Vehicle-mounted normal temperature type striping machine

A marking machine and vehicle-mounted technology, used in roads, buildings, road repair and other directions, can solve the problems of high frequency of problems in the control system, affecting the efficiency of marking construction, increasing equipment costs, etc., to reduce equipment weight and system. Stable and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

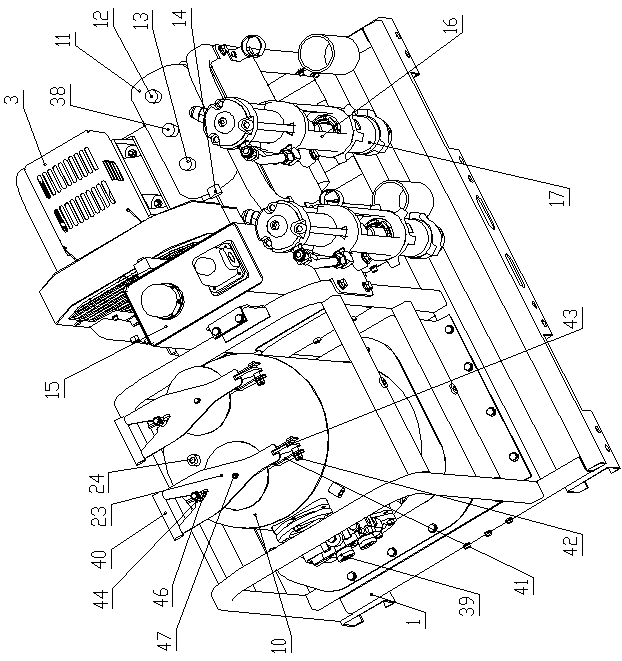

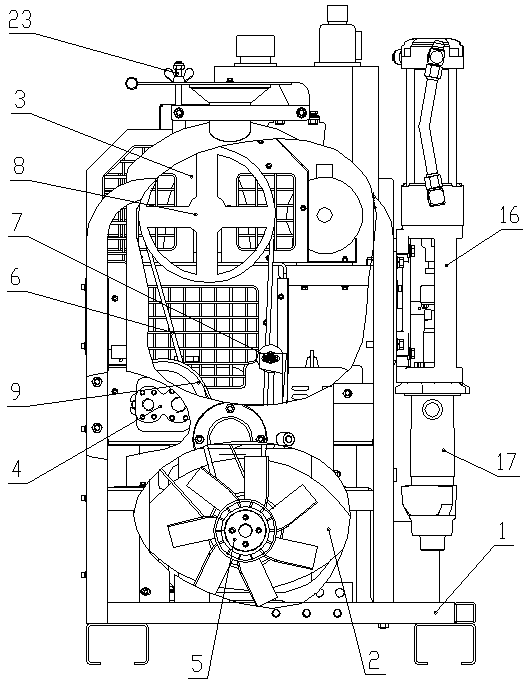

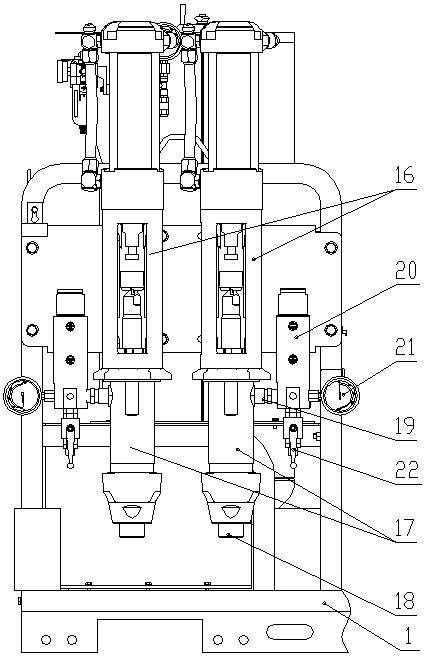

[0023] like Figure 1 to Figure 5 As shown, a vehicle-mounted normal temperature type marking machine of the present invention comprises a frame 1, and a power transmission system, a pneumatic control system and a painting system are arranged on the frame 1, and the power transmission system is connected with the pneumatic control system and the painting system respectively. System transmission connection, the pneumatic control system and the painting system are respectively connected with the external marking system, the pneumatic control system is connected with the external electric control system through the data line,

[0024] The power transmission system includes an engine 2, an air compressor 3 and a hydraulic gear pump 4, and the air compressor 3 is connected to the engine 2 through an engine pulley 5, a V-belt 6 and an air compressor pulley 8. A pinch wheel device 7 for adjusting the tension of the V-belt 6 is installed on the frame 1, and the power input shaft of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com