Batch marking equipment for triangular marks of oil casing screwed joints

A technology for threaded joints and oil casings, applied in printing, typewriters, etc., can solve the problems of time-consuming cost, affecting marking quality, and prone to misalignment, reducing labor and time costs, improving marking quality, and reducing misalignment. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

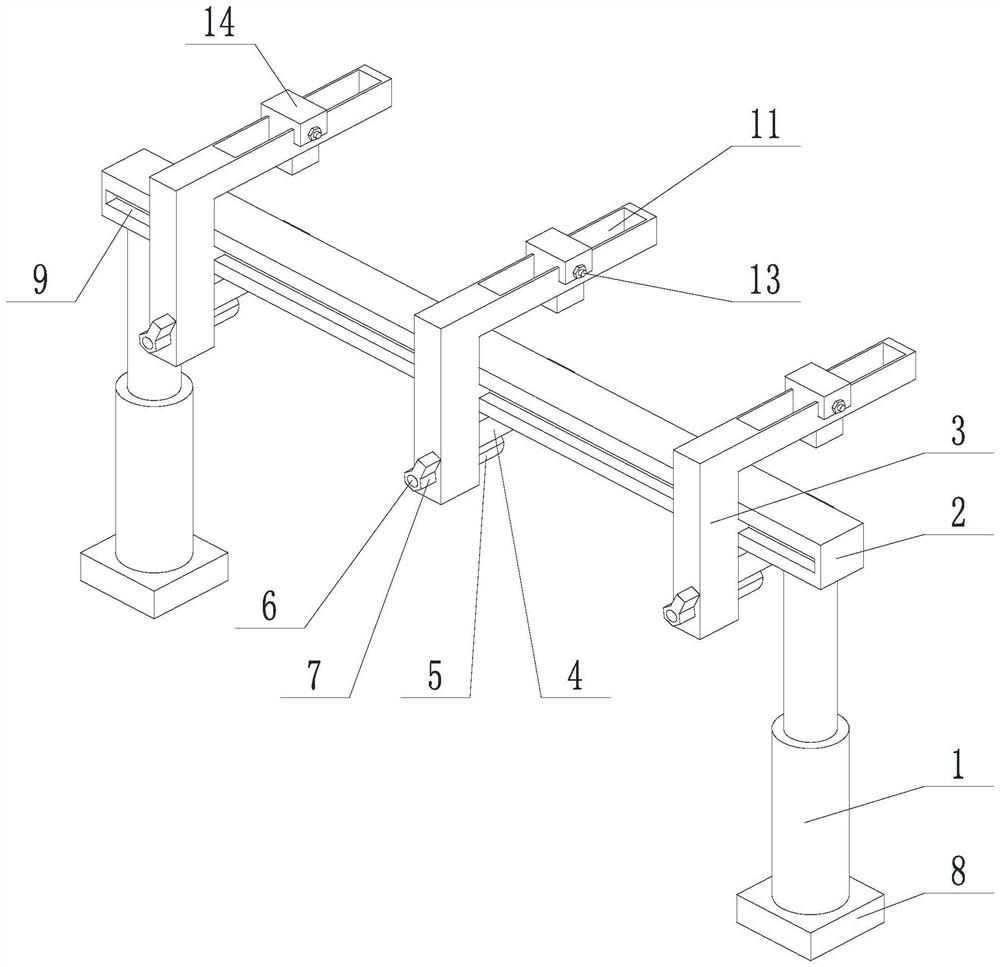

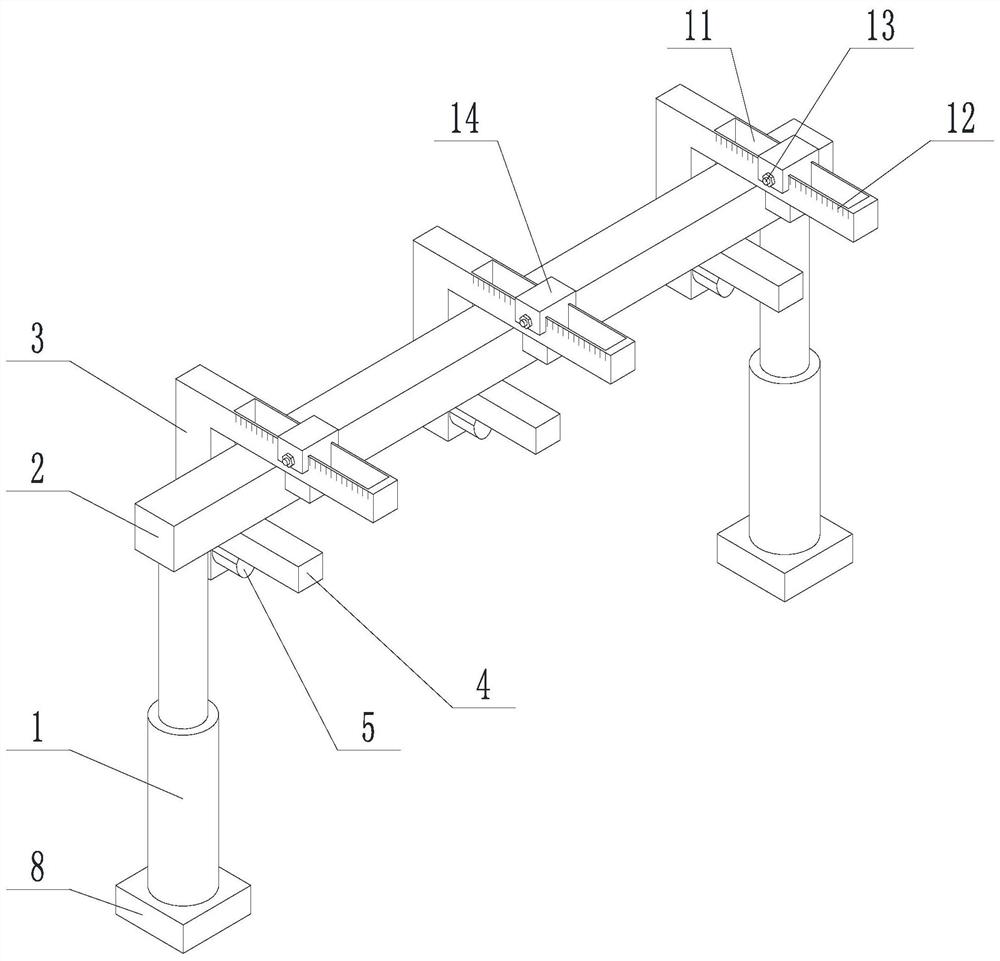

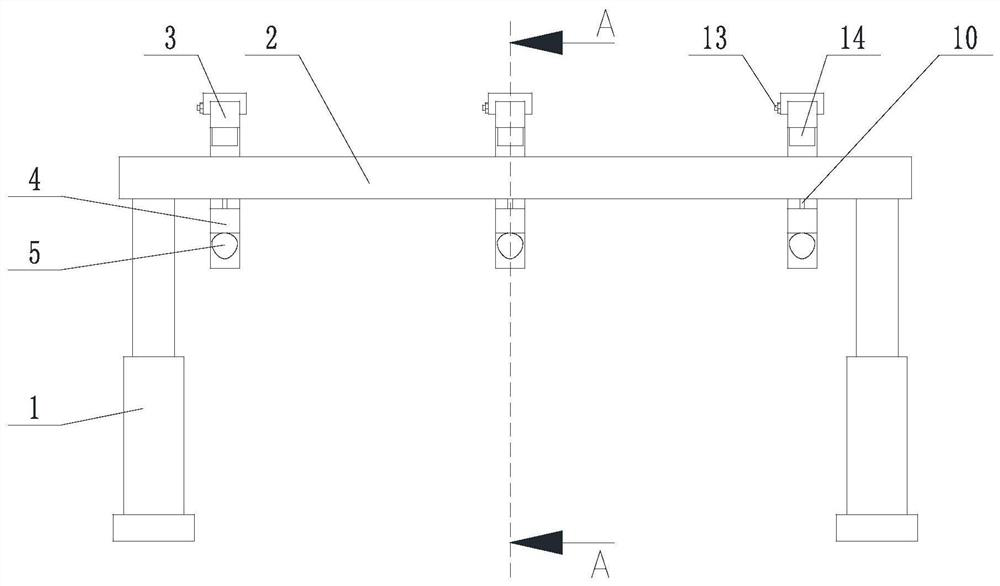

[0048] Such as Figure 1 to Figure 4 The shown oil casing threaded joint triangular mark batch marking equipment includes two support legs 1, a cross bar 2 fixed between the two support legs 1, and a plurality of L-shaped pieces 3 are connected to the cross bar 2. One end of the L-shaped piece 3 is slidingly fitted with the side of the crossbar 2, and the other end is located above the crossbar 2 and straddles the crossbar 2. The L-shaped piece 3 can slide along the axis of the crossbar 2; it also includes a sliding fit on the L-shaped piece 3 on the clamping piece 4, the clamping piece 4 can slide in the longitudinal direction, the clamping piece 4 is located below the cross bar 2 and crosses the cross bar 2, a cam 5 is arranged under the clamping piece 4, and the cam 5 is formed by The drive mechanism is driven to rotate; the end of the L-shaped piece 3 above the cross bar 2 is also provided with a marking assembly. The driving mechanism includes a rotating shaft 6 fixedly ...

Embodiment 2

[0051] Such as Figure 1 to Figure 6 In the shown oil casing threaded joint triangular mark batch marking equipment, on the basis of Embodiment 1, the end of the L-shaped piece 3 above the cross bar 2 is provided with a through groove 11 communicating up and down, and the through groove 11 The long axis is perpendicular to the axis of the cross bar 2 , and the marking assembly can slide along the slot 11 . A scale 12 is provided on the outer wall of the through groove 11 ; and a set bolt 13 for locking the marking assembly on the through groove 11 is also included. The marking assembly includes a slider 14 slidably connected to the through groove 11, a housing cavity 15 is provided at the bottom of the slider 14, and a stamping block 16 is slidably fitted in the housing cavity 15, and a die 17 is arranged at the bottom of the stamping block 16. A threaded blind hole 18 is provided on the top of the stamping block 16; a screw rod 19 matching the threaded blind hole 18 is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com