Plane trimming device and laser marking machine using plane trimming device

A fine-tuning device and plane technology, which is applied in the field of laser marking machines, can solve problems such as difficult position adjustment, low adjustment accuracy, and difficulty in ensuring the marking accuracy and quality of laser marking machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

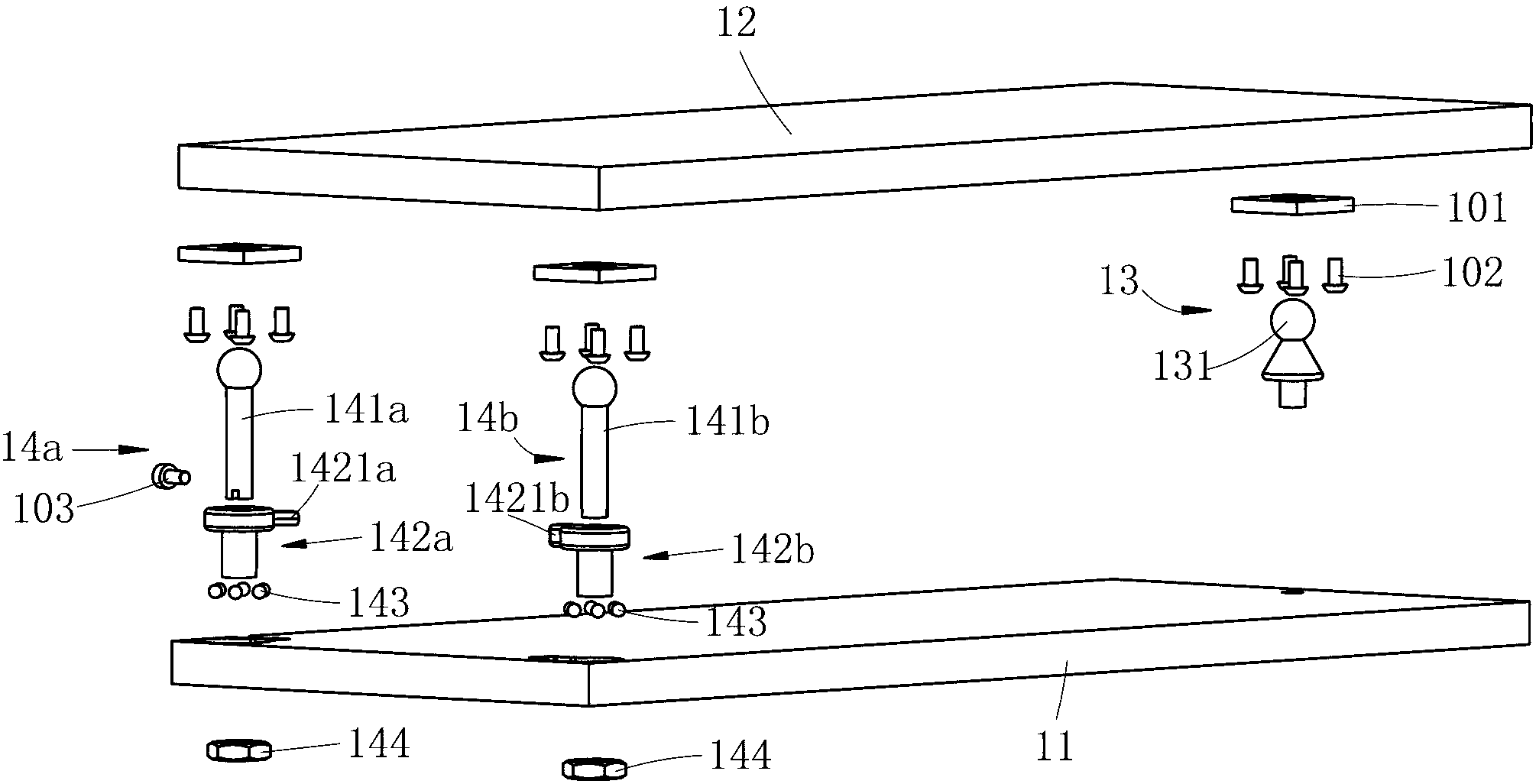

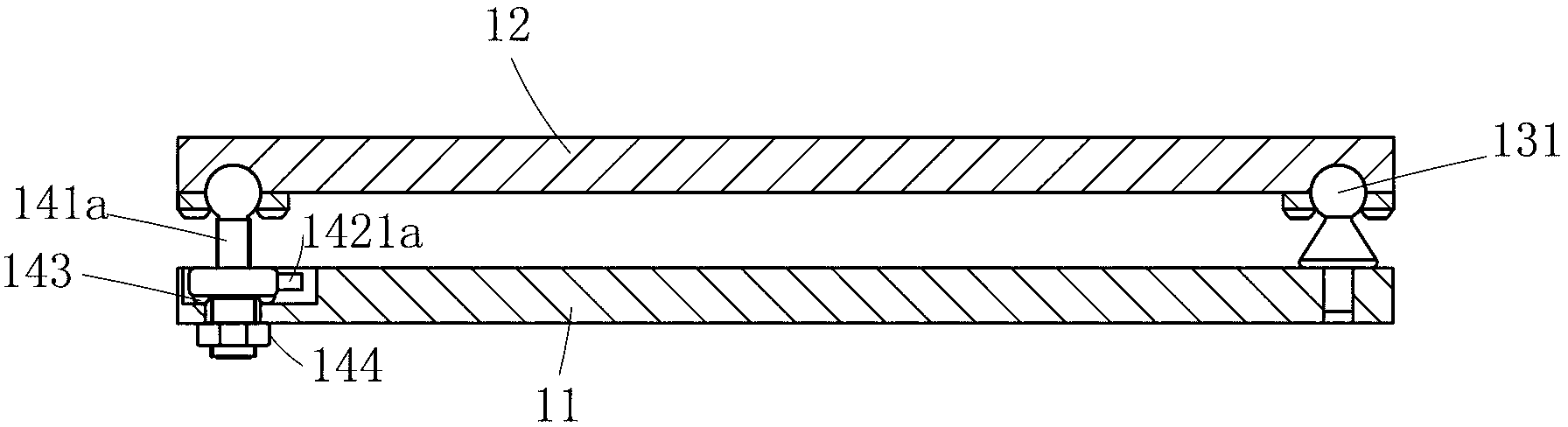

[0024] Figure 1 to Figure 6 Disclosed is a plane fine-tuning device, which includes an adjustment plate 12 used to connect with precision equipment and a fixed plate 11 used to be fixedly connected to a frame. 12 are connected together by three sets of triangularly distributed support assemblies. Among the three sets of support assemblies, one set is a fixed support assembly 13, and the other two sets are adjustment support assemblies, which are respectively the first adjustment support assembly 14a and the second adjustment support assembly 14b.

[0025] like figure 1 As shown, the fixed support assembly 13 includes a ball stud 131, the adjusting plate 12 is provided with a hemispherical pit matching the ball end of the ball stud 131, and the locking block 101 is fixed by four pan head screws 102 below the adjustment plate 12, so that the ball head end of the ball stud 131 is spherically hinged with the adjustment plate 12, and the universal rotation around the center of t...

no. 2 example

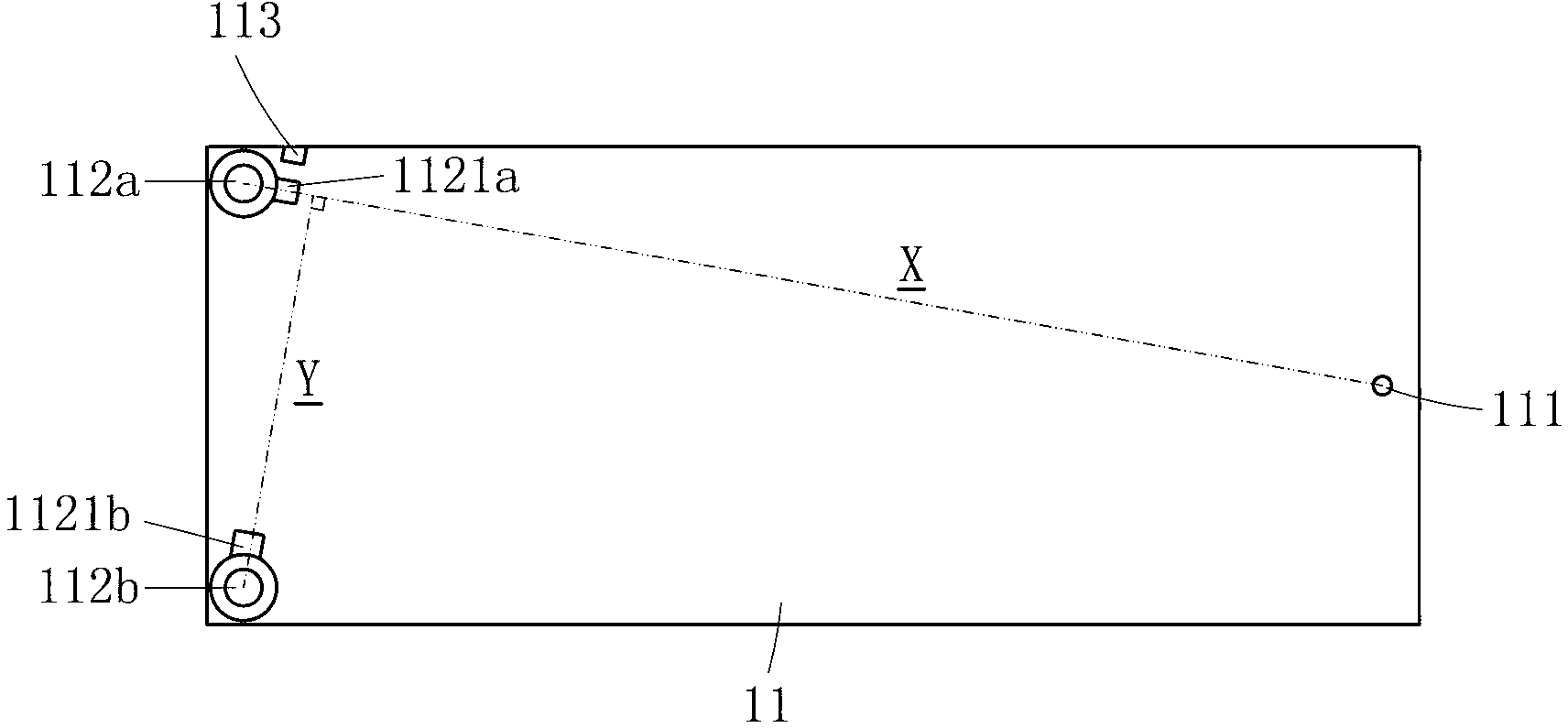

[0041] A plane fine-tuning device, the structure of which is basically the same as that of the first embodiment, the difference lies in the shapes of the nut sleeve and the counterbore. like Figure 7 and Figure 8 As shown, both the first nut set 142a and the second nut set 142b are in the shape of a stepped column whose big head is square and the small head is round, similar to a T-shaped nut, and both the first counterbore 112a and the second counterbore 112b are large holes It is a stepped hole shape with a small square hole and a circle. There is an annular gap between the small head end of the nut sleeve and the inner wall of the corresponding counterbore. The square hole portion of the first counterbore 112a extends along the X direction and connects There is an adjustment gap in the X direction between the big ends of 142a, and the square hole portion of the second counterbore 112b extends along the Y direction and has an adjustment gap in the Y direction and parallel...

no. 3 example

[0044] A laser marking machine is a specific application of the plane fine-tuning device disclosed in the above embodiments. like Figure 7 As shown, it includes a marking head 2, the marking head 2 includes a laser generator 22, the laser generator 22 is connected with a vibrating mirror 23, the vibrating mirror 23 is connected with a flat field mirror 21, and the laser generator 22 bottom is equipped with a Plane fine-tuning device 1.

[0045] During use, the fixed plate 11 of the plane fine-tuning device 1 is fixed on the frame that needs to install the marking head 2, and then the laser generator 22 is fixedly installed on the adjustment plate 12 of the plane fine-tuning device 1, through which the plane fine-tuning device can The parallelism between the flat field lens 21 and the reference plane 3 is fine-tuned, and the precision can reach 0.05mm. For the laser marking machine, by setting the plane fine-tuning device, the marking accuracy and marking quality can be grea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com