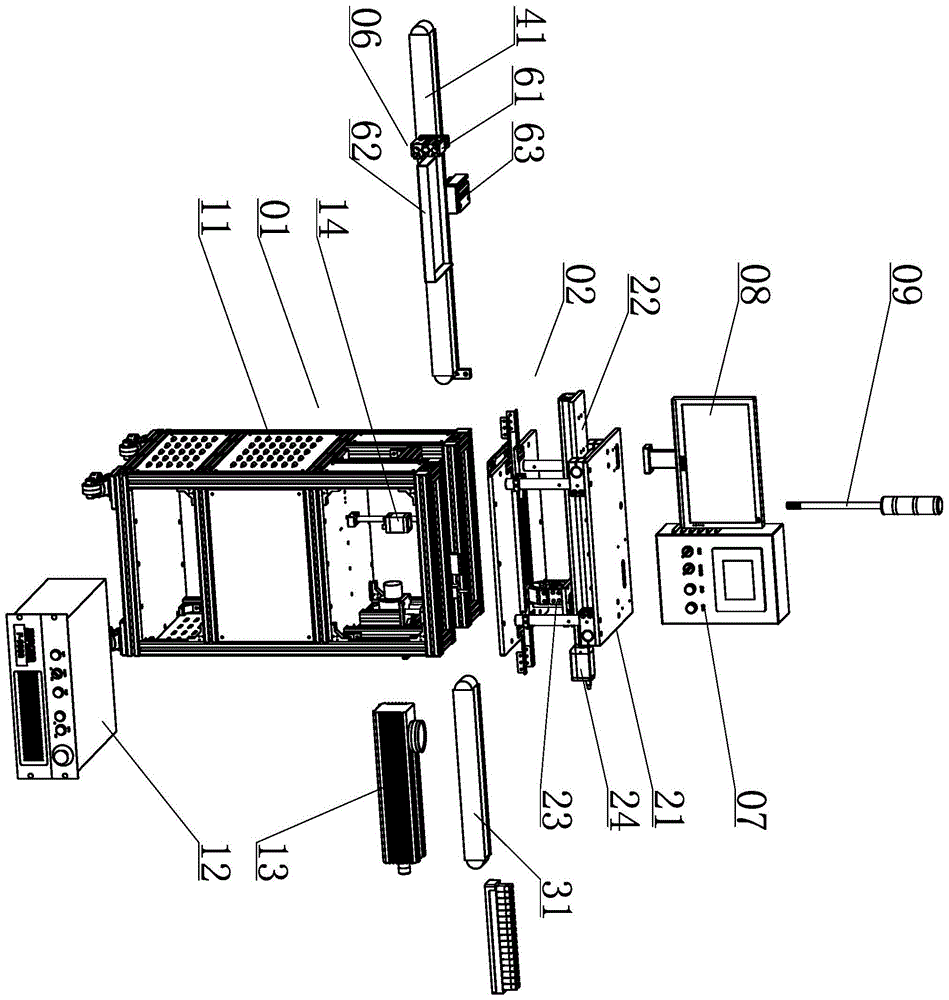

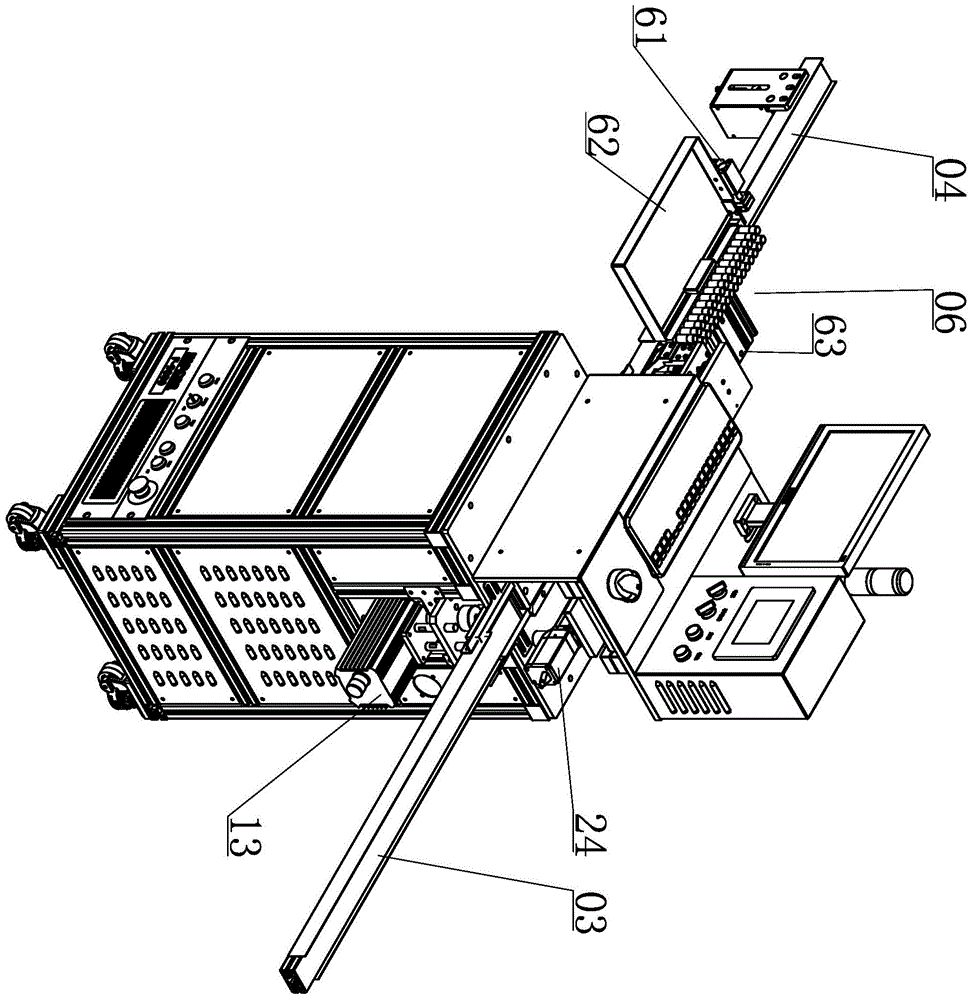

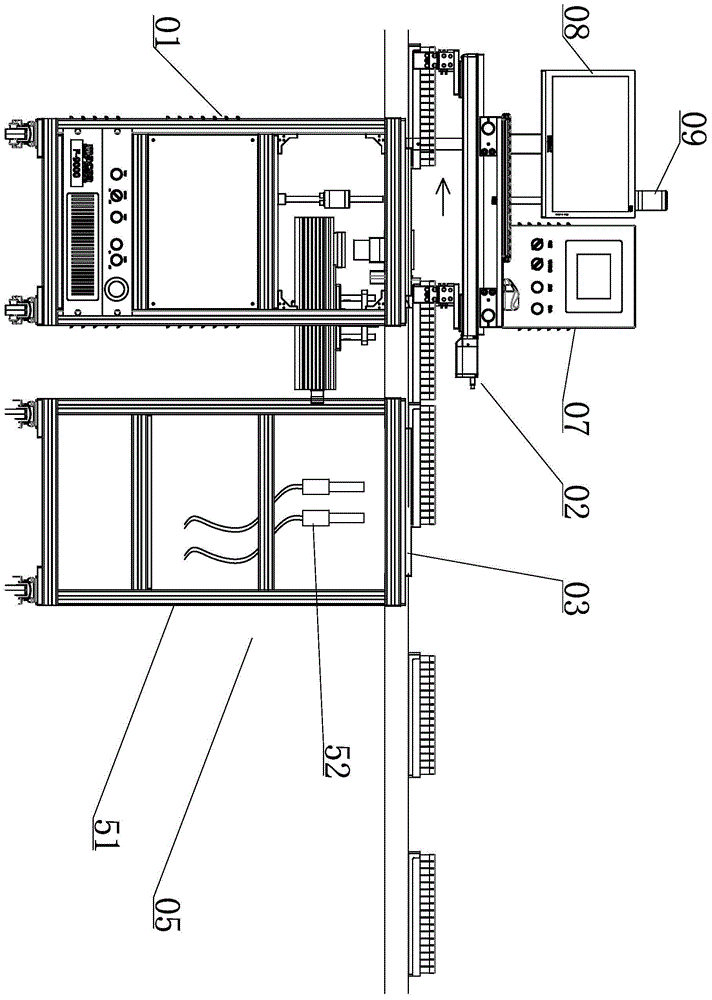

A visual inspection system for lipstick marking

A visual inspection and lipstick technology, applied in the field of lipstick marking visual inspection system, can solve the problems of low work efficiency, easy fatigue of human eyes, etc., and achieve the effects of high work efficiency, automatic rejection of defective products, saving, and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Place 34 pieces of lipstick in the 34 positioning holes of the jig. At the bottom of the positioning hole, there is a through hole with a thickness of 1mm and an inner diameter smaller than the product’s outer diameter of 2mm. The purpose is to prevent the lipstick from falling and not to block the bottom of the lipstick Marking.

[0016] During inkjet marking, when the lipstick carried by the jig is continuously delivered to the front-stage conveyor belt 31, the nozzle 52 is triggered to perform inkjet marking, so that it is triggered and marked continuously once until all markings are completed.

[0017] During laser marking, when the lipstick carried by the jig arrives at the positioning device 02 from the front-stage conveyor belt 31, after the sensor detects for a certain period of time, if it is confirmed that there is still an object above the sensor, it is confirmed that the jig has been in place. At this time, the air claw on the manipulator 23 closes and grasp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com