Inner pot cover marking device and marking method

A technology of inner pot cover and shifting device, which is applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unstable marking quality and low marking efficiency, and achieve stable marking quality and high marking efficiency. High efficiency, improve the effect of marking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

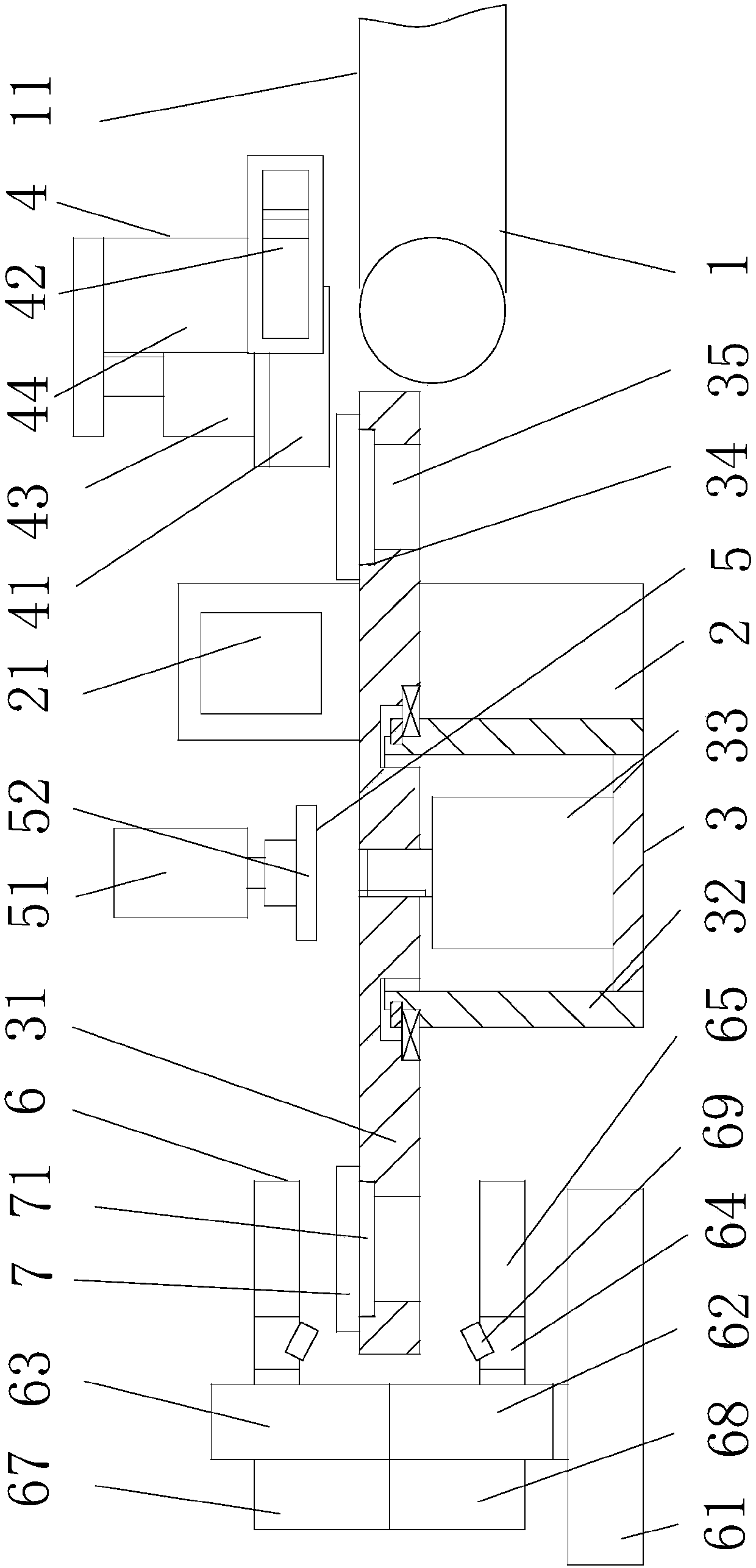

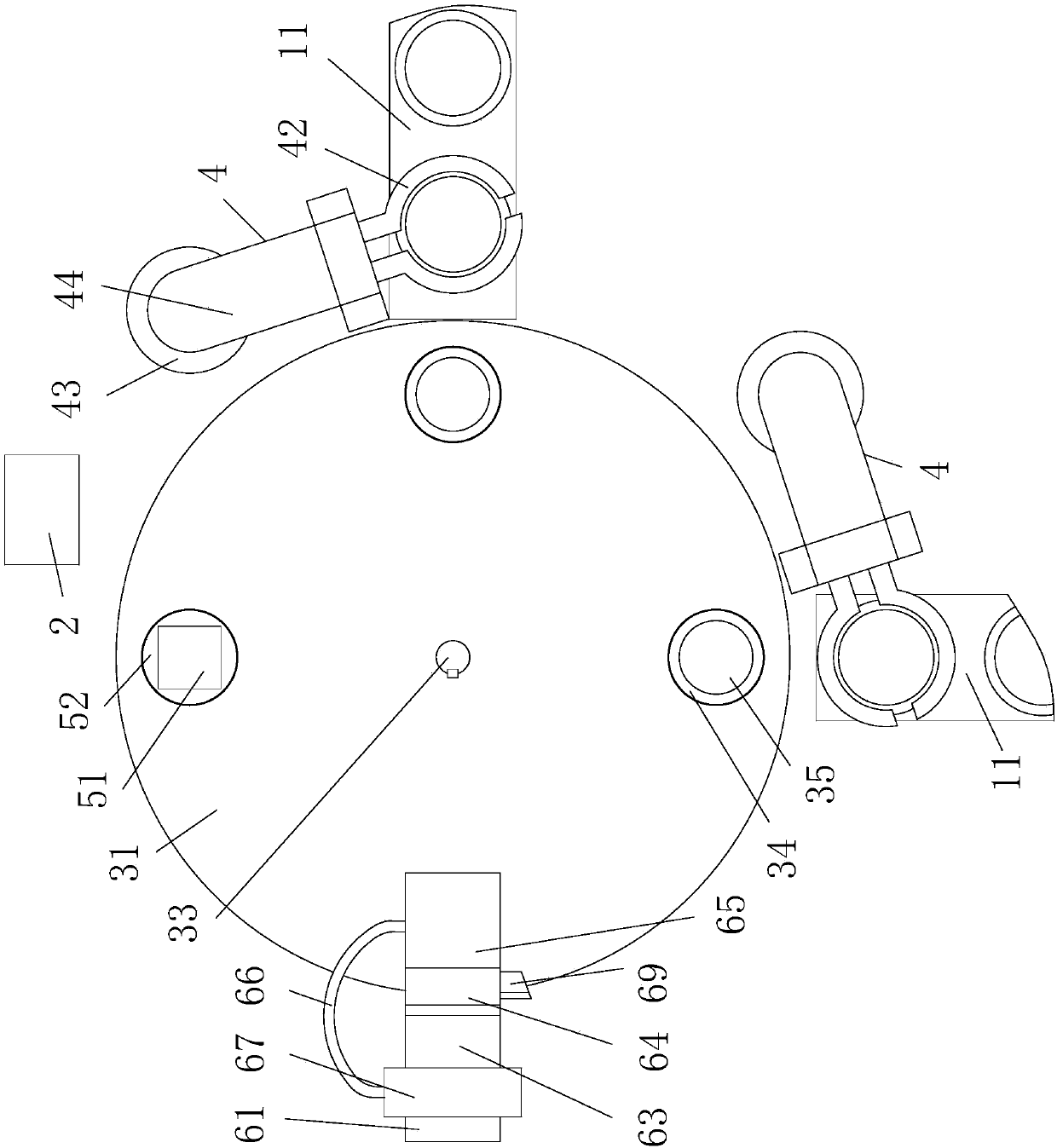

[0017] as attached figure 1 , attached figure 2 Shown: a marking device for inner pot lids, comprising: two stepping conveying devices 1 provided with conveyor belts 11, a controller 2 provided with a display screen 21, a rotating device 3 provided with a turntable 31, The four inner pot lid accommodation holes with the axes evenly distributed on the circumference and connected to the upper and lower ends of the turntable 31 respectively, and the two inner pot lid shifting devices 4 distributed along the sides of the turntable 31 and corresponding to the inner pot lid accommodation holes one by one 1. A position leveling device 5 and a laser marking device 6 located between the two inner pot cover shifting devices 4 ;

[0018] The laser marking device 6 includes: a radial electric slide table 61 arranged on the lower side of the turntable 31 and whose length directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com