Closed scanning galvanometer device for laser machine

A scanning galvanometer and closed technology, which is applied in the field of closed scanning galvanometer devices, can solve the problems of unstable relative position and easy to be interfered by dust in the air, and achieve the effect of compact structure, small influence and precise optical path control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

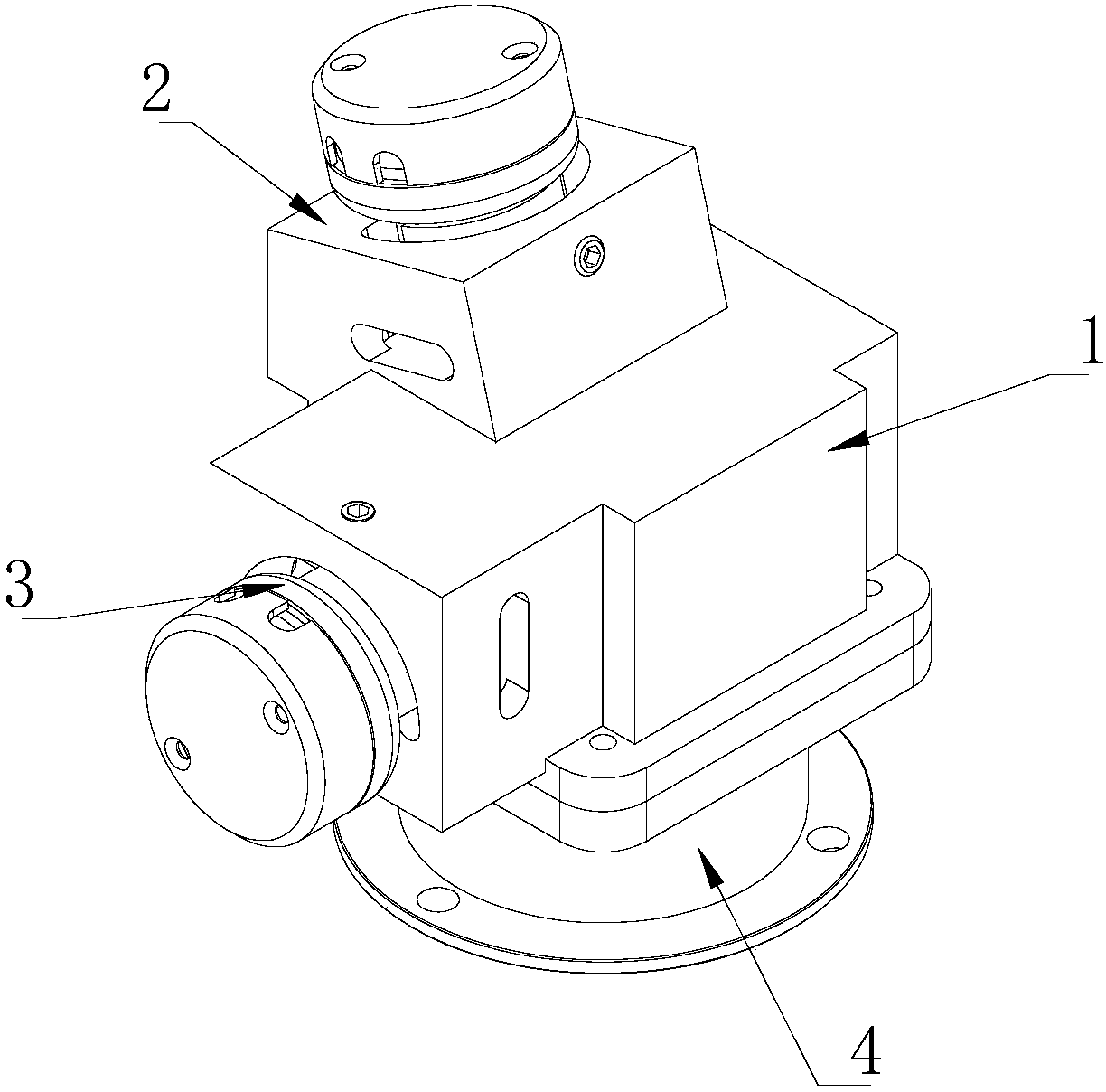

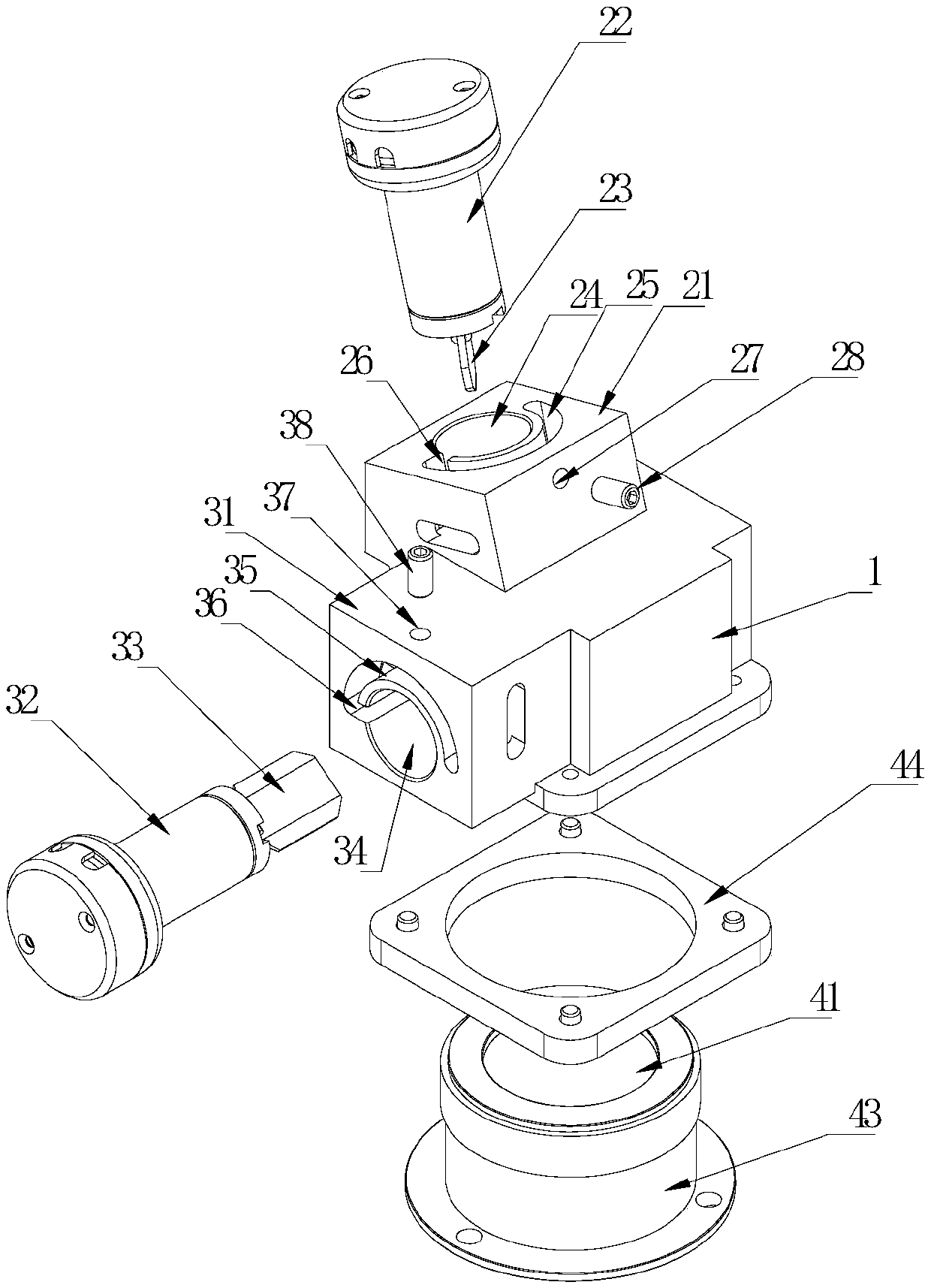

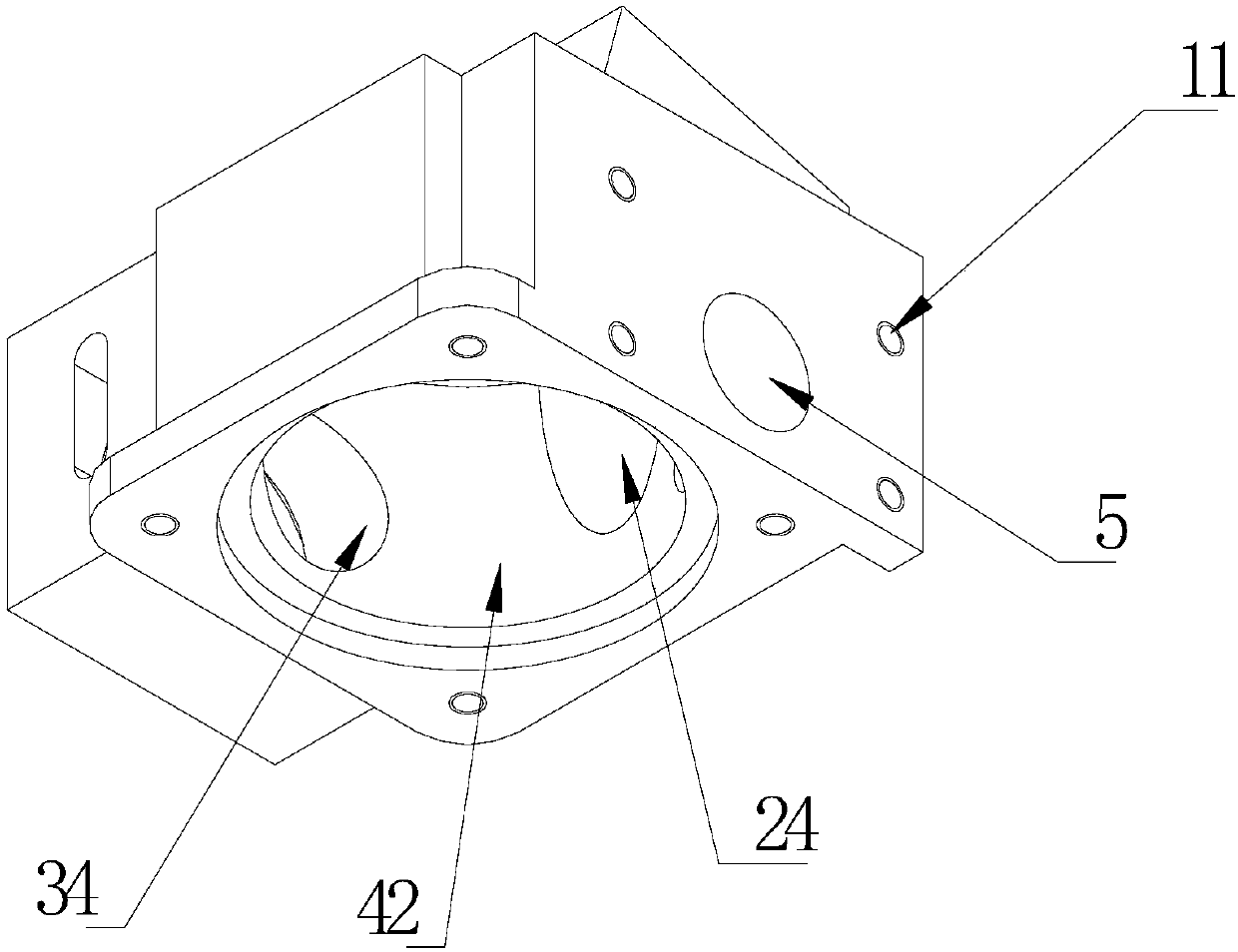

[0038] This embodiment provides a kind of airtight scanning galvanometer device for laser machine, such as figure 1 -3, it should be noted that the "front" and "rear" in this embodiment both refer to the propagation of the laser light from front to back. The sealed scanning vibrating mirror device includes: base 1, X vibrating mirror mechanism 2, Y vibrating mirror mechanism 3, field mirror mechanism 4;

[0039] The X vibrating mirror mechanism 2 includes an X vibrating mirror motor 22, an X vibrating mirror lens 23 driven by the X vibrating mirror motor 22, and an X vibrating mirror seat 21. The X vibrating mirror seat 21 is provided with an X retainer for fixing the X vibrating mirror motor 22. Hole 24.

[0040] The X vibration lens 23 is fixedly connected to the output shaft of the X vibration mirror motor 22, and the X vibration mirror motor 22 drives the X vibration lens 23 to swing.

[0041] The Y vibrating mirror mechanism 3 includes a Y vibrating mirror motor 32, a Y...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com