Patents

Literature

37results about How to "Marking position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

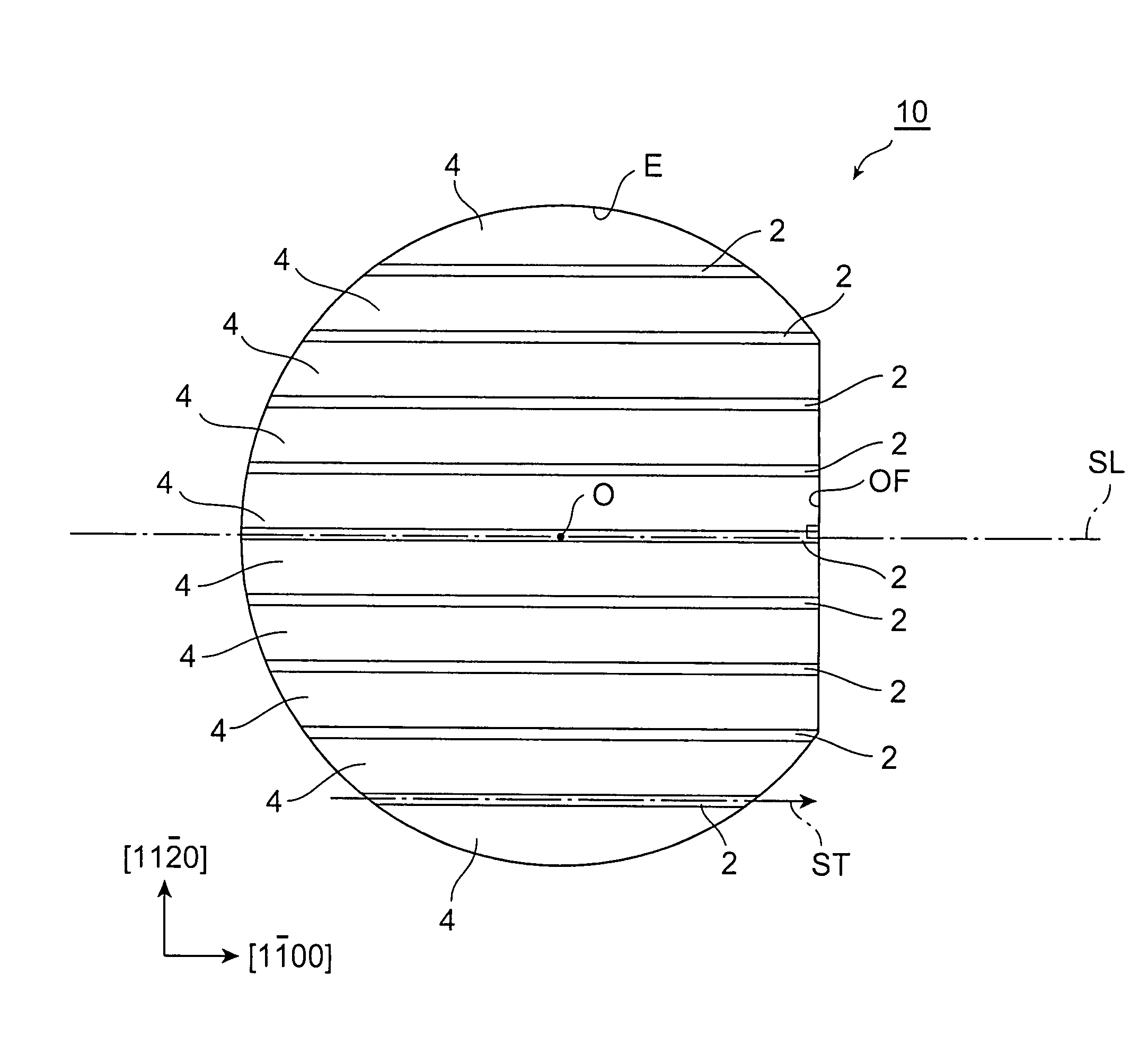

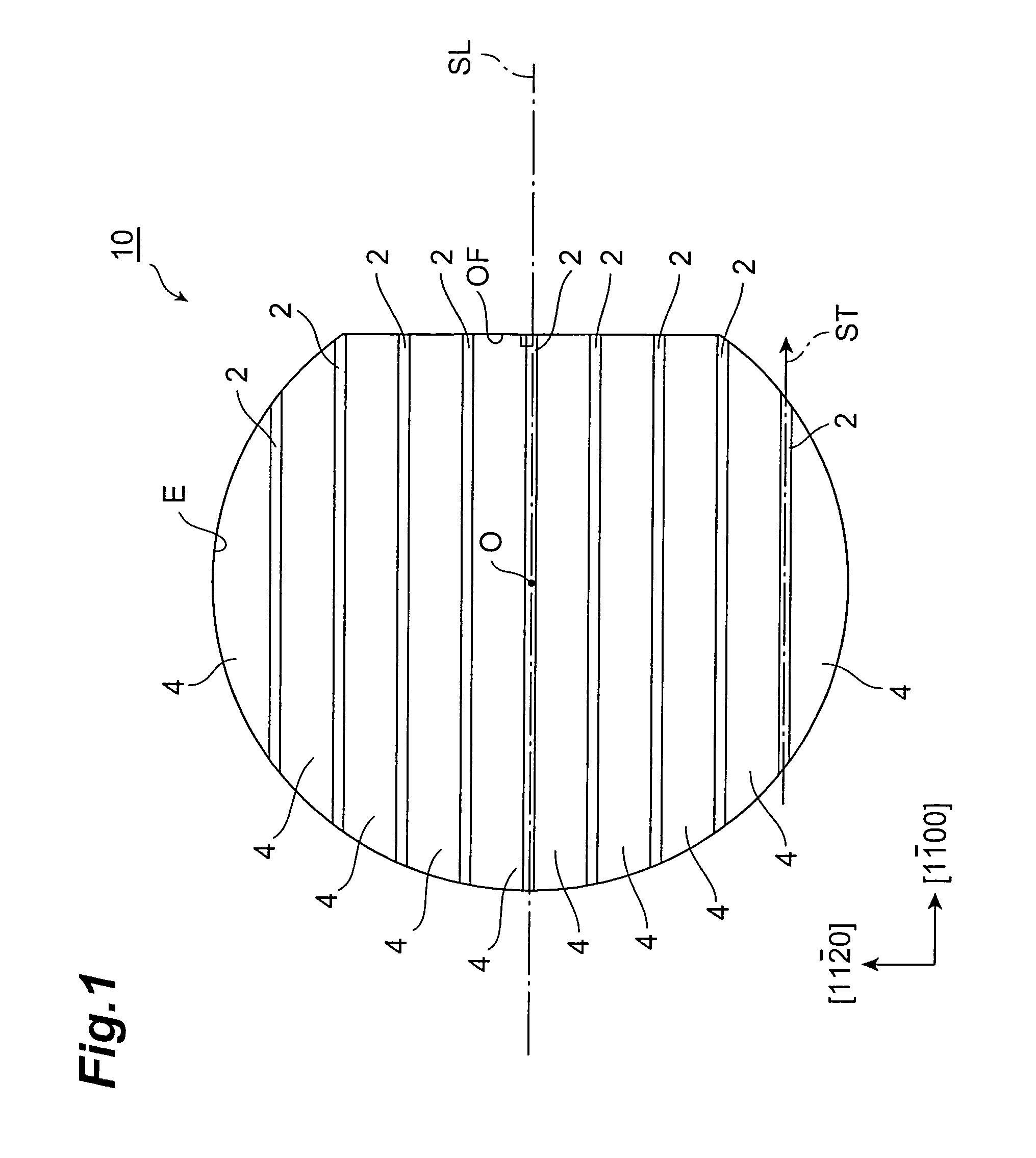

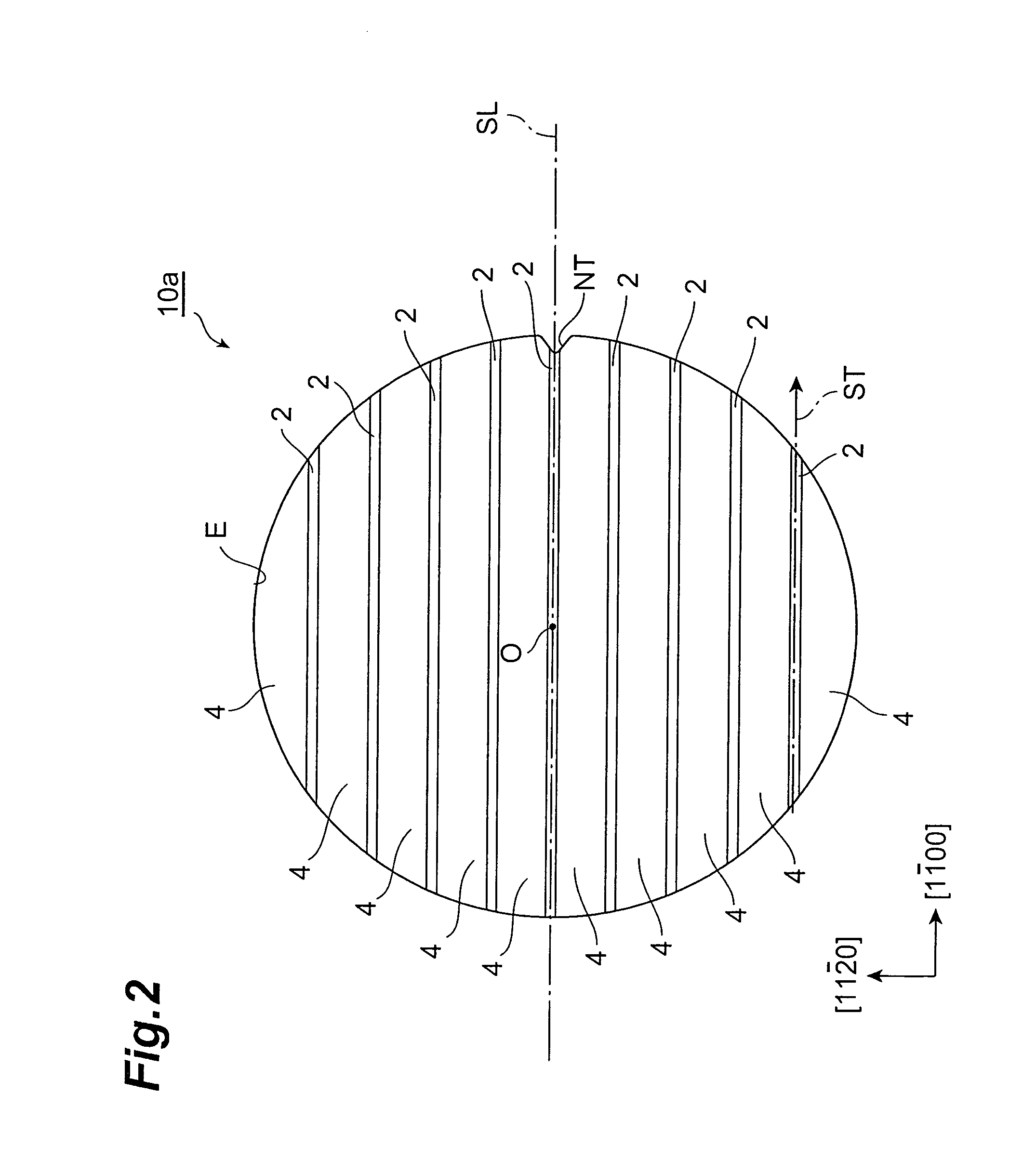

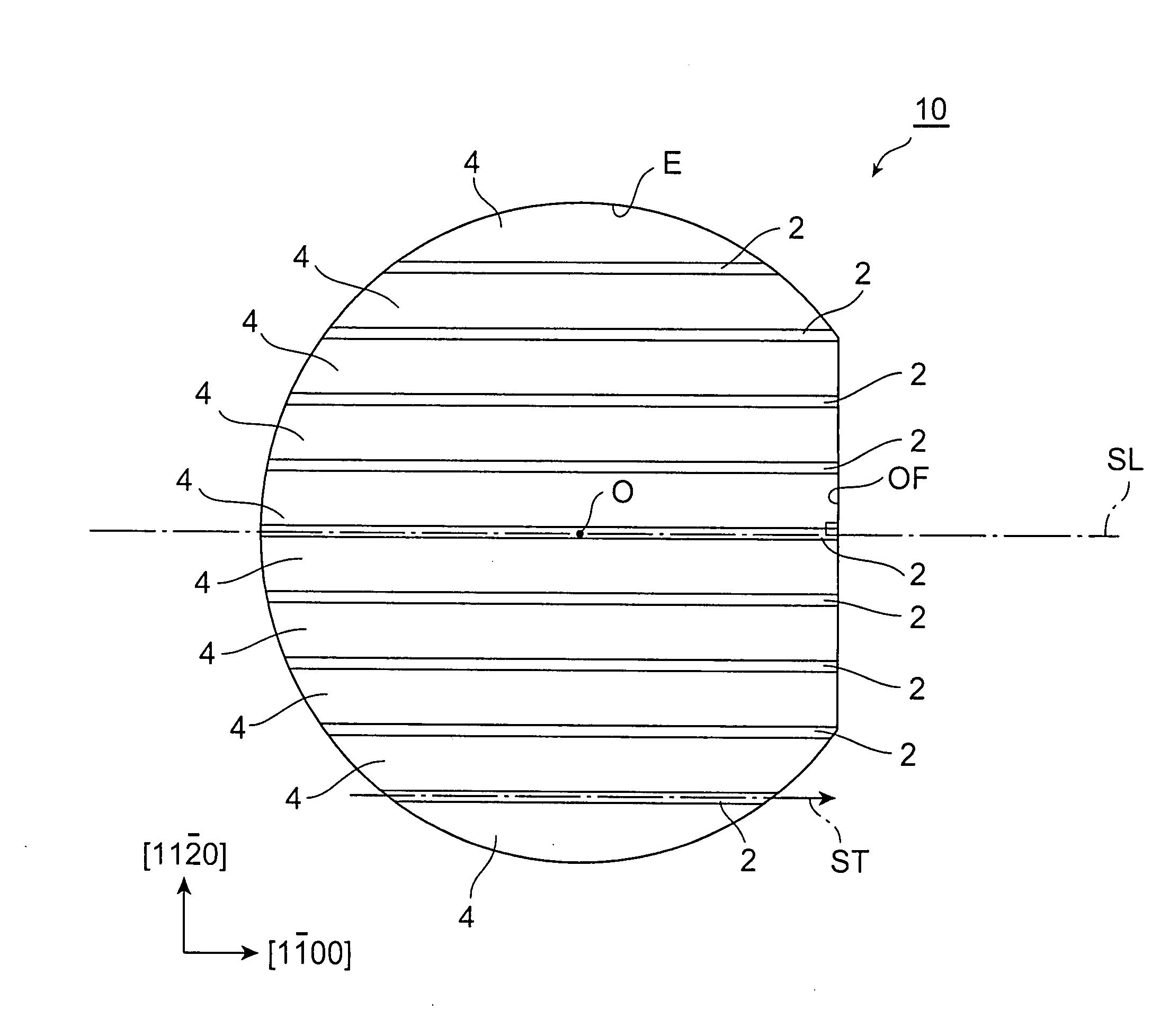

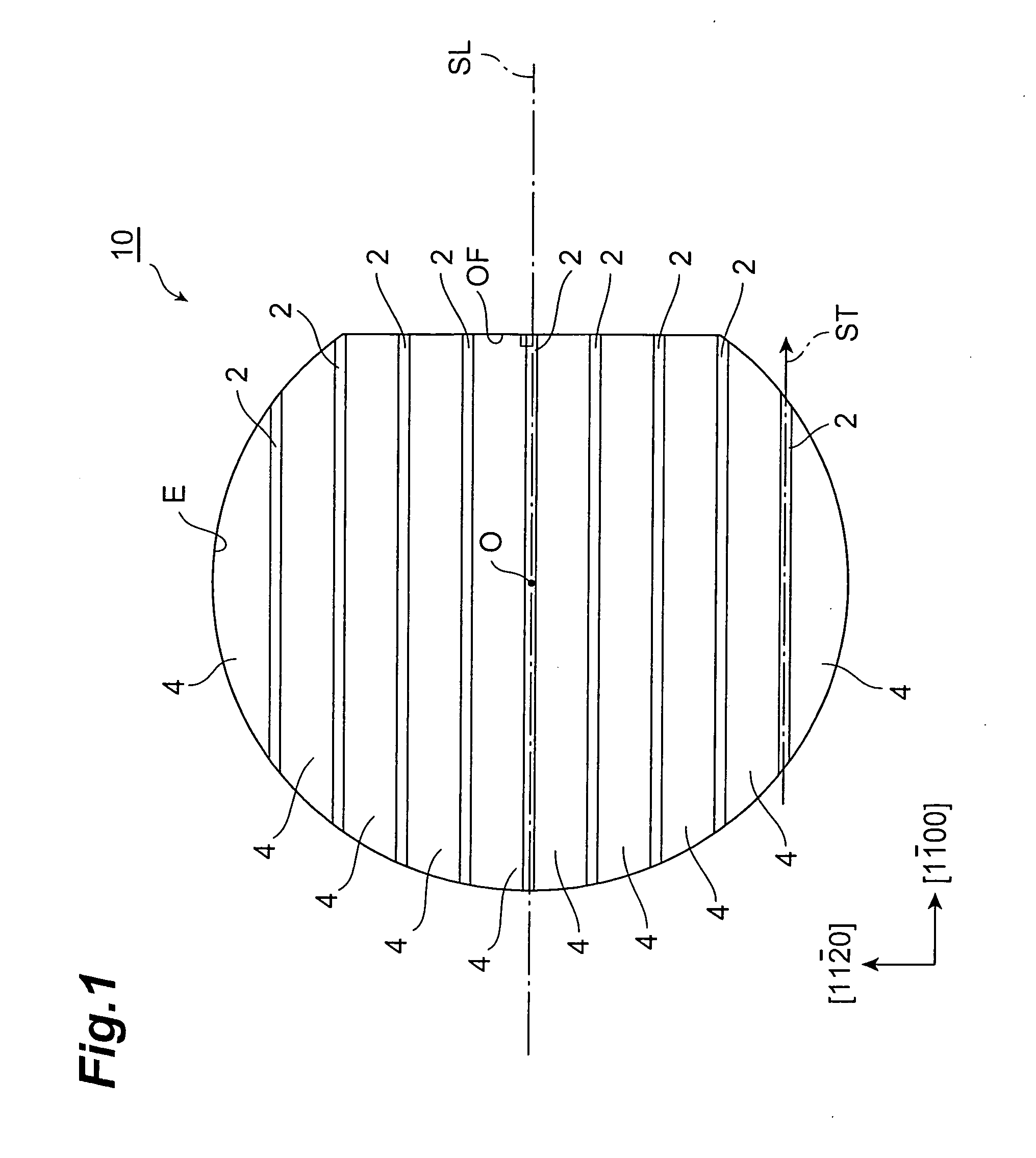

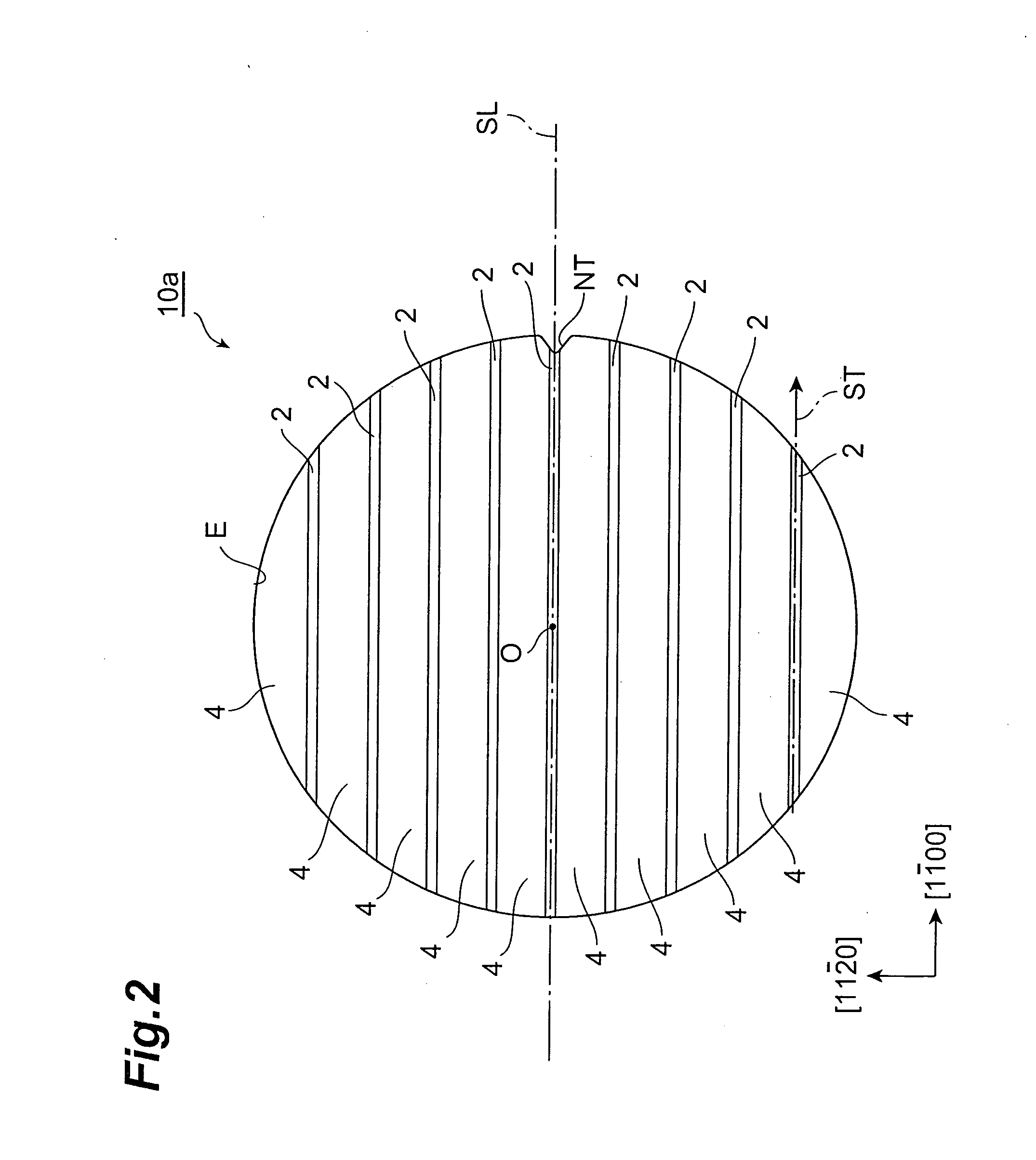

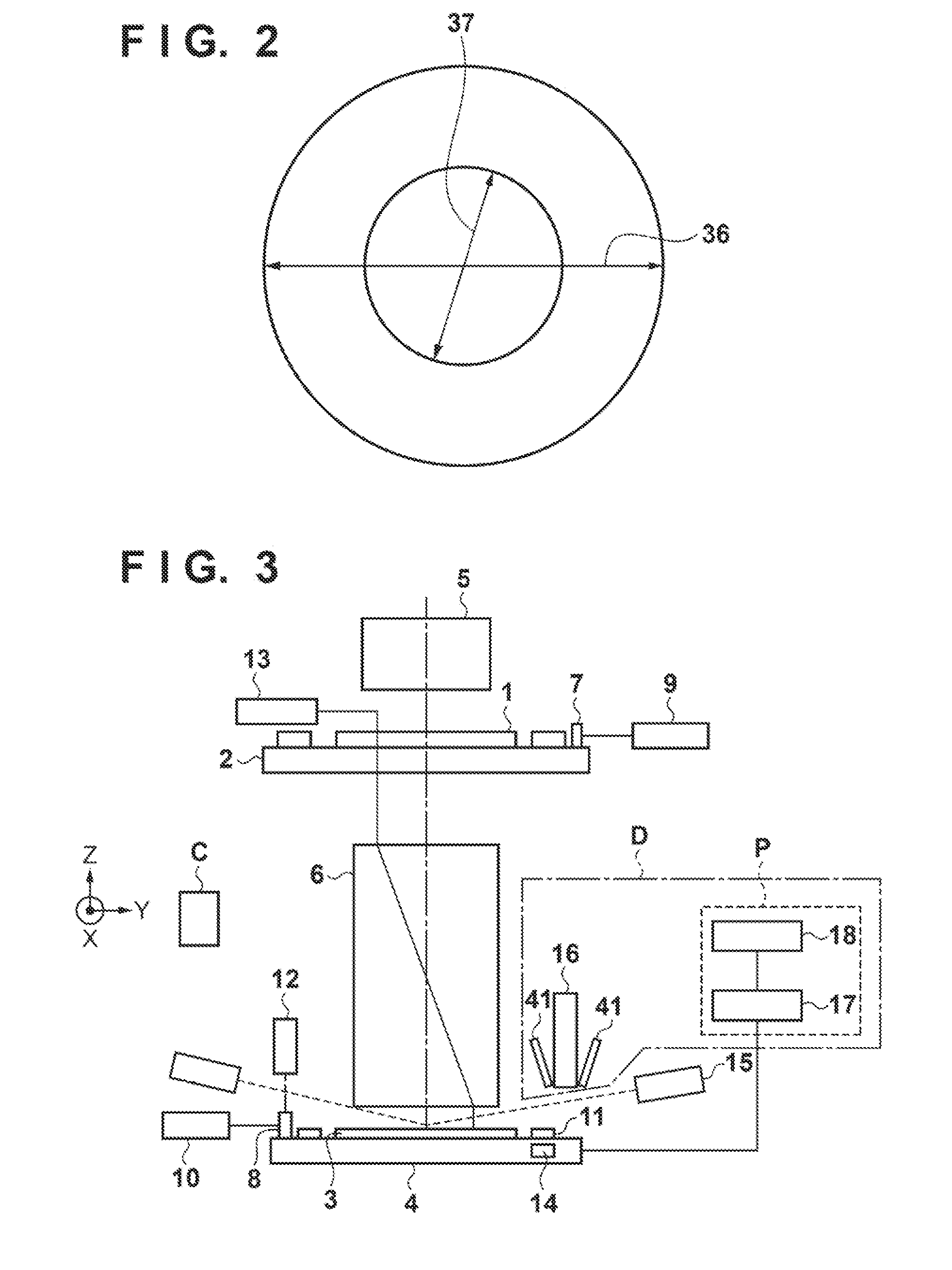

Nitride semiconductor substrate, and method for working nitride semiconductor substrate

InactiveUS7713844B2Marking position is accuratePrecise positioningPolycrystalline material growthAfter-treatment detailsCrystallographic defectNitride semiconductors

A method for working a nitride semiconductor substrate, comprising the steps of: preparing a disk-shaped nitride semiconductor substrate comprising a plurality of striped regions having defect concentration regions in which crystal defect density is higher than in surrounding low defect regions; and forming a cut-out at a specific location along the edge of the nitride semiconductor substrate, using as a reference the direction in which at least one from among the plurality of striped regions extends.

Owner:SUMITOMO ELECTRIC IND LTD

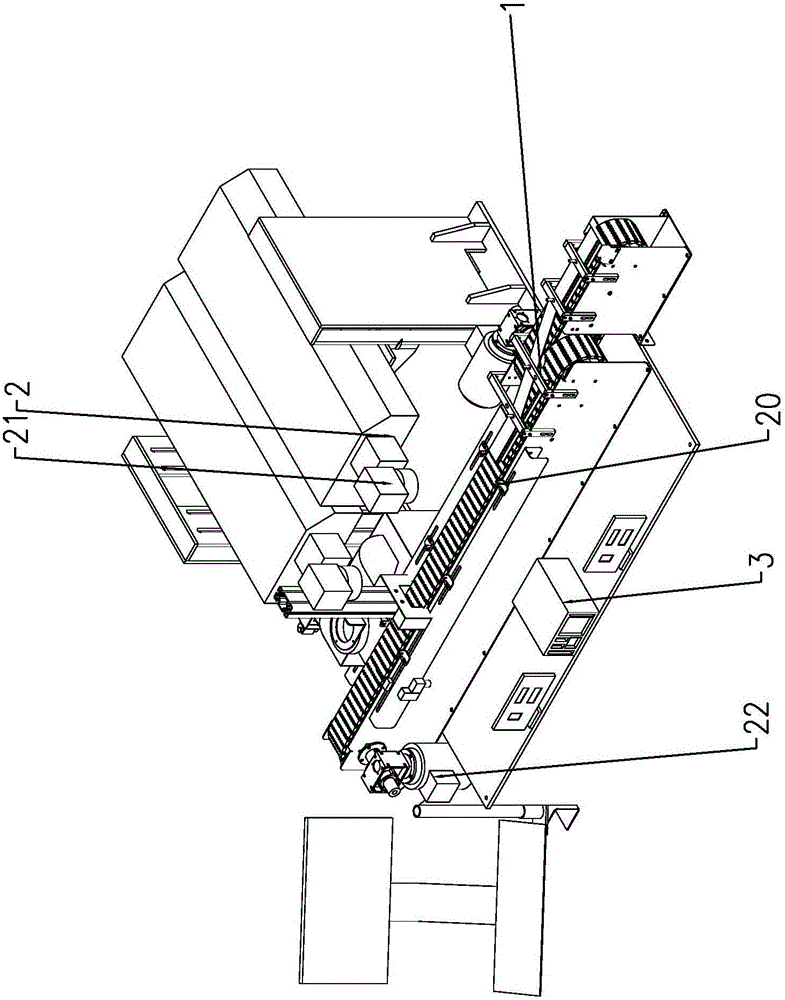

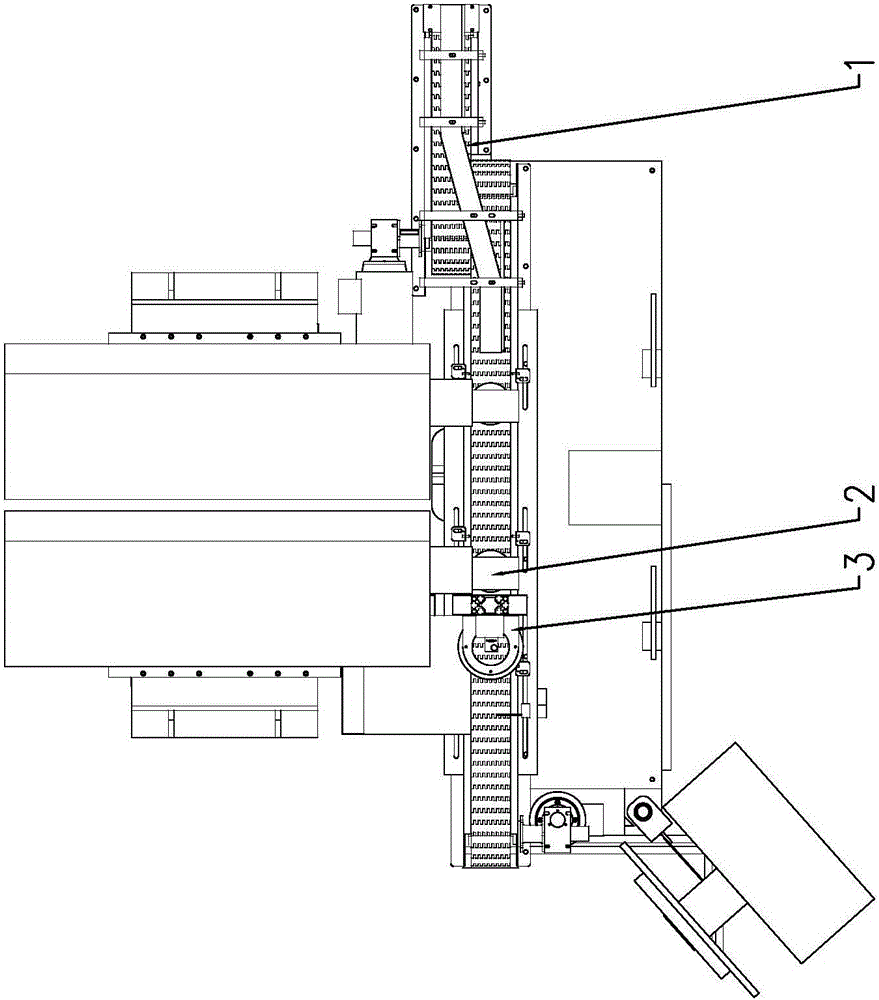

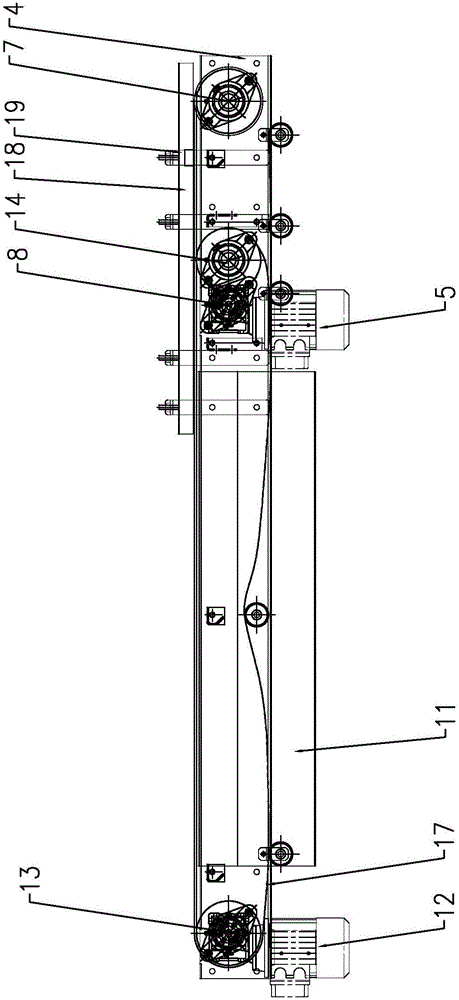

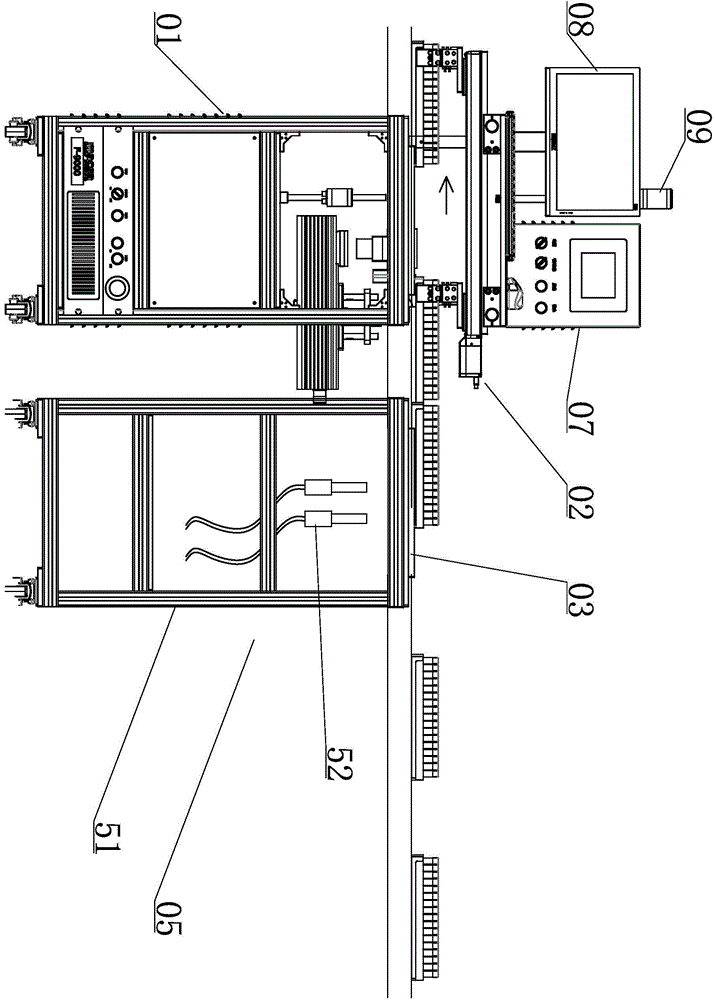

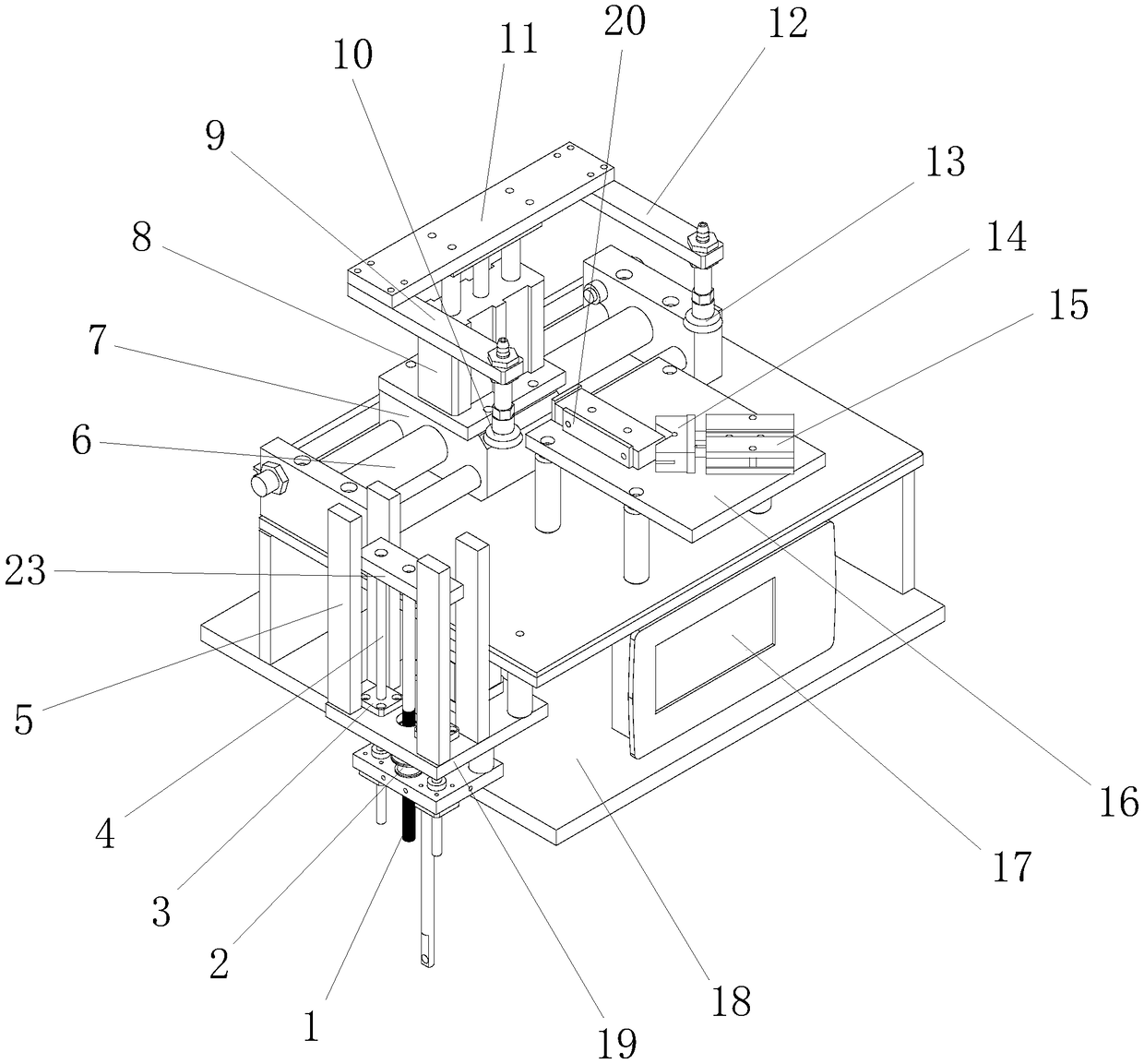

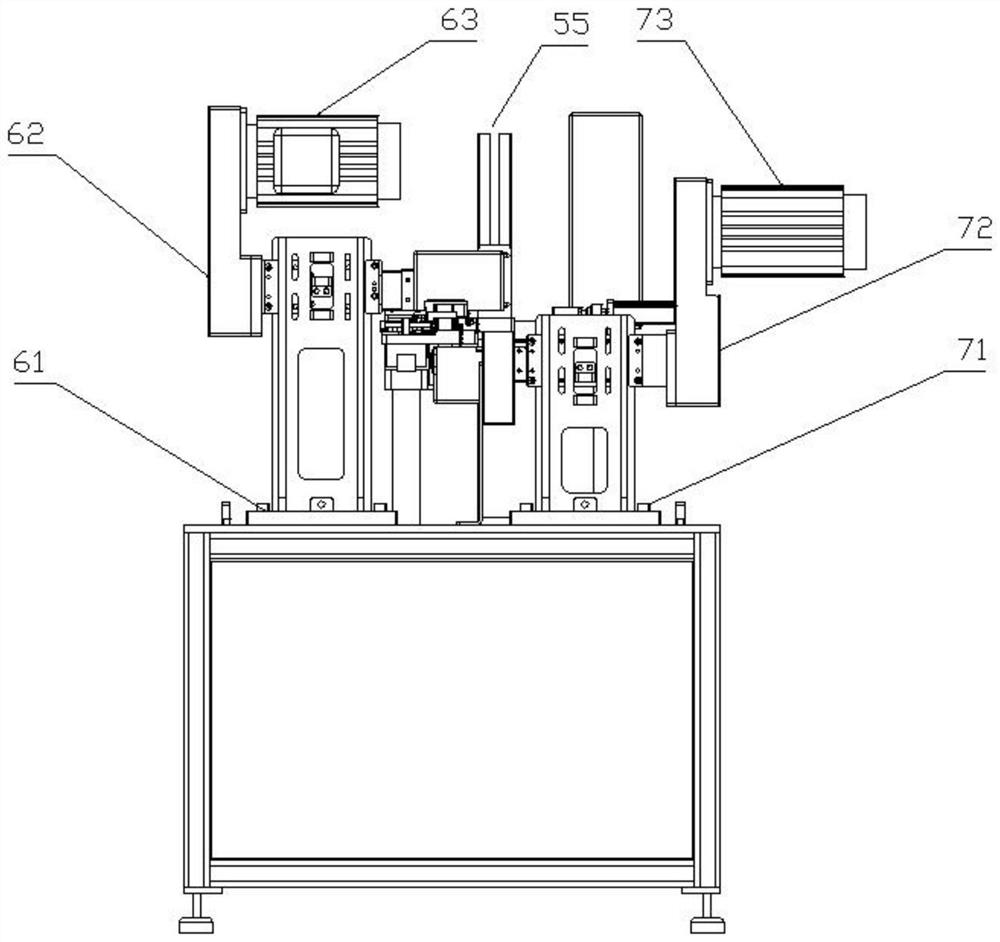

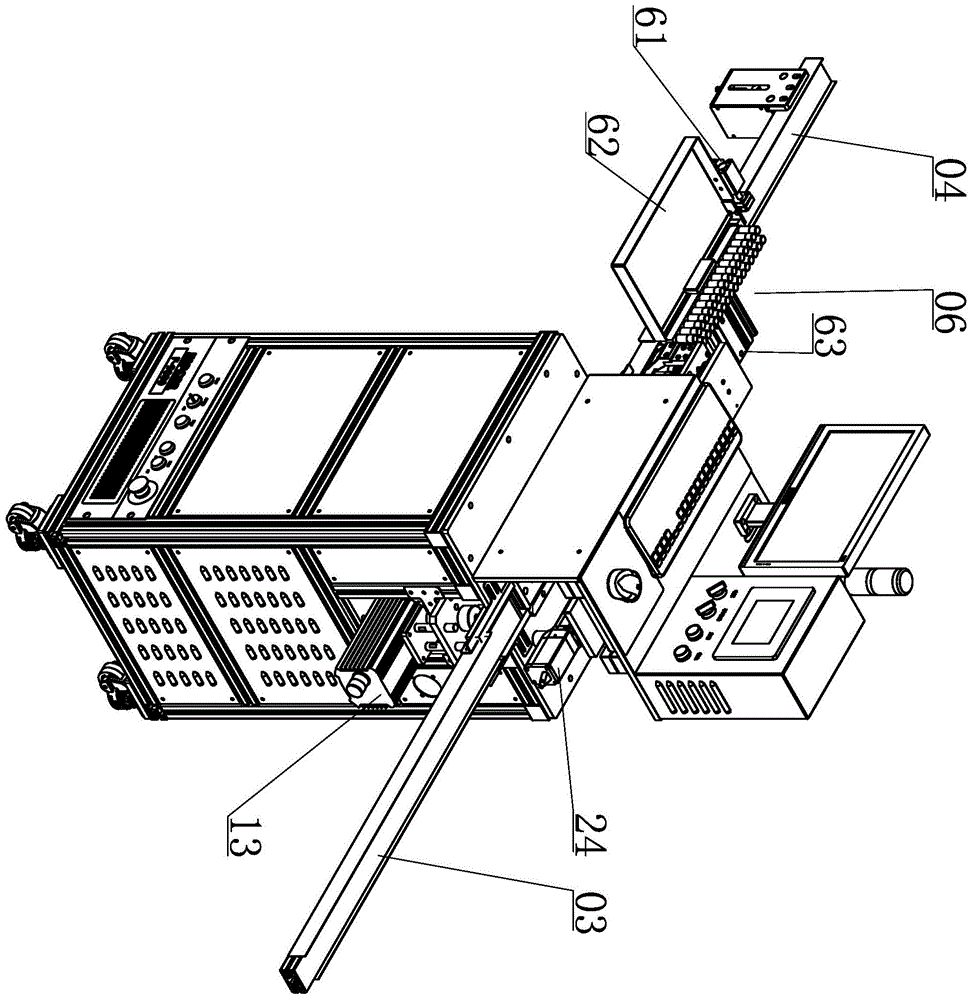

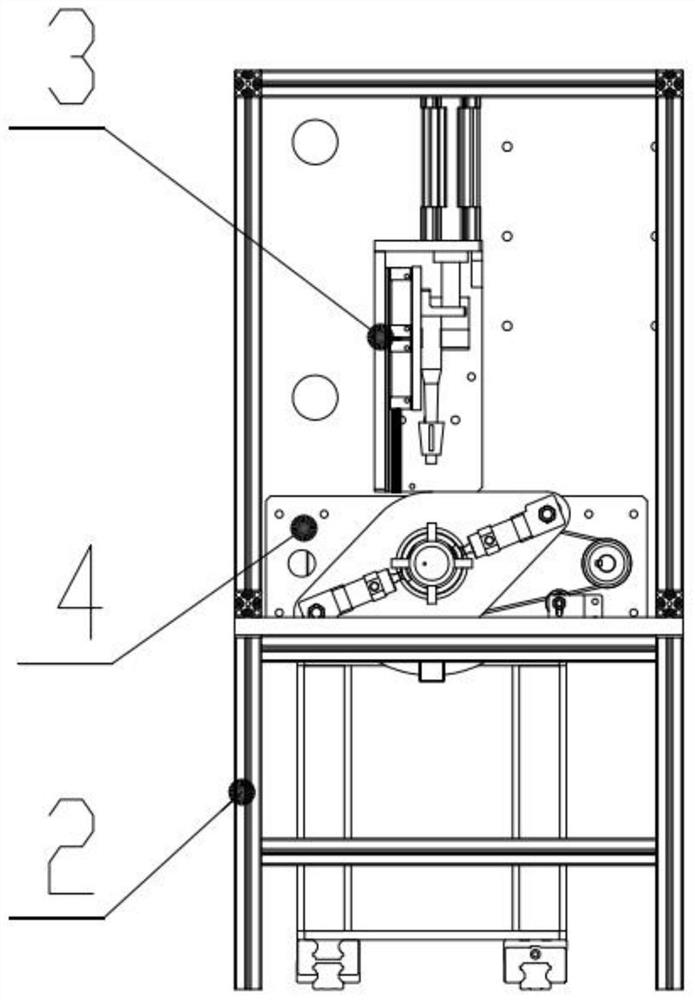

Differential-lid-separating multi-head laser bottle lid flying marking device

InactiveCN105798465ASimple structureCompact structureMetal working apparatusLaser beam welding apparatusEngineeringBottle

The invention relates to a laser bottle lid flying marking device, in particular to a differential-lid-separating multi-head laser bottle lid flying marking device and belongs to the technical field of bottle lid laser marking equipment. The differential-lid-separating multi-head laser bottle lid flying marking device comprises a bottle lid differential separation conveying chain plate mechanism, a laser marking mechanism and a two-dimensional code photographing and code reading mechanism which are sequentially arranged; the bottle lid differential separation conveying chain plate mechanism comprises a bottle lid input mechanism, a bottle lid output mechanism and a bottle lid guiding mechanism; the bottle lid output mechanism is arranged at the tail end of the bottle lid input mechanism; the bottle lid guiding mechanism is located between the tail end of the bottle lid input mechanism and the front end of the bottle lid output mechanism; and the bottle lid guiding mechanism communicates with a conveying channel at the tail end of the bottle lid input mechanism and the front end of the bottle lid output mechanism. According to the differential-lid-separating multi-head laser bottle lid flying marking device, operation can be completed for bottle lids of different sizes and specifications just by adjusting bottle lid guiding plates of different widths, time is saved, and operation is convenient; a marking result is inspected through a photographing and code reading system, and the product marking effect is improved; and the energy consumption is low, and noise is small.

Owner:HUANGCHANG AUTOMATION ENG SHANGHAI CO LTD

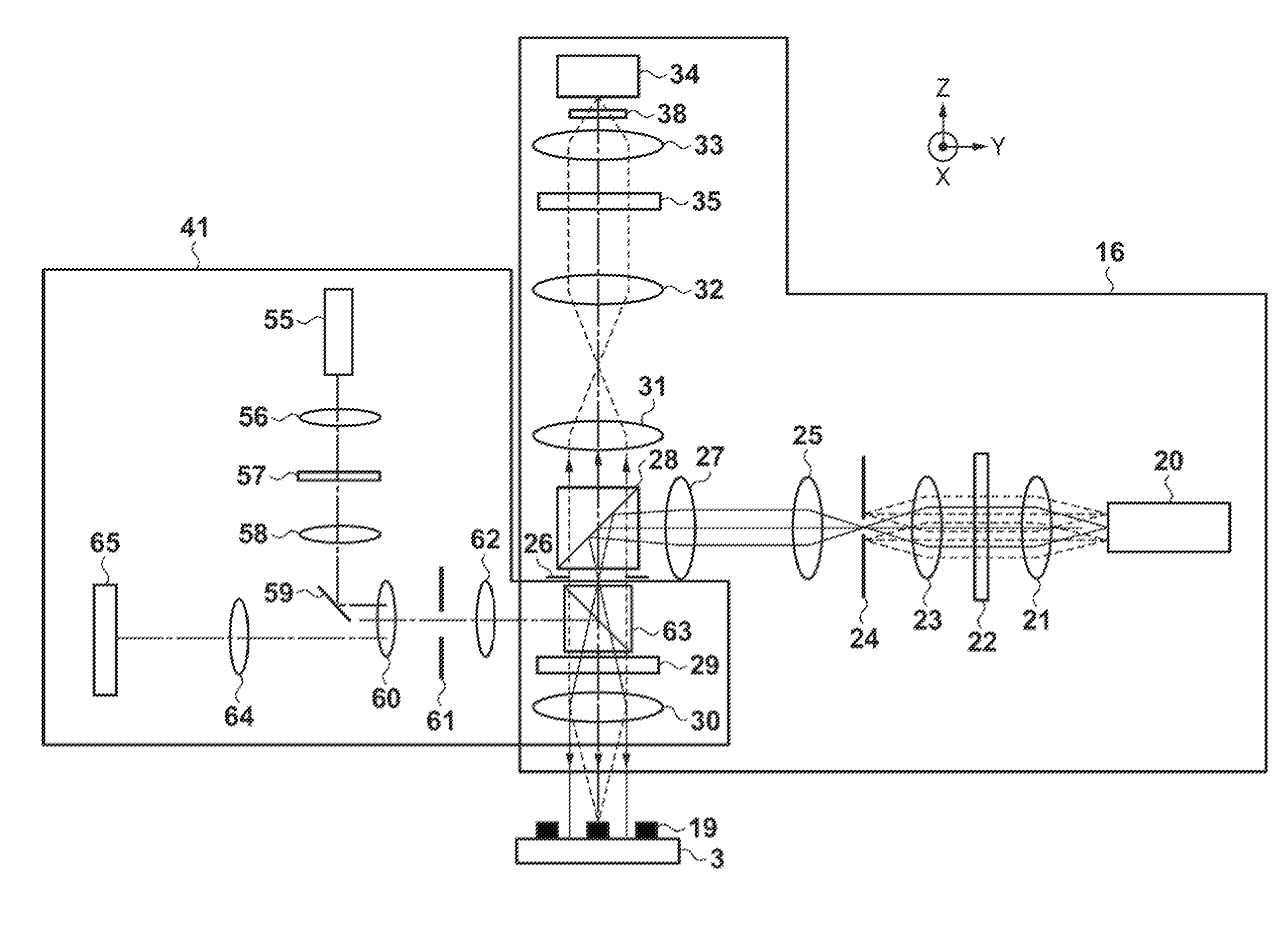

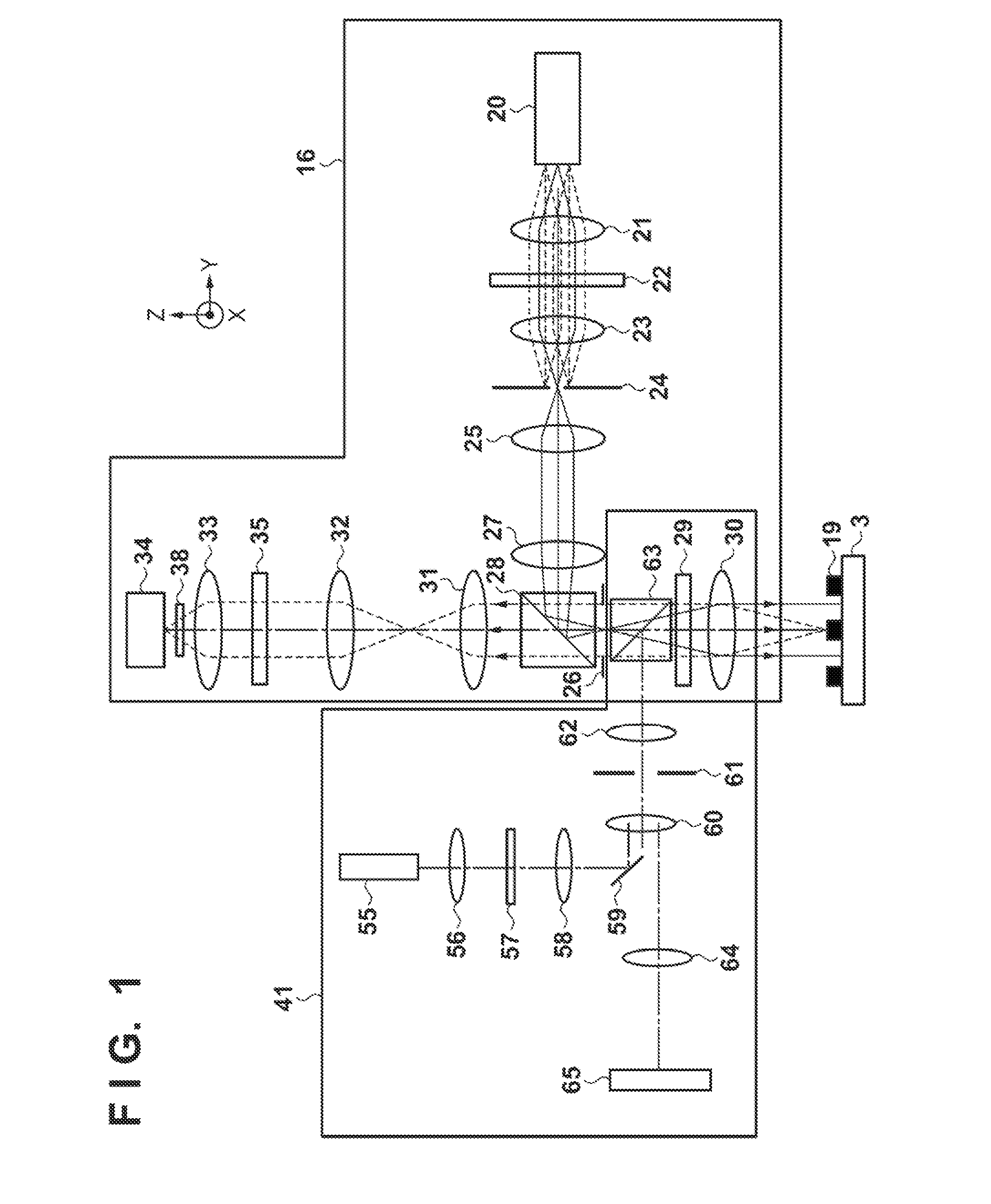

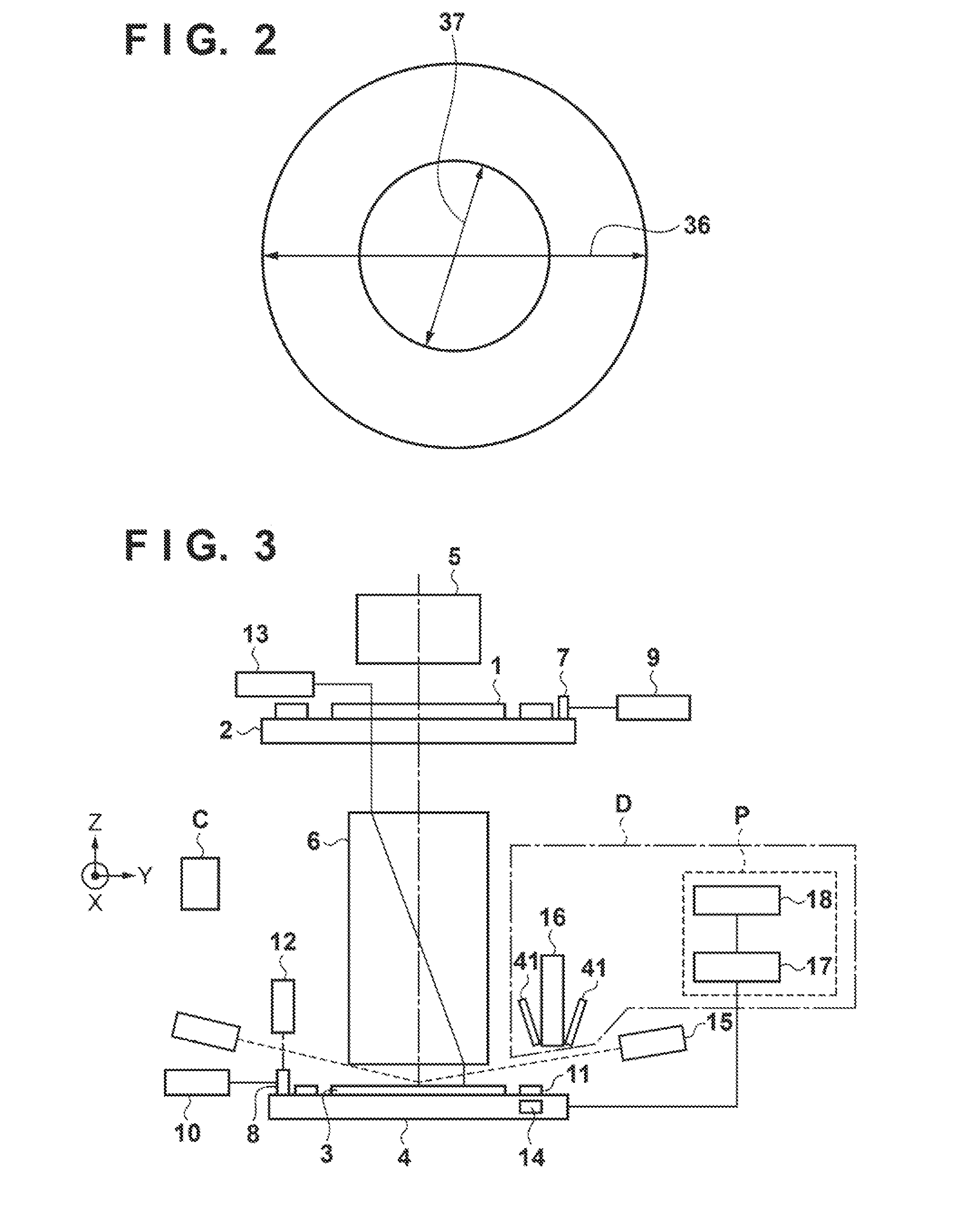

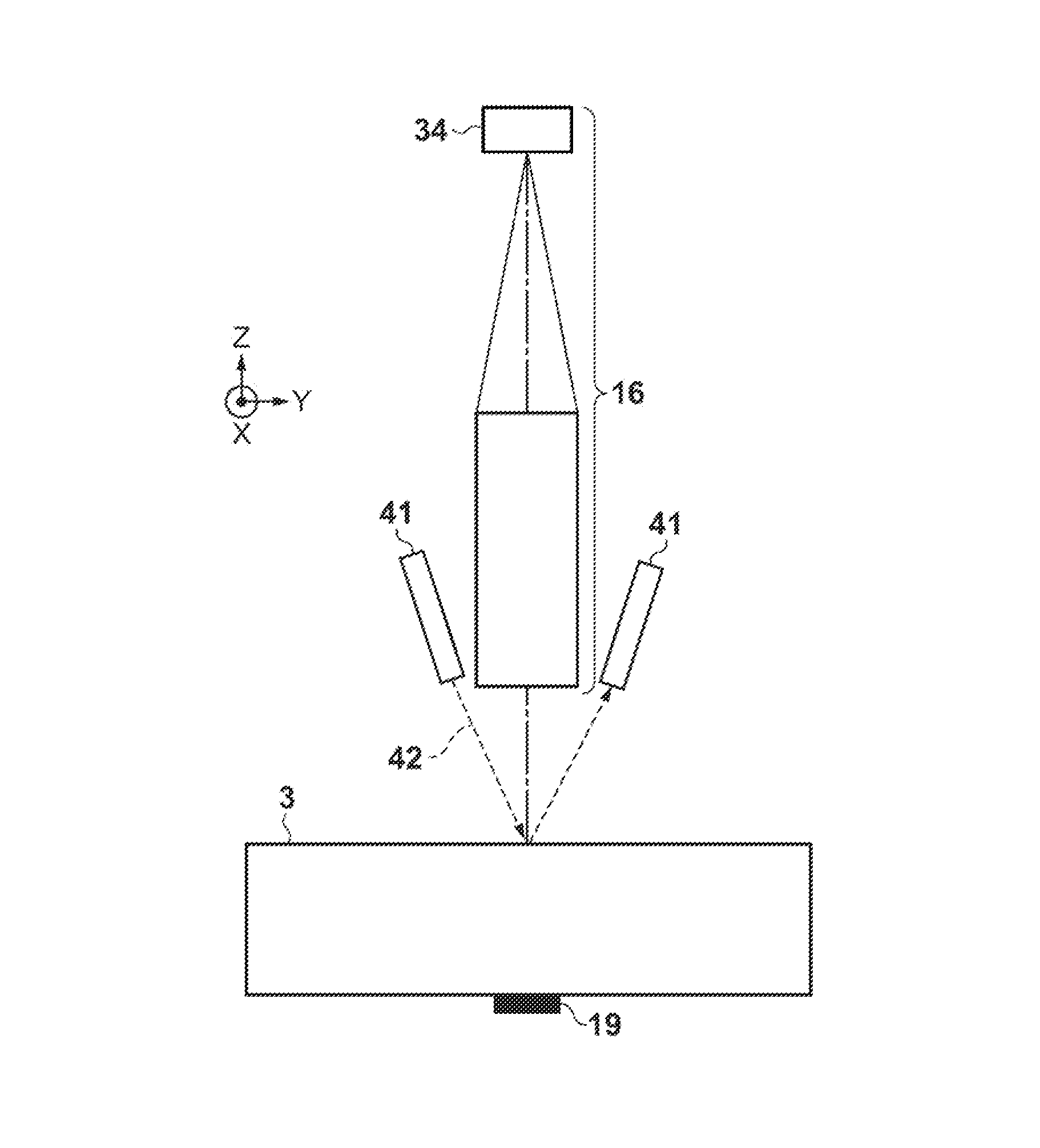

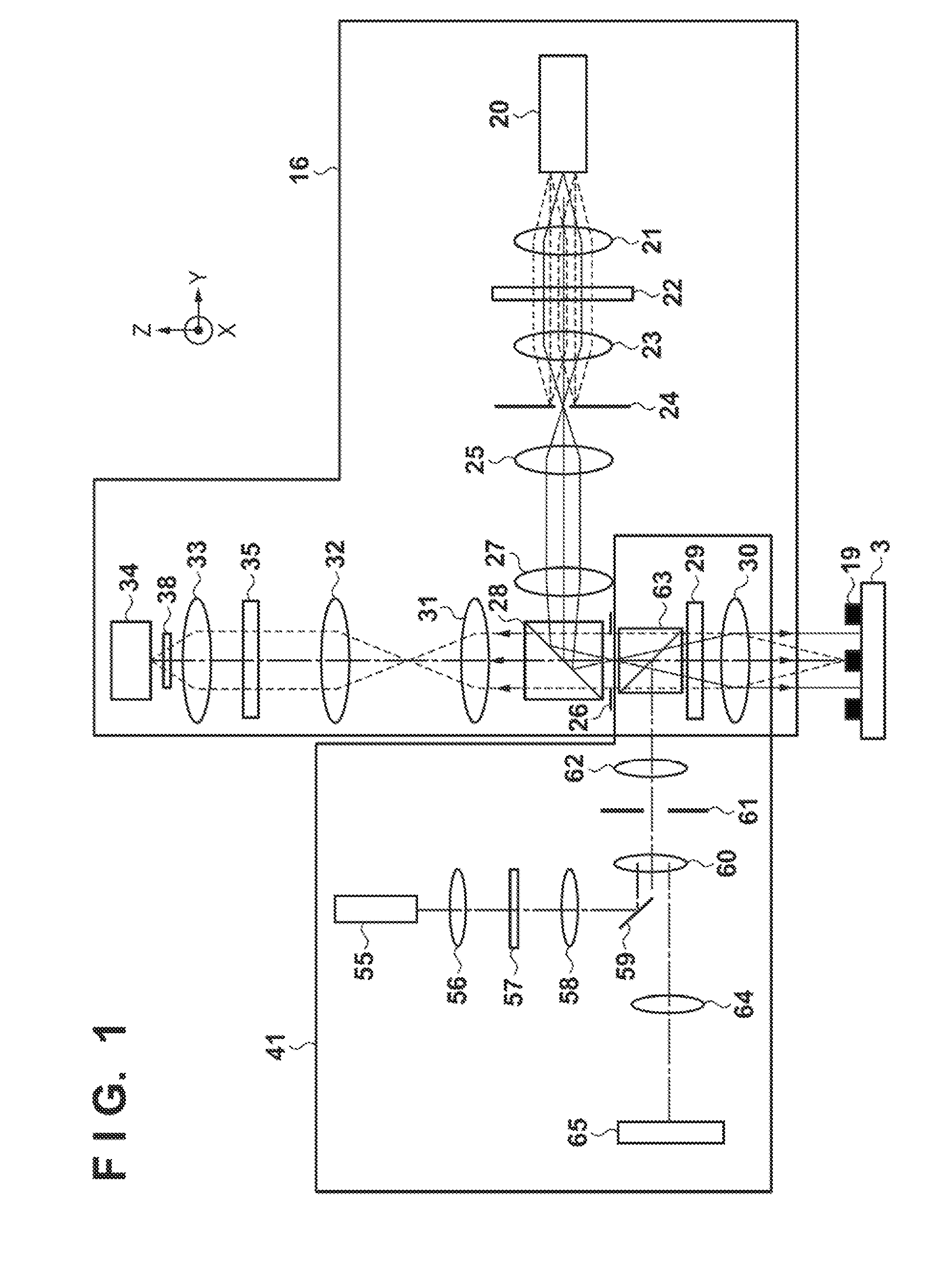

Detection apparatus, exposure apparatus, and method of manufacturing device

ActiveUS20130230798A1Marking position is accurateRadiation pyrometryPhase-affecting property measurementsPhysics

A detection apparatus, which detects a mark formed on a lower surface of a target object, includes: a first detector which illuminates the mark from an upper surface side of the target object to detect an image of the illuminated mark; a second detector which detects an upper surface position of the target object; and a processor which obtains information indicating a focus position to focus on the mark in the first detector, based on the upper surface position detected by the second detector.

Owner:CANON KK

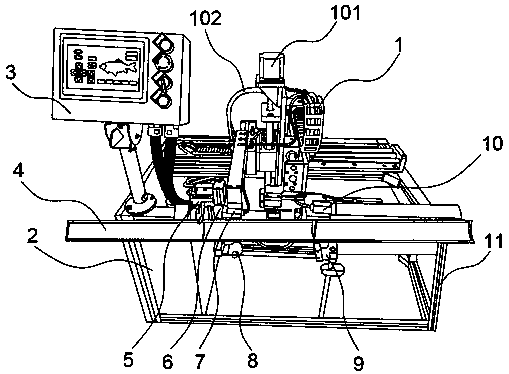

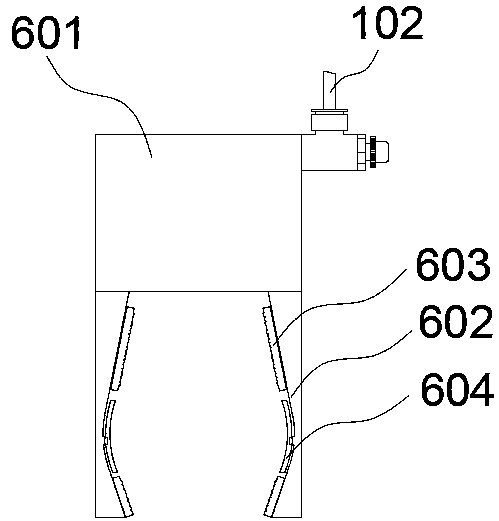

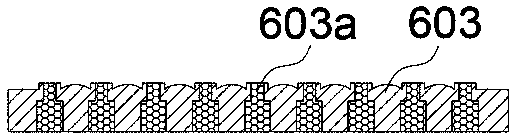

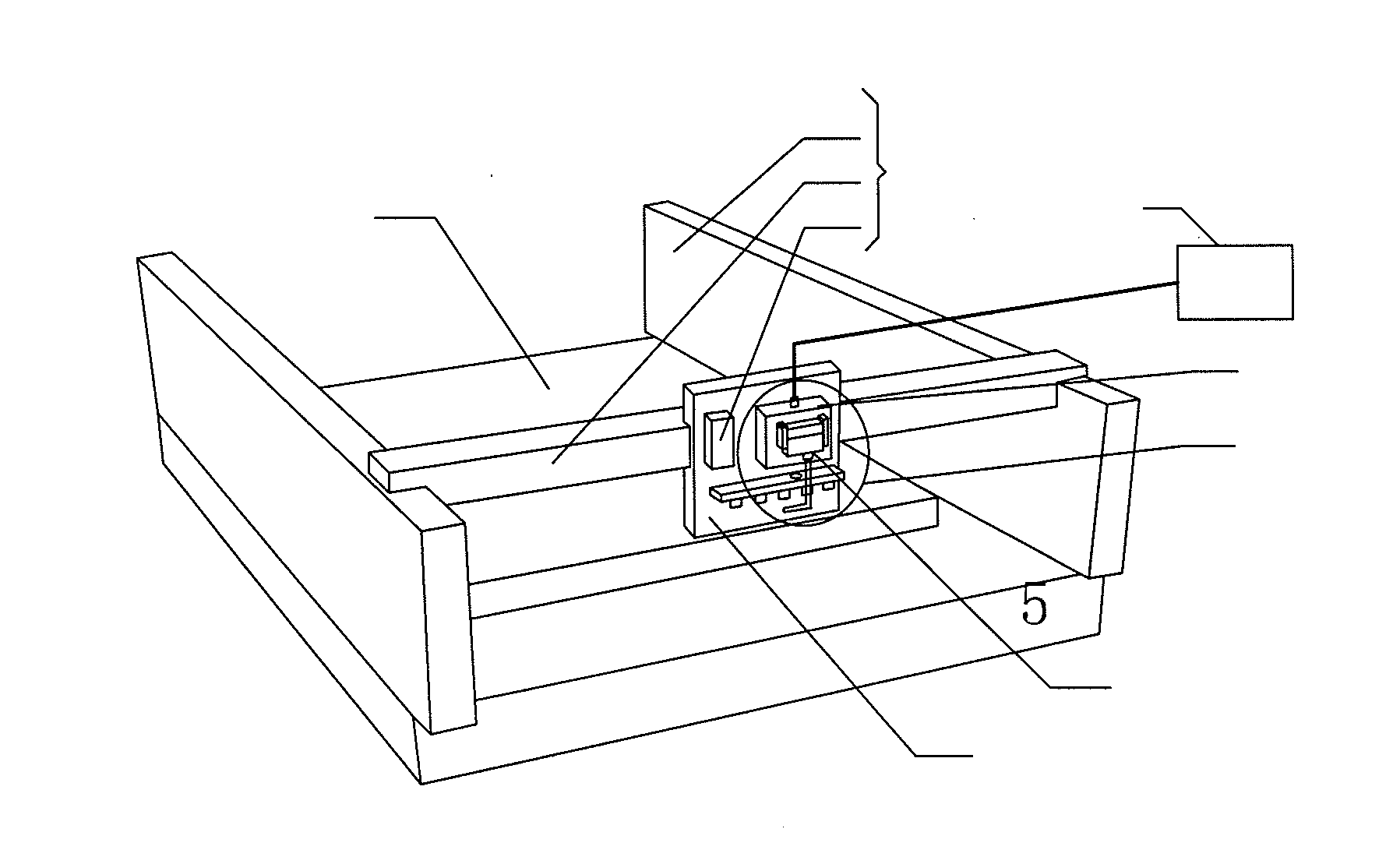

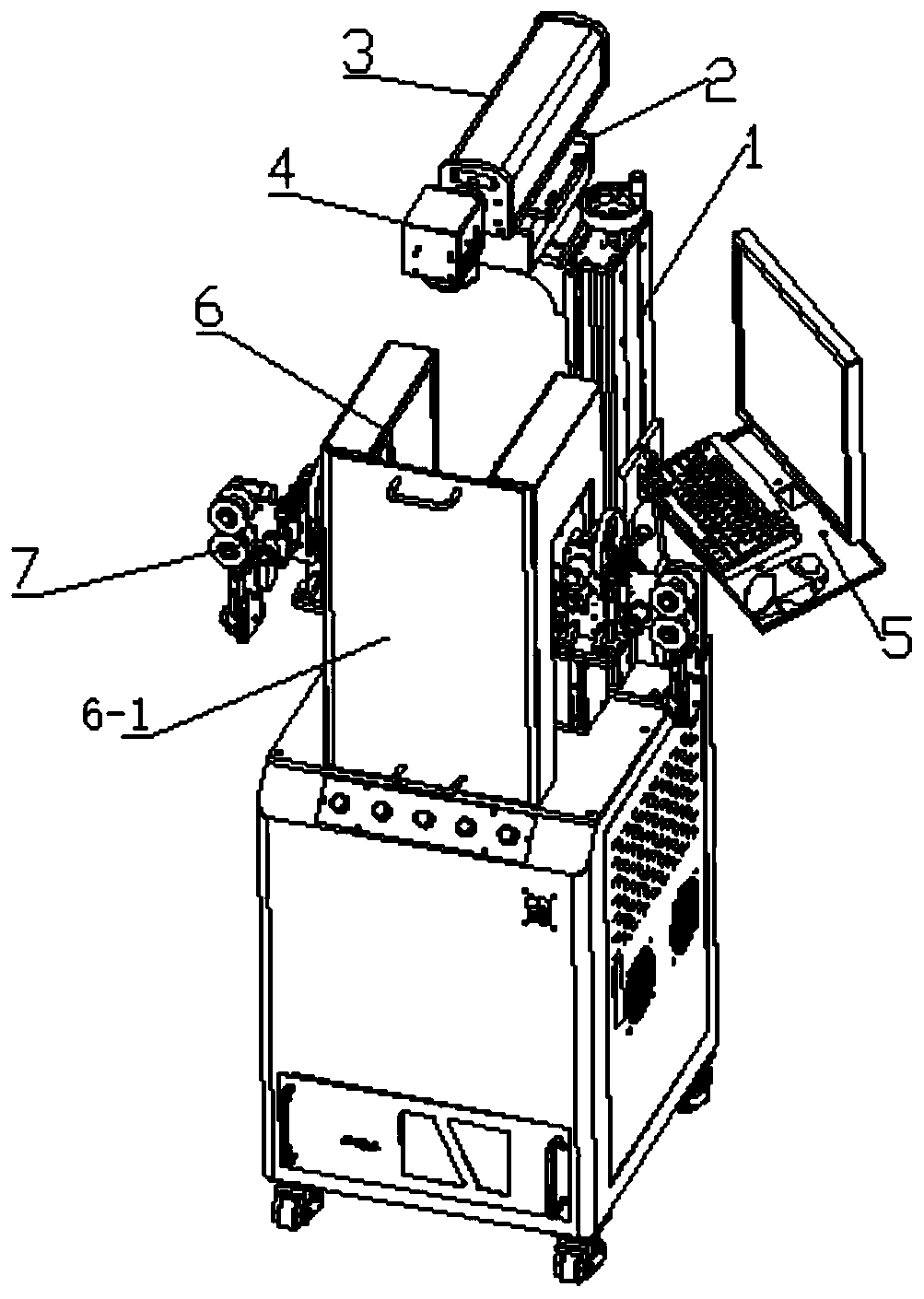

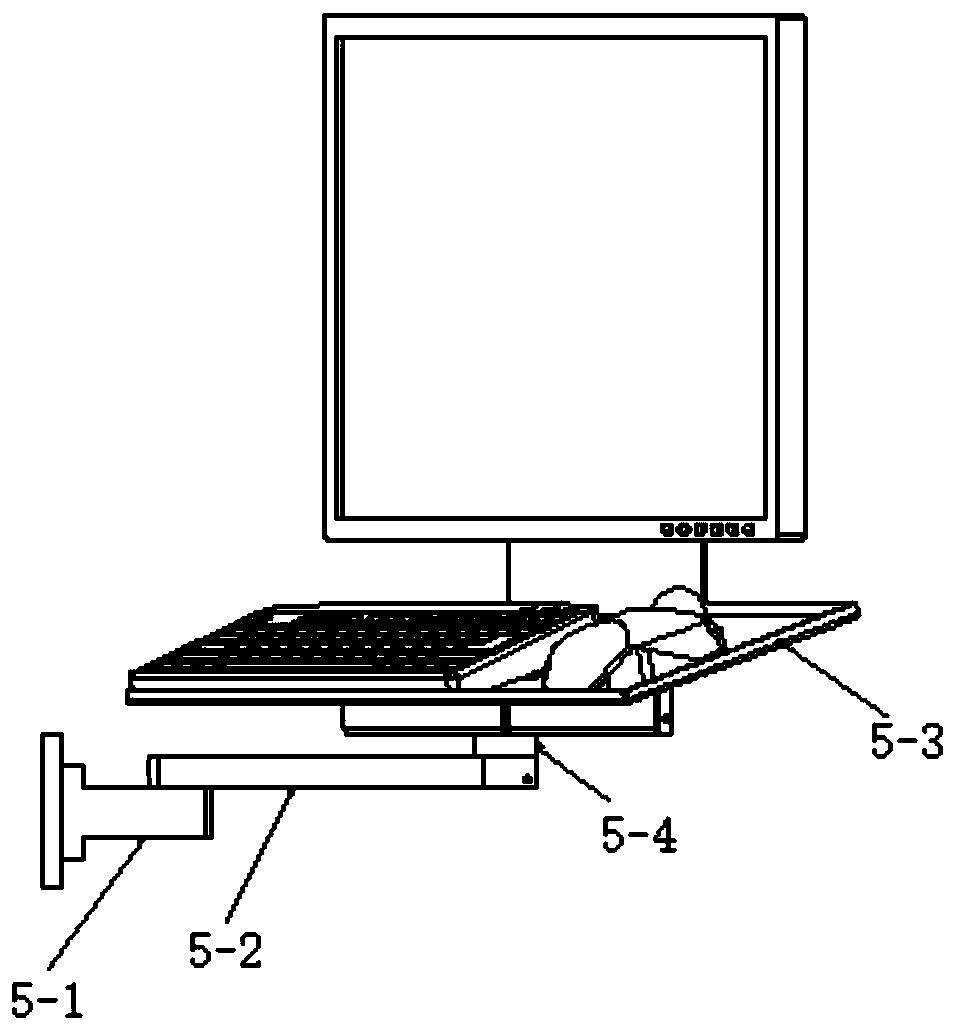

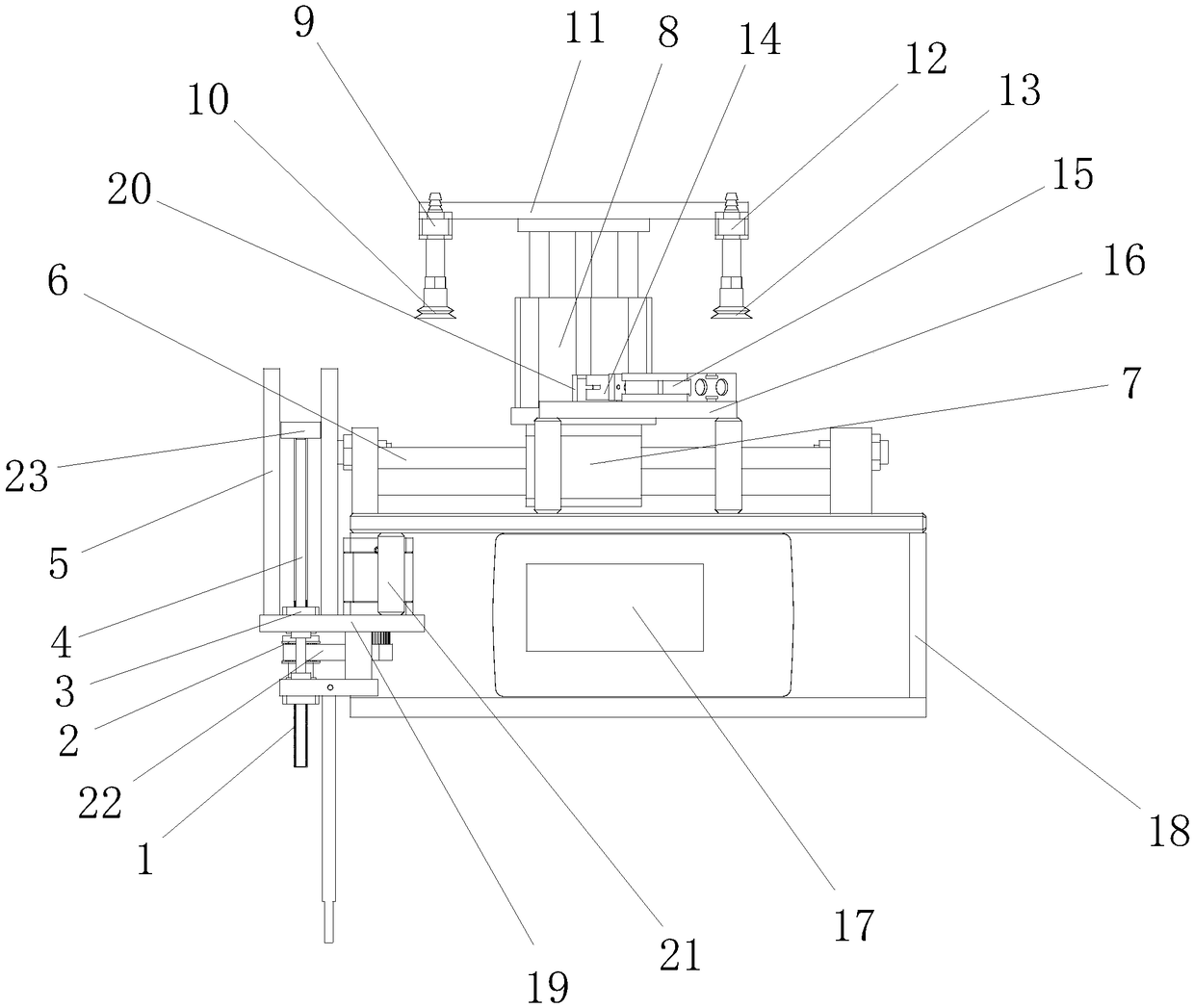

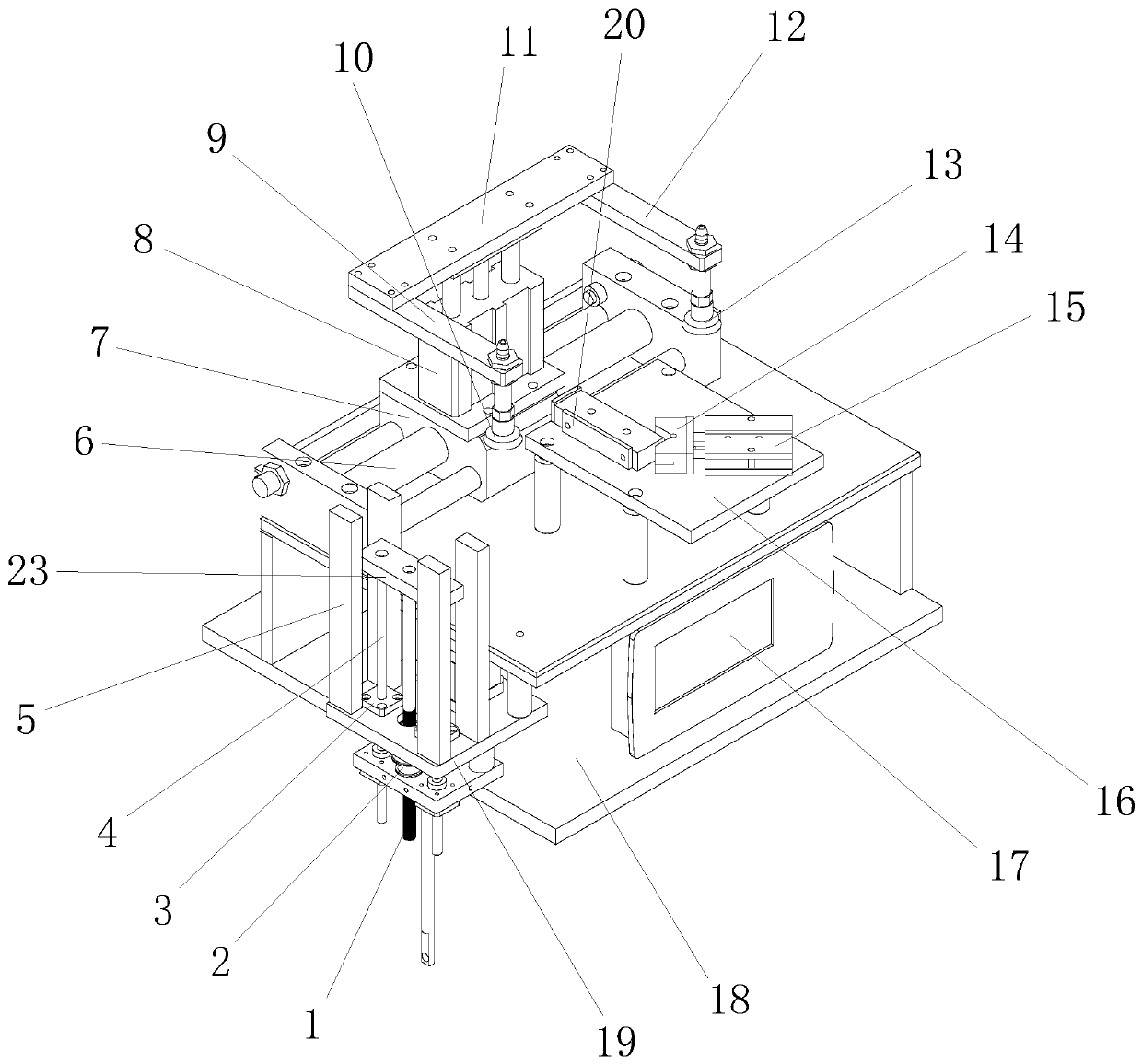

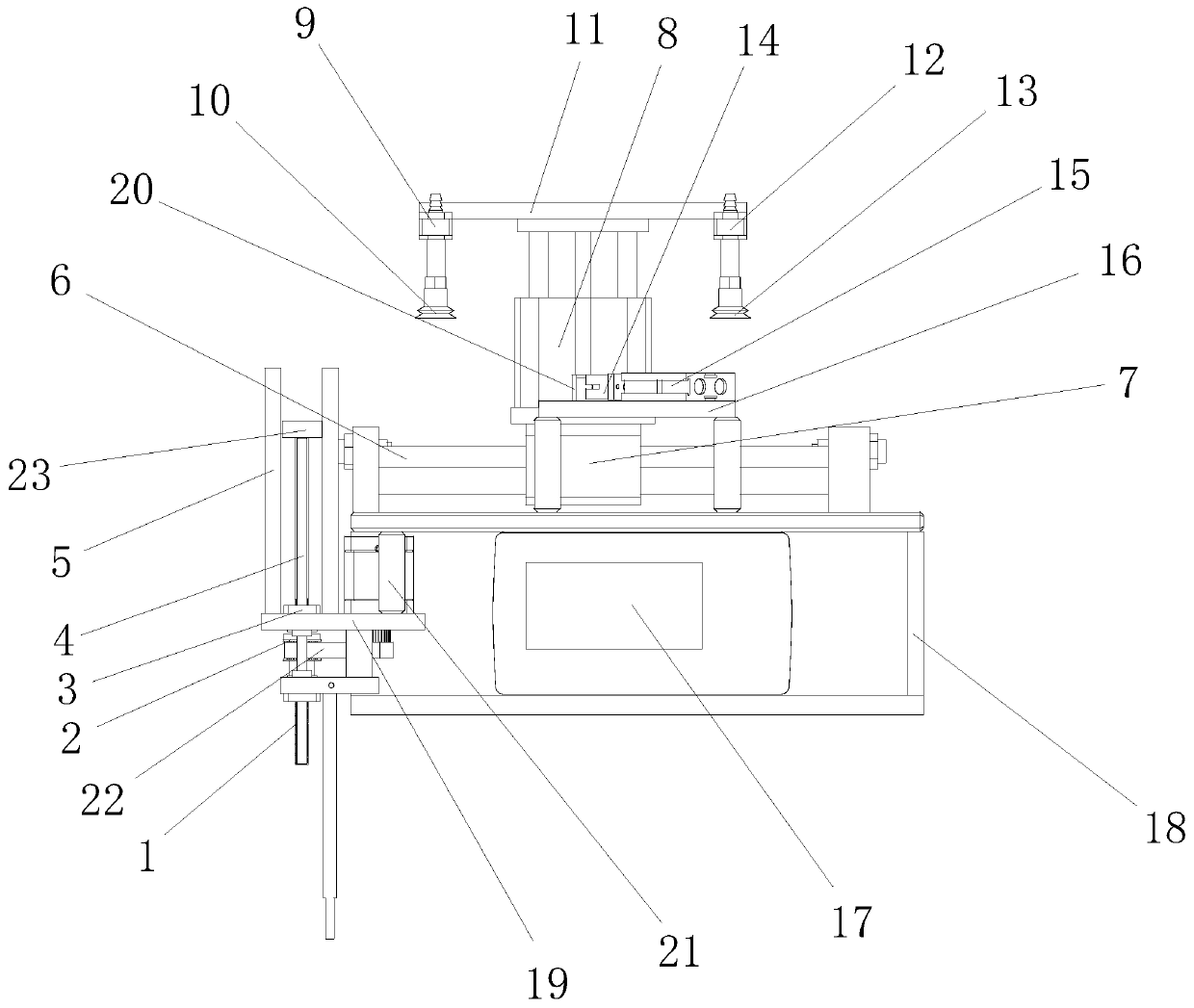

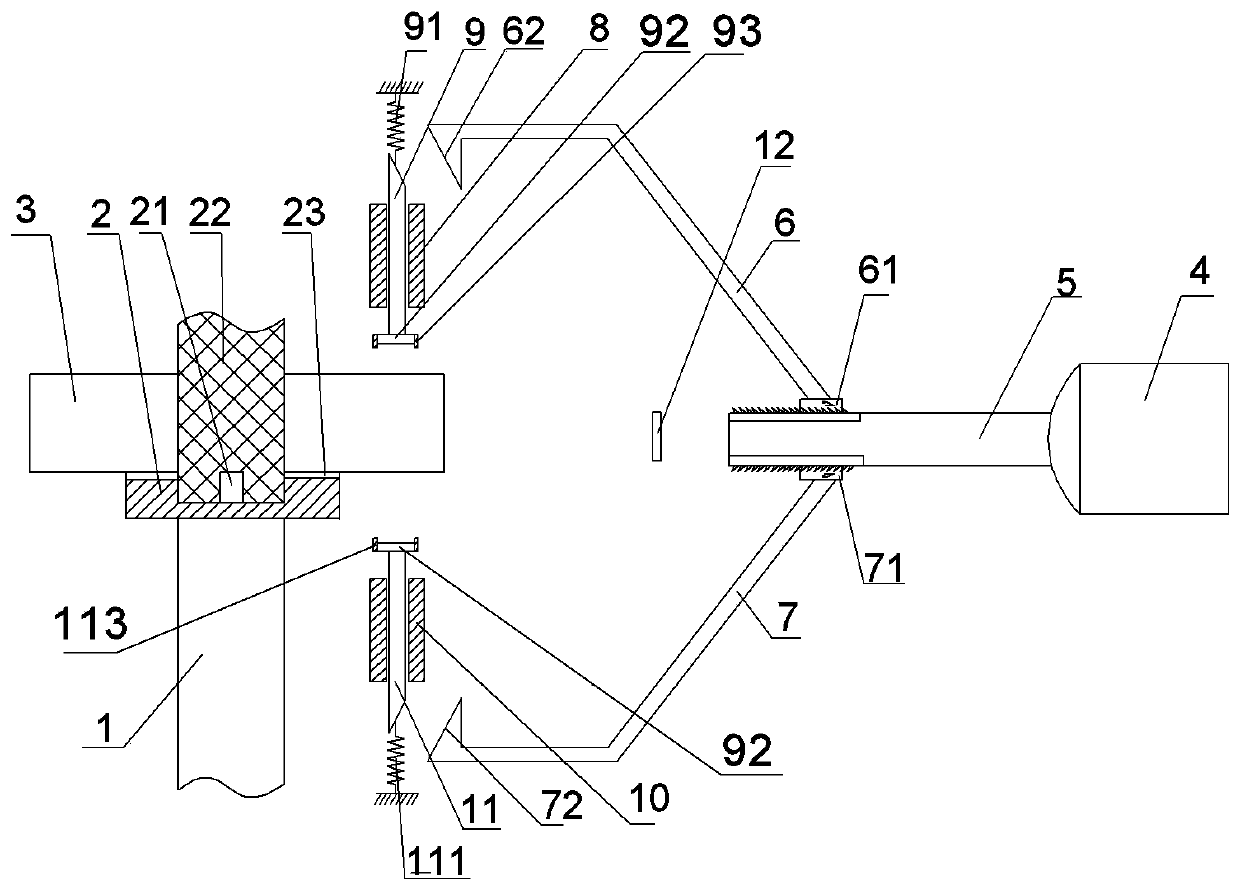

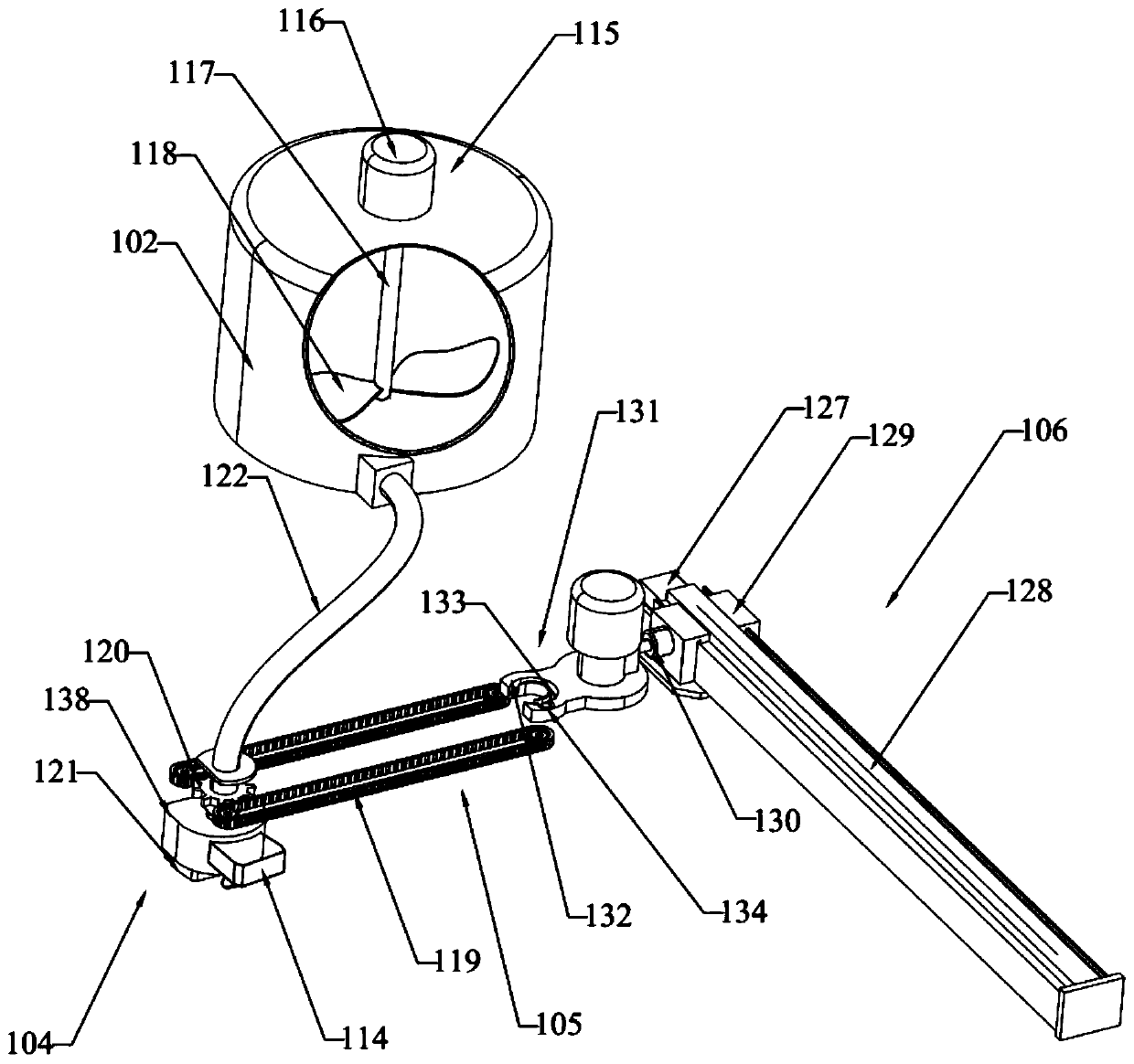

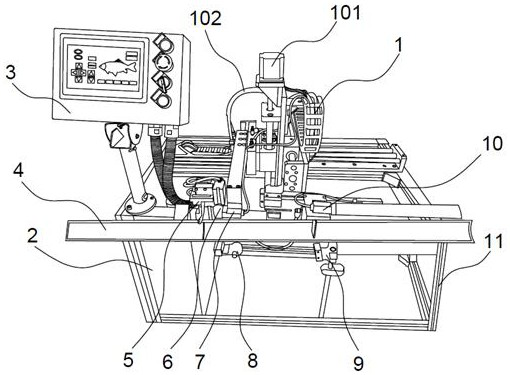

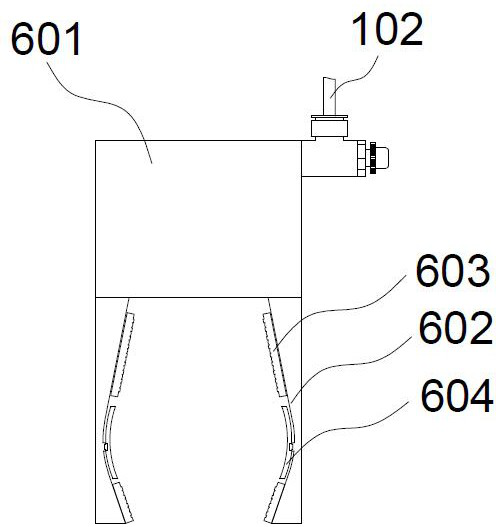

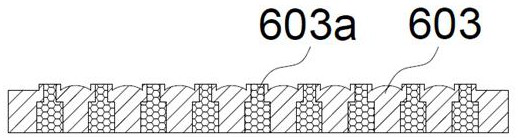

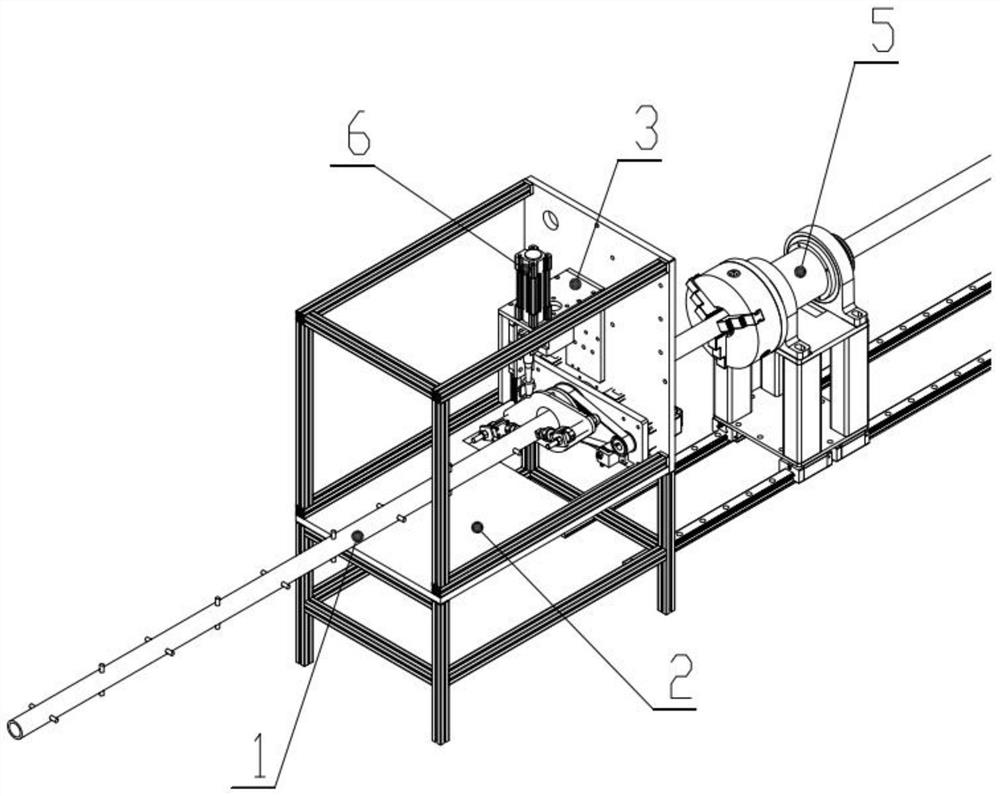

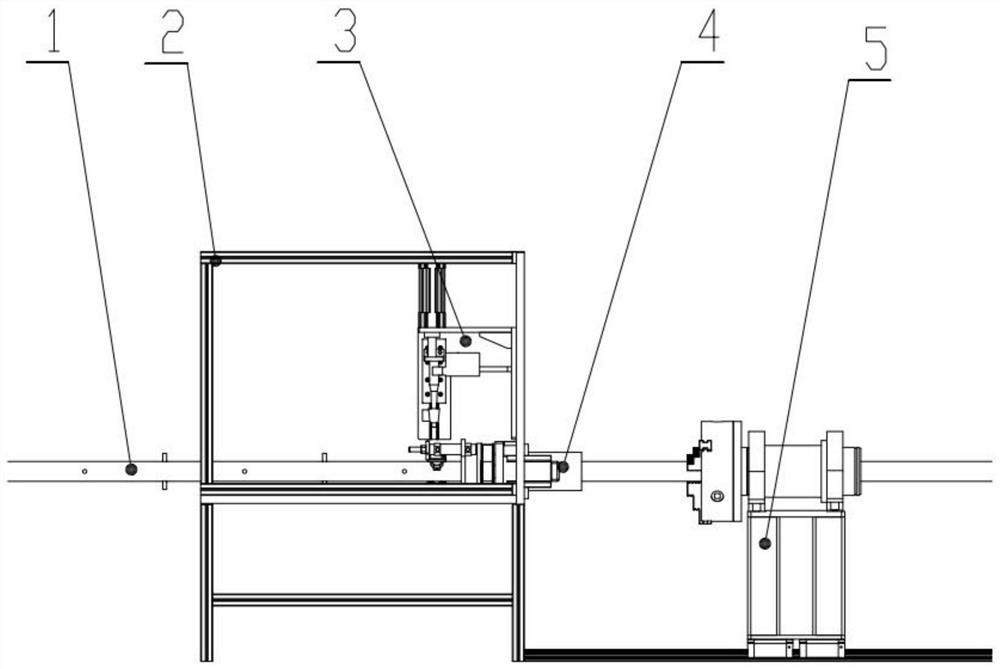

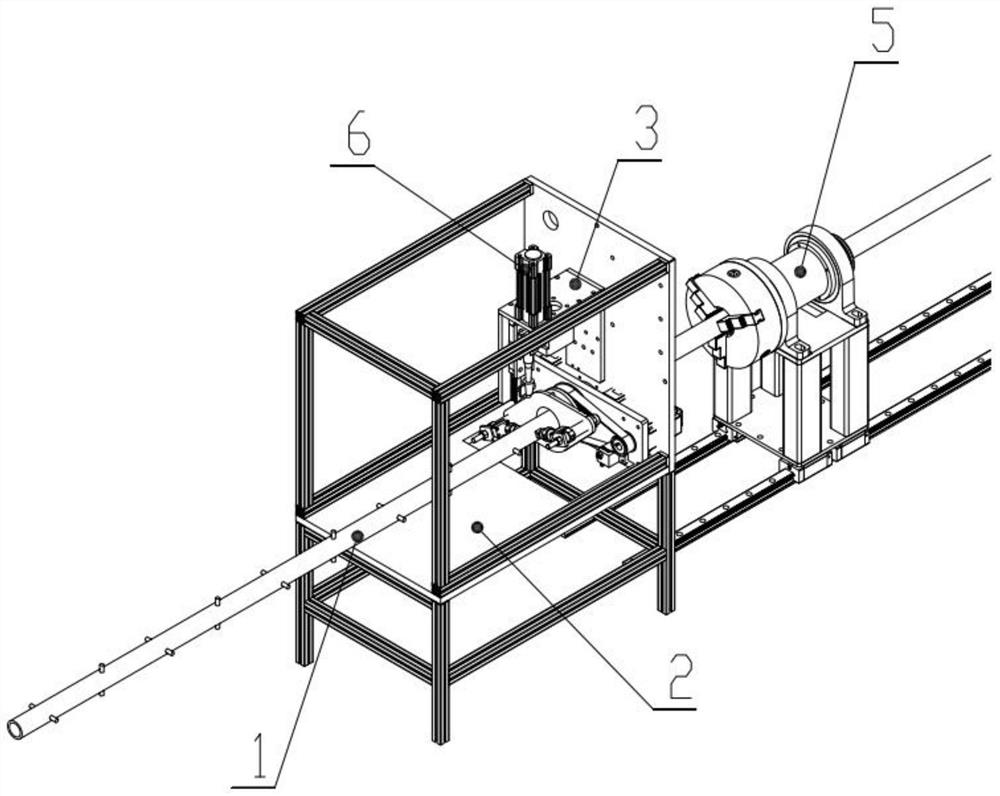

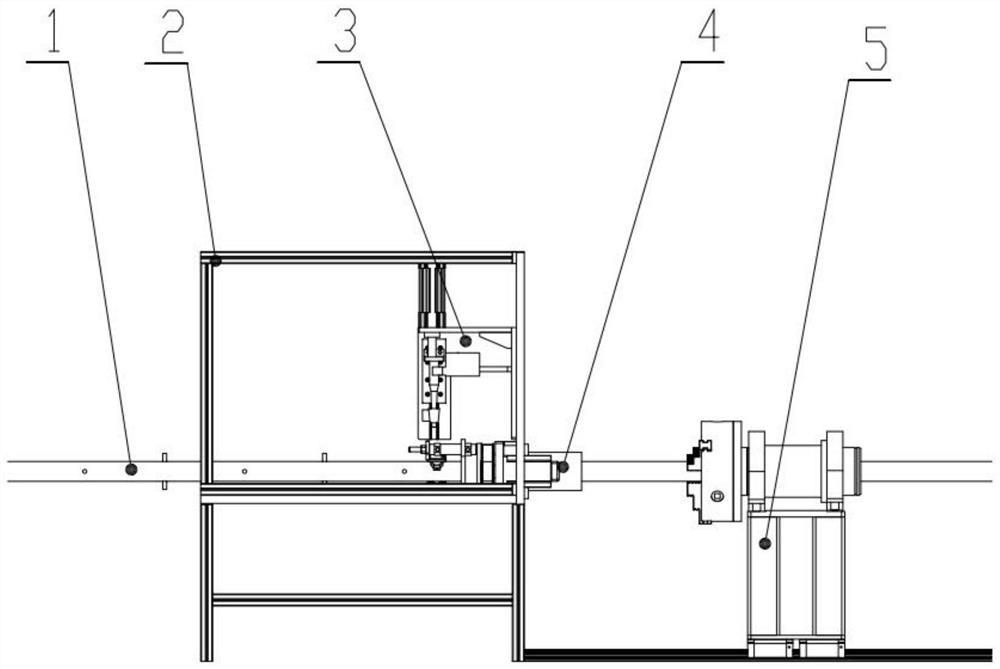

Automatic marking machine and a marking method

The invention discloses an automatic marking machine and a marking method. The automatic marking machine comprises a support, an industrial personal computer arranged on the support, a transmission mechanism connected with the industrial personal computer and a marking device connected with the transmission mechanism; a transmission pipe is arranged on one side of the upper end of the support; a control panel, a second limiting device, a mechanical arm, the marking device and a first limiting device are sequentially arranged above the transmission pipe on the side of the support from left to right; a controller and a length detector are arranged below the transmission pipe; the controller corresponds to the second limiter in position; and the length detector corresponds to the first limiter in position. The automatic marking machine disclosed by the invention can realize that after fishes are put into the machine, then the industrial personal computer and the other parts are used for marking the fishes; the marking positions are accurate; the fishes do not waggle during the marking process; the situation of marking mistake does not occur easily; the marking of each fish is completed within 1s; the marking efficiency is high; the energy consumption is low; and batch marking of fishes can be realized.

Owner:ZHEJIANG OCEAN UNIV

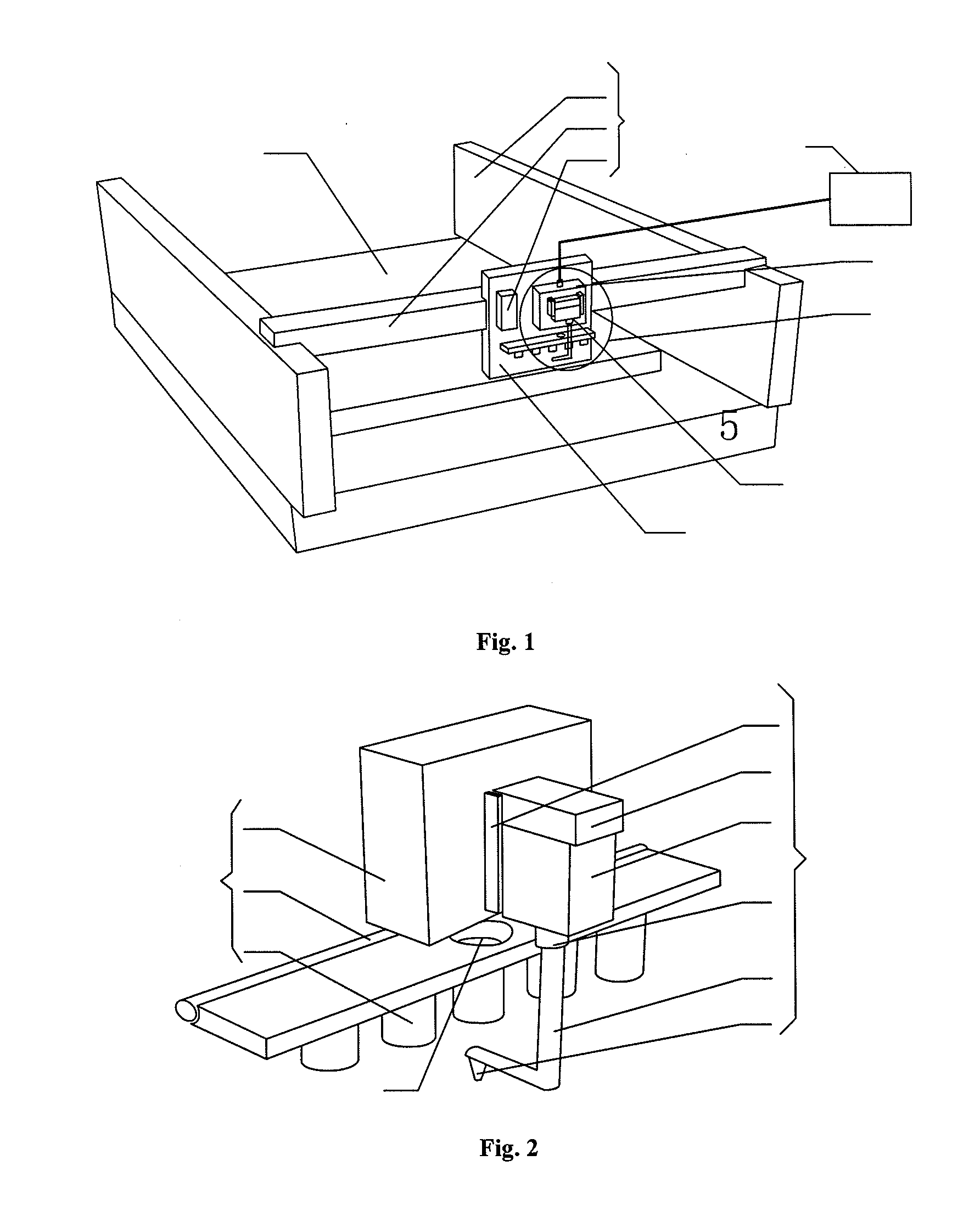

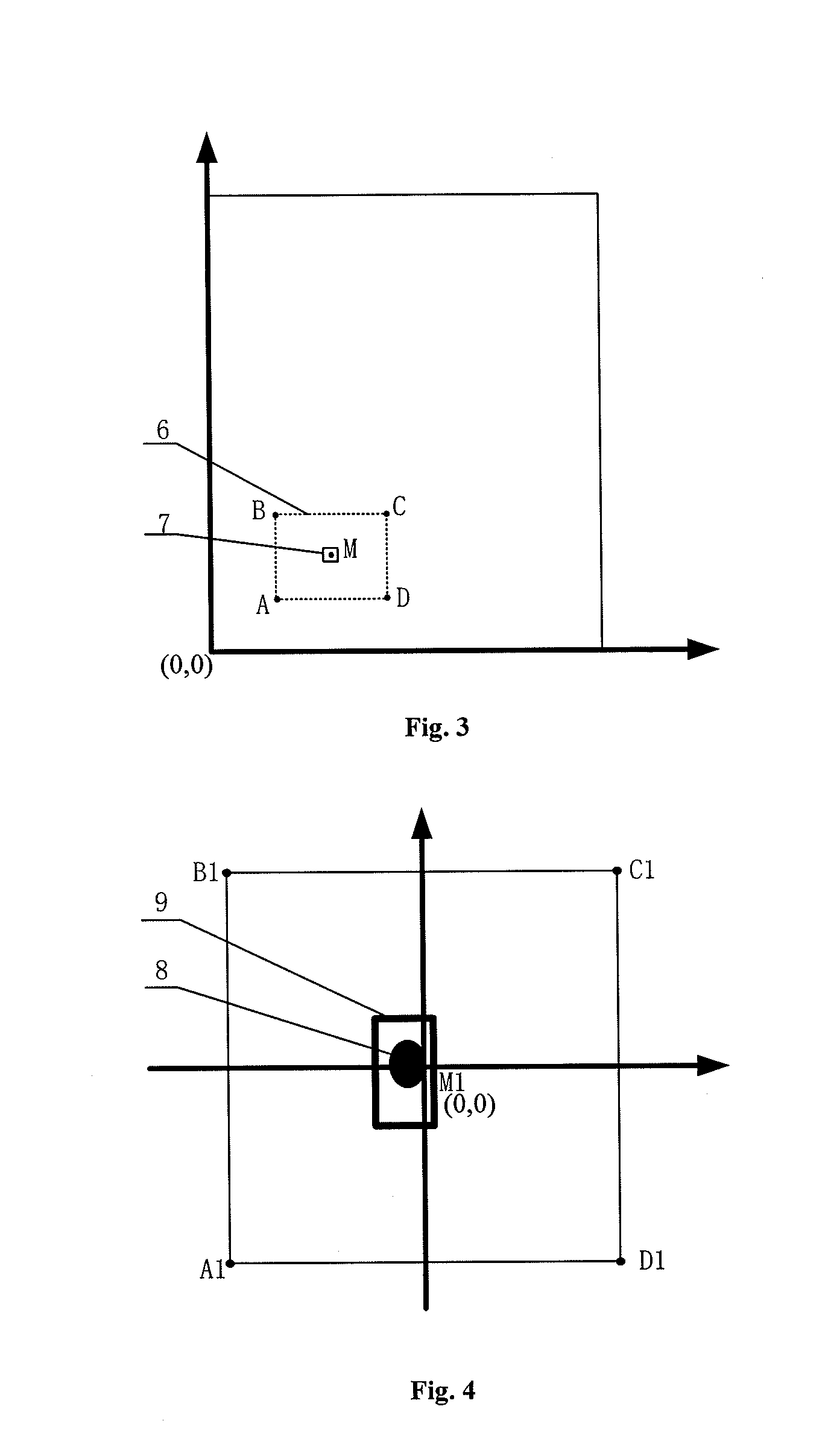

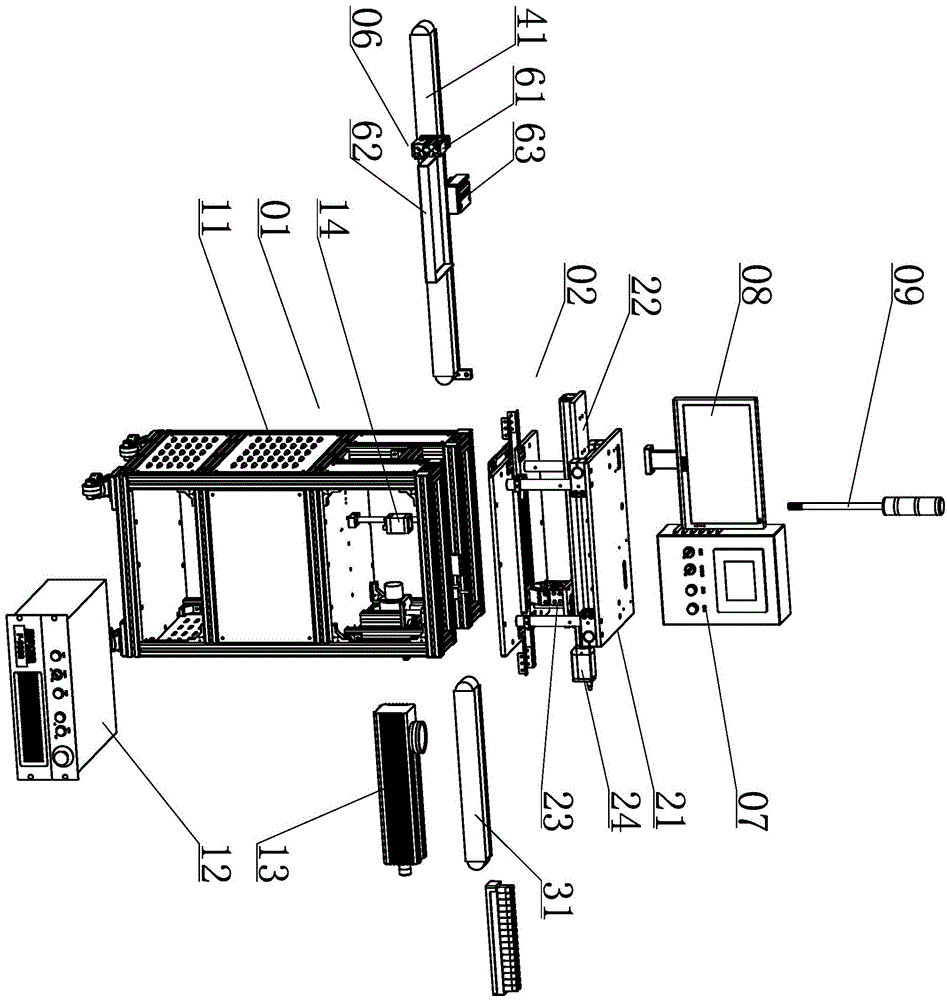

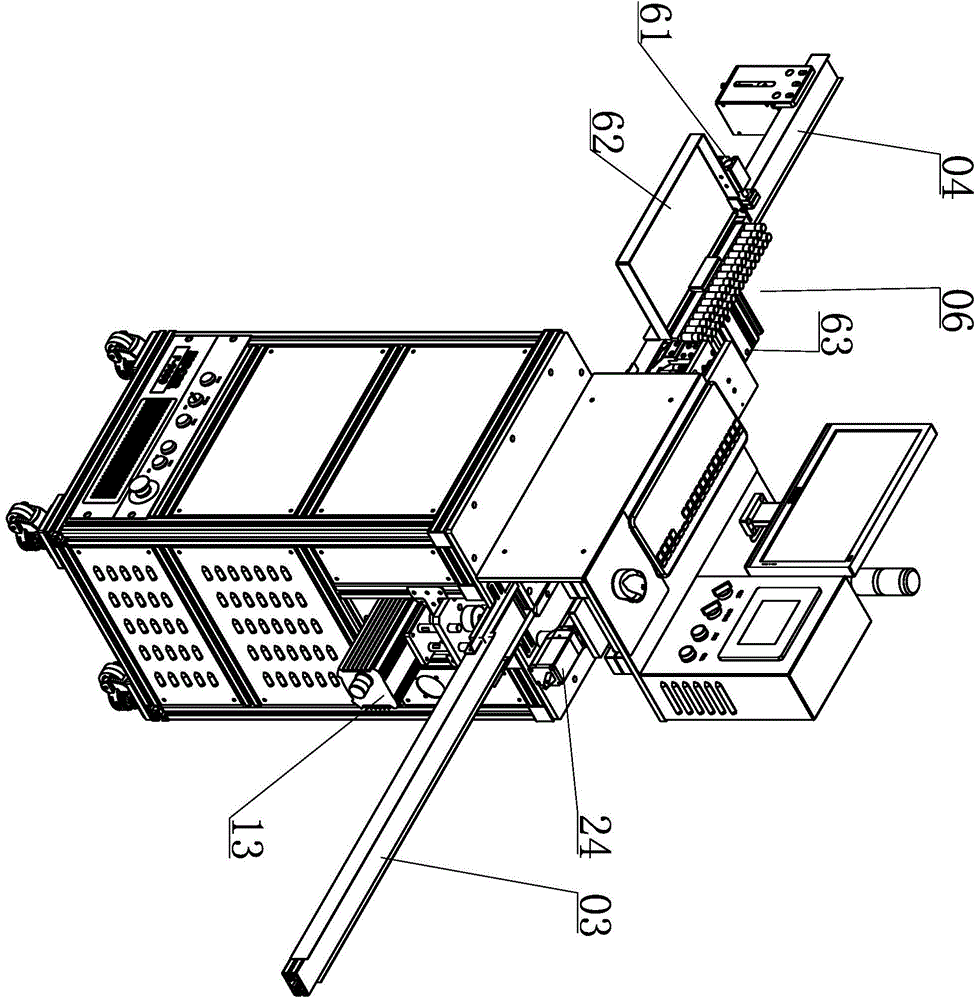

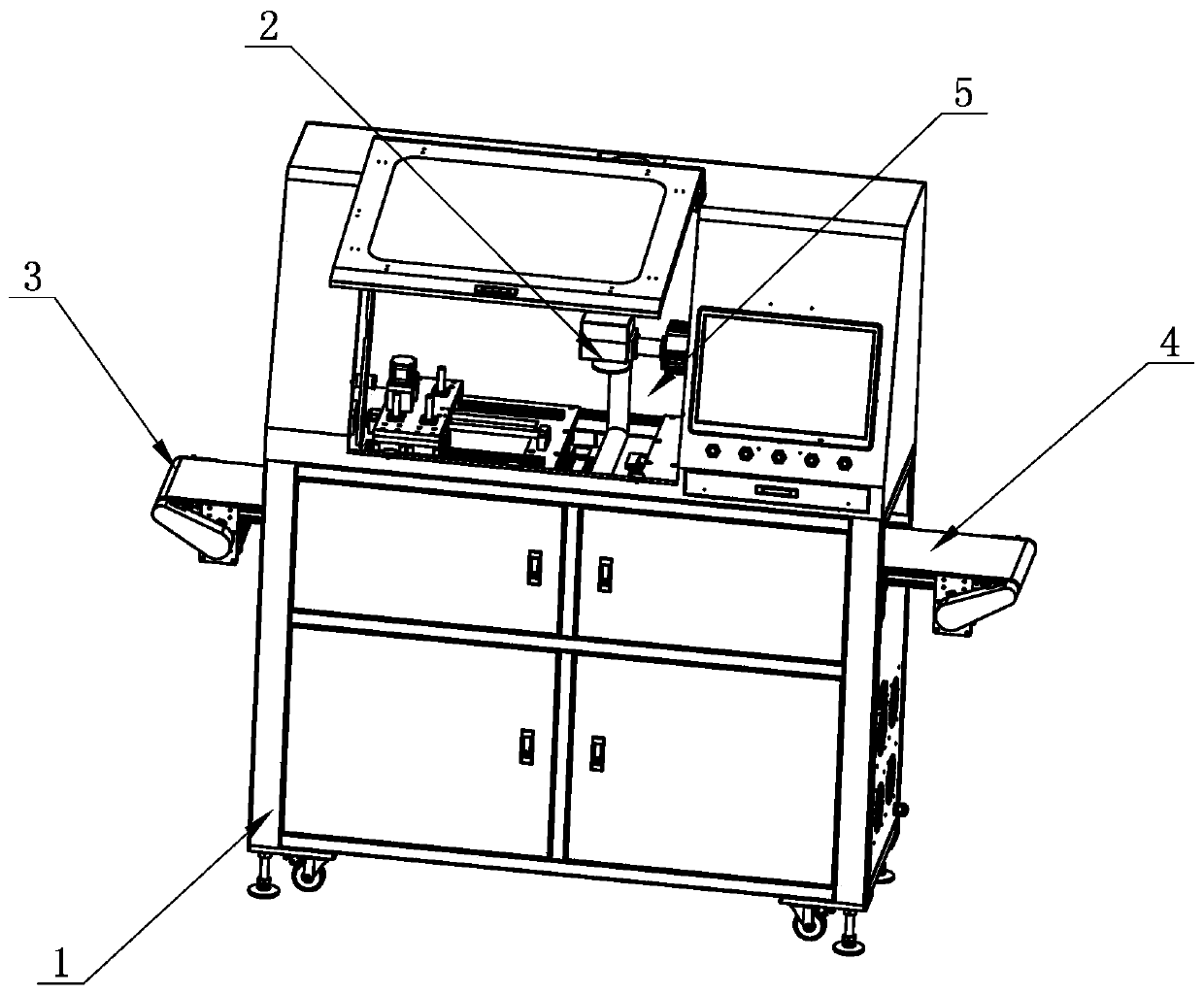

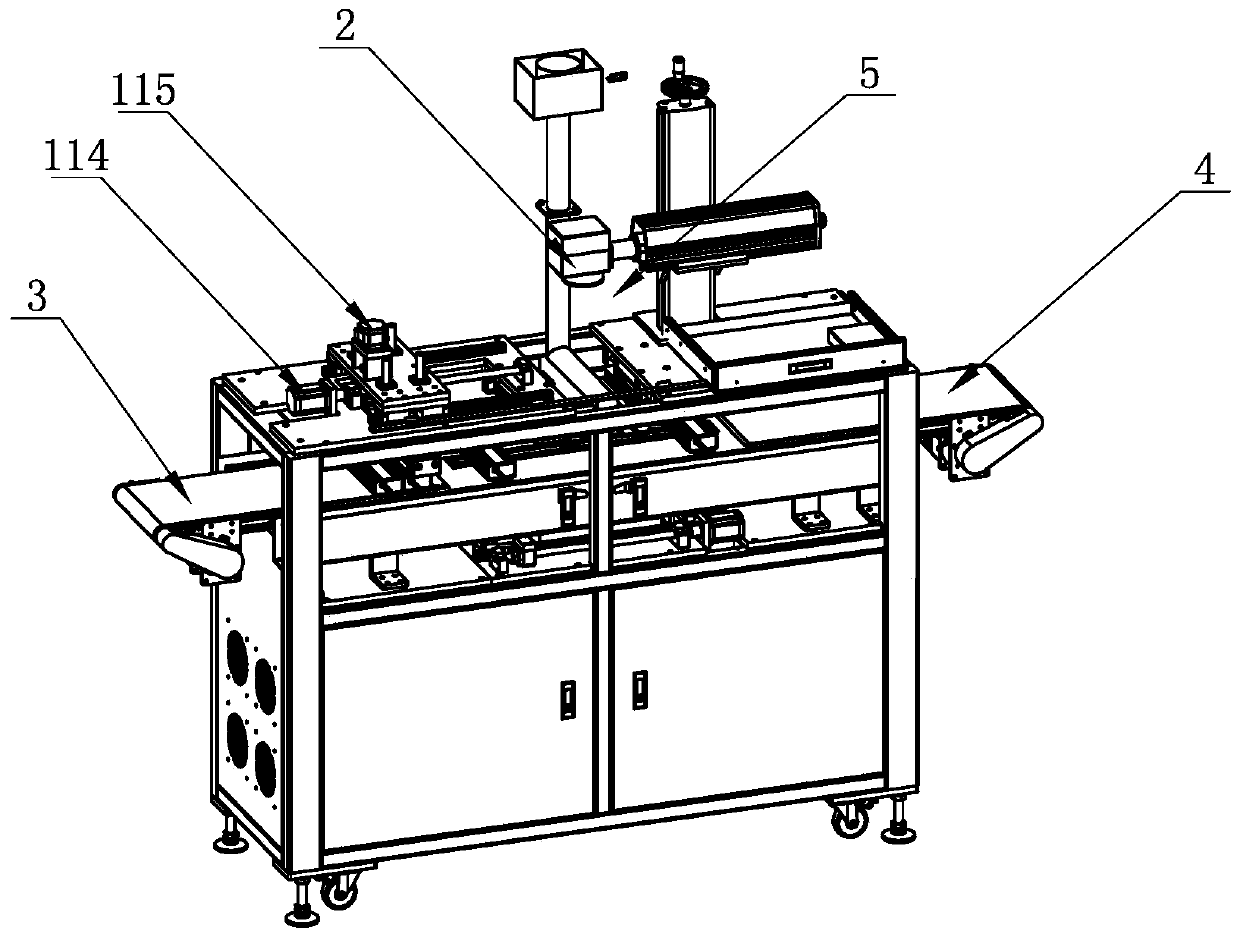

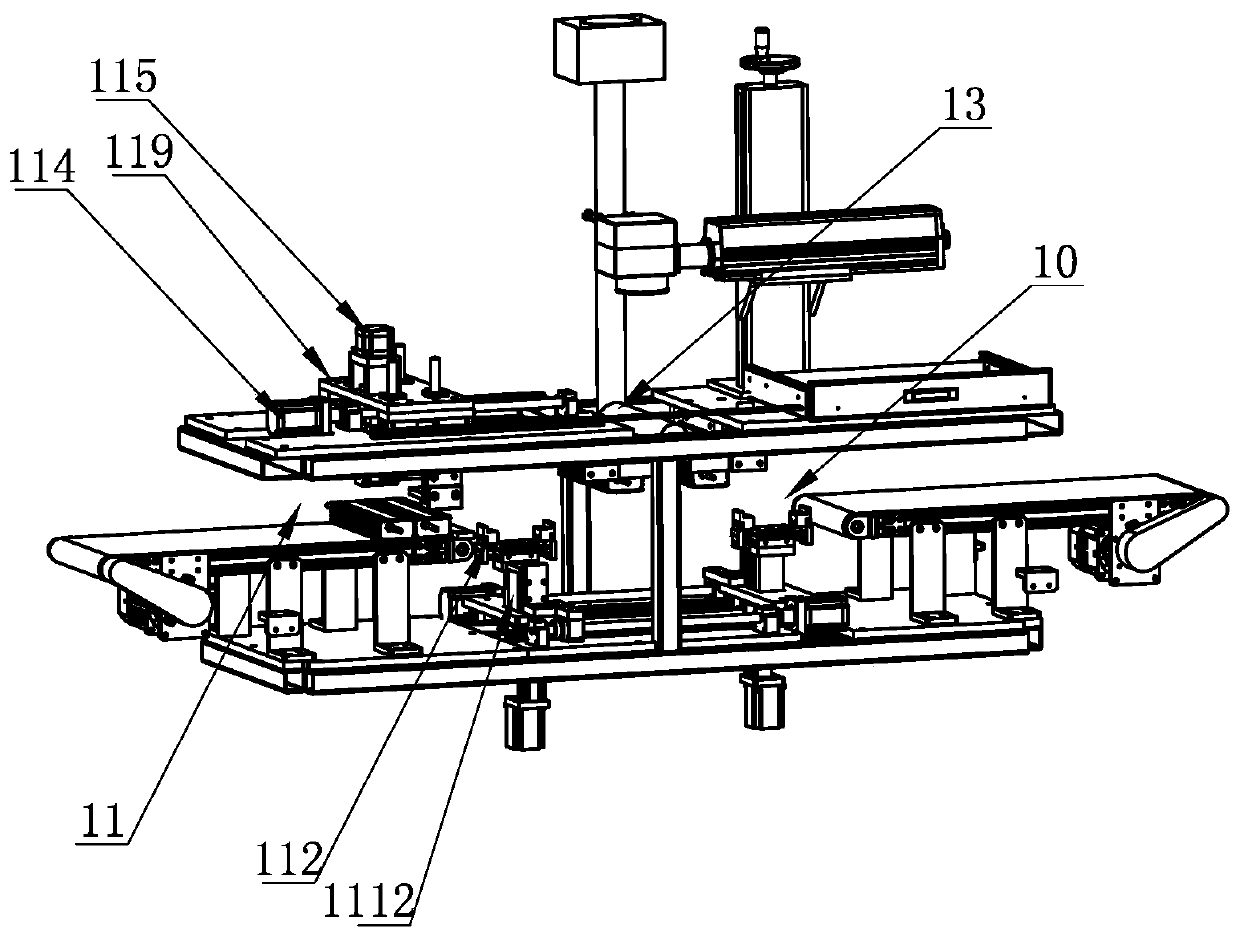

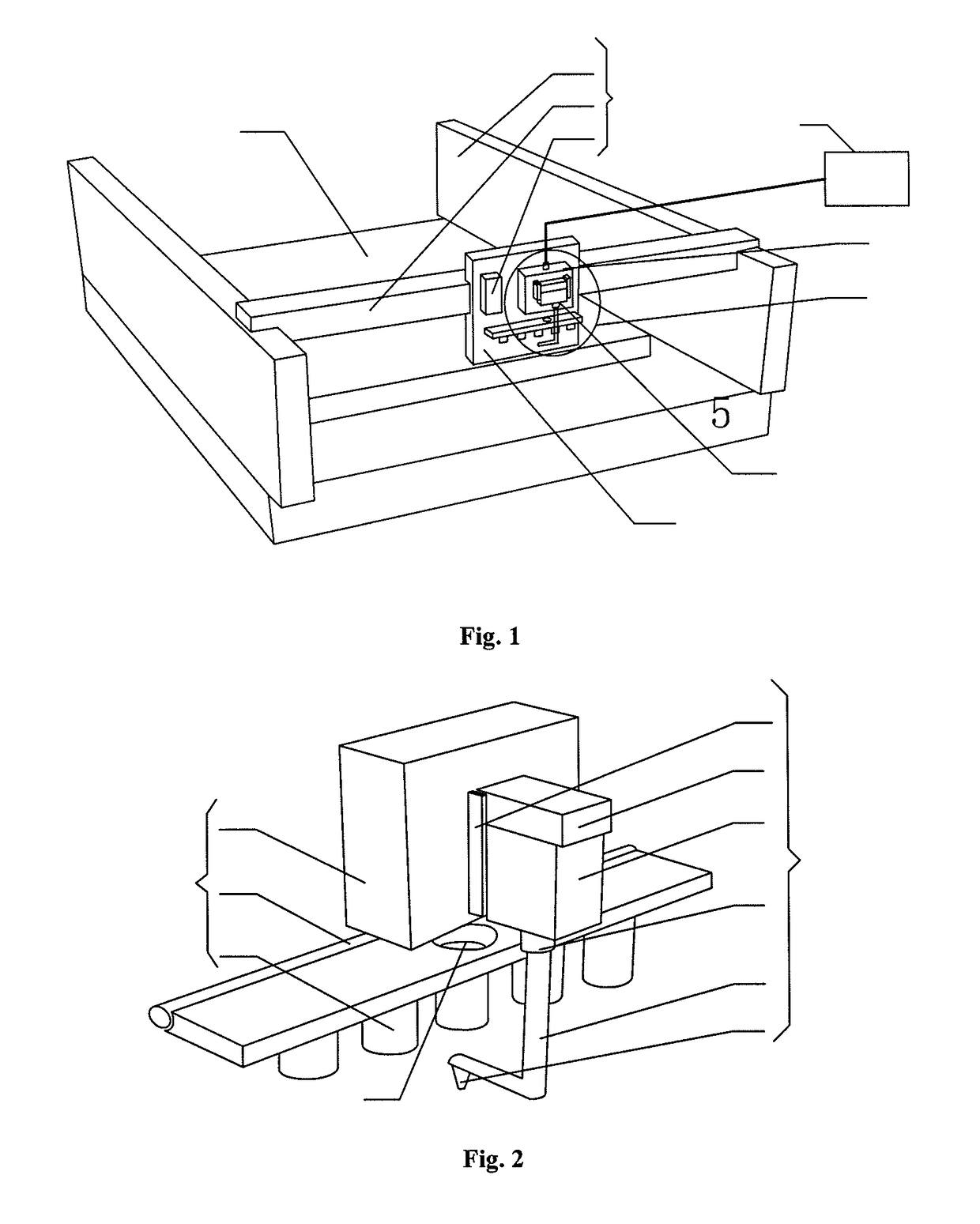

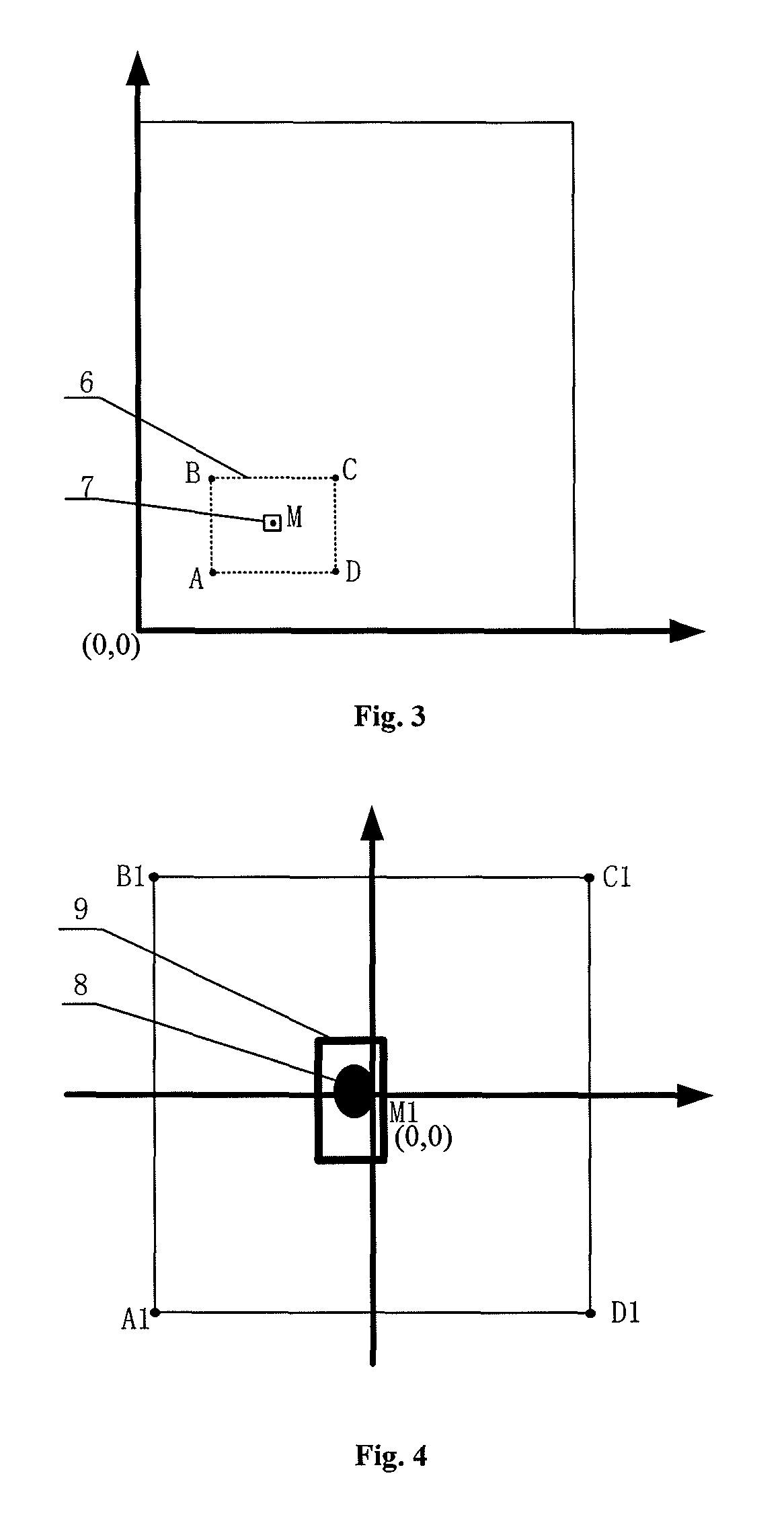

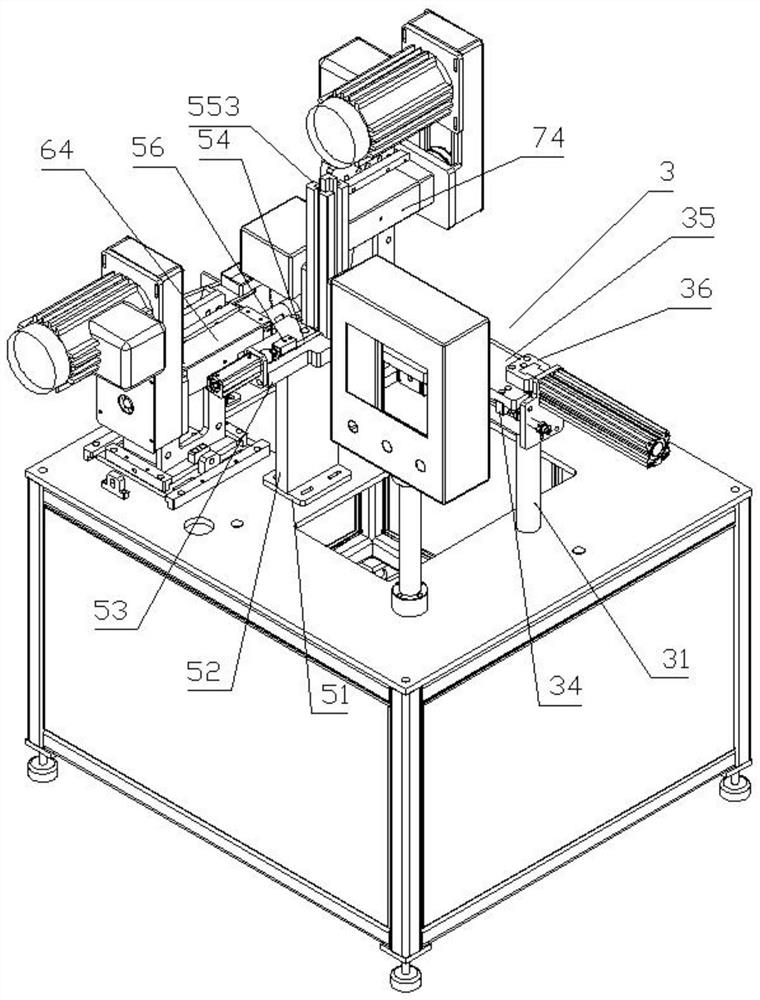

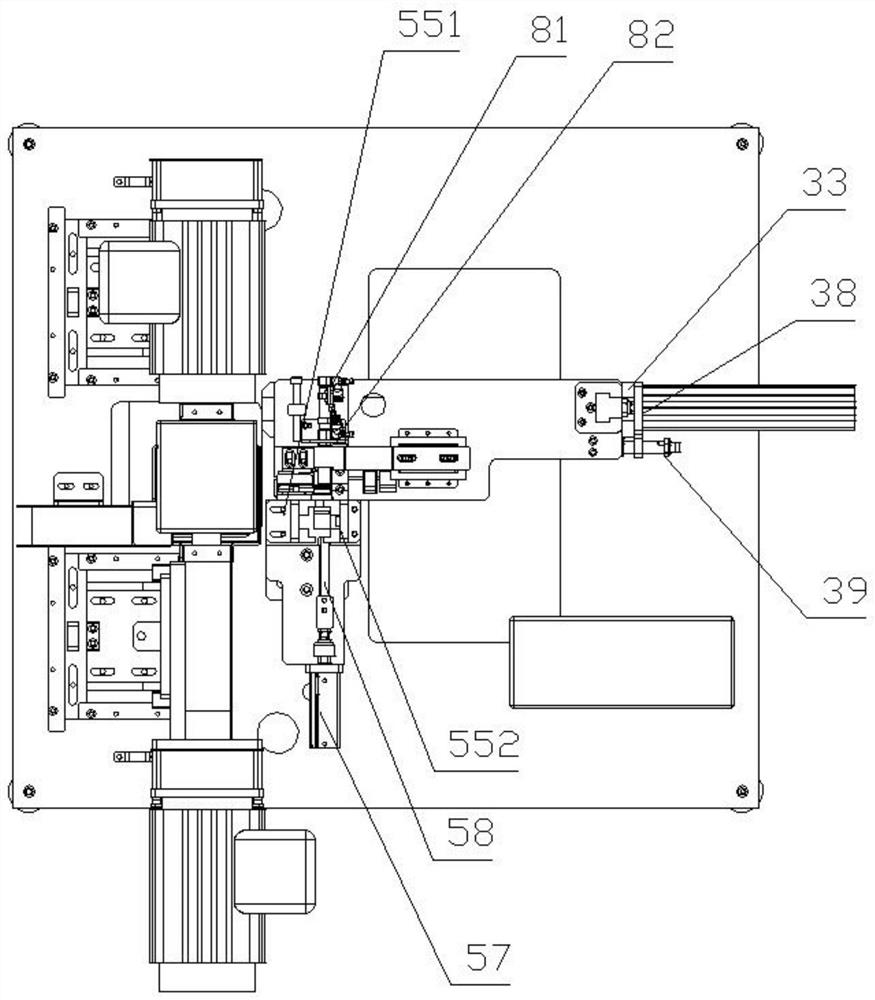

Marking apparatus and marking method for display panel

InactiveUS20150262350A1Marking position is accuratePrecise positioningTelevision system detailsImage analysisSimulationSurface plate

Owner:BOE TECH GRP CO LTD +1

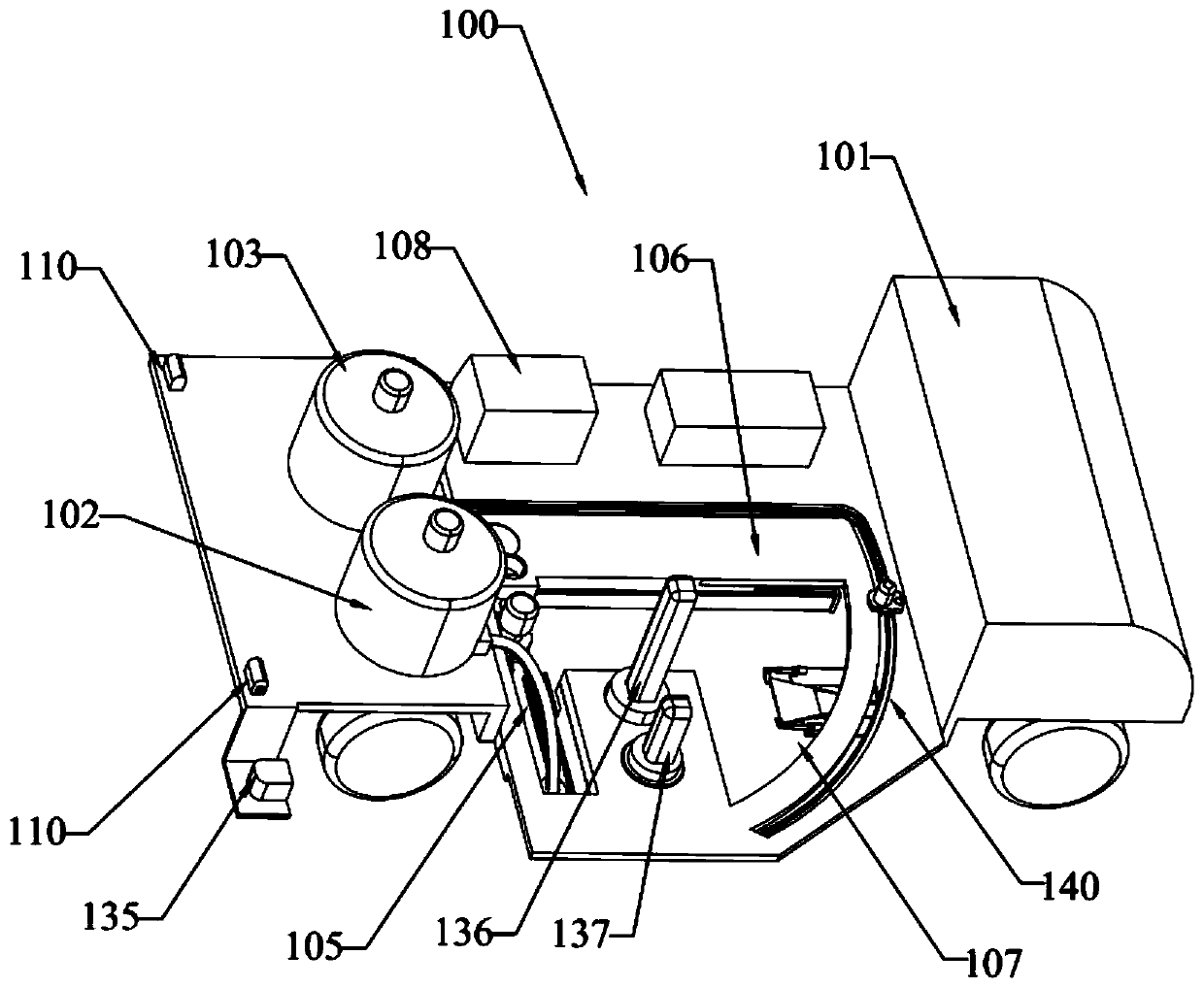

Lipstick-marking visual inspection system

ActiveCN104802534AImprove work efficiencyLabor savingTypewritersOptically investigating flaws/contaminationVisual inspectionEngineering

The invention discloses a lipstick-marking visual inspection system. The lipstick-marking visual inspection system comprises a laser marking unit, a positioning unit, a front-stage conveying unit, a rear-stage conveying unit, and an ink jet marking unit; an ejection unit is arranged on the rear-stage conveying unit; the laser marking unit comprises a first frame, a laser host and a laser head; a visual inspection probe is disposed on the first frame; the positioning unit comprises a support, a sliding rail and a uniform push cylinder; the front-stage conveying unit comprises a first motor and a front-stage conveying belt; the rear-stage conveying unit comprises a second motor and a rear-state conveying belt; the ejection unit comprises a keep-of cylinder, a defective-product collection plate and a pushing cylinder; a manipulator is connected with the visual inspection probe and the laser host respectively, and the visual inspection probe is connected with the keep-off cylinder and the pushing cylinder respectively. By the arrangement, operation efficiency is high, accepted products are automatically ejected, labor force is saved, and the system is multifunctional.

Owner:广东铭钰科技股份有限公司

Laser marking machine

PendingCN110977184AHigh marking accuracyImprove efficiencyLaser beam welding apparatusEngineeringConveyor belt

The invention relates to a laser marking machine. The laser marking machine comprises a rack, a laser marking head, an inputting conveyor belt and an outputting conveyor belt, wherein a marking station is provided with a first clamp and a second clamp which are used for clamping to-be-marked workpieces, a first control piece used for controlling the first clamp to conduct clamping or loosening anda second control piece used for controlling a second control piece to conduct clamping or loosening, the laser marking head is located above the first clamp and the second clamp, and the first clampand the second clamp are located at the two sides of the laser marking head in the horizontal direction respectively. The laser marking machine furthermore comprises a discharging assembly which is used for alternately delivering the workpieces on the first clamp and the second clamp onto the outputting conveyor belt one by one after marking is finished and a feeding assembly which is used for alternately feeding the to-be-marked workpieces on the inputting conveyor belt into the first clamp and the second clamp one by one. According to the technical scheme, the laser marking machine has the advantages of being high in marking precision and efficiency and capable of greatly lowering the cost.

Owner:浙江云景精密设备有限公司

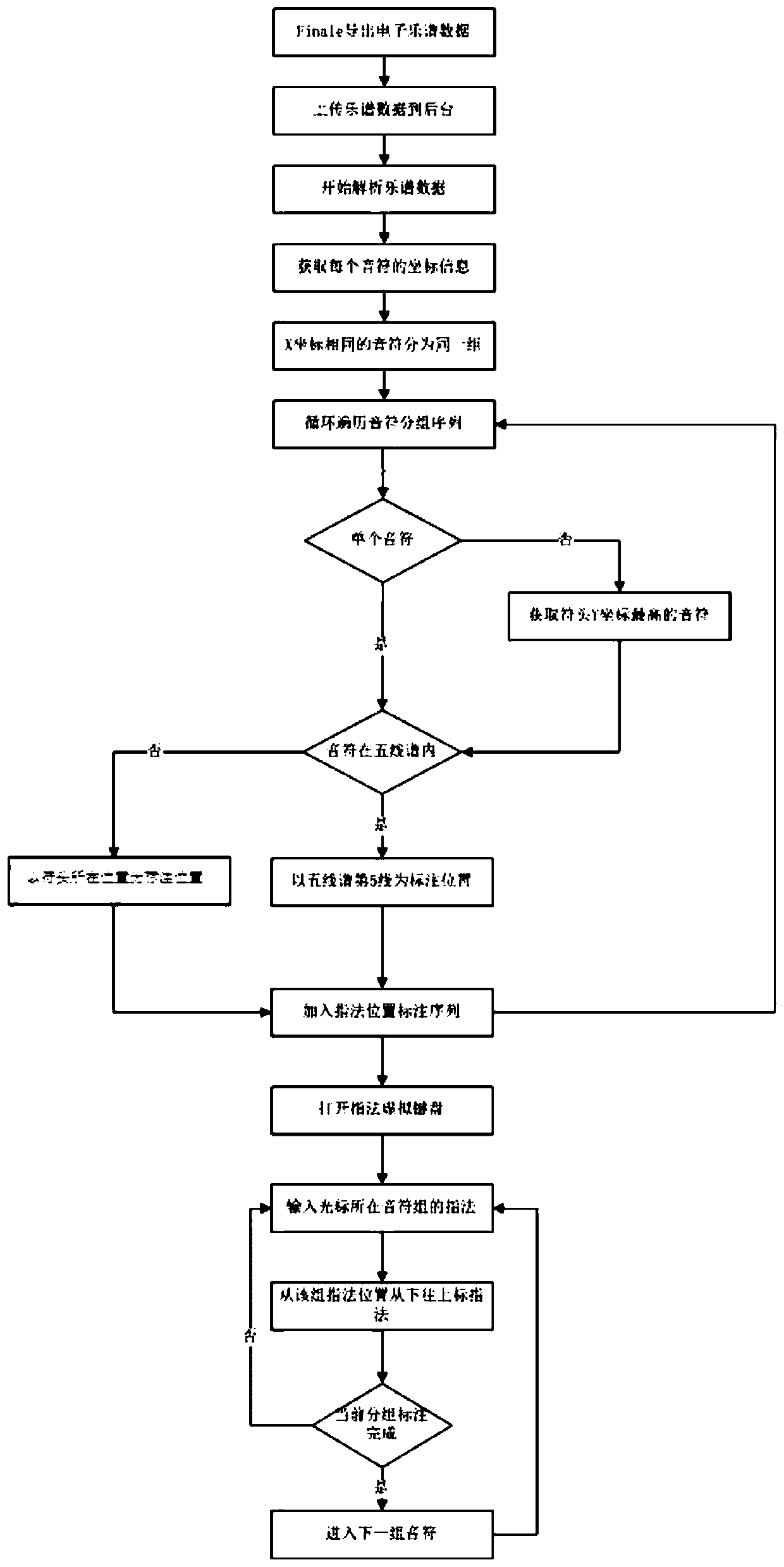

Musical notation fingering rapid annotation method and system

The invention relates to a musical notation fingering rapid annotation method and system. The musical notation fingering rapid annotation method comprises the following steps: S1: converting music score information to be played into music score data of a MusicXML format; S2: parsing the music score MusicXML data to generate the fingering annotation position of each note, wherein the fingering annotation positions are positioned above note heads, and are not coincided with a musical notation; S3: generating a fingering position sequence of all notes of each voice part; and S4: inputting fingering annotation symbols corresponding to the nodes into corresponding fingering position sequences, and displaying the fingering annotation symbols at the fingering annotation positions. The musical notation fingering rapid annotation method and system have the advantages of accurate annotation positions, high annotation efficiency, high speed, easiness in modification and the like, are suitable fordifferent playing ways, and have a wide application prospect.

Owner:玖月音乐科技(北京)有限公司

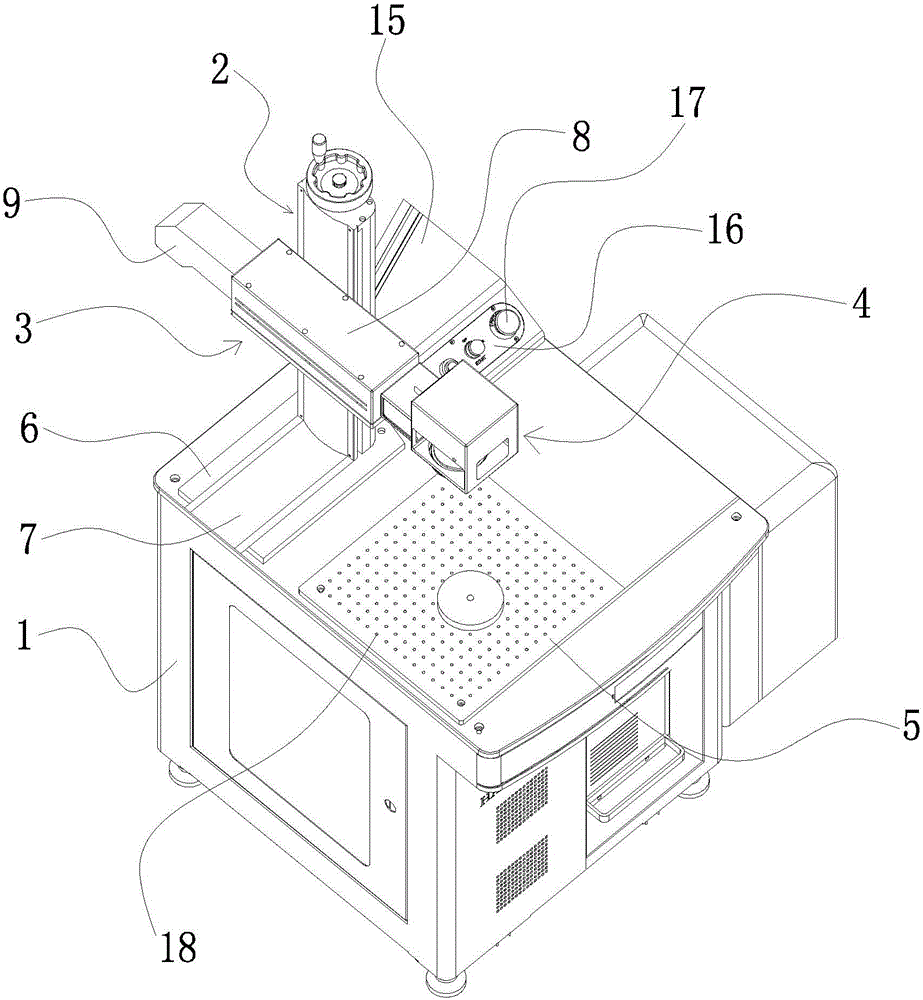

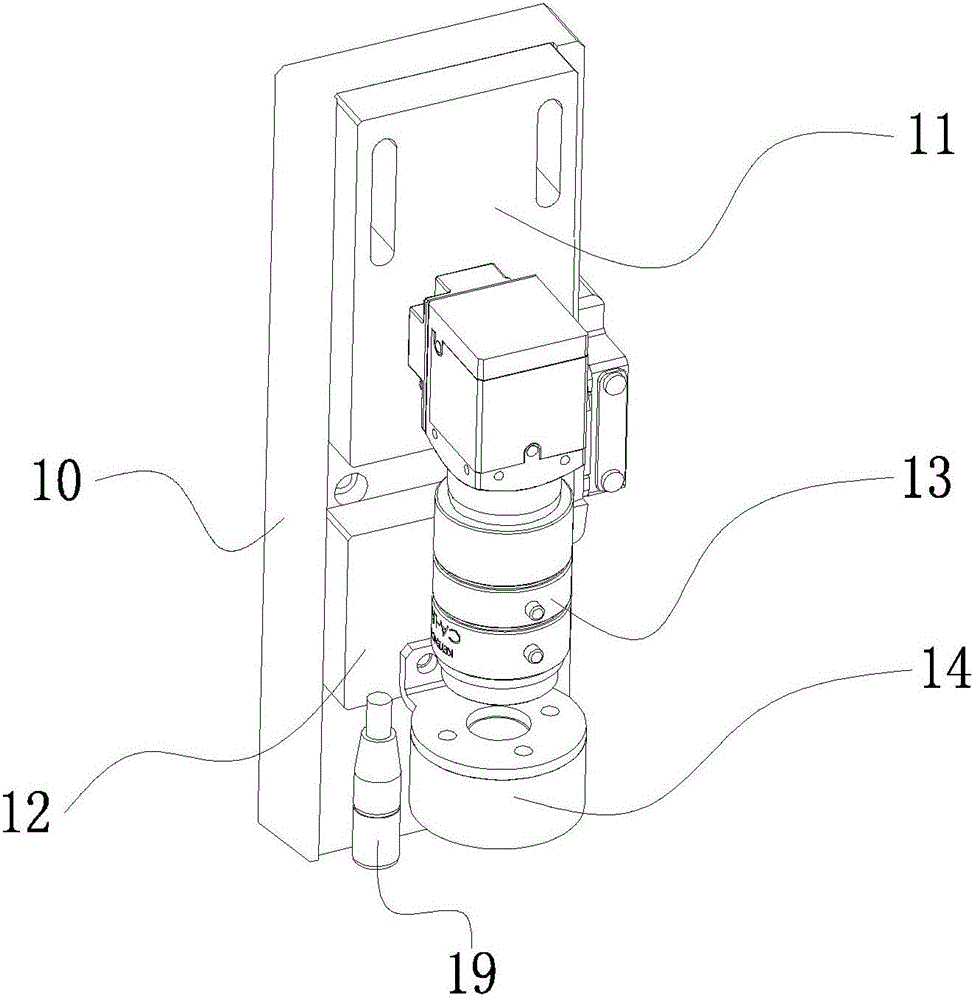

Laser marking machine

InactiveCN106077961AImprove work efficiencyReduce work costsLaser beam welding apparatusEngineeringCcd camera

The invention relates to a laser marking machine. The laser marking machine comprises a workbench, a lifting device and a first laser marking device, wherein the lifting device and the first laser marking device are arranged on the workbench. The first laser marking device is arranged on the lifting device. A second laser marking device pointing at the lower portion is arranged at the end portion of the end portion of the first laser marking device, and the workbench is provided with a marking operation table. The second laser marking device corresponds to the marking operation table in position. Compared with the prior art, through mutual cooperation of the lifting device, the first laser marking device and the second laser marking device, the position of the second laser marking device can be adjusted at will through horizontal transverse moving of the lifting device and horizontal longitudinal moving of the first laser marking device, and therefore marking of workpieces at different positions is achieved, the work efficiency is improved, and the work cost is reduced. Meanwhile, a CCD camera corresponds to the marking operation table, the accurate marking position is achieved, and the marking efficiency and the marking precision are improved.

Owner:平湖拓伟思自动化设备有限公司

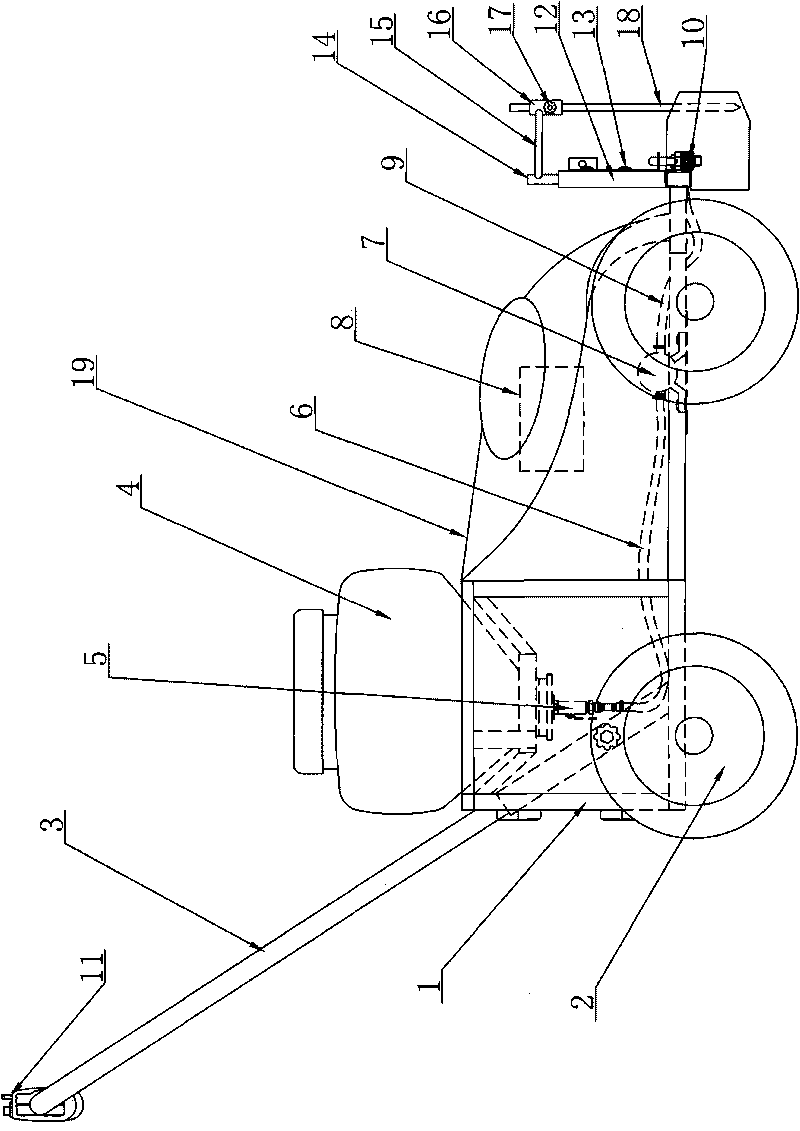

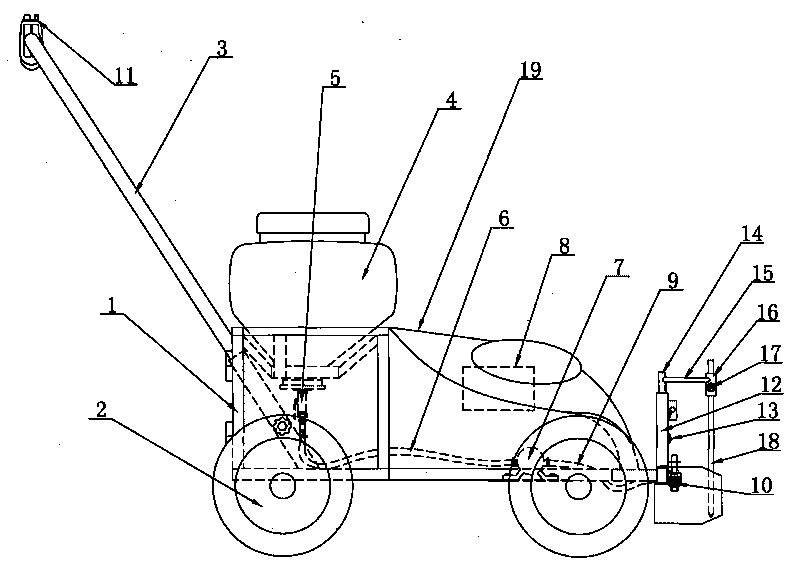

Full-automatic scriber for football field

InactiveCN101732849AImprove work efficiencyMarking position is accurateSki bindingsWater-skiingEngineeringControl switch

The invention discloses a full-automatic scriber for a football field, which comprises a stander. Four wheels are arranged at the lower end of the stander, an armrest and a paint bucket are arranged at the rear end of the stander, a paint valve is arranged at the lower end of the paint bucket, the paint valve is connected with one end of a paint pump arranged on the stander through a first paint tube, the paint pump is connected with a battery cell arranged on the stander, the other end of the paint pump is connected with a spray nozzle arranged at the front end of the stander through a second paint tube, a guide device is arranged at the upper end of the spray nozzle, and the upper end of the armrest is provided with a control switch connected with the battery cell through wires. The full-automatic scriber for the football field has the advantages that the operation is mechanical, the working efficiency is high and the scribing position is more accurate.

Owner:JIANGSU JINLING SPORTS EQUIP

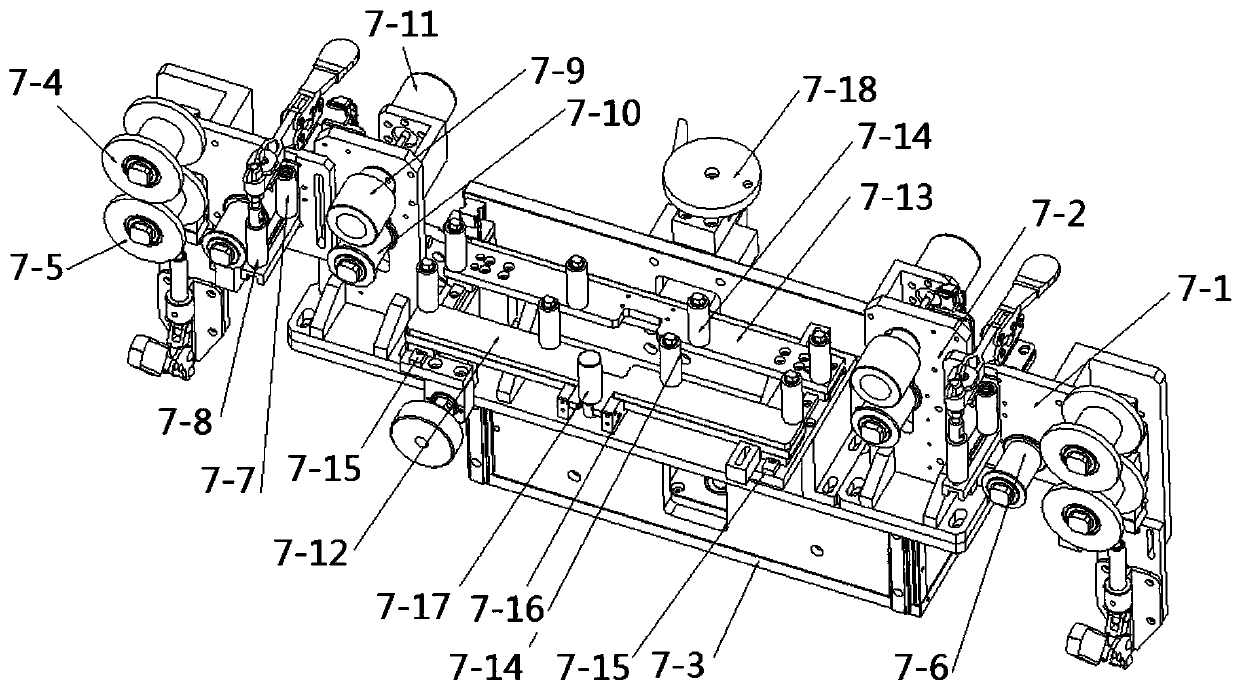

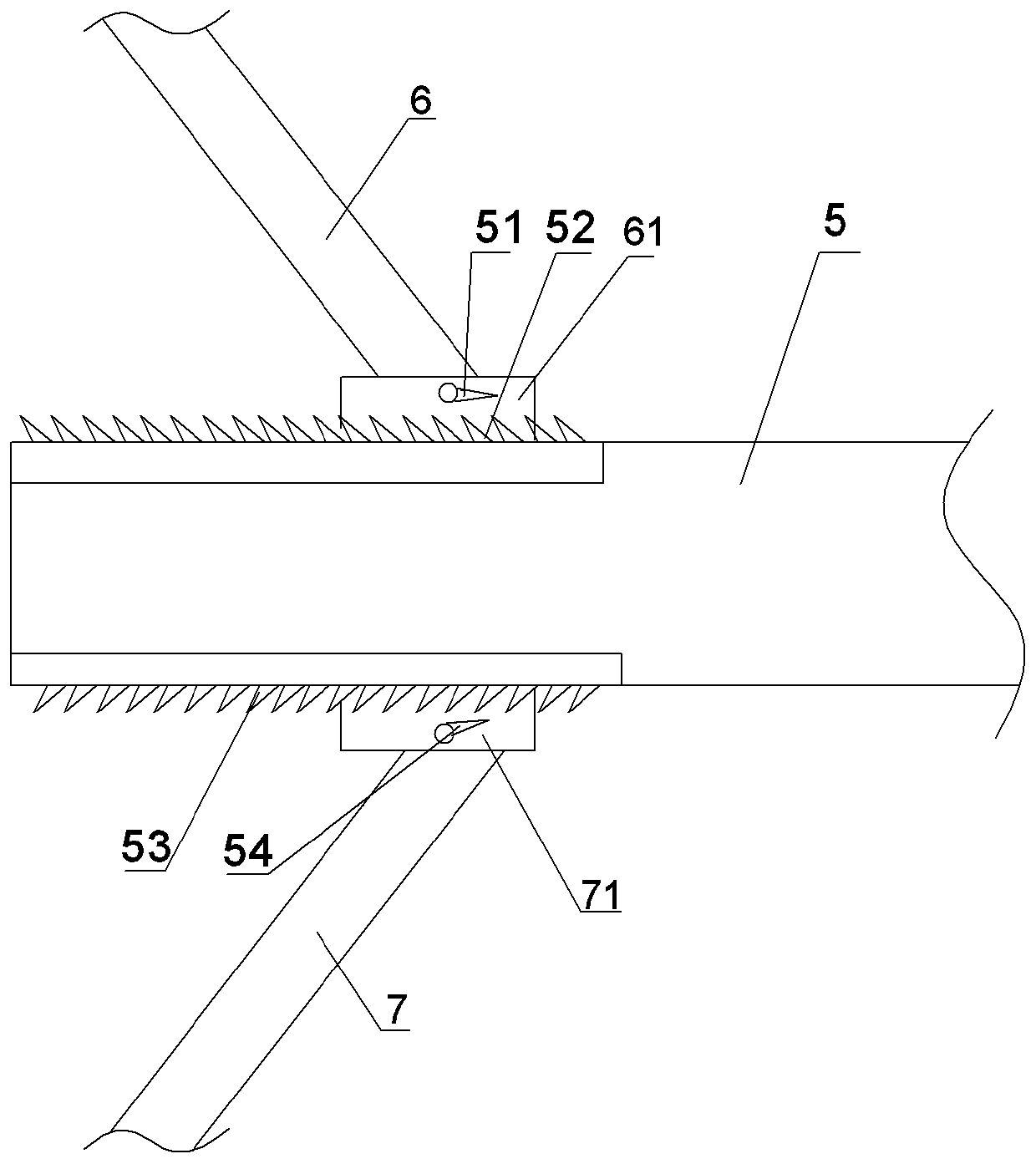

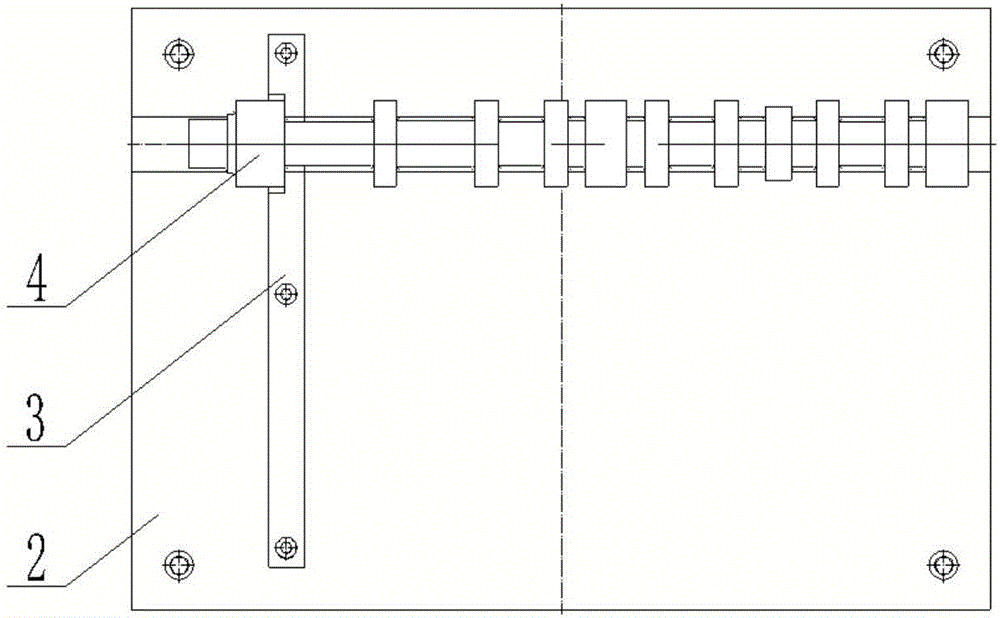

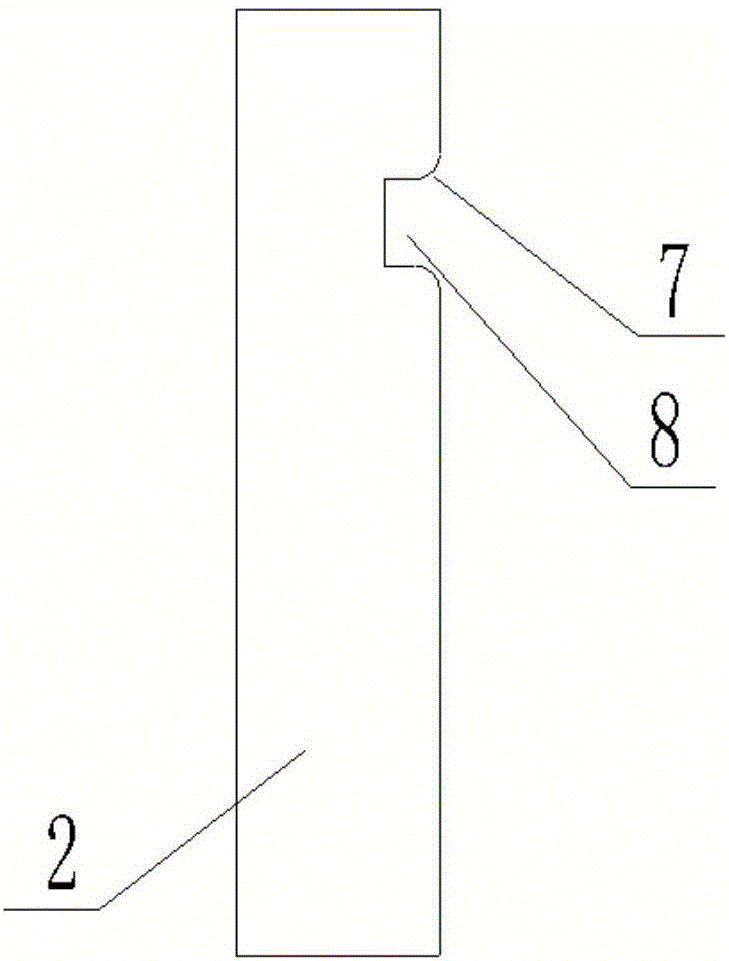

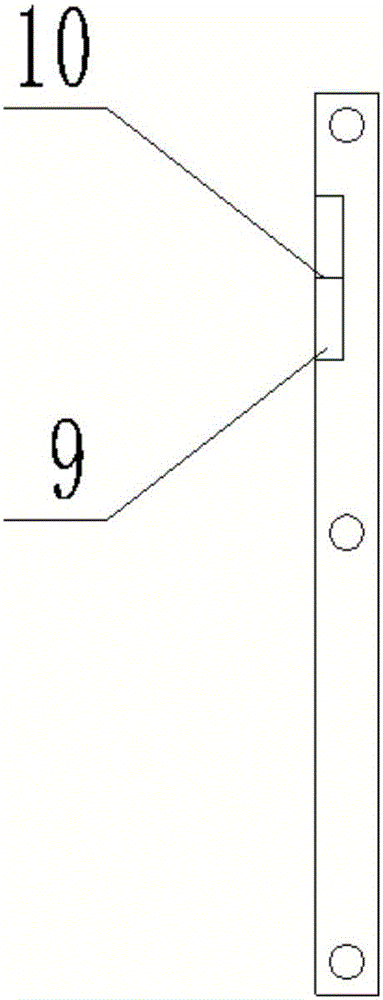

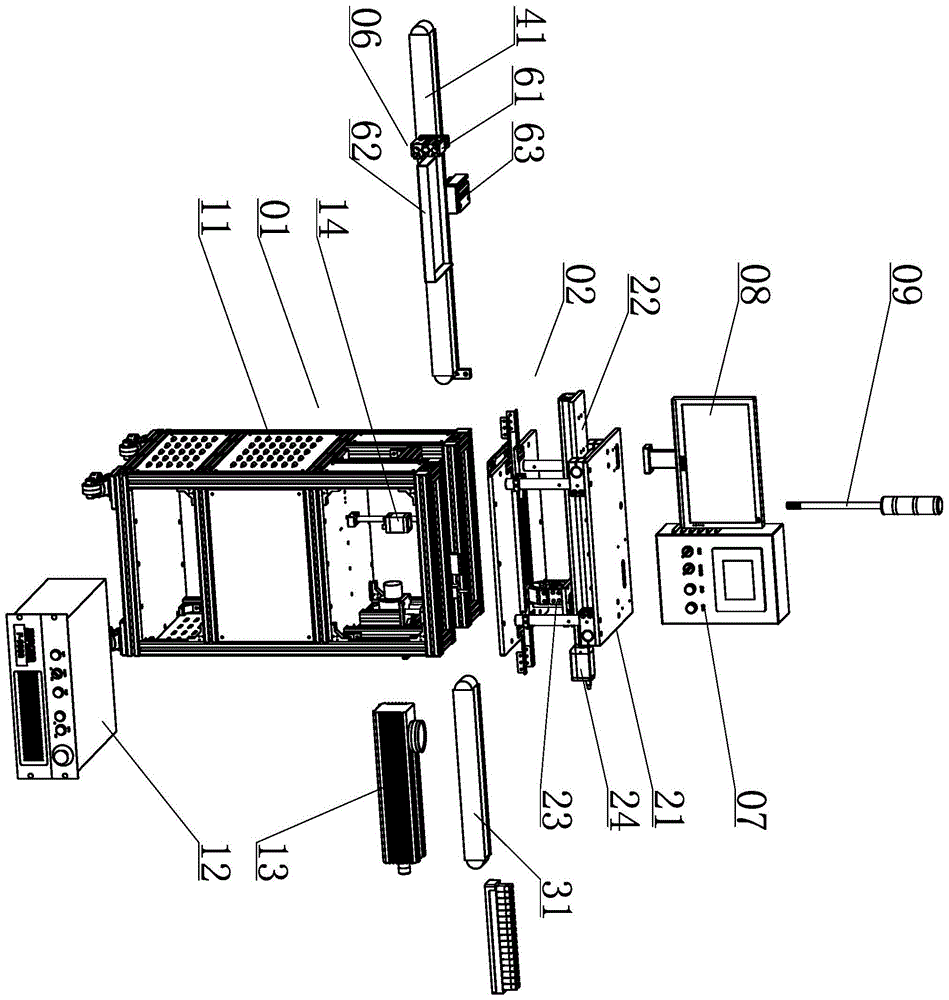

Linear product clamping and guiding tool and high-speed marking equipment

PendingCN110369877AReduce jumpingStable marking positionLaser beam welding apparatusWire rodEngineering

The invention discloses a linear product clamping and guiding tool and high-speed marking equipment. The linear product clamping and guiding tool comprises a support mechanism, preliminary vertical positioning and guiding wheel sets, a vertical guide wheel, a transverse positioning rotary column group and a vertical tightening wheel set, wherein the preliminary vertical positioning and guiding wheel sets are arranged in a bilateral symmetry manner; and the preliminary vertical positioning and guiding wheel sets, the vertical guide wheel, the transverse positioning rotary column group, the vertical tightening wheel set and a width adjustable routing mechanism are arranged in sequence from the end to the interior. The high-speed marking equipment comprises an equipment cabinet, a light source up and down lifting device, a front and rear moving platform, a laser light source, a laser head and the product clamping and guiding tool. The high-speed marking equipment can improve the stabilityof the running track of flight assembly lines such as pipe bodies and wire rods during laser marking, improves the quality of the high-speed laser marking, and can realize the online editing of the marking content.

Owner:苏州市长峰激光技术有限公司

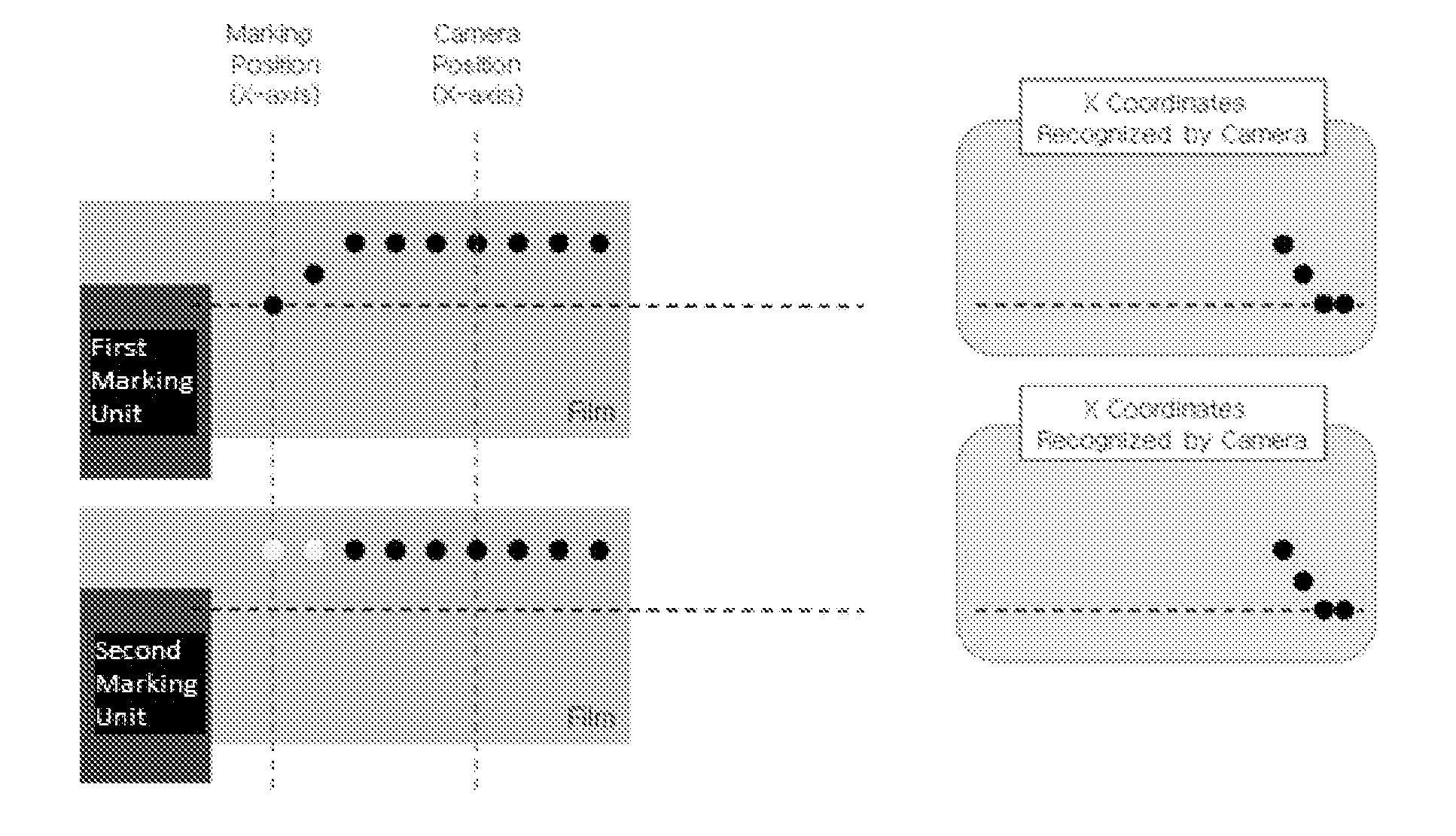

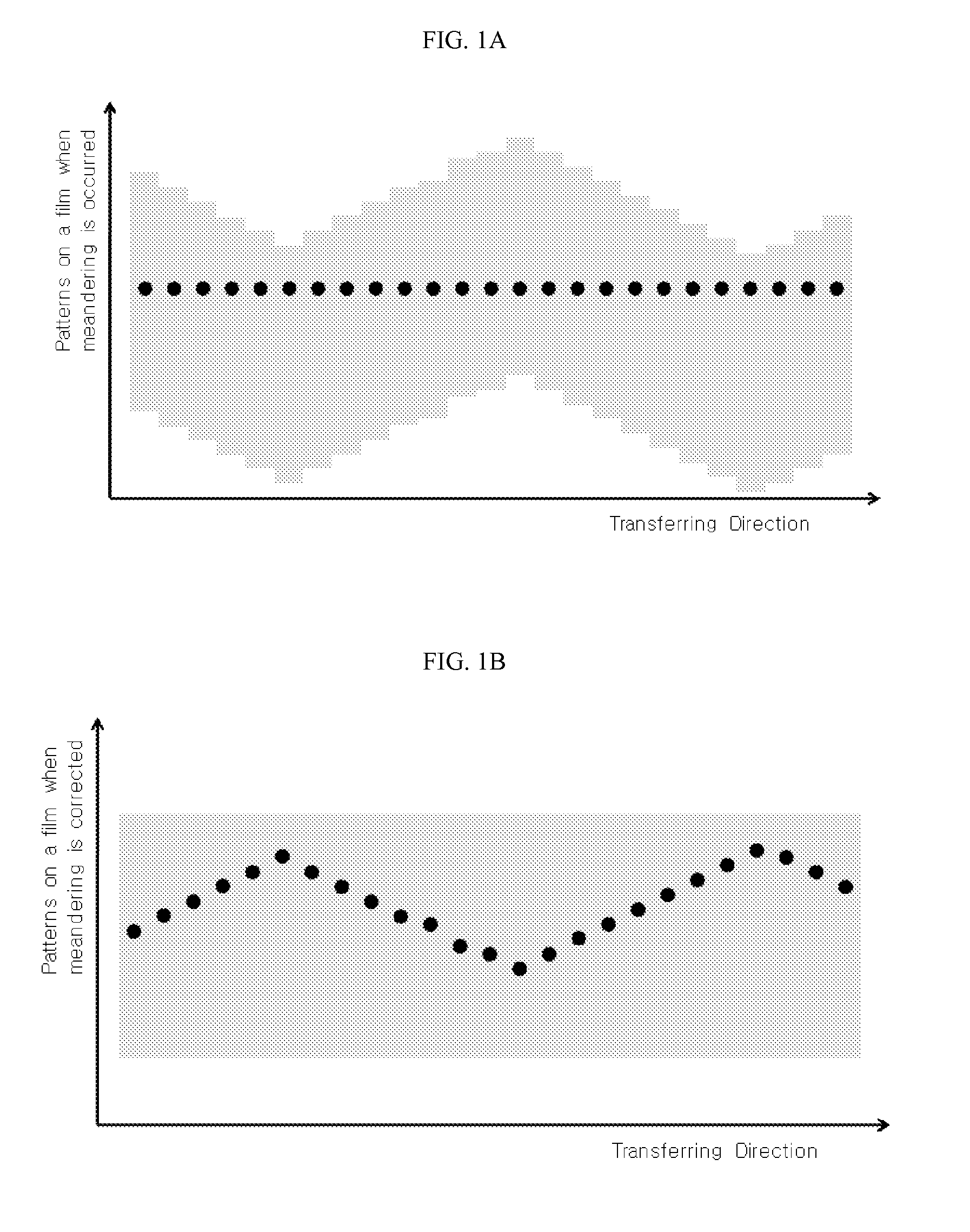

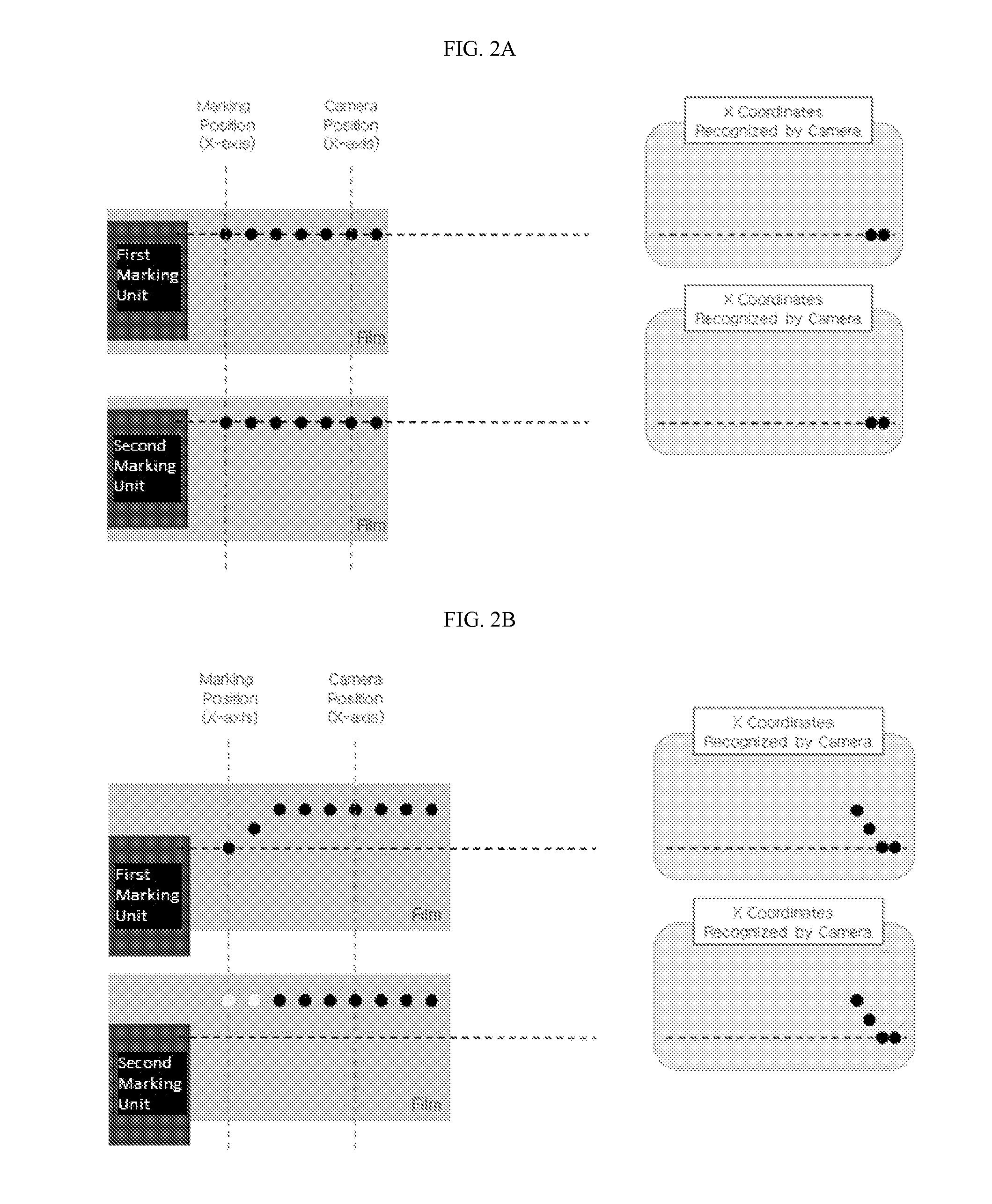

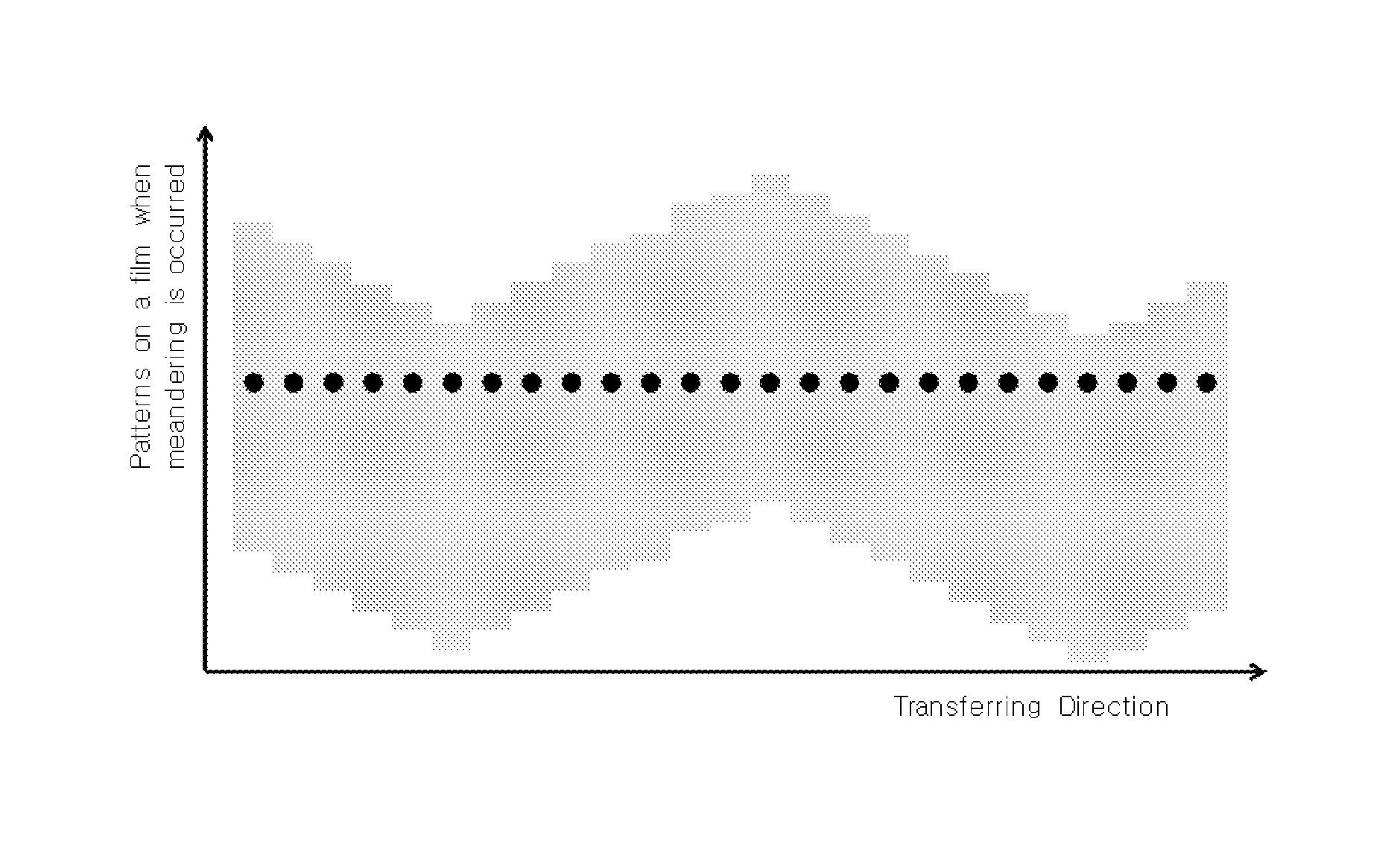

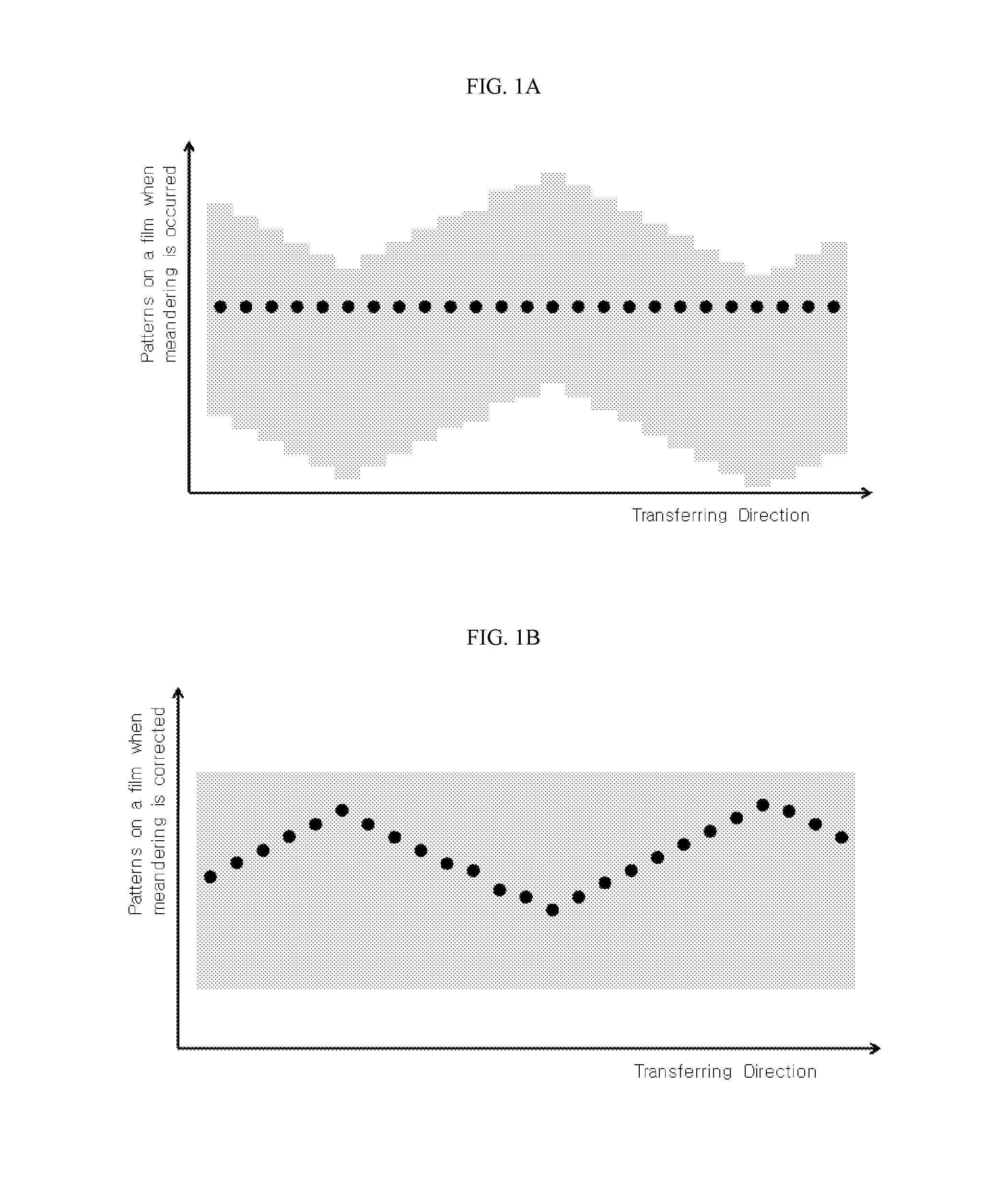

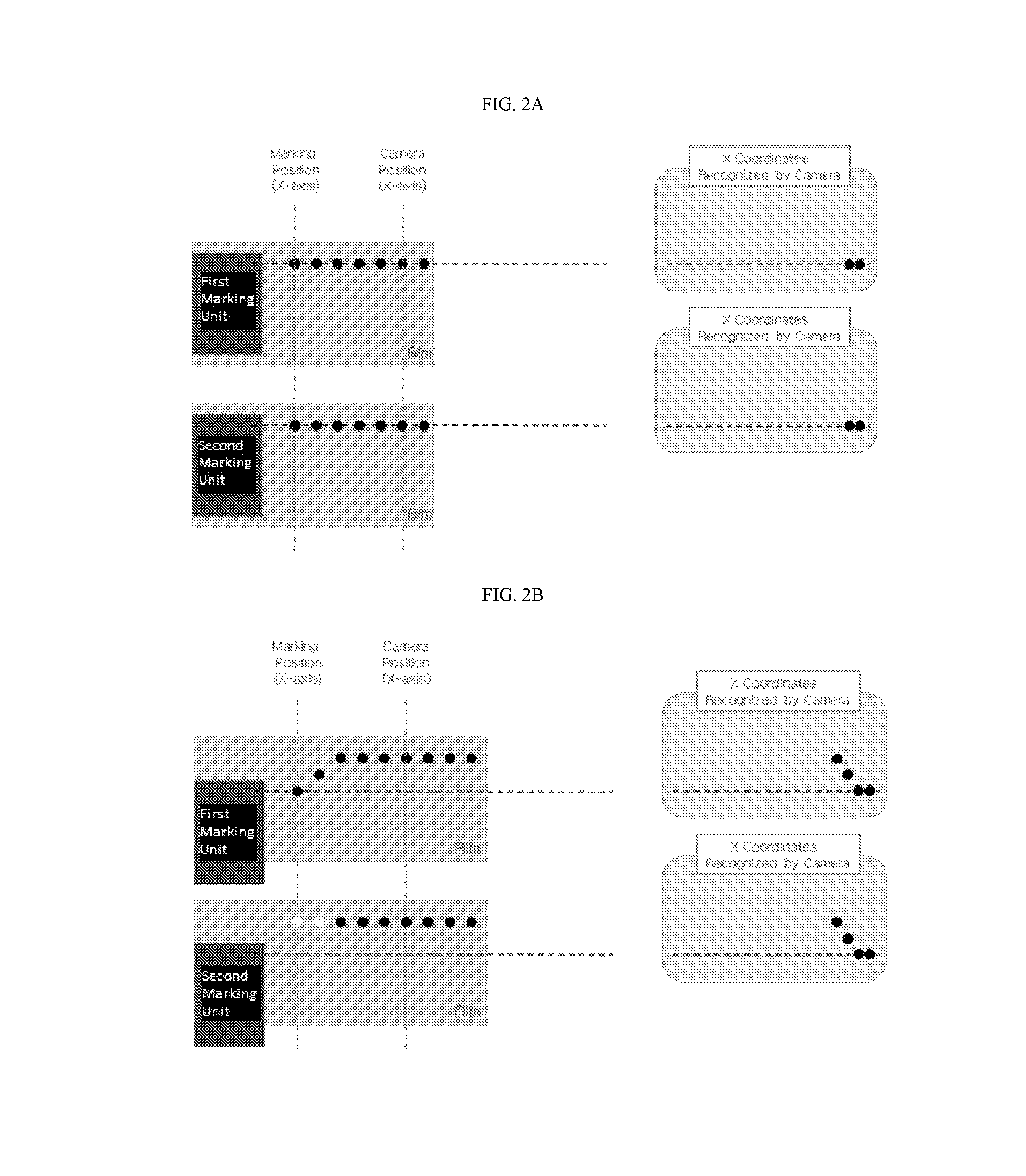

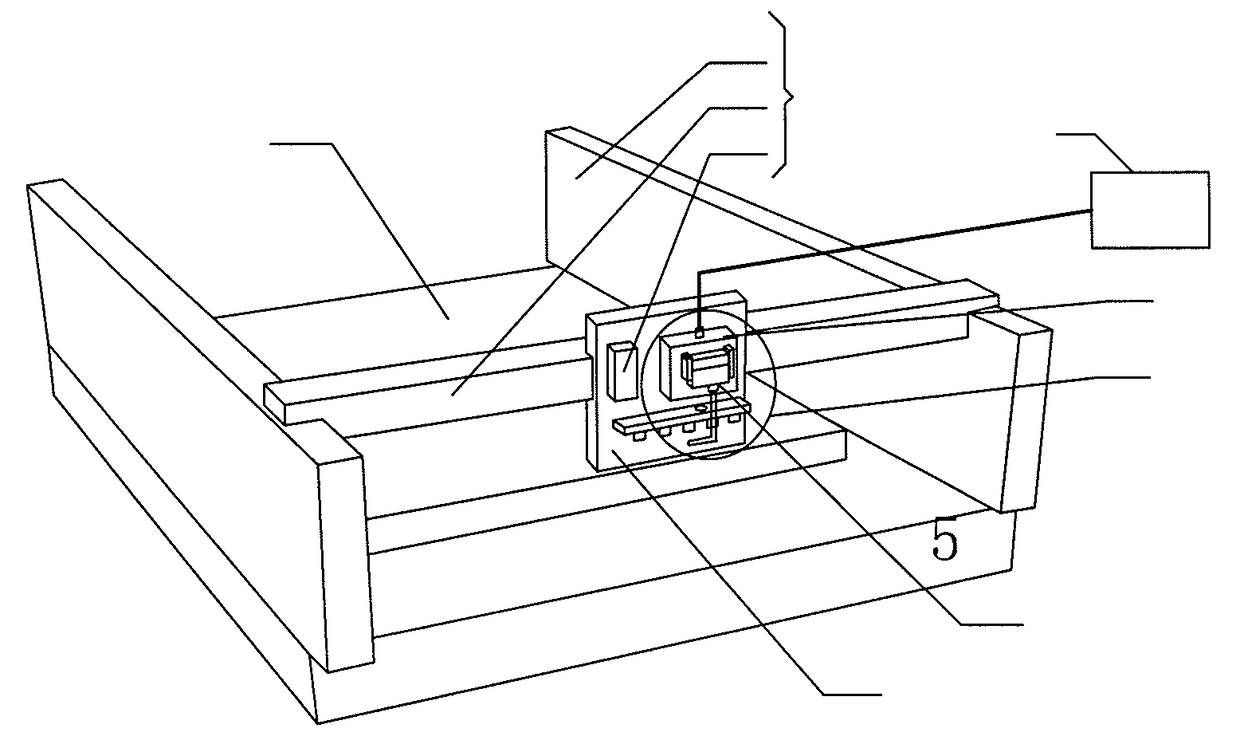

Control device for preventing meandering of patterns on patterned films

ActiveUS20120271447A1Marking position is accuratePrinting pressesComputer controlEngineeringControl unit

A control device for preventing meandering of patterns for use in a patterned film manufacturing device which includes a film transferring equipment and a pattern forming equipment, includes a marking unit that forms markings on a predetermined reference position on the film, a recognizing unit that is located at the rear of the marking unit and recognizes positions of the markings on the film, a computing unit that computes an amount of meandering based on differences between the reference position and the recognized positions of the markings, a control unit that generates a correction signal for correcting positions of the marking unit and the pattern forming equipment corresponding to the computed the amount of meandering, and a correction unit that receives the correction signal and corrects positions of the marking unit and the pattern forming equipment based on the received correction signal.

Owner:DONGWOO FINE CHEM CO LTD

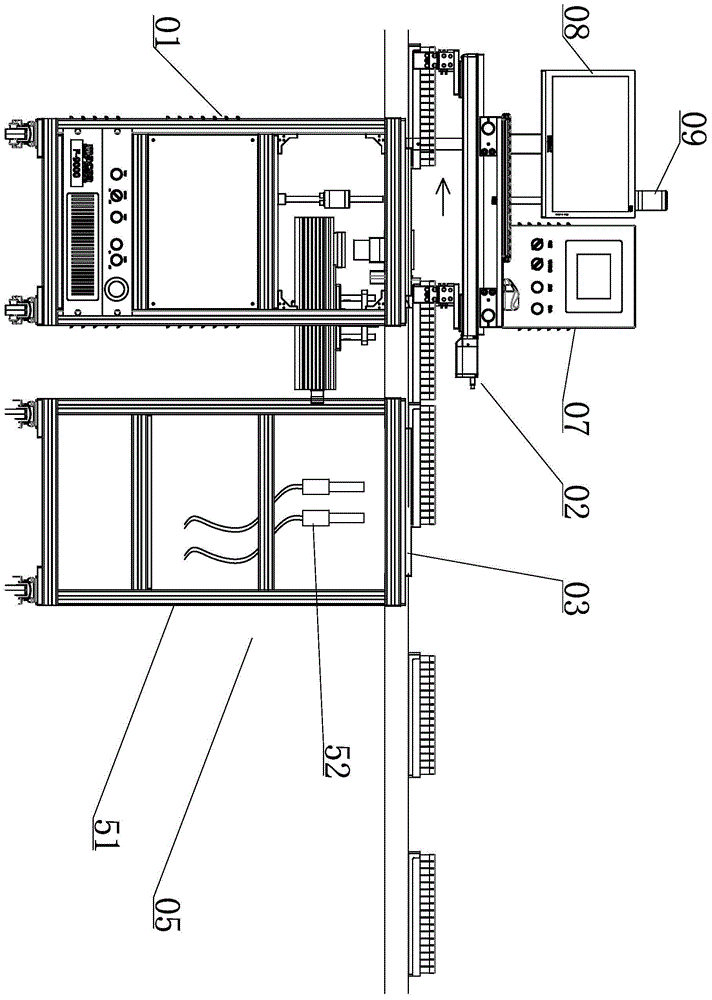

Intelligent feeding conveying laser marking machine

PendingCN109483065AReasonable designImprove work efficiencyLaser beam welding apparatusEngineeringLaser

The invention discloses an intelligent feeding conveying laser marking machine. The intelligent feeding conveying laser marking machine comprises a machine frame and an installation plate arranged onthe machine frame, and the installation plate is provided with an installation frame; an industrial personal computer and a negative pressure generator are installed in the installation frame; one side of the installation frame is provided with a jacking feeding device, and the other side of the installation frame is provided with a finished product collecting device; and two symmetrically-arranged vertical installation plates are installed on the upper portion of the installation frame, a plurality of parallelly-designed slide rods are connected between the two vertical installation plates, and all the slide rods are slidably connected with a slide driving device. The intelligent feeding conveying laser marking machine is reasonable in design, capable of saving time and labor, high in working efficiency and intelligent automation degree in the whole process, capable of completely replacing manpower, high in working efficiency, precise in marking position, capable of ensuring the marking quality, and suitable for popularization.

Owner:江苏昆太工业装备有限公司

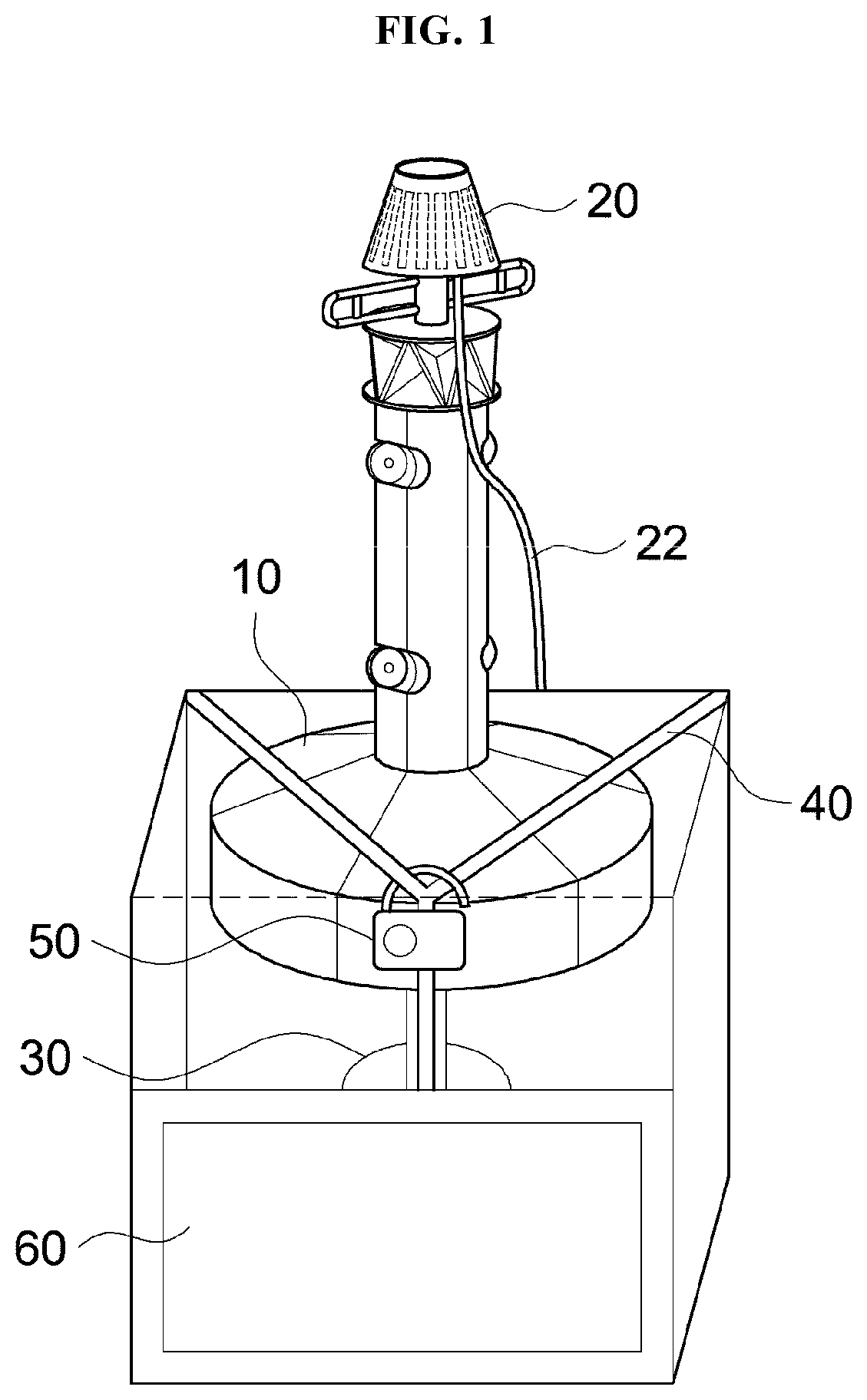

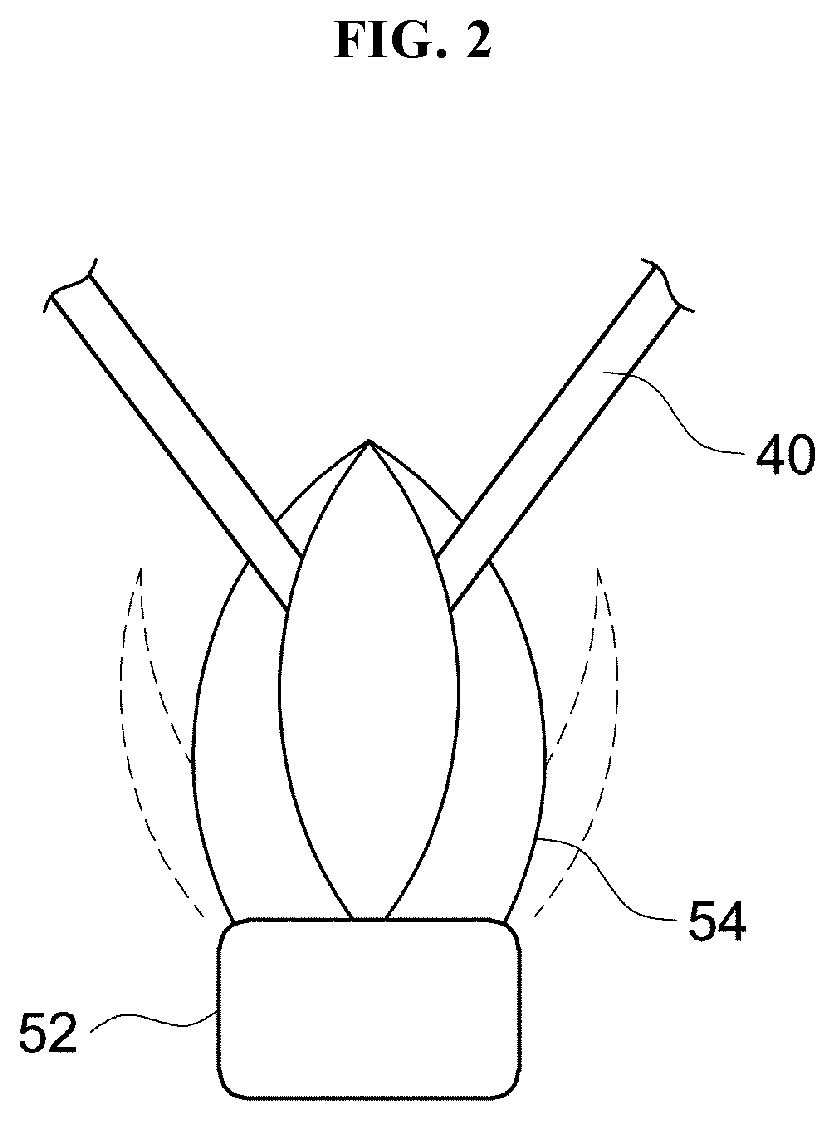

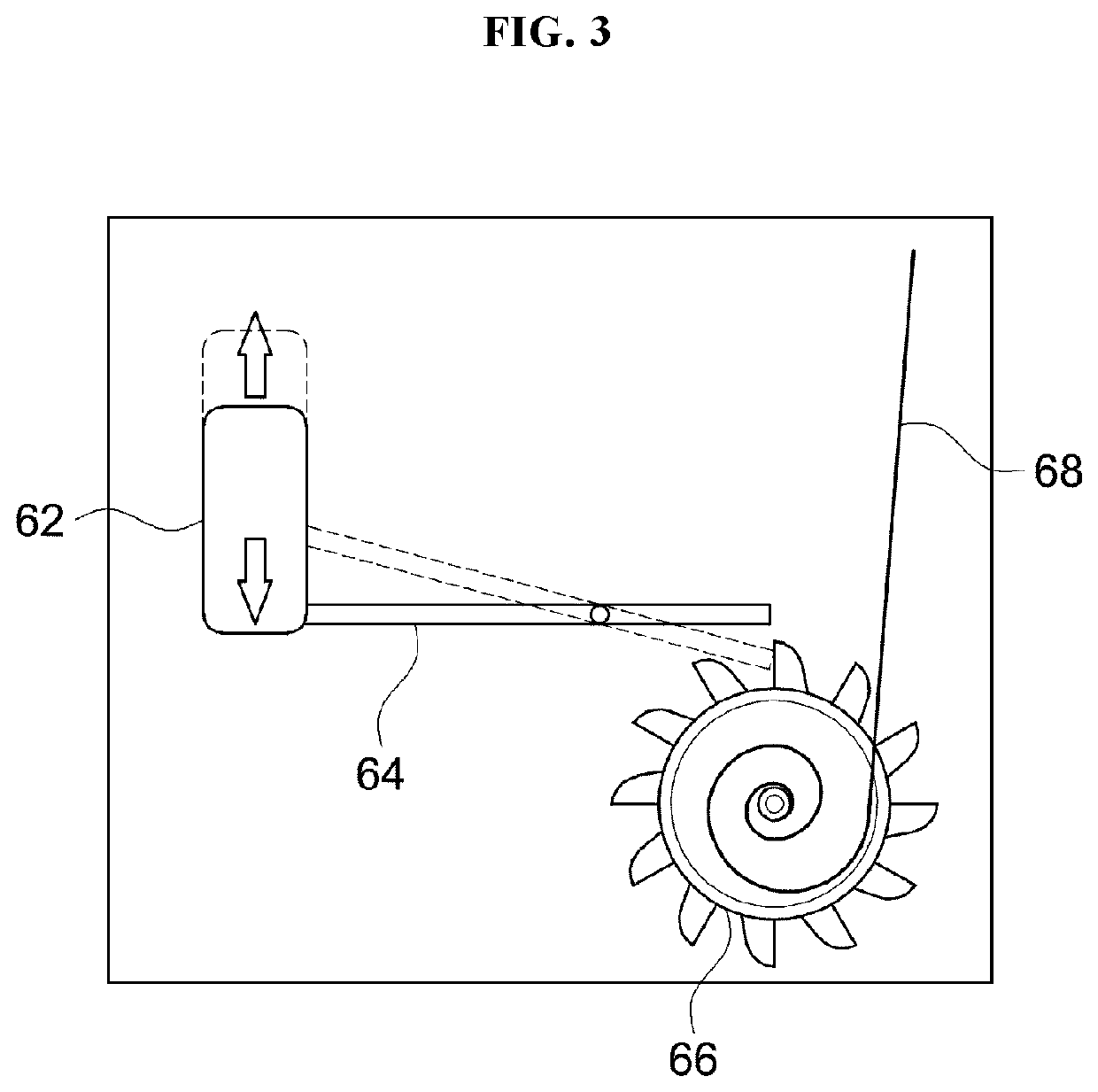

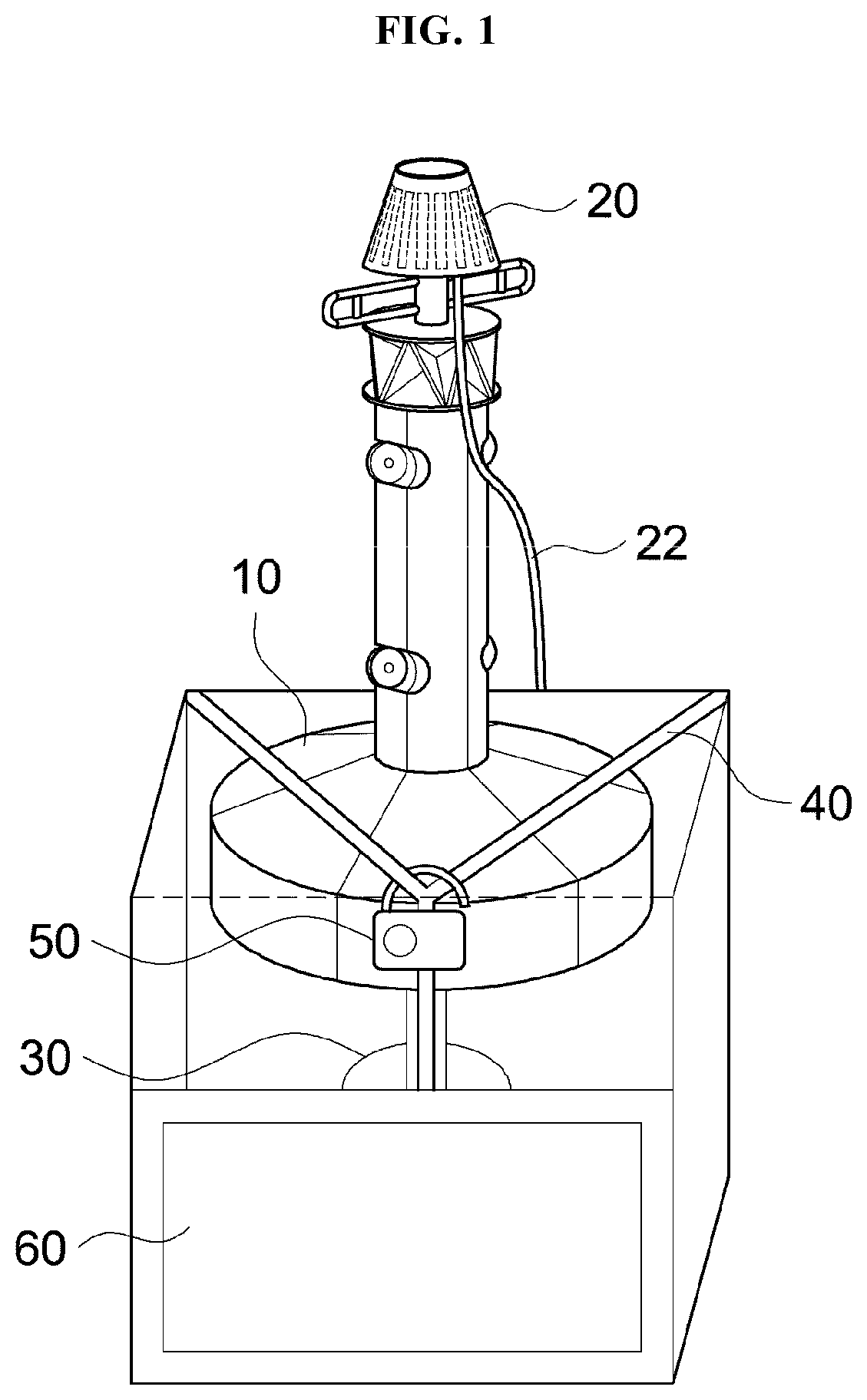

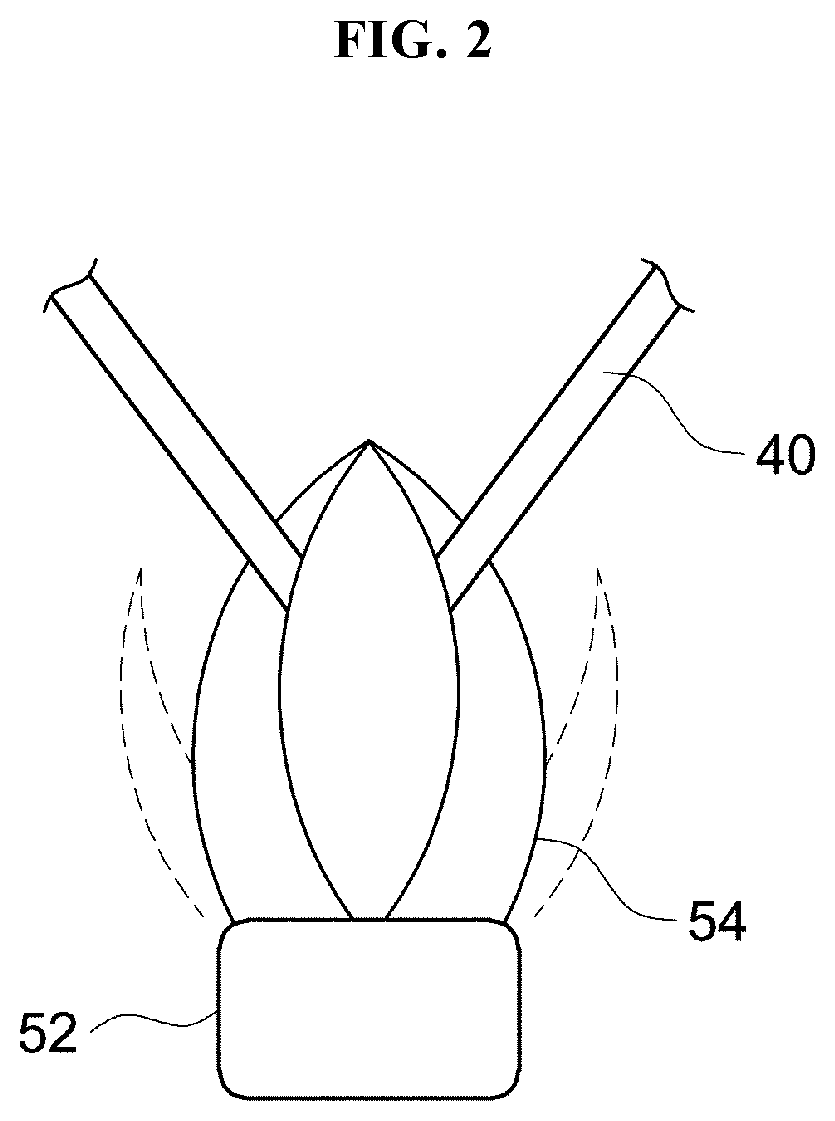

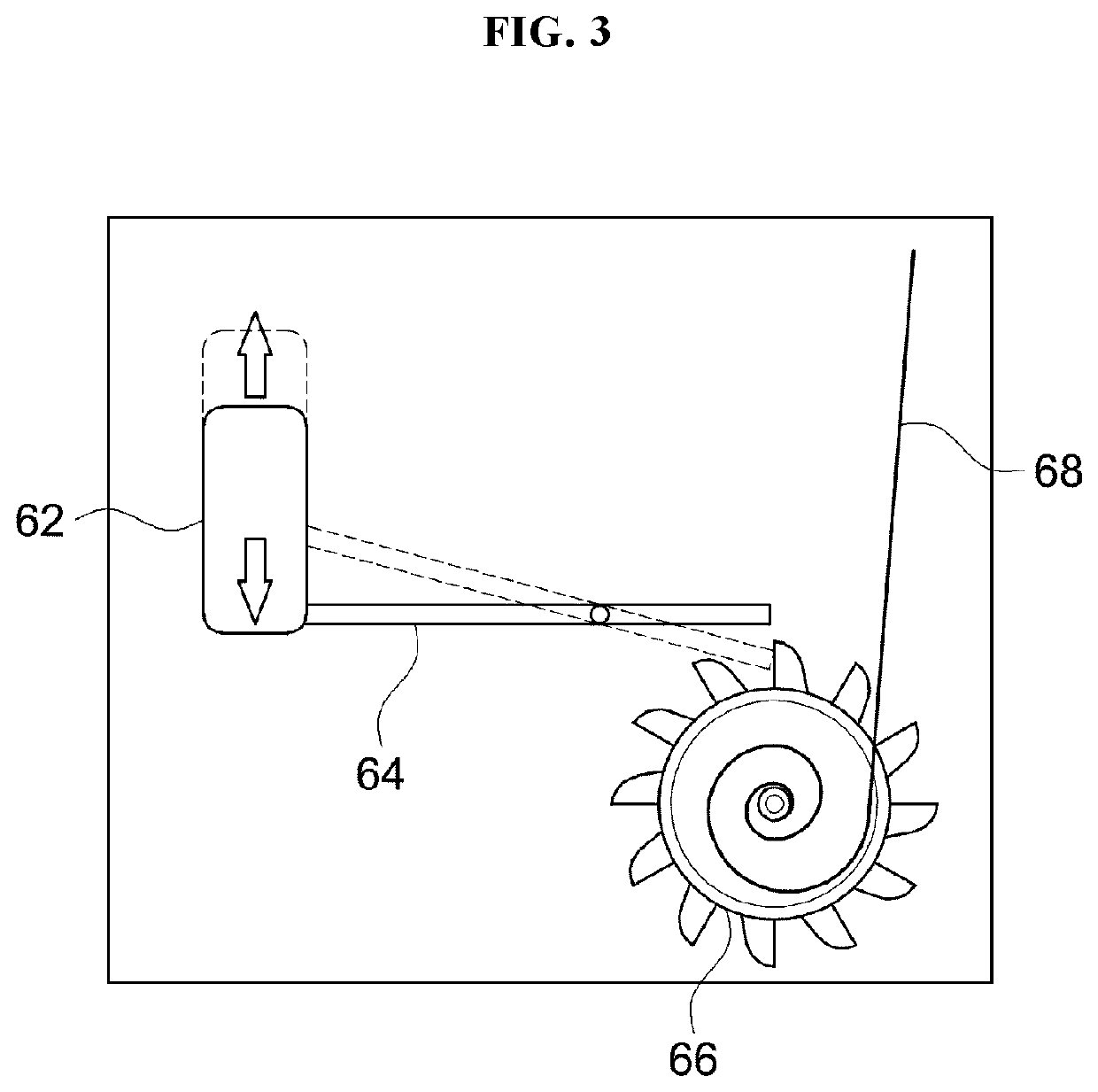

Auto-releasable new danger mark buoy

A buoy system according to one embodiment of the present invention includes a buoy body configured to provide buoyance; a fixing belt configured to fasten the buoy body to a ship structure; an auto-release unit configured to release the buoy body to be buoyed by releasing the fixing belt when a predetermined water pressure is reached; and an auto-reel chain box fixed to the ship structure, being opened in conjunction with releasing of the fixing belt, and including a chain which is reeled out when the buoy body is buoyed, wherein the auto-reel chain box comprises: a weight provided in the auto-reel chain box and being movable upward and downward according to a water pressure and buoyance; a pulley provided in the auto-reel chain box, having the chain wounded thereon and a plurality of teeth on an outer circumferential surface thereof; and a shaft having one end connected to the weight and the other end engaging with the teeth to fix the pulley and provided to be rotatable around a portion fixed in the auto-reel chain box.

Owner:KOREA MARITIME UNIV IND ACADEMIC COOPERATION FOUND

Auto-releasable new danger mark buoy

A buoy system according to one embodiment of the present invention includes a buoy body configured to provide buoyance; a fixing belt configured to fasten the buoy body to a ship structure; an auto-release unit configured to release the buoy body to be buoyed by releasing the fixing belt when a predetermined water pressure is reached; and an auto-reel chain box fixed to the ship structure, being opened in conjunction with releasing of the fixing belt, and including a chain which is reeled out when the buoy body is buoyed, wherein the auto-reel chain box comprises: a weight provided in the auto-reel chain box and being movable upward and downward according to a water pressure and buoyance; a pulley provided in the auto-reel chain box, having the chain wounded thereon and a plurality of teeth on an outer circumferential surface thereof; and a shaft having one end connected to the weight and the other end engaging with the teeth to fix the pulley and provided to be rotatable around a portion fixed in the auto-reel chain box.

Owner:KOREA MARITIME UNIV IND ACADEMIC COOPERATION FOUND

Nitride semiconductor substrate, and method for working nitride semiconductor substrate

InactiveUS20070080366A1Accurately positionMarking position is accuratePolycrystalline material growthAfter-treatment detailsDefect regionCrystallographic defect

A method for working a nitride semiconductor substrate, comprising the steps of: preparing a disk-shaped nitride semiconductor substrate comprising a plurality of striped regions having defect concentration regions in which crystal defect density is higher than in surrounding low defect regions; and forming a cut-out at a specific location along the edge of the nitride semiconductor substrate, using as a reference the direction in which at least one from among the plurality of striped regions extends.

Owner:SUMITOMO ELECTRIC IND LTD

Exposure apparatus with detection apparatus for detection of upper and lower surface marks, and device manufacturing method

ActiveUS9523927B2Marking position is accurateRadiation pyrometryPhase-affecting property measurementsPhysics

A detection apparatus, which detects a mark formed on a lower surface of a target object, includes: a first detector which illuminates the mark from an upper surface side of the target object to detect an image of the illuminated mark; a second detector which detects an upper surface position of the target object; and a processor which obtains information indicating a focus position to focus on the mark in the first detector, based on the upper surface position detected by the second detector.

Owner:CANON KK

Laser marking control system

InactiveCN109719398AReasonable designImprove work efficiencyLaser beam welding apparatusPhotovoltaic detectorsAutomatic control

The invention discloses a laser marking control system which comprises a controller arranged in a rack, a rotating motor in a jacking loading device and a photoelectric detector for detecting height of a material, a sliding motor in a sliding driving device, a vertical lifting air cylinder in a lifting driving device, a positioning air cylinder in a driving positioning device and an infrared detector corresponding to the positioning air cylinder. The laser marking control system is reasonable in design, loads materials by way of automatic loading and suction by a suction disc, unloads the materials by way of suction by the suction disc and collects marked products in a collecting frame. In the full course, automatic marking and loading and unloading are achieved by means of a full-automatic control principle, so that the laser marking control system is time- and labor-saving and high in work efficiency, can replace manpower fully, is precise in marking position, guarantees the markingquality and is suitable for being popularized.

Owner:江苏昆太工业装备有限公司

Ring workpiece marking device

InactiveCN108312720BAvoid ambiguityAmbiguous problems do not occurTypewritersEngineeringMechanical engineering

The invention belongs to the automobile parts manufacturing field and discloses a mark printing device for annular workpieces. The mark printing device comprises a rack; the rack is provided with a fixing mechanism and a mark printing mechanism; the fixing mechanism comprises a fixing disk; the mark printing mechanism is located to one side of the fixing disk and comprises a connection rod; an upper magnetic member is attached to the upper surface of the connection rod; a lower magnetic member is attached to the lower surface of the connection rod; a first electromagnet is slidably connected onto the upper magnetic member; a second electromagnet is slidably connected onto the lower magnetic member; the first electromagnet is fixedly connected with a first curved rod; the second electromagnet is fixedly connected with a second curved rod; the free end of the first curved rod is provided with a first inclined surface; the free end of the second curved rod is provided with a second inclined surface; a first wedge bar is connected with a first annular switch; a second wedge bar is connected with a second annular switch; and the inner sides of the first annular switch and the second annular switch are both provided with mark printing heads. According to the mark printing device for the annular workpieces of the invention, the problem that printed marks on the upper end surface and lower end surface of an annular connecting member are blurred caused by the difference of the thickness of the annular connecting member can be solved.

Owner:SHANDONG TAIKAI PRECISION CASTING

road marking device

ActiveCN108677675BMarking position is accuratePrevent precipitation and solidificationRoads maintainenceEngineeringStructural engineering

The invention discloses a road marking device. The road marking device comprises a vehicle body, a first coating tank, a second coating tank, a spraying device, a first guide device, a second guide device, an arrow forming device, a console and a detection device, wherein the first coating tank, the second coating tank, the spraying device, the first guide device, the second guide device, the arrow forming device, the console and the detection device are all arranged on the vehicle body; the first coating tank and the second coating tank are used for containing coating for marking; the spraying device is used for spraying the coating; the first guide device is used for transversely guide the spraying device to spray the coating; the second guide device is used for moving the spraying device to the arrow forming device; the arrow forming device cooperates with the spraying device to spray an arrow-shaped pattern; the detection device is used for detecting whether the vehicle body deviates from a preset driving direction or not; a user can input an operation command through the console, and control the road marking device to mark. The road marking device can be used for accurately controlling marking positions.

Owner:嘉兴沃瑞科技有限公司

Automatic marking machine and marking method

ActiveCN107581130BImprove stabilityImprove crawling efficiencyPisciculture and aquariaRobot handEngineering

The invention discloses an automatic marking machine and a marking method. The automatic marking machine comprises a support, an industrial personal computer arranged on the support, a transmission mechanism connected with the industrial personal computer and a marking device connected with the transmission mechanism; a transmission pipe is arranged on one side of the upper end of the support; a control panel, a second limiting device, a mechanical arm, the marking device and a first limiting device are sequentially arranged above the transmission pipe on the side of the support from left to right; a controller and a length detector are arranged below the transmission pipe; the controller corresponds to the second limiter in position; and the length detector corresponds to the first limiter in position. The automatic marking machine disclosed by the invention can realize that after fishes are put into the machine, then the industrial personal computer and the other parts are used for marking the fishes; the marking positions are accurate; the fishes do not waggle during the marking process; the situation of marking mistake does not occur easily; the marking of each fish is completed within 1s; the marking efficiency is high; the energy consumption is low; and batch marking of fishes can be realized.

Owner:ZHEJIANG OCEAN UNIV

Control device for preventing meandering of patterns on patterned films

InactiveUS9134634B2Marking position is accuratePrinting pressesOptical articlesControl unitElectrical and Electronics engineering

A control device for preventing meandering of patterns for use in a patterned film manufacturing device which includes a film transferring equipment and a pattern forming equipment, includes a marking unit that forms markings on a predetermined reference position on the film, a recognizing unit that is located at the rear of the marking unit and recognizes positions of the markings on the film, a computing unit that computes an amount of meandering based on differences between the reference position and the recognized positions of the markings, a control unit that generates a correction signal for correcting positions of the marking unit and the pattern forming equipment corresponding to the computed the amount of meandering, and a correction unit that receives the correction signal and corrects positions of the marking unit and the pattern forming equipment based on the received correction signal.

Owner:DONGWOO FINE CHEM CO LTD

Marking apparatus and marking method for display panel

InactiveUS9774773B2Marking position is accuratePrecise positioningTelevision system detailsColor television detailsSimulationSurface plate

Owner:BOE TECH GRP CO LTD +1

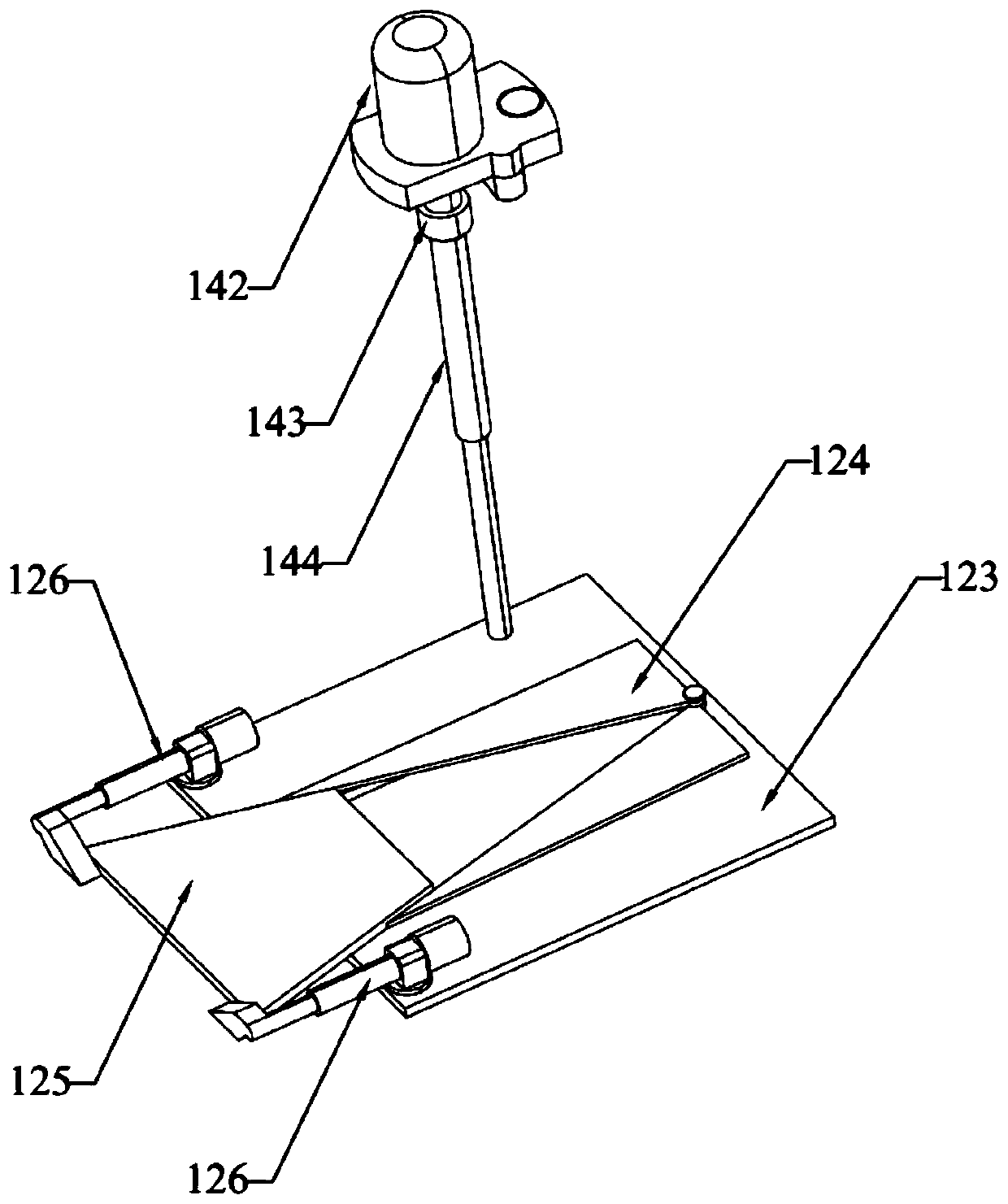

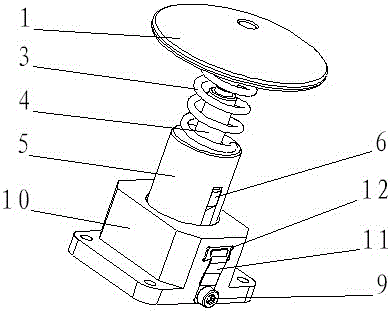

An oblique tongue marking device

ActiveCN107901017BSimple structureRealize automatic markingAssembly machinesOther workshop equipmentDisplay deviceEngineering

The invention discloses a line-marking device for a latch bolt. The device comprises a support, wherein a panel is arranged on the support; a processing device is arranged on the panel, a display device and a feeding device are sequentially arranged on one side of the processing device, and a first line-marking device and a second line-marking device are arranged on the two sides of the front endof the processing device correspondingly. The device is simple in structure and can adapt to products with different sizes and with different positions to be machine; automatic line-marking is achieved, manpower and material resources are saved, and the production efficiency is improved; and the device failure rate is low, and the line-marking position is accurate.

Owner:WUXI ZHONGWANG 4D TECH

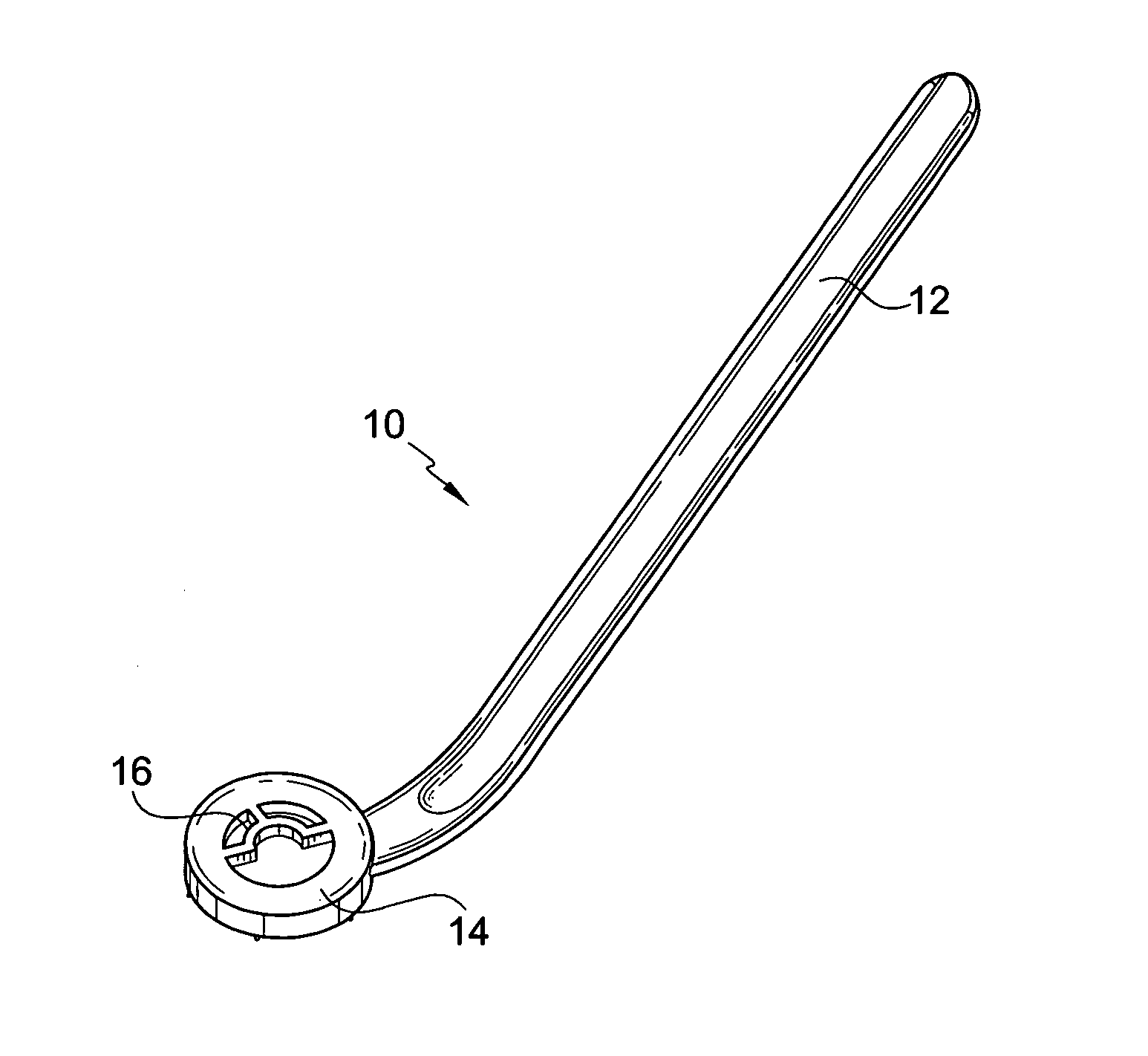

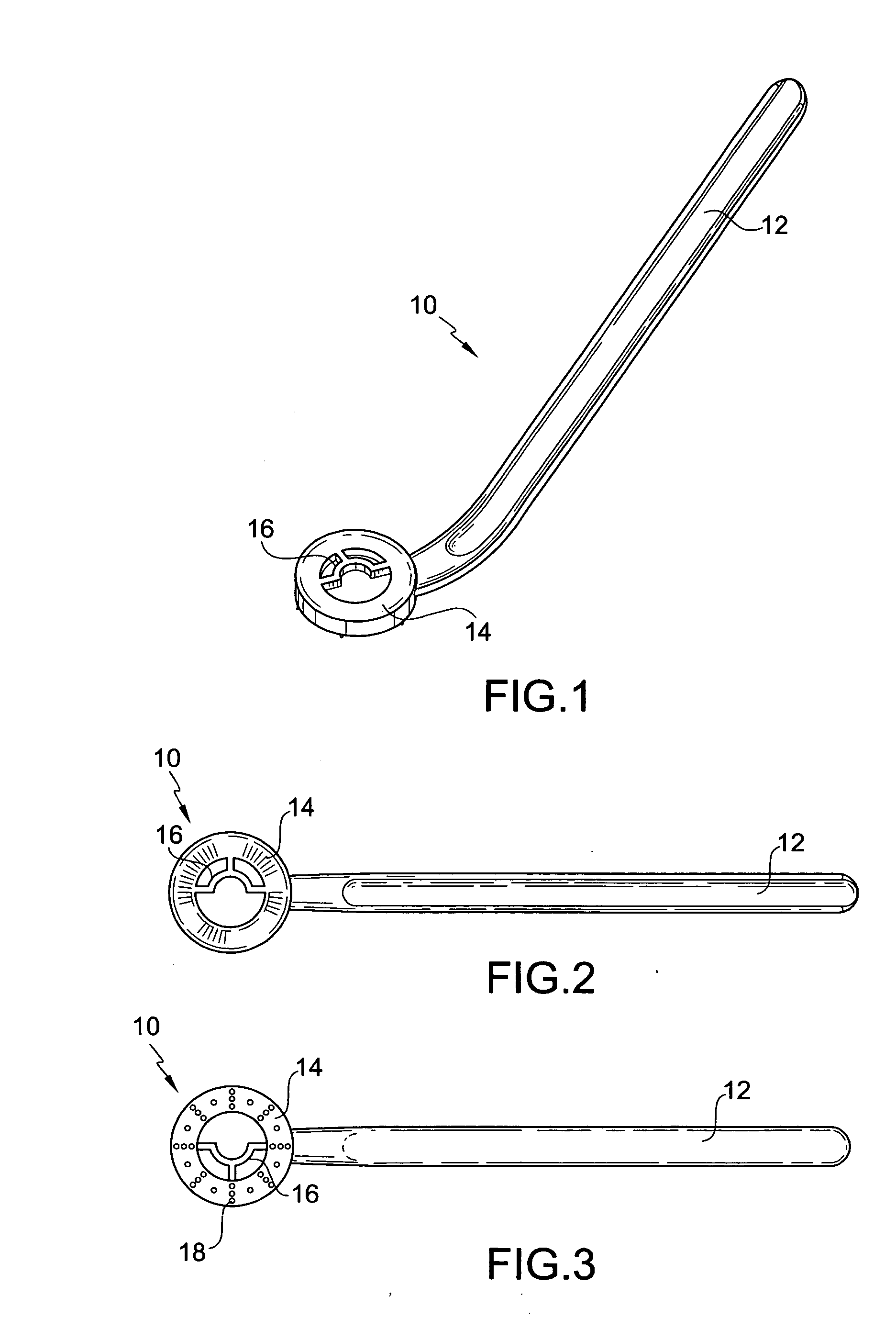

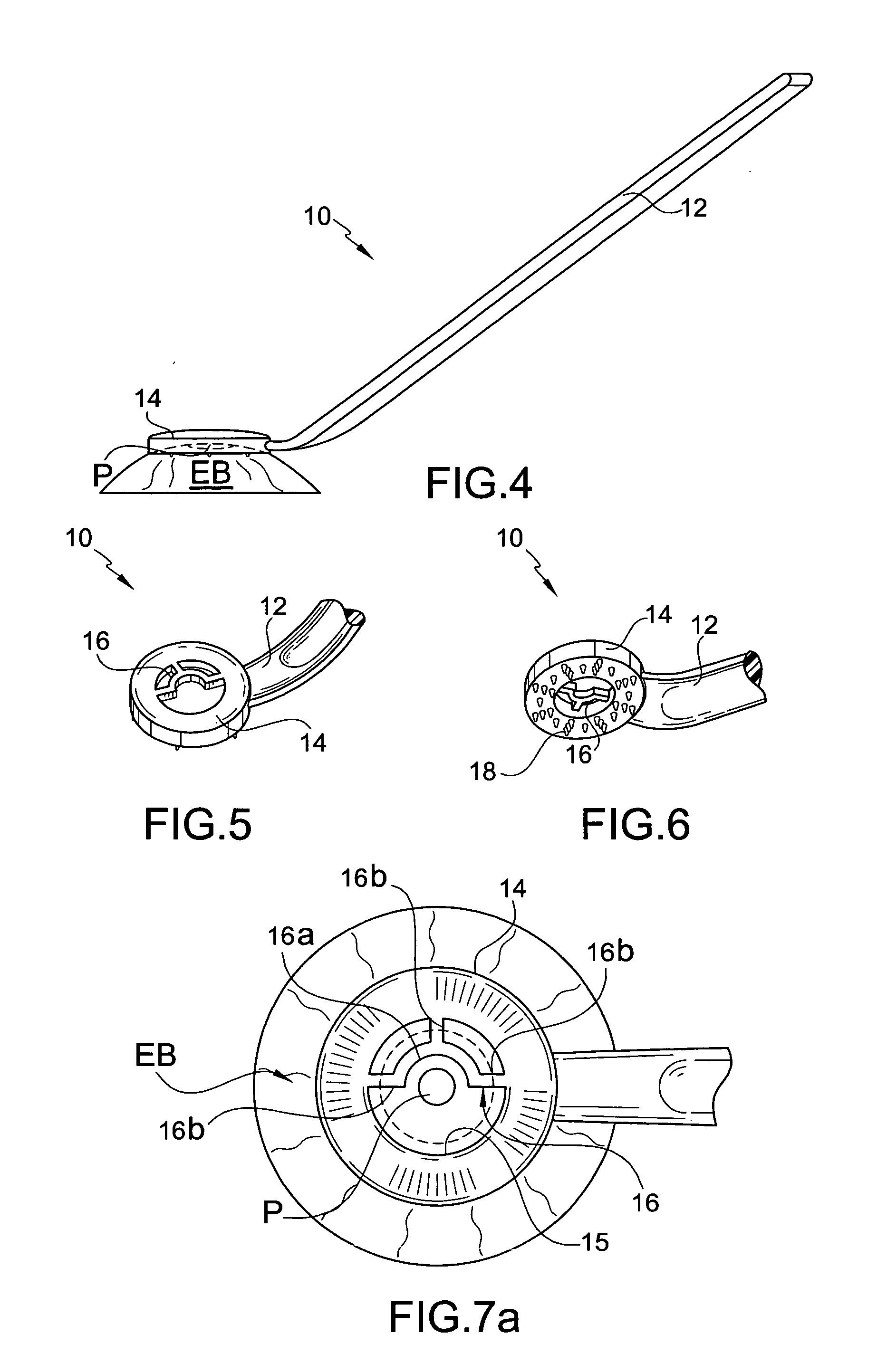

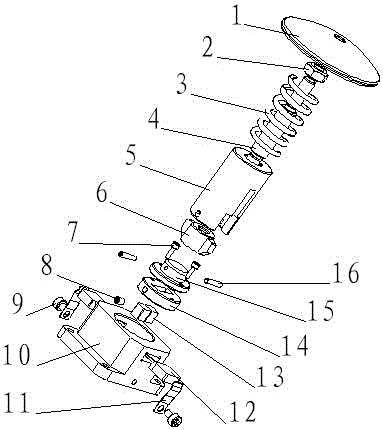

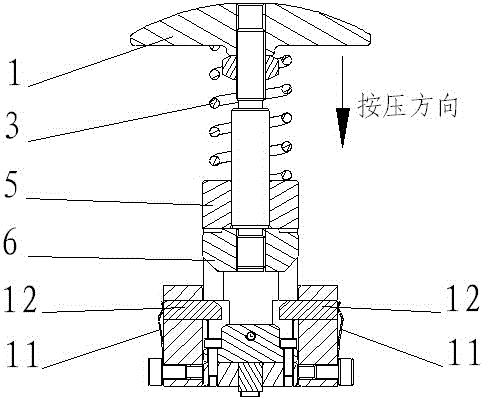

A manual one-piece punching and marking tool for part surface marking

A manual one-piece stamping and marking tool used for part surface identification comprises a potential energy storage / release assembly, a driving hammer and control block assembly, a steel figure and steel figure clamping assembly and a base assembly with unlocking and locking functions. The potential energy storage / release assembly comprises a handle, a guide rod, a ham nut and a compression spring, wherein a threaded hole is formed in the middle of the handle, the two ends of the guide rod are provided with threaded segments, and the guide rod is sleeved with the compression spring. The driving hammer and control block assembly comprises a driving hammer and a control block, wherein the upper portion of the driving hammer is provided with a round hole which is in tiny clearance fit with a cylindrical section at the lower end of the guide rod, and the control block is fixedly connected with the lower end of the guide rod through a threaded pair. The steel figure and steel figure clamping assembly comprises a steel figure, a figure clamp, a figure seat, a first jackscrew and a second jackscrew, wherein the figure seat is fixedly connected with the figure clamp through two first bolts, and the figure seat is floatingly connected with the bottom of the driving hammer through the second jackscrew. The base assembly comprises a base, a lock tongue and a reset spring, wherein the face, making contact with the control block, of the lock tongue is an inclined face. The manual one-piece stamping and marking tool used for part surface identification has the advantages that manual operation is facilitated, efficiency is high, marking positions are accurate, the definition is stable, and the labor intensity is low.

Owner:CHERY AUTOMOBILE CO LTD

Marker machine positioning device

The invention discloses a marker machine positioning device, including a positioning grooved plate and a positioning bar embedded above the positioning grooved plate, the positioning grooved plate is connected with a marker machine work bench, a positioning groove is provided above the positioning grooved plate, the positioning groove laterally tunnels through the positioning groove, one side part above the positioning bar is provided with a gap, the center of the gap and the center of the positioning groove are coaxial, the positioning bar is perpendicular to the positioning groove, the positioning groove atop is provided with a circle arc angle, one end of the circle arc angle is connected with the upper surface of the positioning groove, the center of the gap is provided with a tick mark line, the tick mark line and the center of the positioning groove are coaxial, the gap restricts the axial direction of a work piece, the positioning groove restricts the radial direction of the work piece. The device is simple in operation, convenient to use, increases production efficiency, is accurate in the positioning of a work piece, and has high marking quality.

Owner:HUBEI XINYEGANG STEEL AUTO PARTS

A visual inspection system for lipstick marking

ActiveCN104802534BImprove work efficiencyLabor savingTypewritersOptically investigating flaws/contaminationVisual inspectionEngineering

The invention discloses a lipstick-marking visual inspection system. The lipstick-marking visual inspection system comprises a laser marking unit, a positioning unit, a front-stage conveying unit, a rear-stage conveying unit, and an ink jet marking unit; an ejection unit is arranged on the rear-stage conveying unit; the laser marking unit comprises a first frame, a laser host and a laser head; a visual inspection probe is disposed on the first frame; the positioning unit comprises a support, a sliding rail and a uniform push cylinder; the front-stage conveying unit comprises a first motor and a front-stage conveying belt; the rear-stage conveying unit comprises a second motor and a rear-state conveying belt; the ejection unit comprises a keep-of cylinder, a defective-product collection plate and a pushing cylinder; a manipulator is connected with the visual inspection probe and the laser host respectively, and the visual inspection probe is connected with the keep-off cylinder and the pushing cylinder respectively. By the arrangement, operation efficiency is high, accepted products are automatically ejected, labor force is saved, and the system is multifunctional.

Owner:广东铭钰科技股份有限公司

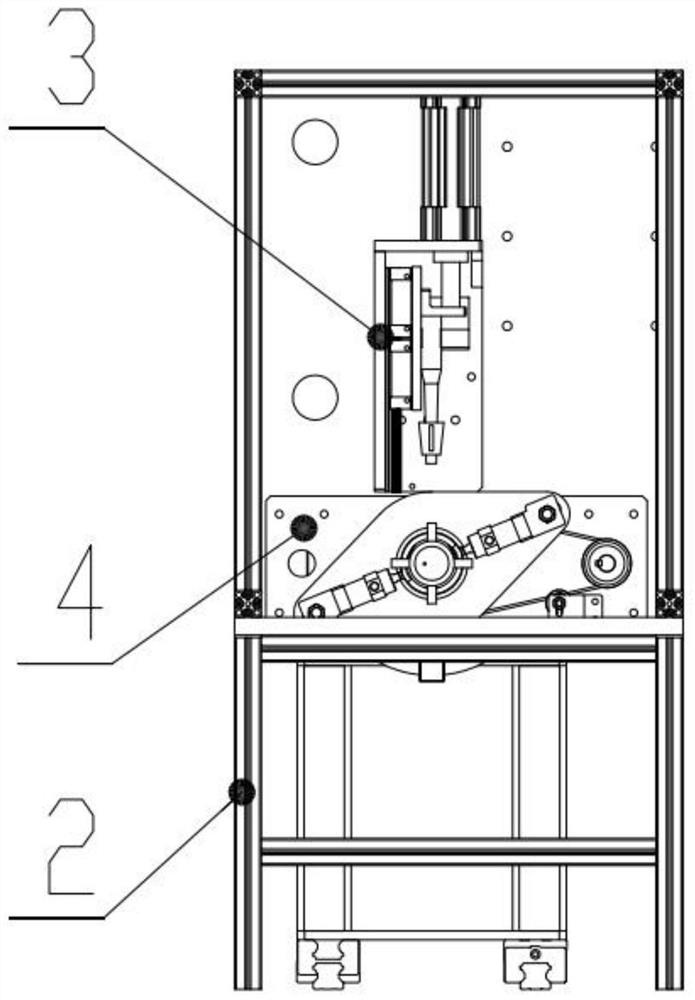

Automatic welding machine for round pipe heat preservation nail

ActiveCN112091384AAvoid leaningAvoid inaccurate welding positionsWelding accessoriesProcess engineeringHeat conservation

The invention discloses an automatic welding machine for a round pipe heat preservation nail. The automatic welding machine comprises a rack, wherein a heat preservation nail welding machine assemblyand a clamping mechanism are arranged on the rack, the clamping mechanism is used for clamping a to-be-welded pipefitting, the heat preservation nail welding machine assembly is used for welding the heat preservation nail on the to-be-welded pipefitting, and a welding gun of the heat preservation nail welding machine assembly is perpendicular to the axis of the to-be-welded pipefitting. The preservation nail is welded by using the automatic welding machine. The to-be-welded pipefitting is fixed by the clamping mechanism, and the heat preservation nail is welded by the heat preservation nail welding machine assembly without holding the welding machine manually, so that the problem that the heat preservation nail inclines is avoided. Furthermore, the welding gun of the heat preservation nailwelding machine assembly is arranged perpendicular to the axis of the to-be-welded pipefitting, so that the problem that the welding position of the heat preservation nail is inaccurate as a lineation position is inaccurate is avoided. The automatic welding machine reduces the manual operations greatly and guarantees the accurate welding position. The heat preservation nails are uniform in welding parameter and good in quality. The automatic welding machine is high in welding speed and improves the production efficiency and the production quality.

Owner:HARBIN KENENG CLADDING TECH +2

An automatic welding machine for round pipe insulation nails

ActiveCN112091384BAvoid leaningAvoid inaccurate welding positionsWelding accessoriesEngineeringHeat conservation

Owner:HARBIN KENENG CLADDING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com