Laser marking control system

A control system and laser marking technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting the marking effect, high labor cost, time-consuming and laborious, etc., and achieve high work efficiency and marking position. Precise, quality-assured results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

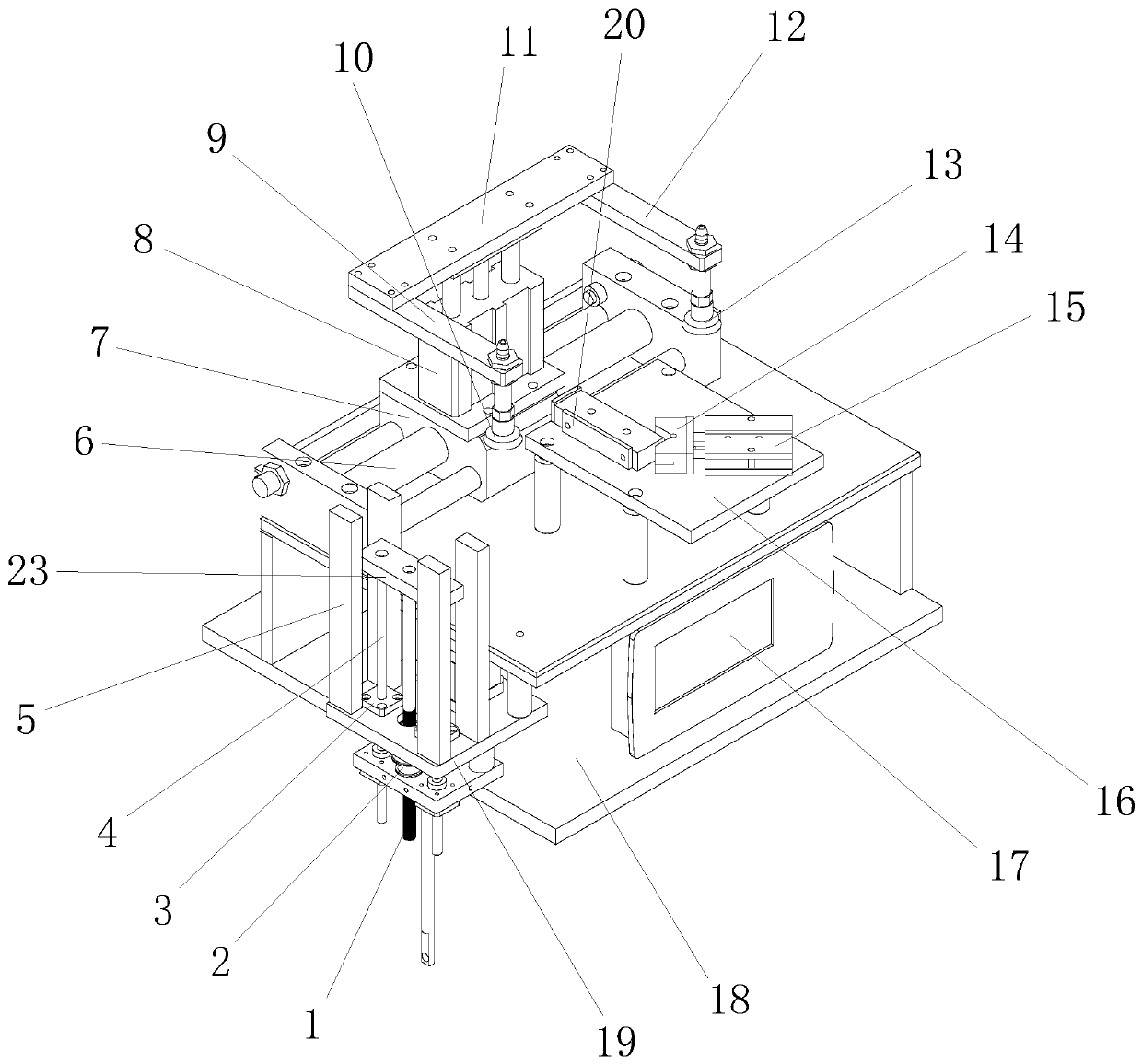

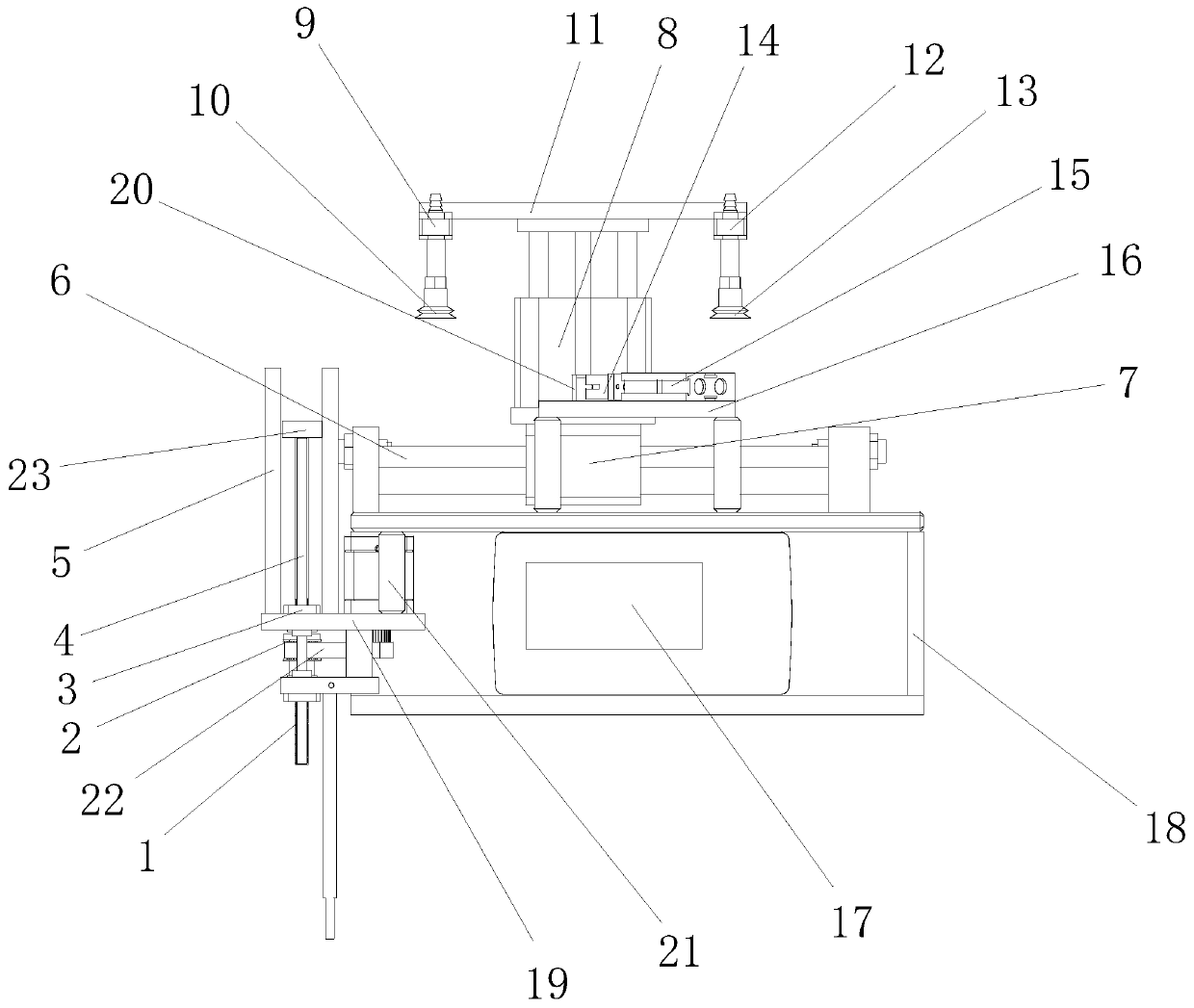

[0031] Such as Figure 1-2 As shown, a laser marking control system corresponds to the laser marking machine, and the control system is the core system for controlling the entire laser marking machine.

[0032] The laser marking machine includes a frame and a mounting plate arranged on the frame, and a mounting frame 16 is arranged on the mounting plate. An industrial computer 17, a touch screen and a negative pressure generator are installed in the mounting frame 16.

[0033] One side of the installation frame is provided with a jacking and feeding device, and the other side is provided with a finished product collecting device. The finished product collection device is a collection frame installed on the side of the installation frame. The jacking and feeding device includes a feeding plate 19 installed in the frame, and the feeding plate 19 is provided with four vertical fixing plates 5, and the four vertical fixing plates 5 form a frame for placing OEM products. A rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com