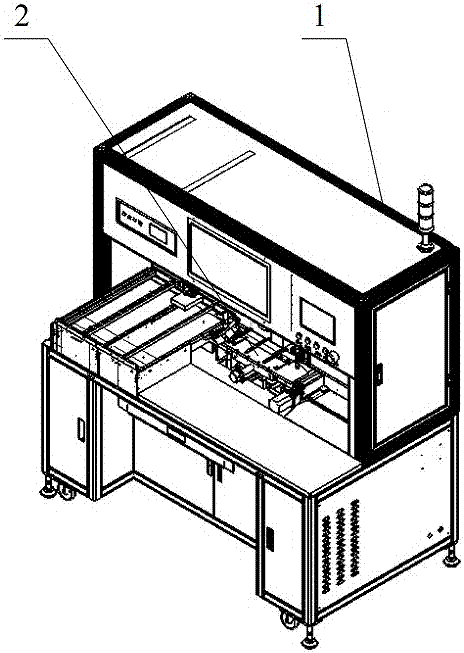

Automatic lithium battery laser marking machine

A laser marking and lithium battery technology, applied in laser welding equipment, welding equipment, metal processing, etc., can solve problems such as low efficiency, inability to guarantee the labeling position and clarity, and inability to meet the huge needs of consumers and high quality requirements. , to achieve the effect of improving marking efficiency and improving marking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

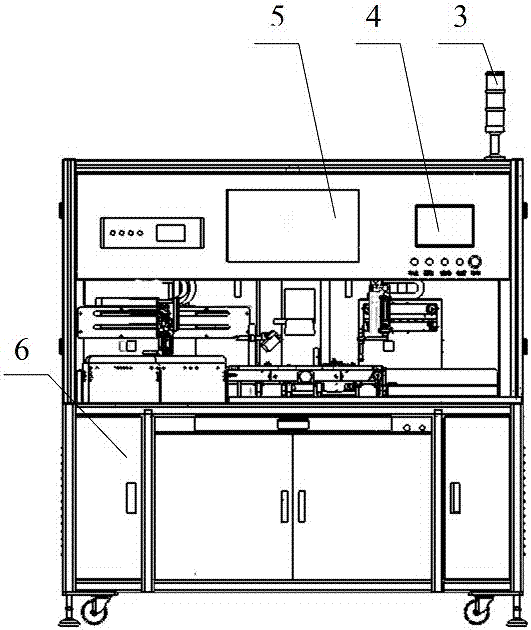

[0046] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0047] Put one group of lithium batteries into 7, the lithium battery input mechanism, and 7, the lithium battery input mechanism transports the lithium battery group to a blocking plate at the front end of 7, the lithium battery input mechanism for positioning.

[0048] Further, 8. The feeding moving mechanism uses 15. vacuum suction cups to pick up and place each lithium battery successively on 10. the middle conveyor belt assembly.

[0049] Further, 10. The central conveyor belt assembly transports the lithium battery to 9. The laser marking assembly. 9. 16. The laser marking device on the laser marking assembly starts to perform laser marking on the lithium battery.

[0050] Further, 10. The central conveyor belt component transports the laser-marked lithium battery to 19. The code scanning component. 19. The code scanning component scans the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com