Ring workpiece marking device

A ring-shaped workpiece and a ring-shaped technology, applied in the field of ring-shaped workpiece marking devices, can solve the problems of ring-shaped connecting piece vibration, different distances, and blurred markings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further detailed explanation through specific implementation mode below:

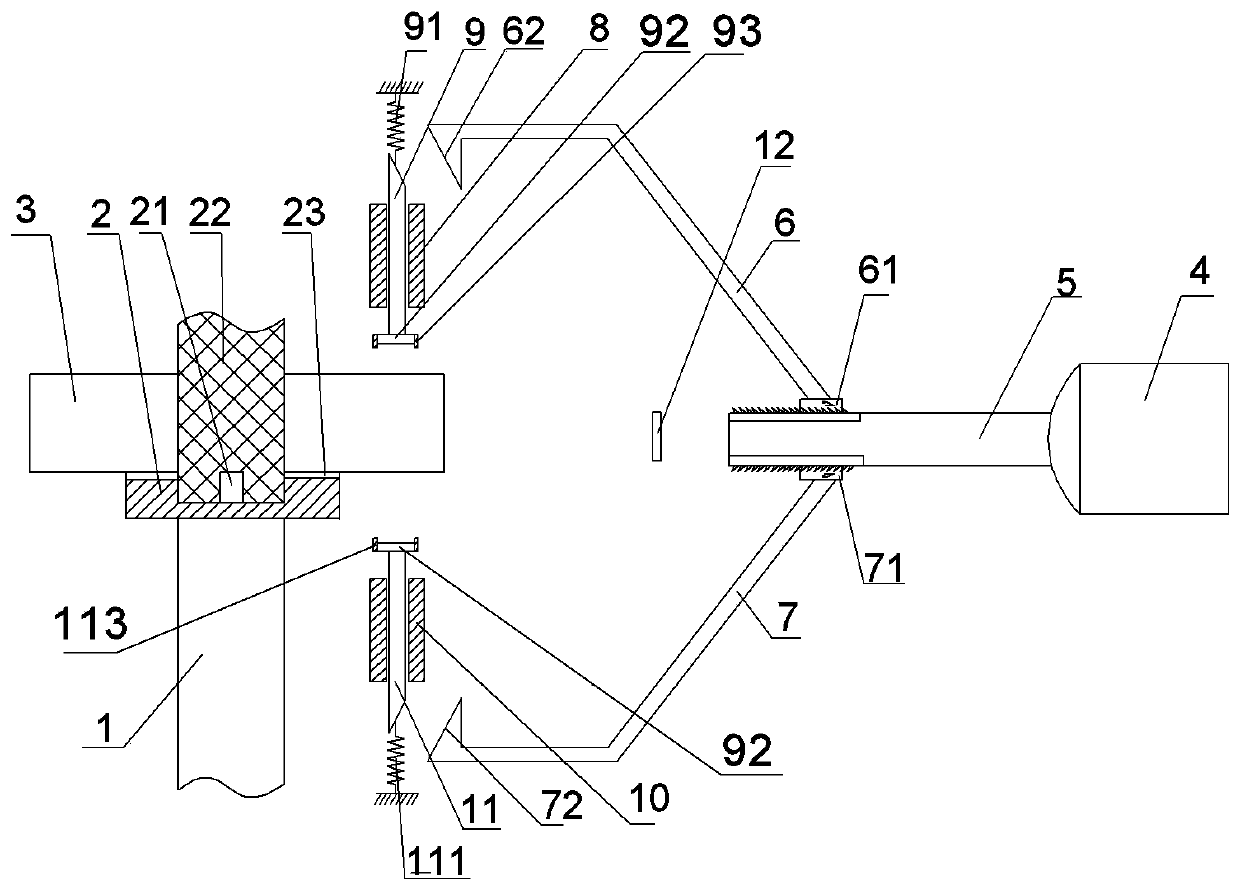

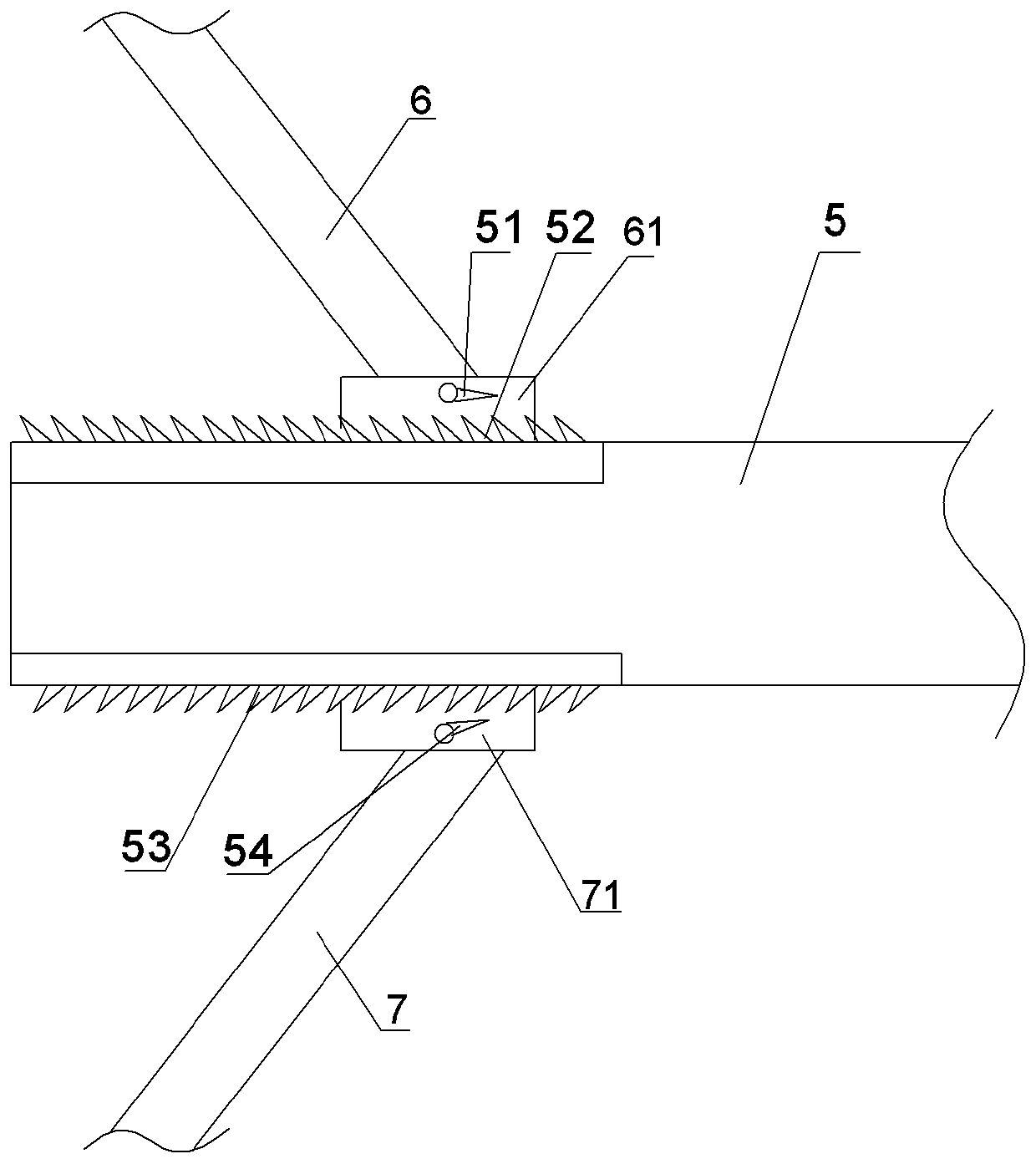

[0023] The reference signs in the drawings of the description include: fixed disk 2, bayonet pin 21, positioning column 22, electromagnet disk 23, ring connector 3, linear motor 4, connecting rod 5, first pawl 51, first ratchet 52 , the second ratchet 53, the second pawl 54, the first curved rod 6, the first electromagnet 61, the first slope 62, the second curved rod 7, the second electromagnet 71, the second slope 72, the first One chute 8, the first wedge bar 9, the first return spring 91, the printing head 92, the first annular pressing member 93, the second chute 10, the second wedge bar 11, the second return spring 111, the second Annular pressing part 113, marking switch 12.

[0024] Such as figure 1 As shown, the ring-shaped workpiece marking device of this embodiment includes a frame, and the frame is provided with a fixing mechanism and a marking mechanism.

[0025] The fixing mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com