Linear product clamping and guiding tool and high-speed marking equipment

A product-oriented technology, applied in the direction of metal processing equipment, welding equipment, laser welding equipment, etc., can solve the problems of unadjustable marking spacing, low processing efficiency, unstable marking effect, etc., and achieve easy non-contact non-destructive marking Marking, improving the degree of automation, and the effect of stable marking position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

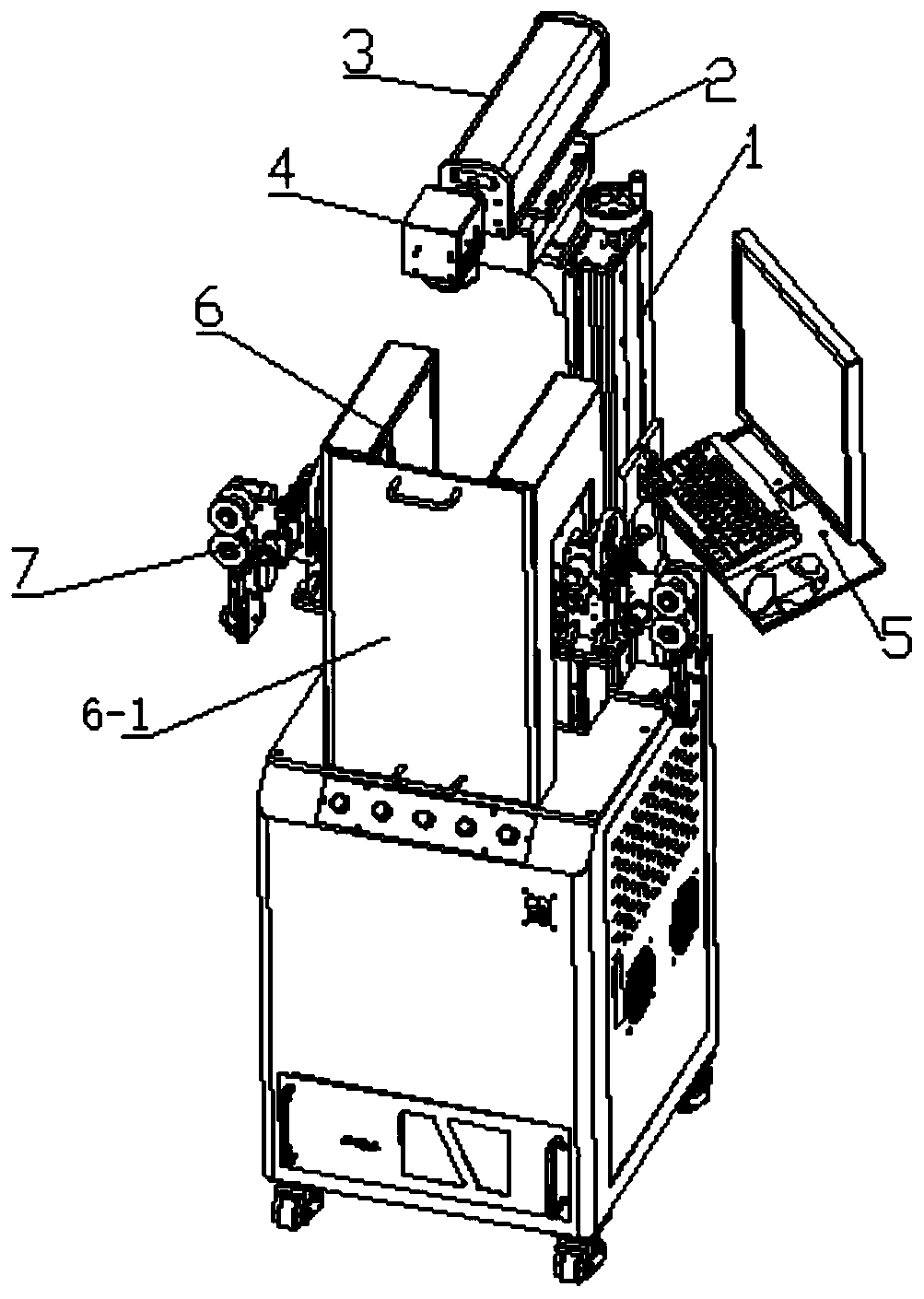

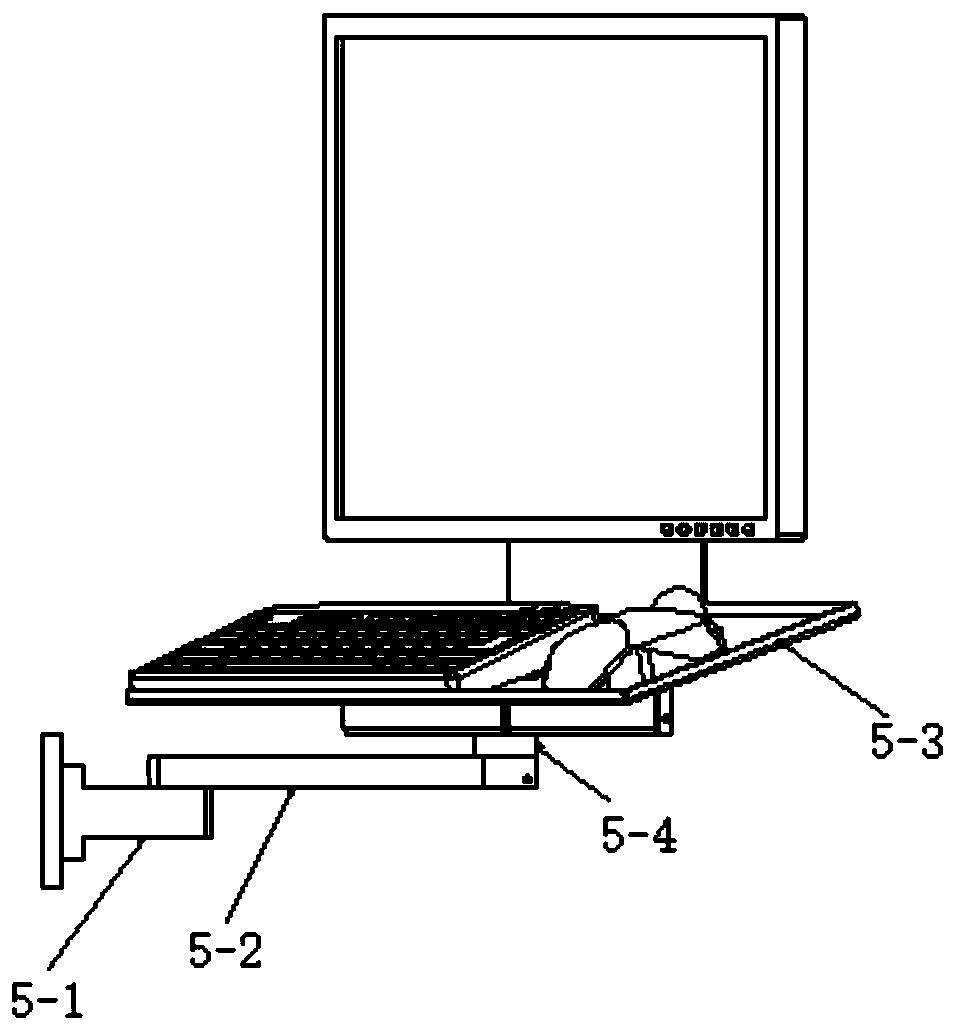

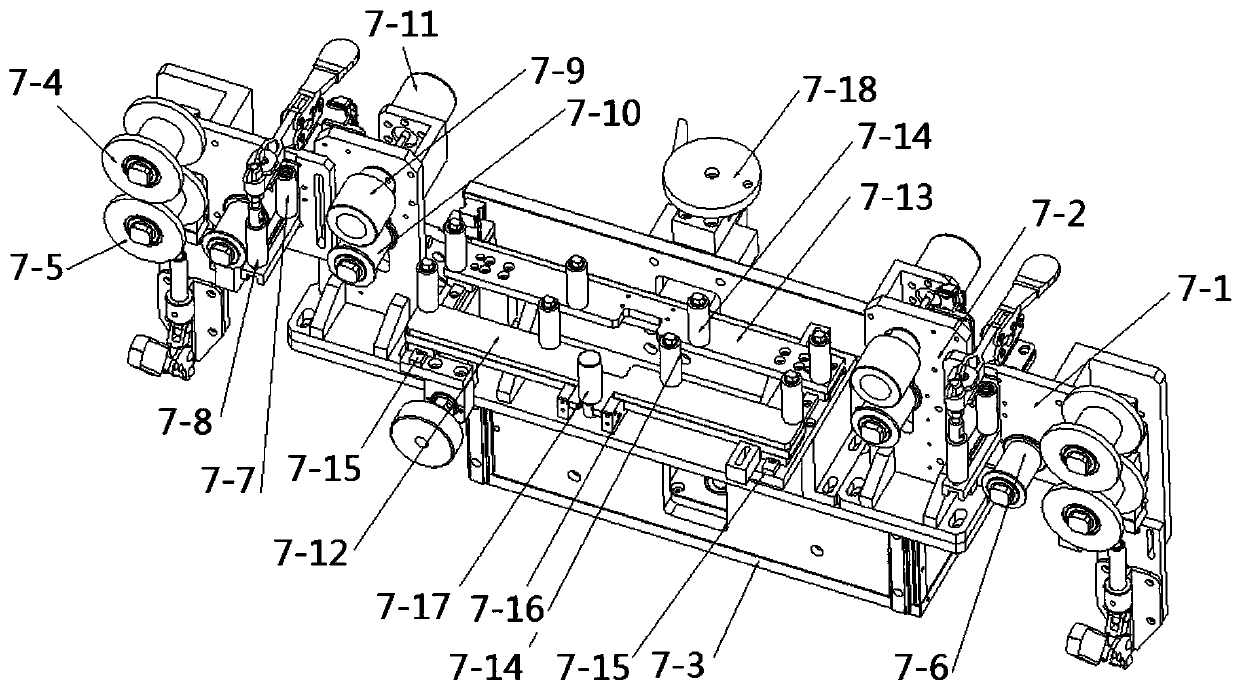

[0033] like figure 1 Shown is an assembly line flying high-speed marking equipment, including a cabinet, a product clamping and guiding tooling 7, a light source up and down lifting device 1, a front and rear moving platform 2, a laser light source 3 and a laser head 4; the light source up and down lifting device 1 includes The upright column connected by the slide rail mechanism and the up and down moving platform, the upright column is fixed on the rear area of the cabinet table top; The head 4 is installed at the end of the laser light source 3; the product clamping guide tooling 7 is installed on the middle area of the table top of the cabinet through the lifting mounting bracket 7-18, and clamps the left and right sides of the product to be marked area, The area to be marked of the product is located directly below the laser head 4.

[0034] As shown in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com