Laser marking machine

A laser marking machine and laser marking technology, applied in the field of laser marking machines, can solve problems such as affecting production efficiency, reducing work efficiency, reducing equipment utilization, etc., to improve marking efficiency and marking accuracy, and reduce work. cost, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

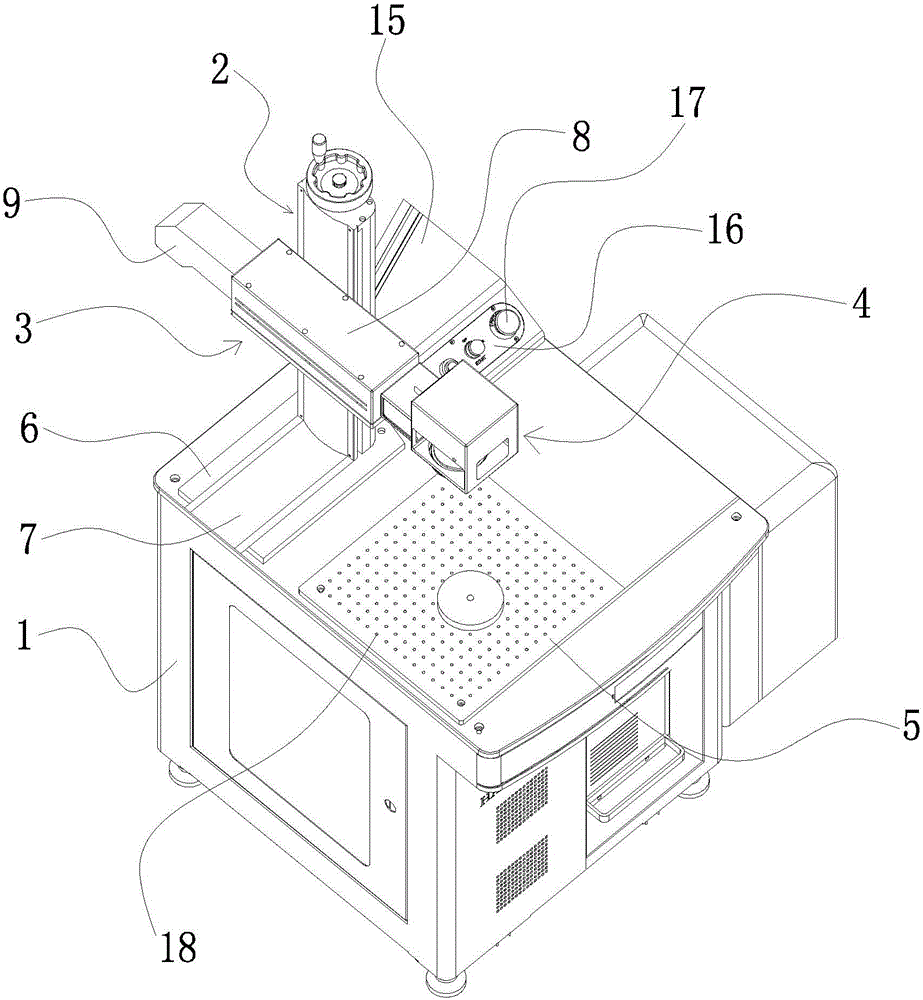

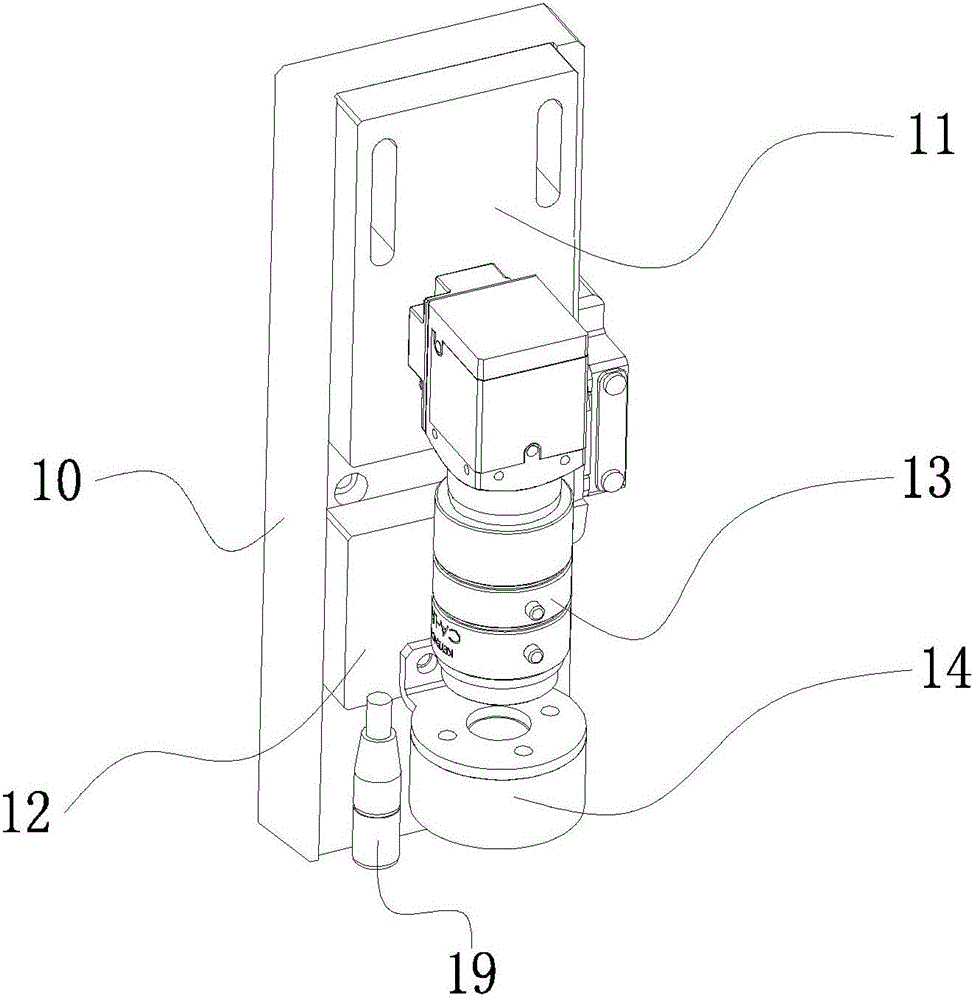

[0021] Example: such as Figure 1-2 As shown, a laser marking machine includes a workbench 1, a lifting device 2 arranged on the workbench 1 and a laser marking device 3, the laser marking device 3 is arranged on the lifting device 2, and the laser marking A laser marking device 4 pointing downward is provided at the end of the marking device 3 , and a marking console 5 is provided on the workbench 1 , and the position of the laser marking device 4 corresponds to the marking console 5 .

[0022] The rear end of the workbench 1 is fixed with a mounting plate 6, the mounting plate 6 is provided with a slideway 7, and the lifting device 2 is slidably arranged on the slideway 7, and the lifting device 2 moves left and right through the slideway 7; And laser marking device 3 can adjust the height of marking head 19 and CCD camera (laser optical path).

[0023] The workbench 1 is provided with a control device, the control device automatically controls the operating system, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com