Vibration reduction type electrode tool for mold machining and vibration reduction method

A technology for mold processing and tooling, which is applied in the field of vibration-absorbing electrode tooling and vibration reduction for mold processing, can solve problems such as the decline in the processing quality of the mold cavity surface, the vibration of the electrode tooling rod, and the electrode wear, so as to improve the processing quality and realize the Vibration reduction measures, the effect of reducing electrode wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

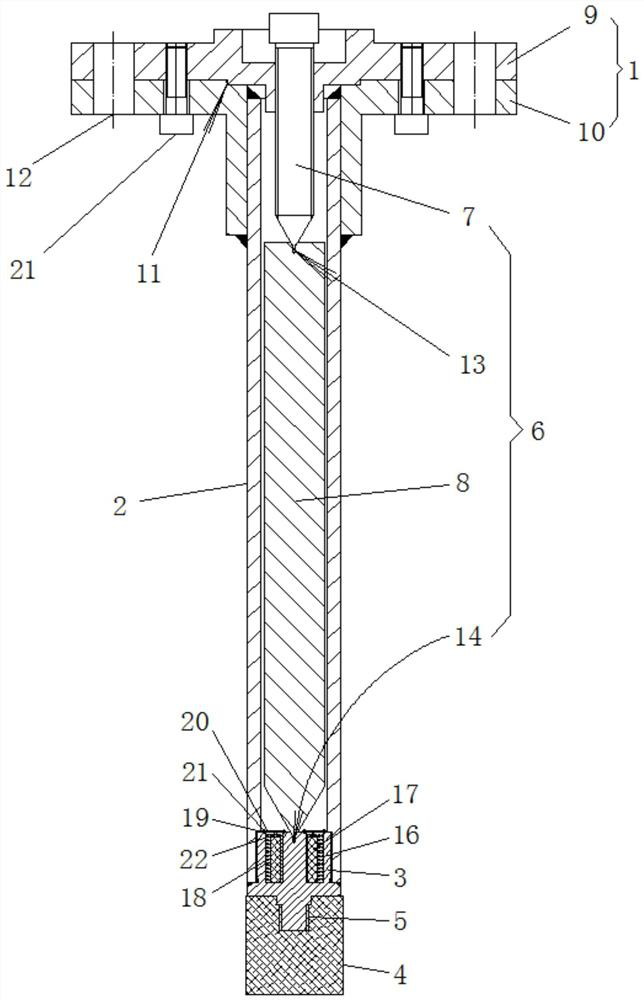

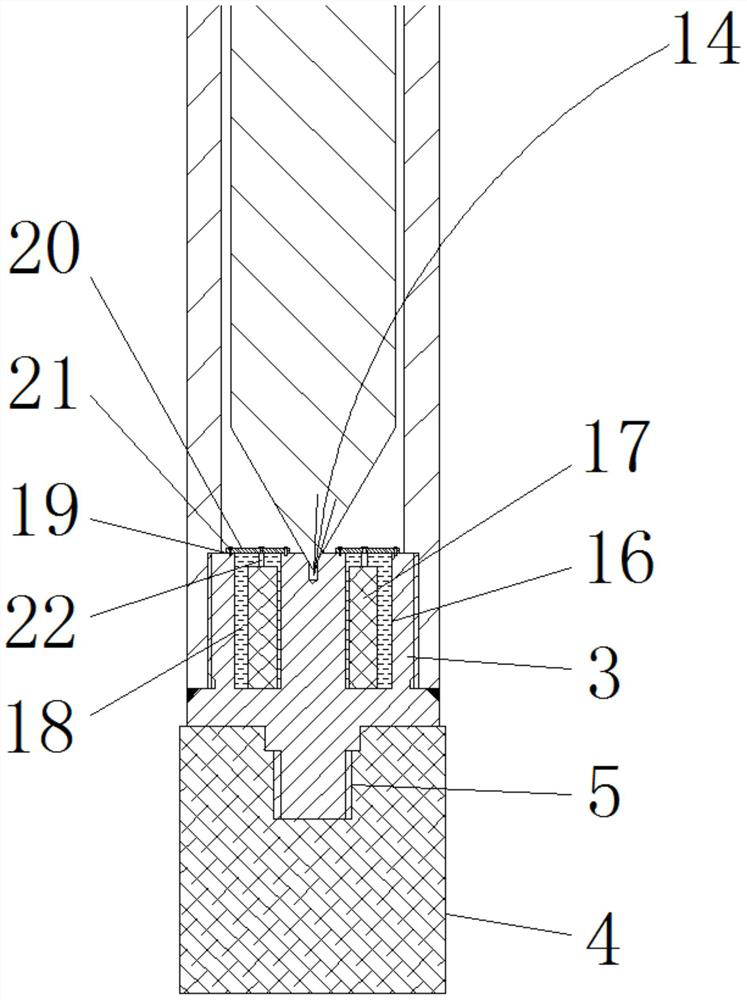

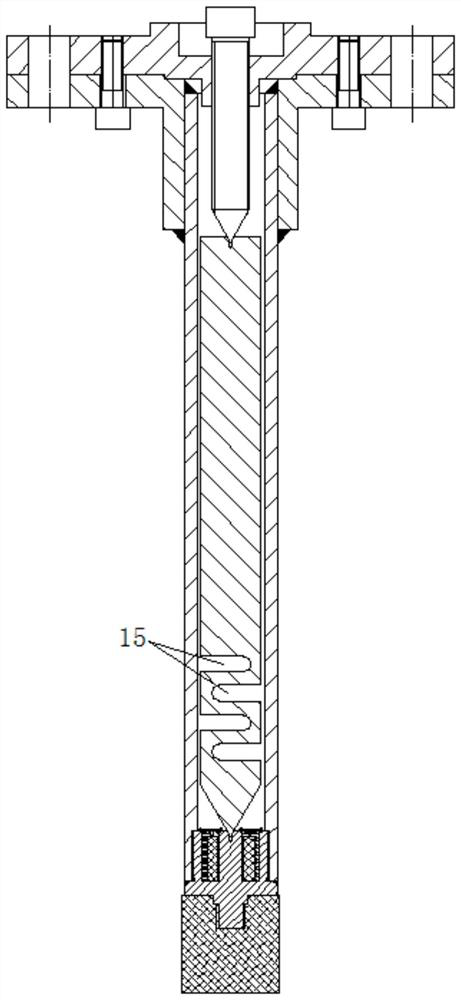

[0038] like Figures 1 to 3 Shown is an embodiment of a vibration-damping electrode tooling for mold processing of the present invention, including a base 1 for connecting with the spindle of an electric discharge machine tool, and a tube body 2 erected in the middle of the base 1 , the threaded bulkhead 3 arranged at the cantilever end of the pipe body 2 through thread fit connection, the threaded connection column 5 arranged at the front end of the threaded bulkhead 3 for installing the electrode 4, the axial direction of the pipe body arranged in the pipe body 2 Tensile vibration damping device 6, the axial tension vibration damping device 6 of the pipe body includes a threaded thimble 7 arranged at the center of the base 1, arranged in the pipe body 2 and located between the threaded bulkhead 3 and An axial ejector rod 8 between the threaded ejector pins 7 is used to apply an axial tensile pre-tightening force to the tubular body 2 .

[0039] In order to facilitate the ad...

Embodiment 2

[0049] A method of vibration reduction using the vibration-damping electrode tooling for mold processing of Embodiment 1, comprising the steps of:

[0050] (1) Tooling preparation: design and manufacture a vibration-damping electrode tooling in advance; wherein, the damping fluid 18 in the vibration-damping electrode tooling is prepared in advance with several damping fluids 18 of different viscosity specifications for replacement according to the size of the viscosity; The annular damping ring 17 in the vibration-damping electrode tooling is prepared in advance with several types of annular damping rings with different matching clearances according to the size of the matching gap between the inner hole of the annular damping ring 17 and the adjacent side of the annular groove 16 17 for replacement;

[0051] (2) Test piece installation: install a test piece instead of mold parts on the EDM machine tool;

[0052] (3) Electrode tooling installation: install the electrode toolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com