Device for producing and machining mailboxes

A letterbox and work frame technology, applied in decorative arts, embossed ornaments, etc., can solve problems such as low work efficiency, poor marking effect, and unguaranteed quality, and achieve convenient operation, simple structure, and improved marking speed and quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

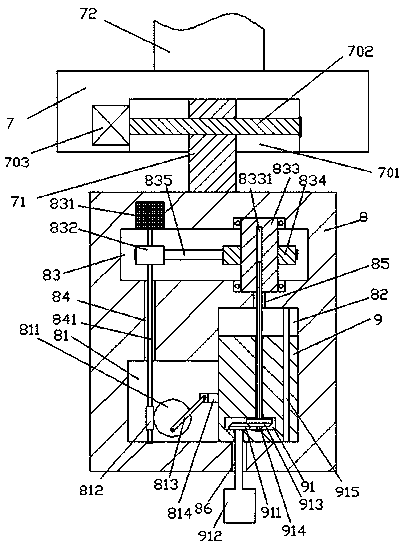

[0010] Such as Figure 1-Figure 2 As shown, a device for producing and processing letter boxes of the present invention includes a hanger 7 and a work frame 8 installed on the lower side of the hanger 7, and a hanger 702 is installed directly above the top of the hanger 7. The above-mentioned hanger 7 is provided with a left and right cavity 701 with the mouth facing downward, and a connecting column 71 that is expanded downward is installed in the left and right cavity 701 in translation, and the screw in the connecting column 71 is equipped with a left and right expanding setting. Screw shaft 702, the right tail of the screw shaft 702 is rotationally connected with the right end wall of the left and right chambers 701, the left tail of the screw shaft 702 is mounted in cooperation with the main motor 703, and the outer surface of the main motor 703 is installed It is fixedly fitted and connected in the left end wall of the left and right cavity 701, and the bottom end surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com