Machine and method for marking articles

a marking machine and marking technology, applied in the field of machine and a marking method, can solve the problems of increased rigidity and more significant shape defects, unsuitable support means and fixed support rollers, and too large overhang span between the means supporting the ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

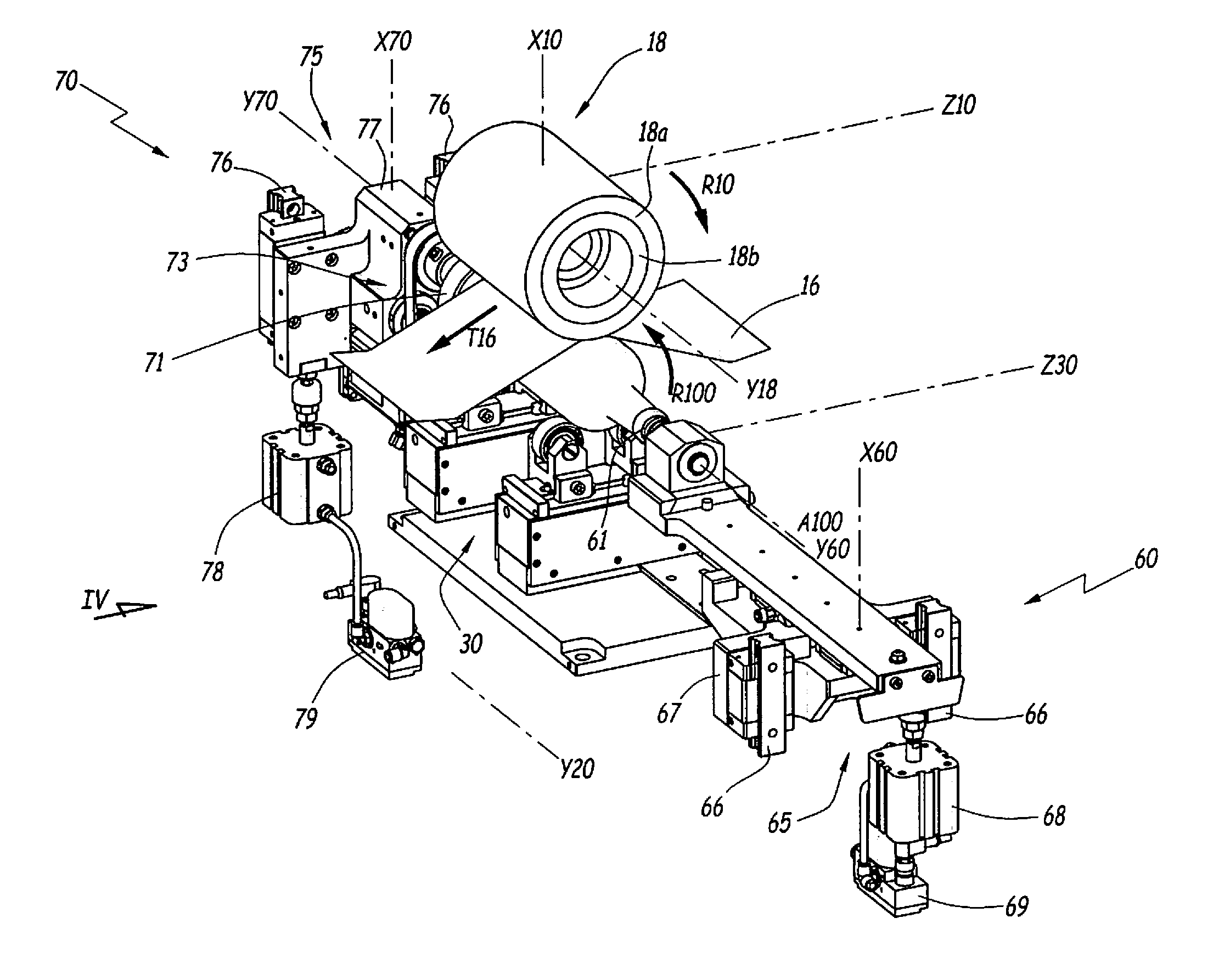

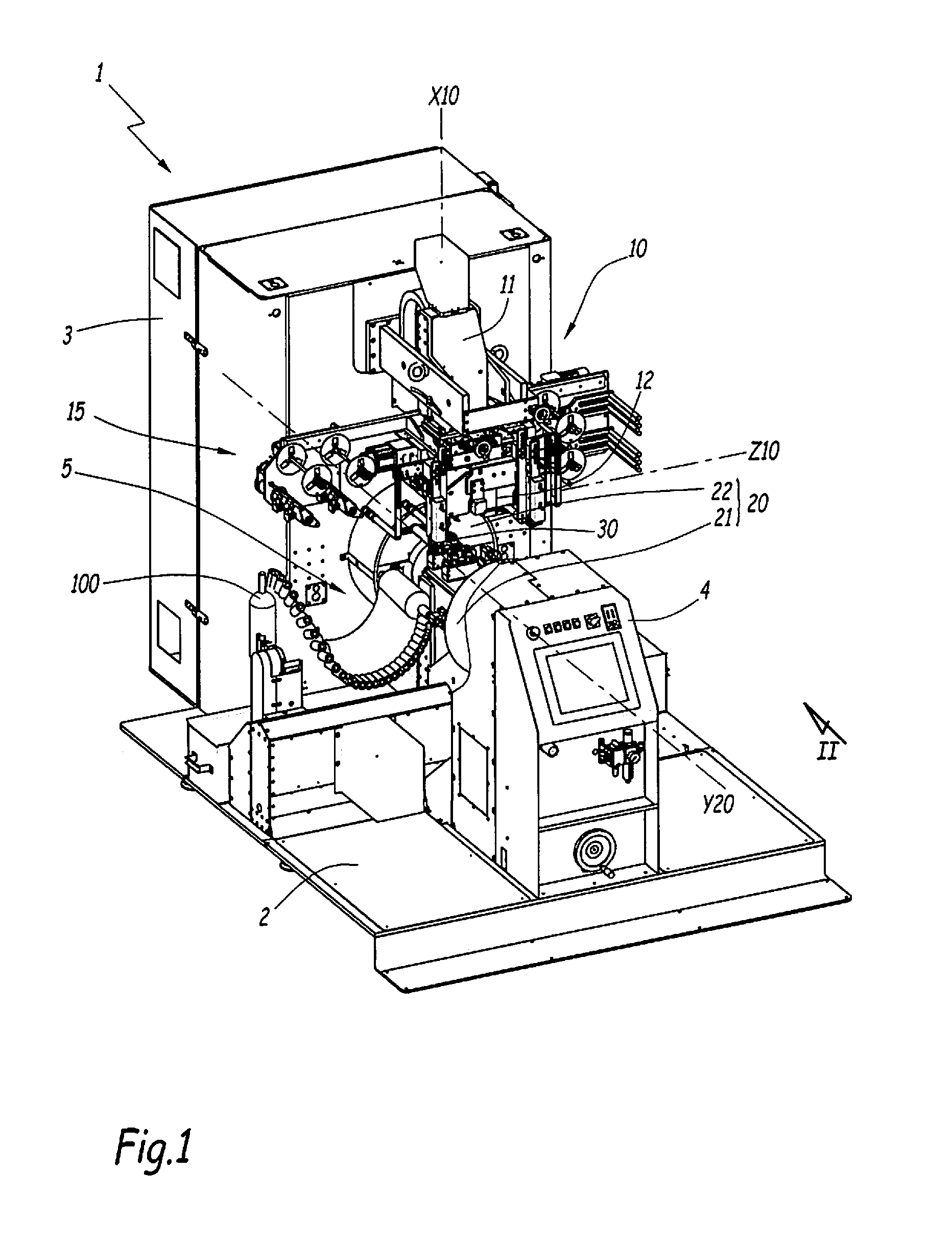

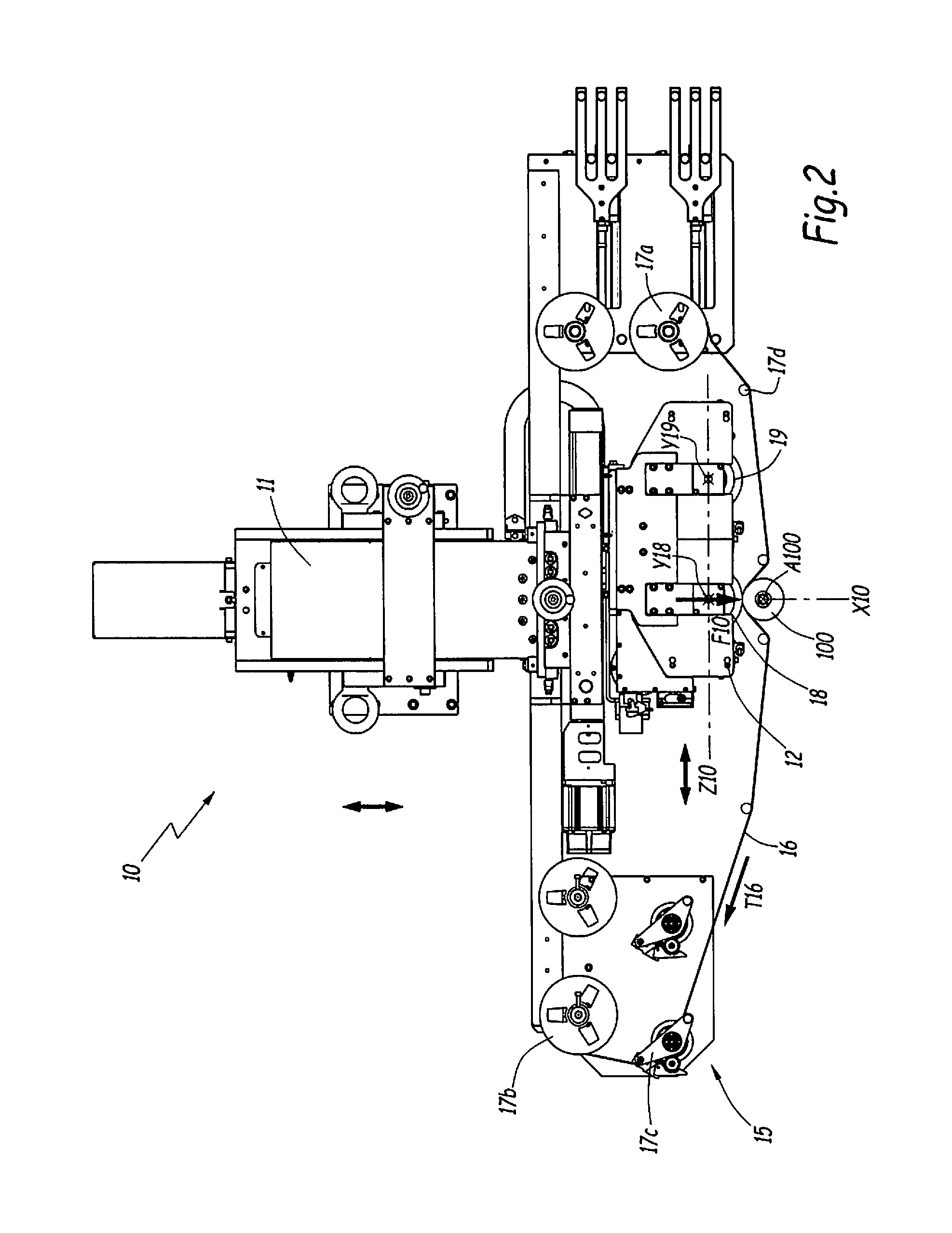

[0036]The machine 1 is intended to be used for decorating articles 100 by way of applying a marking on the external surface. In particular, the machine 1 is suitable for the hot stamp marking of containers 100.

[0037]The machine 1 comprises a base 2 for ground anchoring, an electrical cabinet 3, a control station 4, a system 5 for feeding the machine 1 with containers 100, a marking head 10, a system 20 for transporting and positioning of containers 100 so as to face the marking head 10, from the feeding system 5, as well as a system 30 for supporting the container 100 during the marking process. The housing for the electrical cabinet 3 and the housing for the control station 4 are fixed at the base 2. The machine 1 also comprises a system for unloading the marked containers 100, this system is not shown for the sake of simplification.

[0038]In the example in FIGS. 1 to 6, the containers 100 are glass bottles of a generally cylindrical shape. The containers 100 extend along a central ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of freedom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com