Inner hole laser marking equipment used for sucker rod coupling and marking method thereof

A technology of laser marking equipment and laser marking methods, applied in typewriters, printing, etc., can solve the problems of easy wear and tear of lettering, high manual labor intensity, and poor marking quality, so as to achieve protection traceability, improve production efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

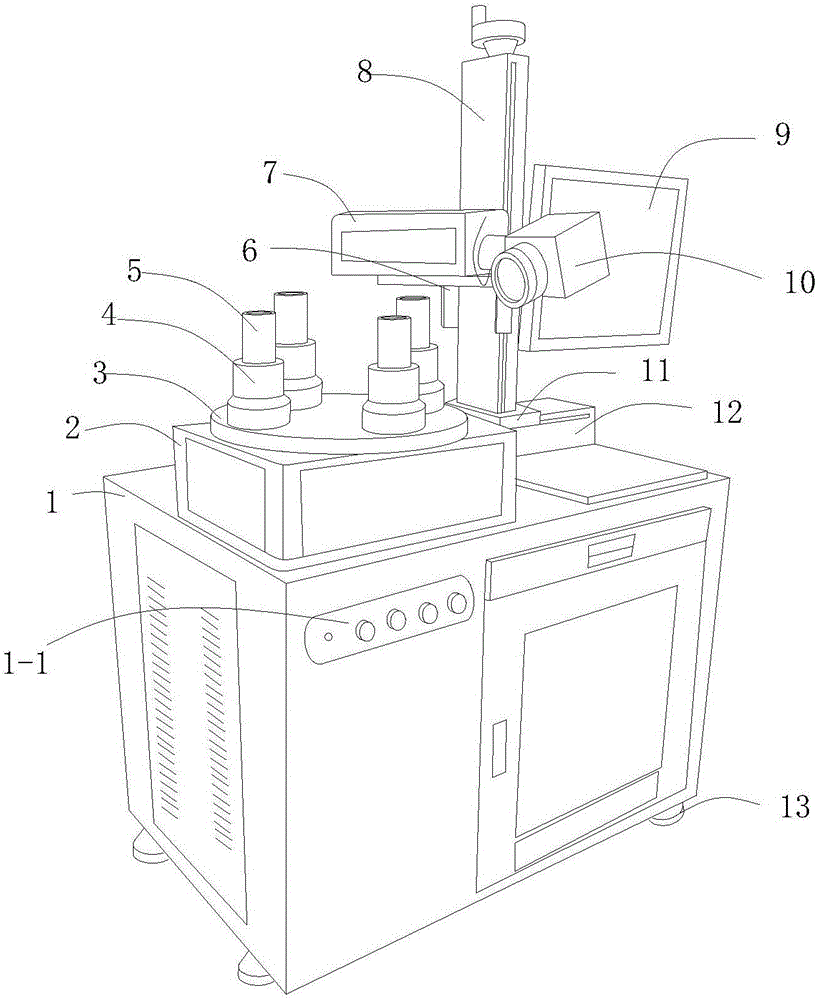

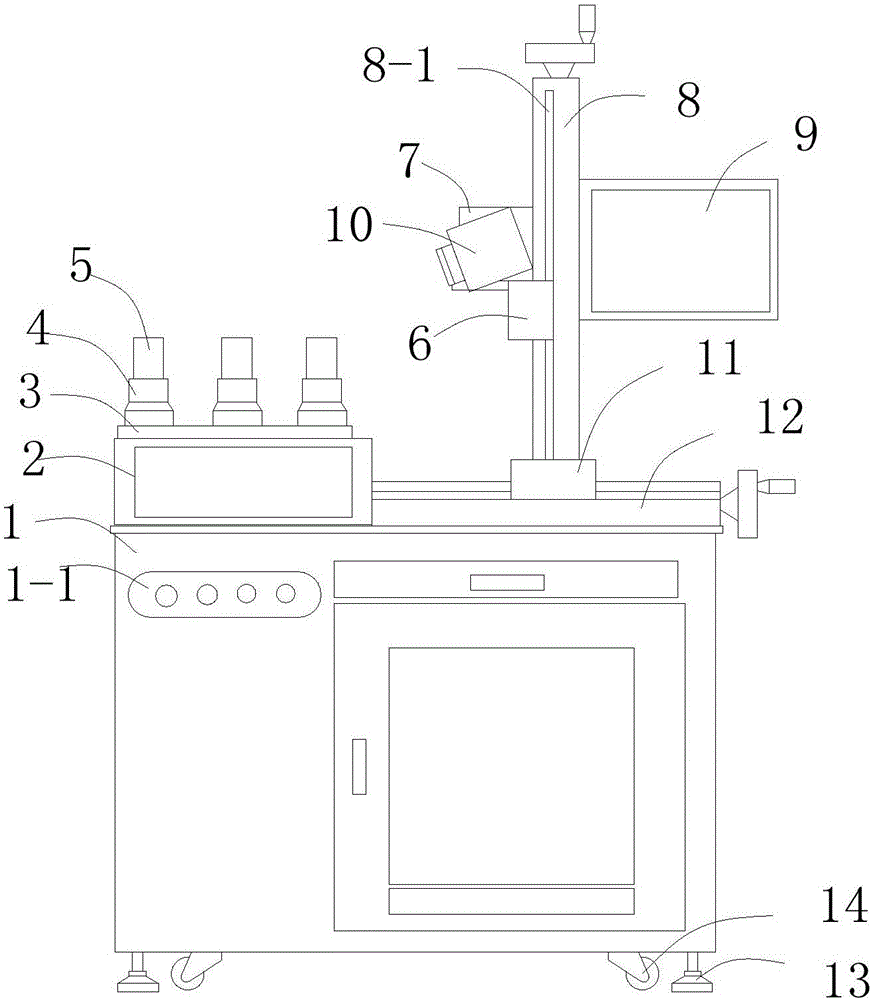

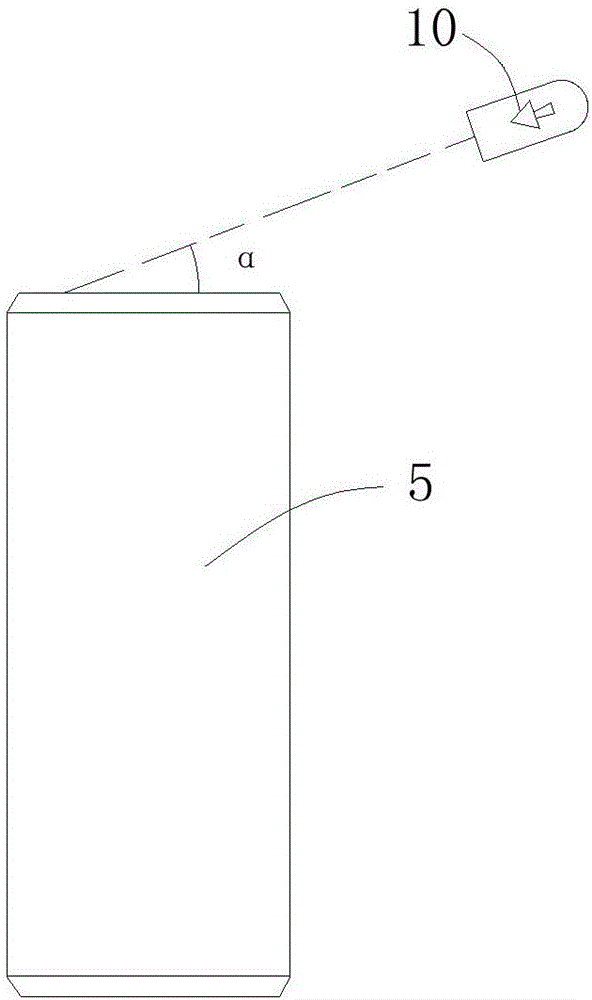

[0045] Such as Figures 1 to 3As shown, this embodiment provides a laser marking device for inner holes of sucker rod couplings, including an electric control cabinet 1, an intermittent divider 2 is arranged on the electric control cabinet 1, and a turntable is connected to the intermittent divider 2 3. The intermittent divider 2 controls the intermittent rotation of the turntable 3. On the turntable 3, there are a plurality of receiving sleeves 4 for installing the collar 5 to be marked evenly distributed on the circumference. The side of the intermittent divider 2 on the electric control cabinet 1 is provided with The horizontal guide rail 12 is connected with the vertical support 8 that can reciprocate along the horizontal guide rail 12 through the clip A11. The vertical support 8 is provided with a vertical guide rail groove 8-1, and the vertical support 8 One side is provided with a laser 7 that moves up and down along the vertical rail groove 8-1, and a rotating laser he...

Embodiment 2

[0050] This embodiment is further improved on the basis of Embodiment 1, specifically:

[0051] The rotating laser head 10 can rotate 360° around the laser 7 .

[0052] The number of said receiving sleeves 4 is four.

[0053] The laser adopts 100-200W fiber laser from Chongqing Liangke Laser Technology Co., Ltd.

Embodiment 3

[0055] This embodiment is further optimized on the basis of embodiment 1 or 2, specifically:

[0056] The receiving sleeve 4 is plug-fitted with the collar 5 to be marked, and three spring duck tongues are arranged in the receiving sleeve 4 to assist in pressing the collar 5 to be marked.

[0057] The receiving sleeve is mated with the coupling to be marked, and there are three spring duck tongues in the sleeve to assist in pressing the coupling to be marked. The built-in spring solves the problem caused by the slight difference in the outer diameter of the same model product. The clamping problem; the duck tongue provides an effective contact length in the axial direction, which ensures the automatic centering of product installation and increases the marking quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com