Laser marking machine

A laser marking machine and laser technology, used in typewriters, printing and other directions, can solve the problems of difficult matching, high consumption, affecting work efficiency, etc., to save the waste of materials, waste of labor hours, and the rate of defective products. The effect of reducing and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

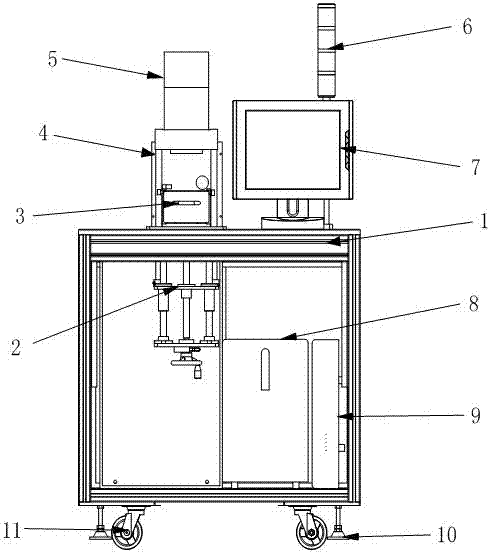

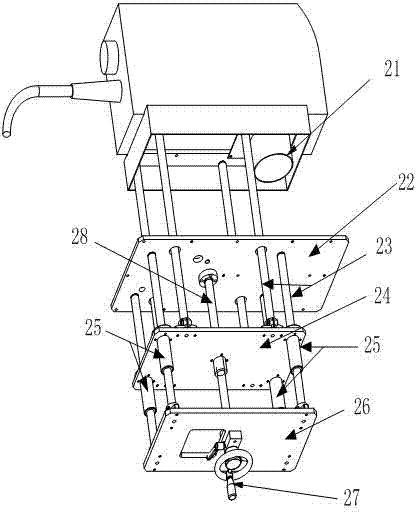

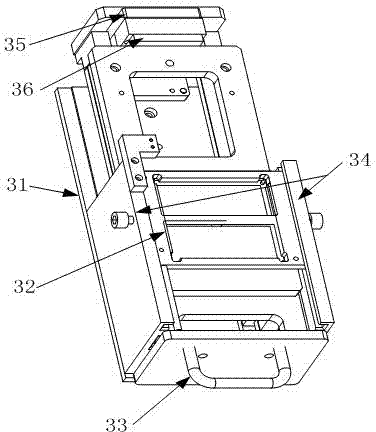

[0018] Such as figure 1 As shown, the laser marking machine includes a frame 1. The frame 1 is a cube made of profiles and a hollow workbench in the middle. A transmission device is fixed on one side of the workbench through a transmission fixing plate 22. The transmission device is based on the table surface of the workbench. It is divided into laser part 4 and transmission part 2. The laser part 4 is located above the table top, and the transmission part 2 is located below the worktable table and in the hollow of the workbench. The transmission part 2 cooperates with the laser part 4 through the transmission pair 28 , the top of the laser part 4 is provided with a laser head device 5, and the transmission fixing plate 22 of the transmission device is fixed with a sliding table mechanism 3, and the sliding table mechanism 3 is in the inside of the laser part 4, and the sliding table mechanism 3 and the laser head device 5 Cooperate with each other, the other side of the workb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com