Heavy six-link 180-degree casement hinge

A six-link and link technology, which is applied to hinges with pins, door/window fittings, folding panels, etc., can solve the problems of affecting the bearing strength of the window sash, the installation connection is not firm, and the thickness of the link is limited, and the connection is achieved. Quick and convenient, increase thickness, and optimize the effect of matching clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

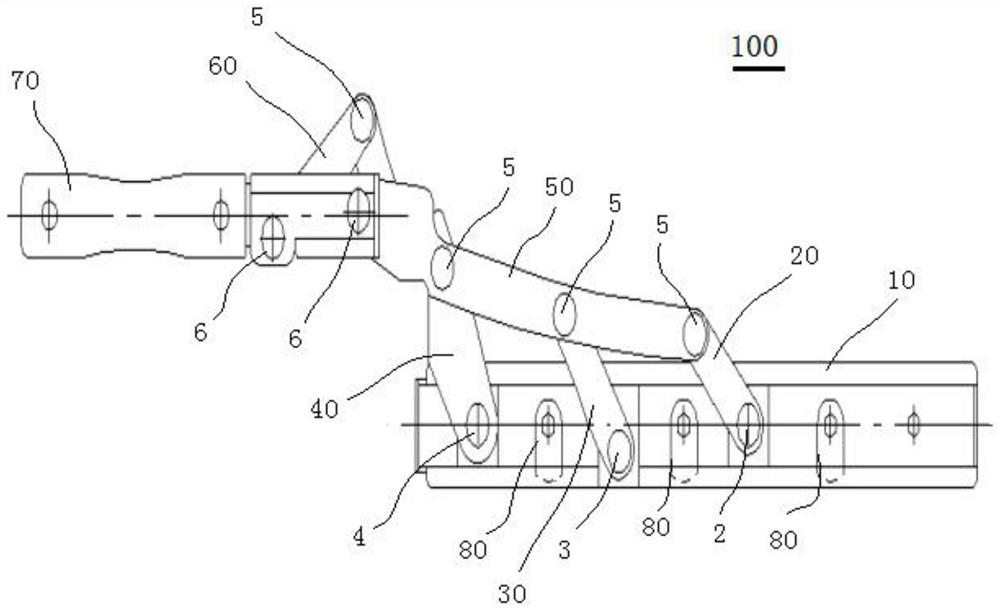

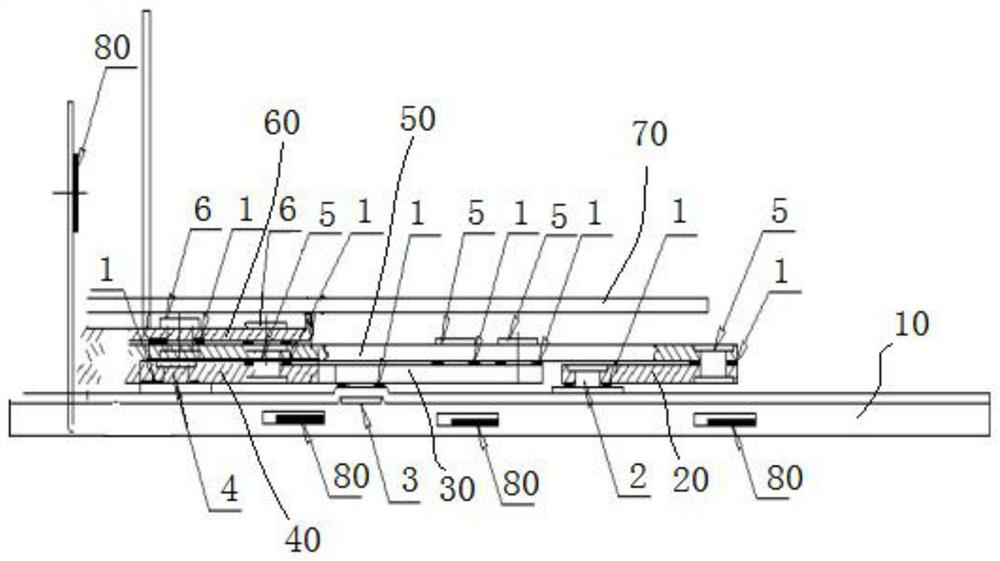

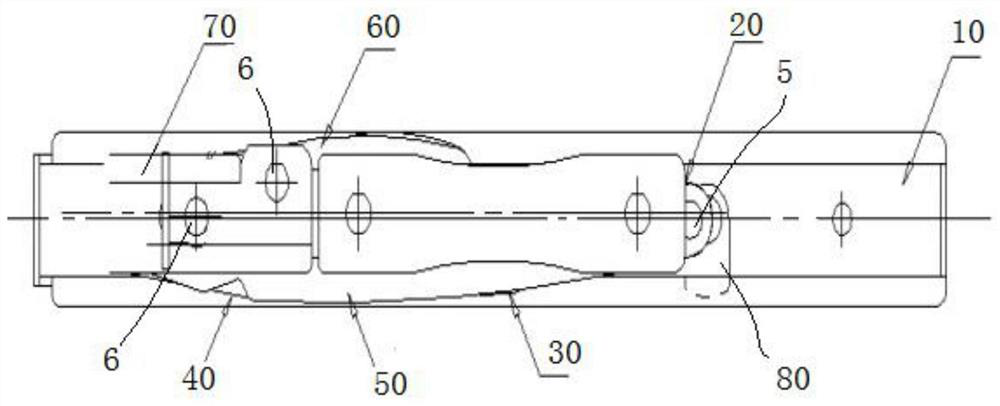

[0056] figure 1It is a schematic structural diagram of a heavy-duty six-link 180° casement hinge in an open state according to an embodiment of the present application. figure 2 yes figure 1 Schematic front view of the heavy six-link 180° casement hinge shown in the closed state. image 3 yes figure 2 top view. Figure 4 yes figure 2 side view. Such as figure 1 shown, see also Figure 2-Figure 4 , this embodiment provides a heavy-duty six-link 180° casement hinge, which is used to be installed on a window to drive the window to open or close. The window includes a window frame and a window sash. The heavy-duty six-link 180° flat hinge is made of metal, including: a grooved bottom plate 10, a starting link 70, a short link 60, a long link 50, a long link 40, a middle link 30 and Short branch link 20. The grooved bottom plate 10 is used to be installed at the window frame, and the grooved bottom plate 10 is provided with a one-way hanging piece configured to quickly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com