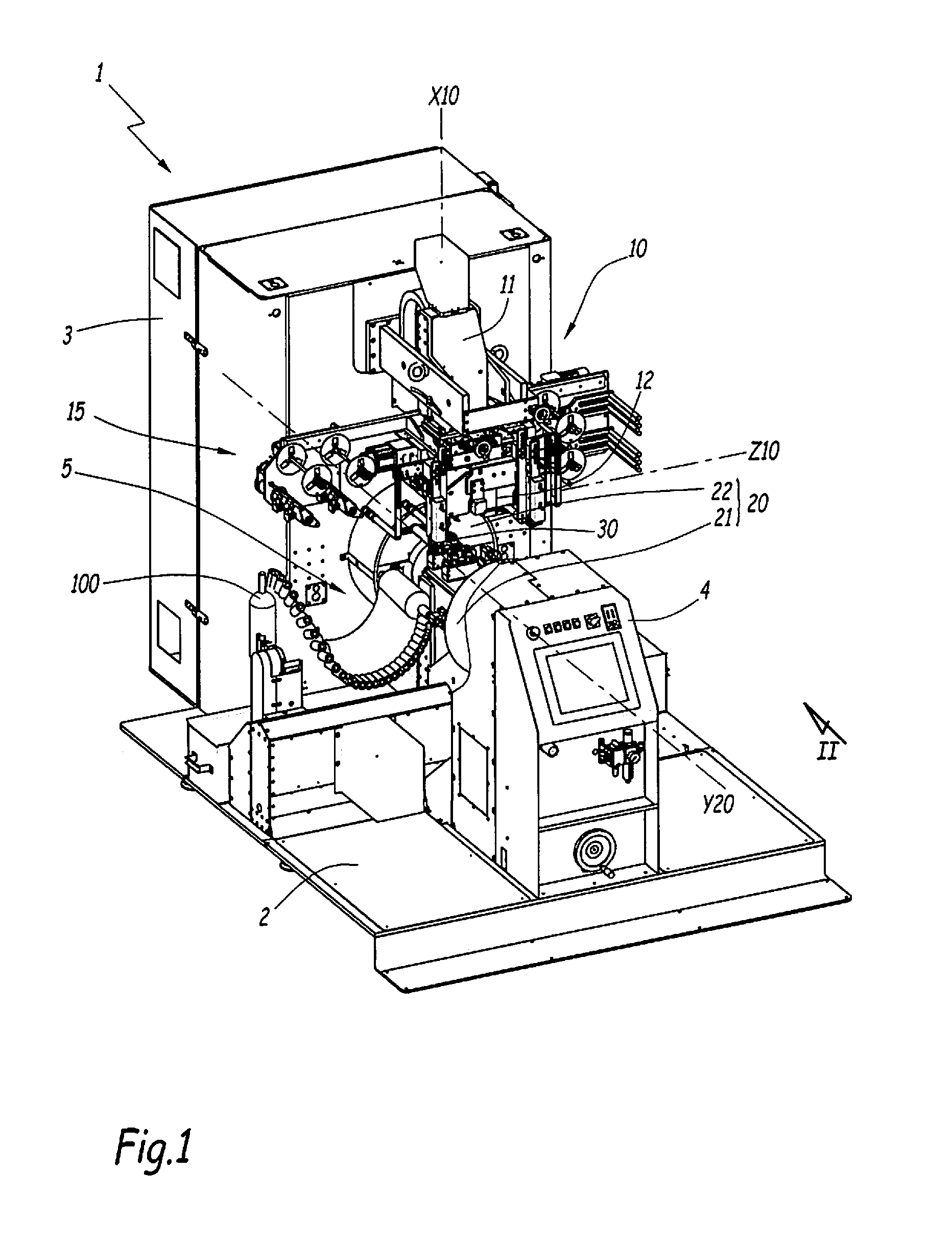

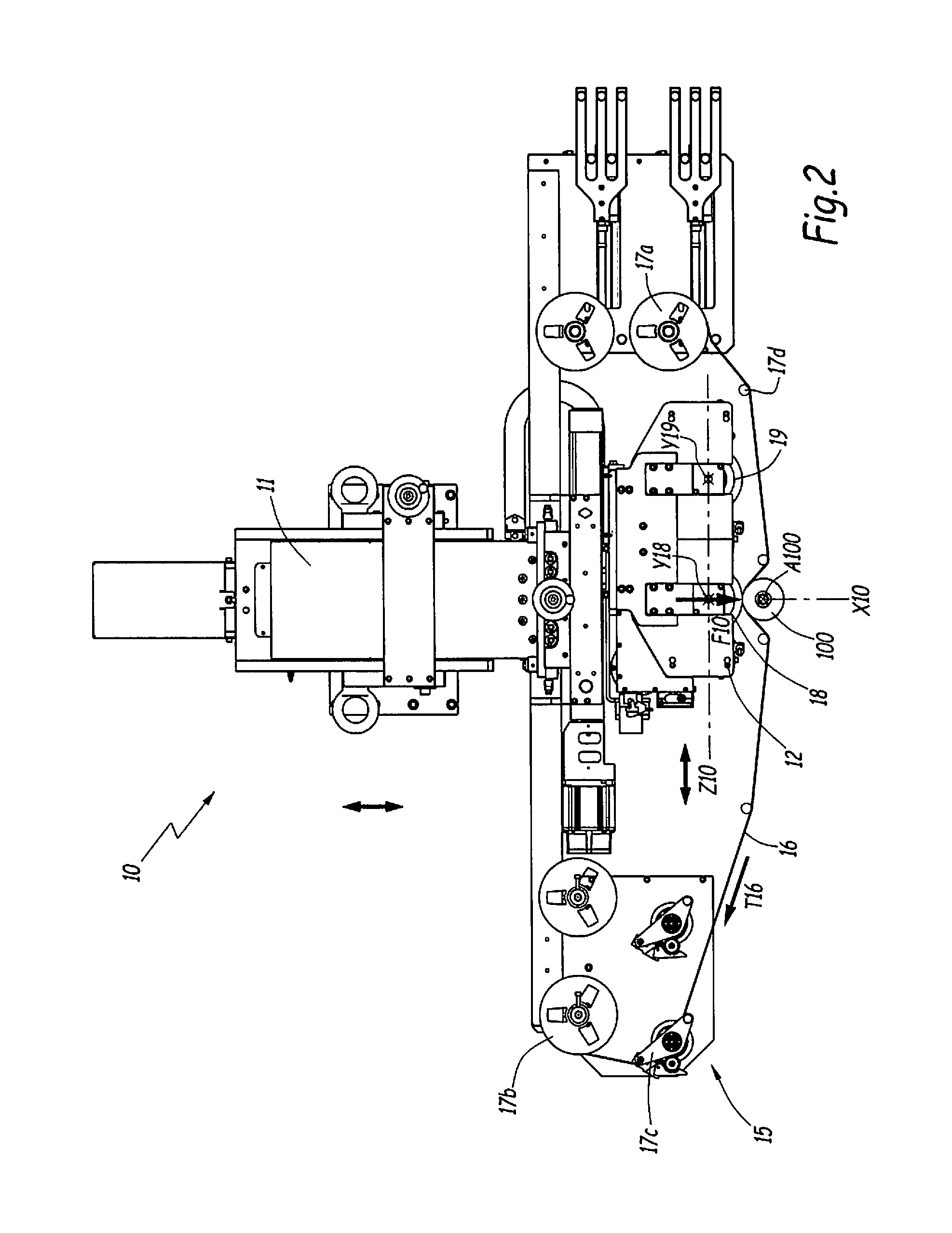

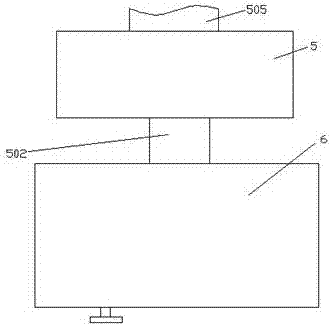

Machine and method for marking articles

ActiveUS8800443B1Precise positioningImprove marking qualityTransfer printingPlaten pressesSupporting systemEngineering

The present invention relates to a machine for marking articles that includes a marking head applying a marking force on an article along to a first axis; a positioning system positioning the article facing the marking head and generally along a perpendicular second axis; and a support system supporting the article during marking by the marking head. The positioning system comprises at least one carriage-turret for supporting the article. When the article is positioned facing the marking head by the at least one carriage-turret, this carriage-turret has a degree of freedom along a direction parallel to the first axis. The support system and / or the at least one carriage-turret includes backlash means along a direction parallel to a perpendicular third axis, to compensate for the shape defects of the article during application of the marking force.

Owner:ILLINOIS TOOL WORKS INC

Automatic mold stripping, cooling, marking and charging equipment

ActiveCN111761795ARealize fully automated operationSimple structureLaser beam welding apparatusRobot handEngineering

The invention relates to automatic mold stripping, cooling, marking and charging equipment. The equipment comprises an injection molding machine, a cooling device, a marking machine and a charging device, wherein the marking machine comprises a rack, a first sliding plate and a second sliding plate, wherein the first sliding plate is arranged on the rack and can slide front and back, the second sliding plate is arranged on the first sliding plate and can slide left and right, four sets of positioning mechanisms used for containing railway fasteners are arranged on the second sliding plate in arectangular array mode, and the positioning mechanisms can overturn the railway fasteners; a laser head is arranged above the rack, three sets of water absorption devices are arranged above the rackin the left-right direction, the heights of the water absorption devices correspond to the height of the railway fastener on the positioning mechanism, and the arrangement interval of the water absorption devices is the same as the left-right arrangement interval of the positioning mechanism. The automatic mold stripping, cooling, marking and charging equipment disclosed by the invention is simplein structure and ingenious in design, the injection molding machine, the cooling device, the marking machine and the charging device are matched with a manipulator, full-automatic operation of railway fastener machining is achieved, and the production efficiency and the product quality are greatly improved.

Owner:HEBEI TIEKE YICHEN NEW MATERIAL TECH CO LTD +1

Machine and method for marking articles

ActiveUS20140216281A1Precise positioningImprove marking qualityTransfer printingMechanical working/deformationSupporting systemEngineering

The present invention relates to a machine for marking articles that includes a marking head applying a marking force on an article along to a first axis; a positioning system positioning the article facing the marking head and generally along a perpendicular second axis; and a support system supporting the article during marking by the marking head. The positioning system comprises at least one carriage-turret for supporting the article. When the article is positioned facing the marking head by the at least one carriage-turret, this carriage-turret has a degree of freedom along a direction parallel to the first axis. The support system and / or the at least one carriage-turret includes backlash means along a direction parallel to a perpendicular third axis, to compensate for the shape defects of the article during application of the marking force.

Owner:ILLINOIS TOOL WORKS INC

Marking device with cargo lifting mechanism for logistics distribution

InactiveCN112374127AImprove scalabilityEasy to unloadTypewritersOther printing apparatusStructural engineeringMachine

The invention discloses a marking device with a cargo lifting mechanism for logistics distribution. The marking device comprises a support, a conveying mechanism arranged on the support, a lifting mechanism and a centering mechanism, wherein a marking machine is arranged above the conveying mechanism; the lifting mechanism is arranged on one side of the conveying mechanism and used for lifting cargoes; the centering mechanism is arranged on one side of the lifting mechanism and used for centering the cargoes; and the lifting mechanism and the centering mechanism are connected with the support.A flat plate of the lifting mechanism is arranged in a lifting and rotating mode, and meanwhile, the U-shaped sliding block arranged on the lower side of the flat plate pushes the cargoes, so that the cargoes are convenient to lift and unload, and manual carrying of the cargoes is reduced. Moreover, the cargoes are centered through symmetrically-arranged guide plates before being marked, so thatthe cargoes are aligned to the marking machine, and thus the marking quality and efficiency of the cargoes are improved.

Owner:鄂光照

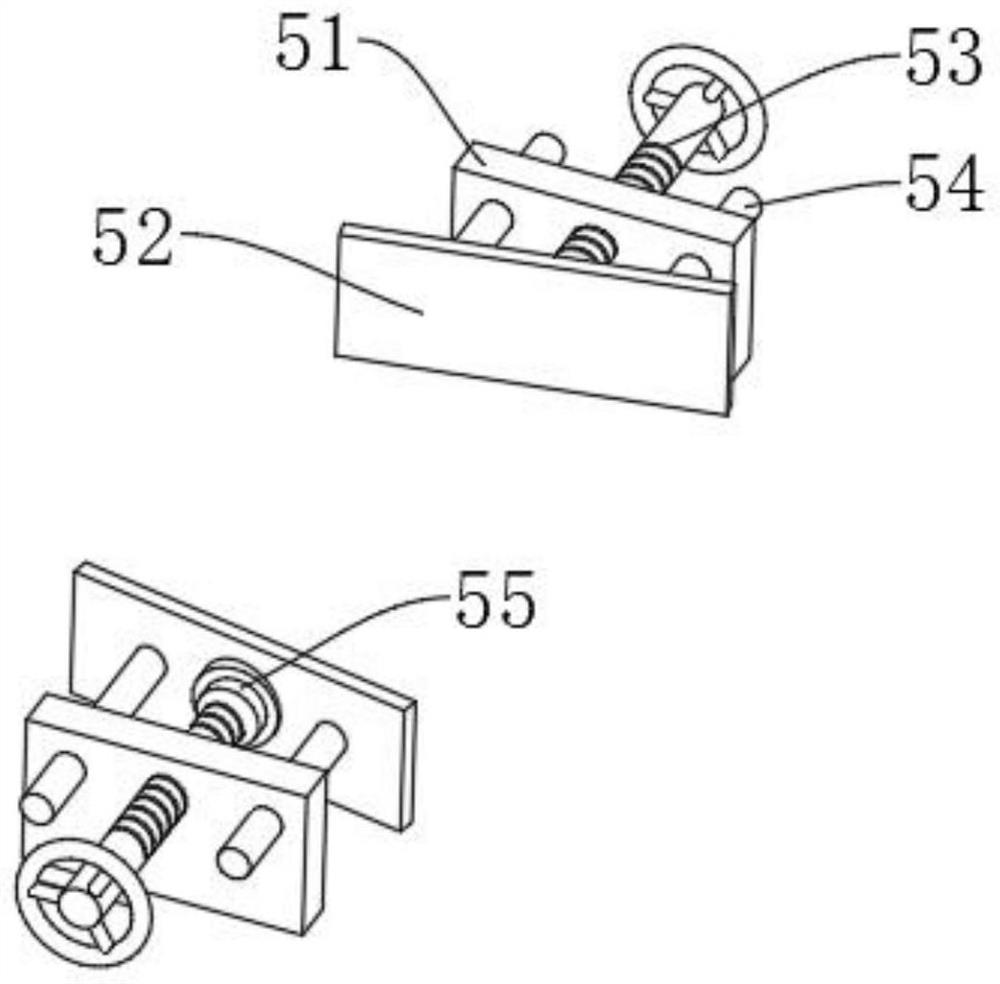

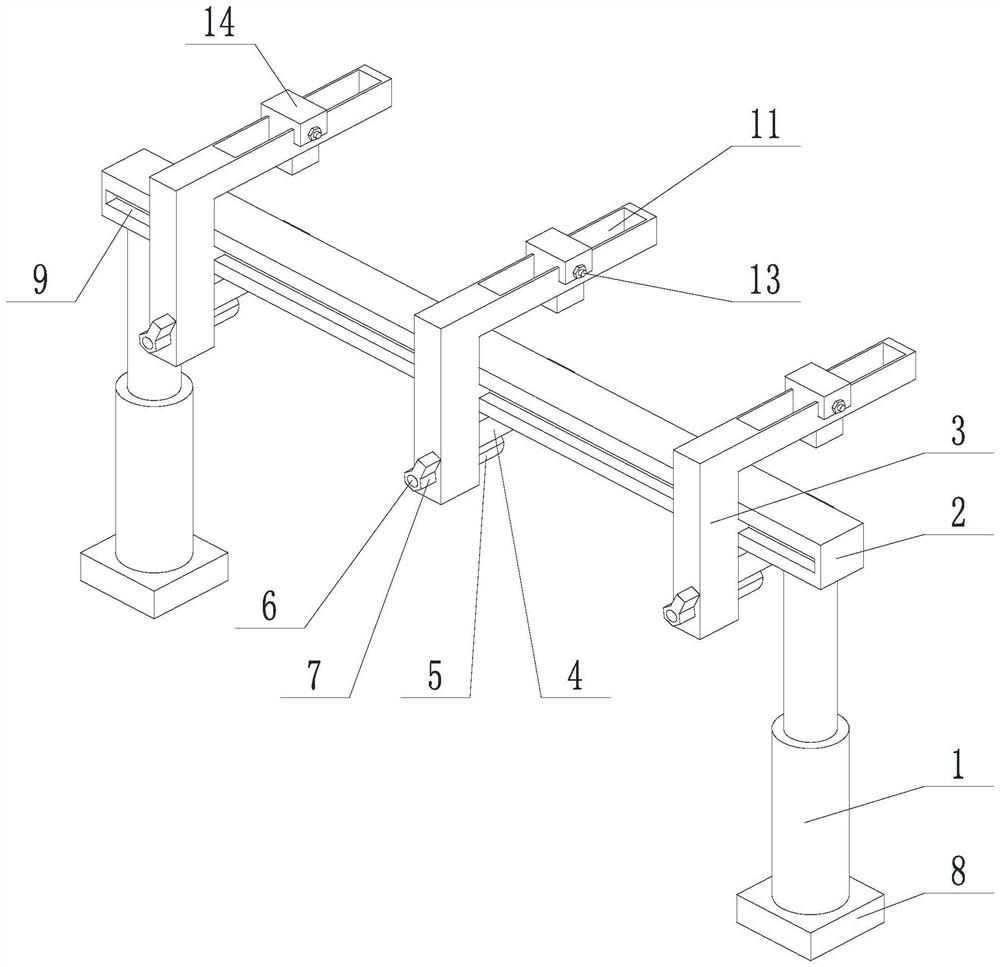

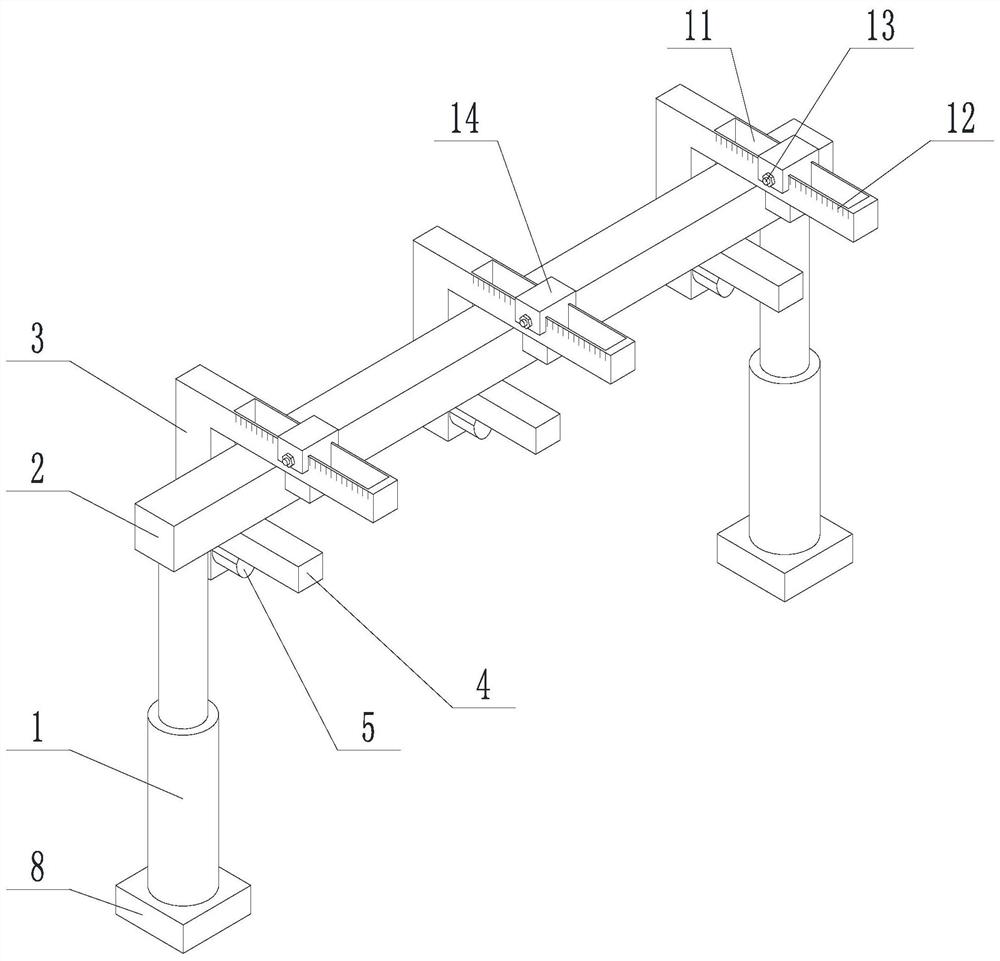

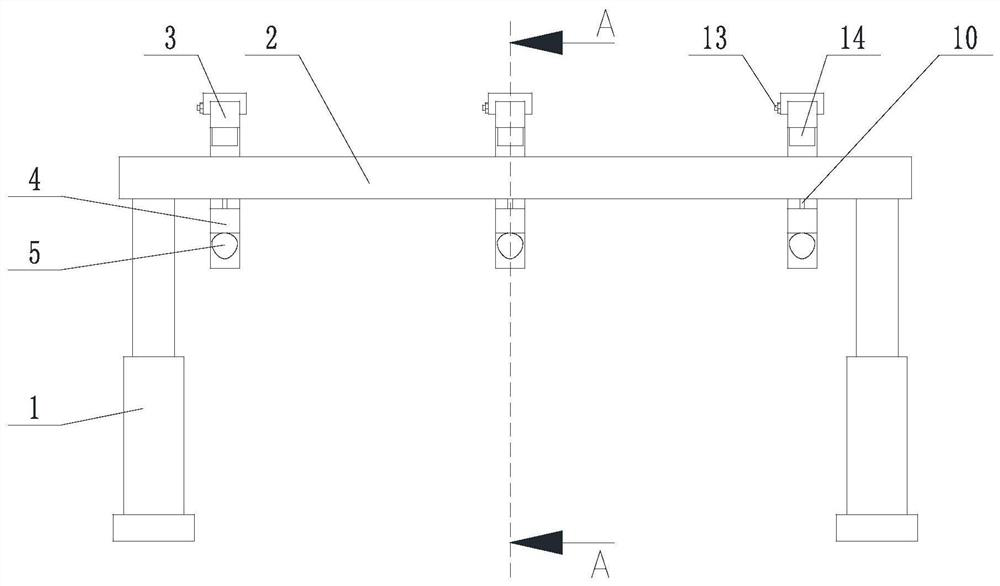

Batch marking equipment for triangular marks of oil casing screwed joints

ActiveCN112248661AOvercoming the problem of root-by-root markingImprove work efficiencyTypewritersCamScrew joint

The invention discloses batch marking equipment for triangular marks of oil casing pipe screwed joints. The equipment comprises two supporting legs and a transverse rod fixed between the two supporting legs; a plurality of L-shaped pieces are connected onto the transverse rod; one end of each L-shaped piece is in sliding fit with the side surface of the transverse rod, the other end is located above the transverse rod and strides over the transverse rod; the L-shaped pieces can slide along the axis of the transverse rod; the equipment further comprises clamping pieces in sliding fit with the L-shaped pieces; the clamping pieces can slide in the longitudinal direction; the clamping pieces are located below the transverse rod and stride across the transverse rod; cams are arranged below theclamping pieces; the cams are driven by a driving mechanism to rotate; the end, located above the transverse rod, of each L-shaped piece is further provided with a marking assembly. According to the batch marking equipment for the triangular marks of the oil casing pipe screwed joints, the technical problem of low efficiency due to the fact that casing pipes are required to be marked one by one inthe prior art is solved, and the purpose that the triangular marks are printed on a row of laid casing pipes in batches at the same time is achieved.

Owner:熊勇

An intelligent scoring method for subjective questions

ActiveCN110413741BSolving inefficienciesSolve the problem of uneven marking qualitySemantic analysisNeural architecturesSemantic vectorSemantic matching

An intelligent marking method for subjective questions, including preprocessing the candidate's answer text and the reference answer text to obtain the corresponding word vector sequence representation; using the semantic feature extraction network to extract the semantics of the sentences in the candidate's answer and the reference answer Vector; use the fusion attention mechanism to calculate the semantic matching degree of the examinee's answer and the reference answer sentence vector; use this matching result to calculate the weighted sentence vector of the examinee's answer; the sequence of sentence vectors for the complete examinee's answer and the weighted sentence vector based on the fusion attention mechanism sequence; use the semantic feature extraction network to calculate the semantic vector of the complete answer and the semantic vector based on the attention of the reference answer; glue the two vectors to form the final vector representation of the candidate's answer. The final vector representation of the examinee's answer is scored using a multi-layer feed-forward neural network. By using the invention, automatic marking of subjective questions can be realized, and the efficiency of marking can be greatly improved.

Owner:山东山大鸥玛软件股份有限公司

Laser marking machine

The invention provides a laser marking machine, which comprises a rack, wherein the rack is a workbench; the workbench is a cube made of section bars; the middle of the workbench is hollow; one side of the workbench is fixedly provided with a transmission device by a transmission fixing board; the transmission device is divided into a laser component and a transmission part by the table board of the workbench; the laser component is positioned above the table board of the workbench; the transmission component is positioned below the table board of the workbench and is positioned in the hollow part of the workbench; the transmission component is cooperated with the laser component by a transmission pair; the top of the laser component is provided with a laser head device; the transmission fixing board of the transmission device is fixedly provided with a sliding table mechanism; the sliding table mechanism is positioned in the laser component; the sliding table mechanism is mutually cooperated with the laser head device; the other side of the workbench is provided with a PC (personal computer) display; and the PC display is provided with an indicating lamp device. The cooperation of a movable product placement table on the sliding table mechanism and the transmission pair in the transmission component can be controlled by a PC host to realize marking, so that the yield of the laser marking machine is improved, the laser marking machine is simple to operate, and the production efficiency is improved.

Owner:SUZHOU LOCUS TECH

Mailbox producing and processing equipment

The invention discloses a letter box production and processing equipment, which comprises a suspension platform and a processing main frame installed on the lower side of the suspension platform in left and right translation, a suspension arm is installed directly above the top of the suspension platform, and a cavity is arranged in the suspension platform. The mouth of the adjustment slot is facing downward, and the connecting arm that is expanded downward is installed in the adjusting slot in translation. The screw in the connecting arm is equipped with a screw shaft that is expanded left and right. The right end wall of the adjustment slot is rotationally and cooperatively connected, the left tail of the screw shaft is mounted in cooperation with the main motor, the outer surface of the main motor is installed in the left end wall of the adjustment slot and is fixedly connected, and the connecting arm The bottom end surface is fixedly installed directly above the processing main frame, and the bottom end surface of the processing main frame is provided with concave cavities extending left and right; the invention has simple structure, convenient operation, improves marking work efficiency and marking quality, and improves stability sex.

Owner:楼一

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com