Intelligent feeding conveying laser marking machine

A laser marking machine and material feeding technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the marking effect, high labor cost, mutual pushing, etc., and achieve high work efficiency, High degree of automation, quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

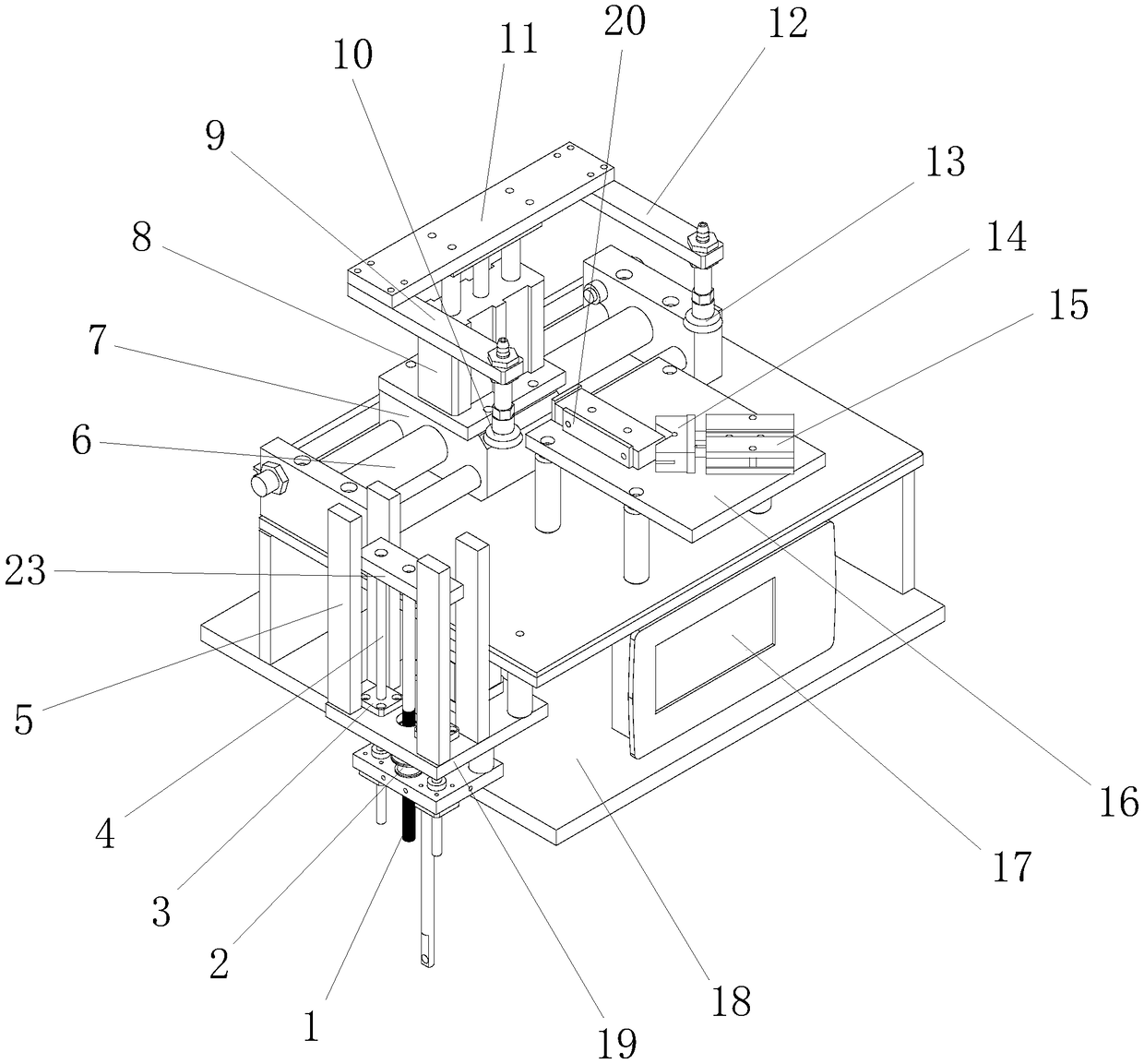

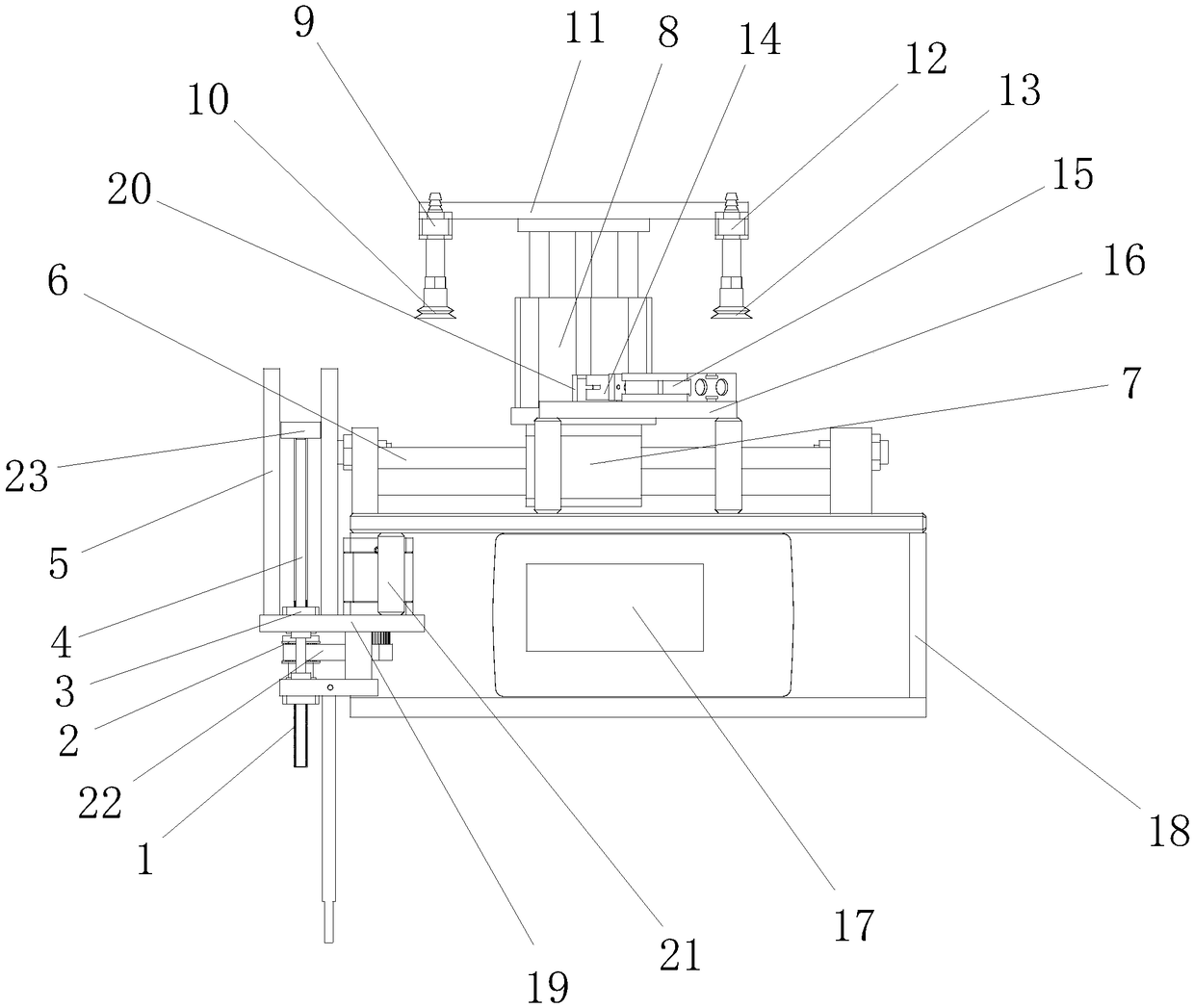

[0021] Such as Figure 1-2 As shown, an intelligent feeding and conveying laser marking machine includes a frame and a mounting plate arranged on the frame, and a mounting frame 16 is arranged on the mounting plate. An industrial computer 17 and a negative pressure generator are installed in the mounting frame 16 .

[0022] One side of the installation frame is provided with a jacking and feeding device, and the other side is provided with a finished product collecting device. The finished product collection device is a collection frame installed on the side of the installation frame. The jacking and feeding device includes a feeding plate 19 installed in the frame, and the feeding plate 19 is provided with four vertical fixing plates 5, and the four vertical fixing plates 5 form a frame for placing OEM products. A rotatable lifting screw 1 is installed through the feeding plate 19, and a lifting plate 23 is installed on the top of the lifting screw 1, and the lifting plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com