Full-automatic wafer rear marking machine

A marking machine, fully automatic technology, applied in the direction of conveyor objects, electrical components, semiconductor/solid-state device manufacturing, etc., can solve the problems of high equipment cost and material cost, slow marking speed, etc., to improve marking quality, The effect of faster opening speed and higher production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

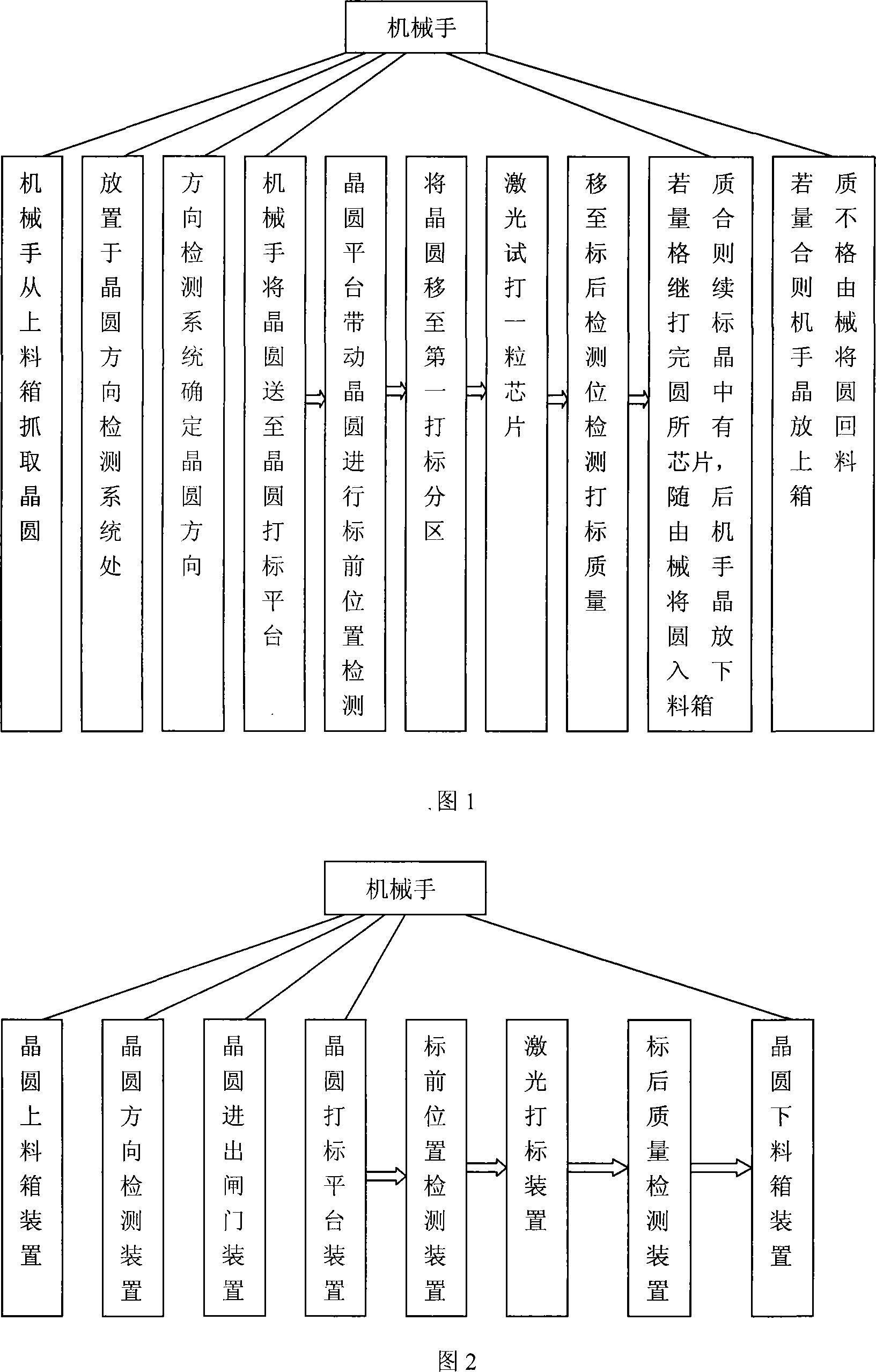

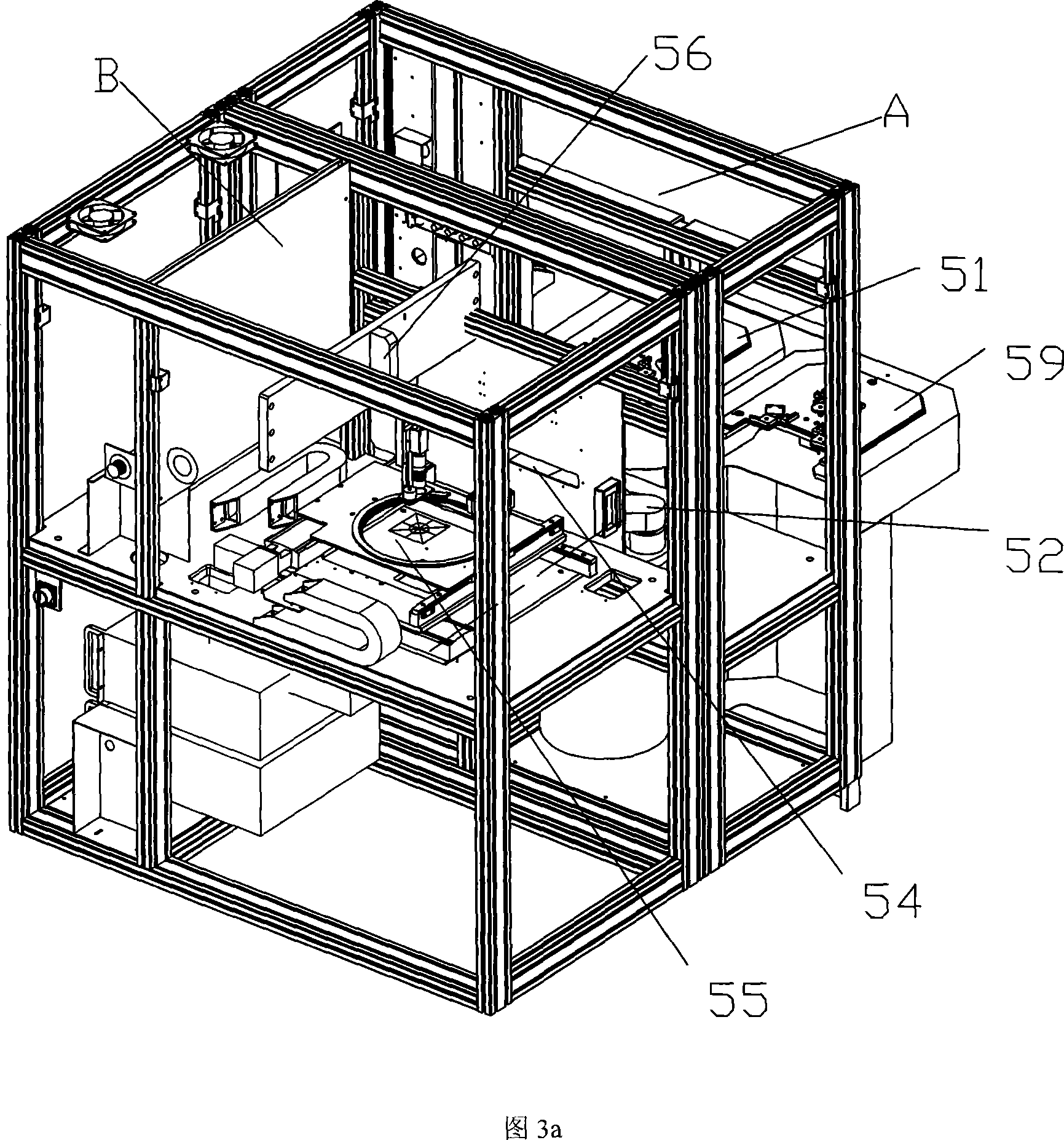

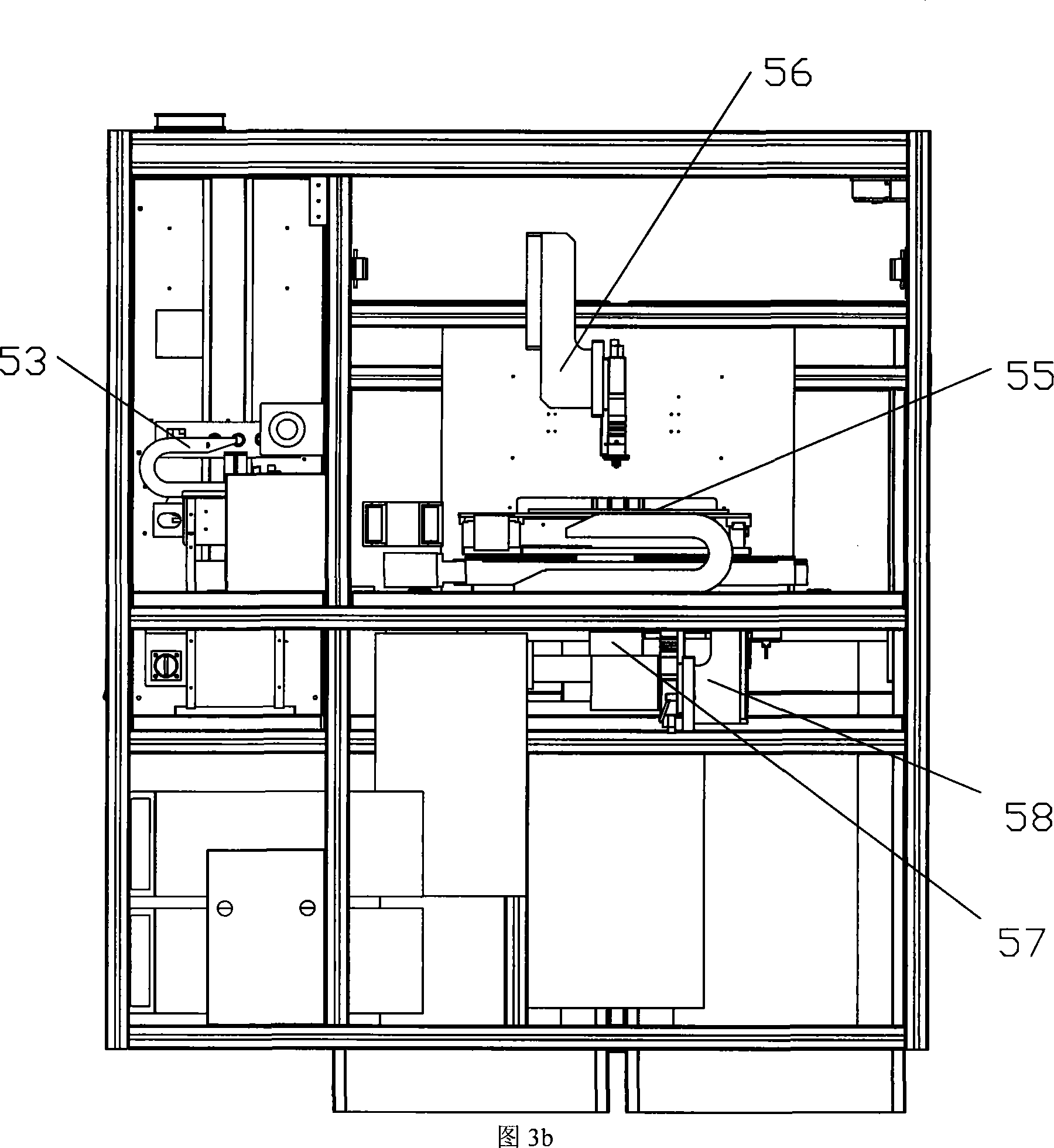

[0034] As shown in Figure 3a to Figure 3d, a fully automatic marking machine for the back of a wafer is composed of front and rear areas, wherein an electric control device 510 and a PC 511 are arranged on the front area, A partition is provided between the front area A and the rear area B, and a gate import and export device 54 is arranged on the partition, and an upper material box device 51 and a lower material box device 59 are arranged on the outside of the front area A, and the front area A A manipulator 52 and a wafer direction detection device 53 are provided inside the rear area; a wafer marking platform device 55 is provided inside the rear area, and a pre-marking detection device 56 and a post-marking detection device are respectively provided above and below the marking platform device 55 58.

[0035] As shown in Figures 4a to 4d, the described loading box device includes a box support frame 7, a box seat 6 installed on the box support frame 7, and a box cover 1 pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com