Self-adaption lateral-bending-wear-resisting oil cylinder structure

An anti-side bending and self-adaptive technology, applied in the direction of fluid pressure actuators, etc., can solve the problems of cylinder straightness not as good as short stroke, direct contact, mutual scraping, too long installation distance, etc., so as to improve assembly efficiency and extend Service life, avoiding the effect of unilateral force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

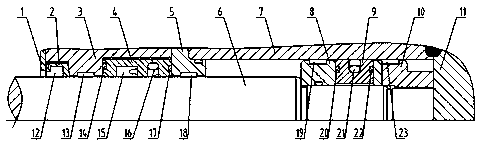

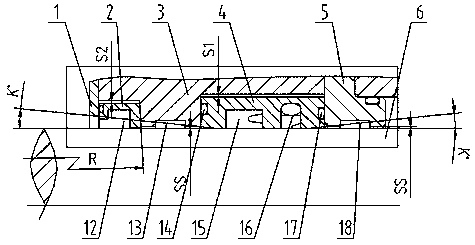

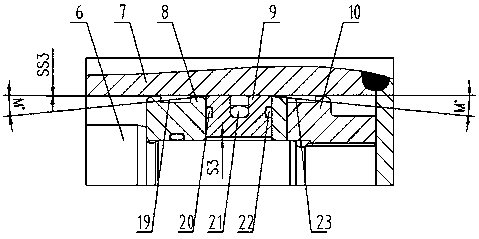

[0021] attached Figure 1-3 It is a specific embodiment of the present invention. The invention is an adaptive anti-side bending wear cylinder structure, including a cylinder 7, a piston rod end structure and a piston end structure, the cylinder 7 is provided with a piston rod 6, the cylinder 7 and the piston rod 6 The piston rod end structure and the piston end structure are respectively provided with separate support structures and sealing structures. The piston end structure is located at the end of the piston rod 6 in the cylinder barrel 7 close to the cylinder bottom 11, and the piston rod at the other end of the piston rod 6 The end structure is located at the cylinder 7, a guide sleeve is provided between the gland 1 and the cylinder 7, and the sealing structure is located between the guide sleeve and the piston rod 6.

[0022] Further, the supporting structure of the piston end structure includes a first split piston 8 and a second split piston 10, the sealing structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com