Valve stem coupled high-pressure common rail injector

A high-pressure common rail and fuel injector technology, applied in engine components, machines/engines, fuel injection devices, etc., can solve the problems of scrapped fuel injectors, drop of fuel injection pressure, poor sealing performance of fuel injectors, etc. The effect of reducing the use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

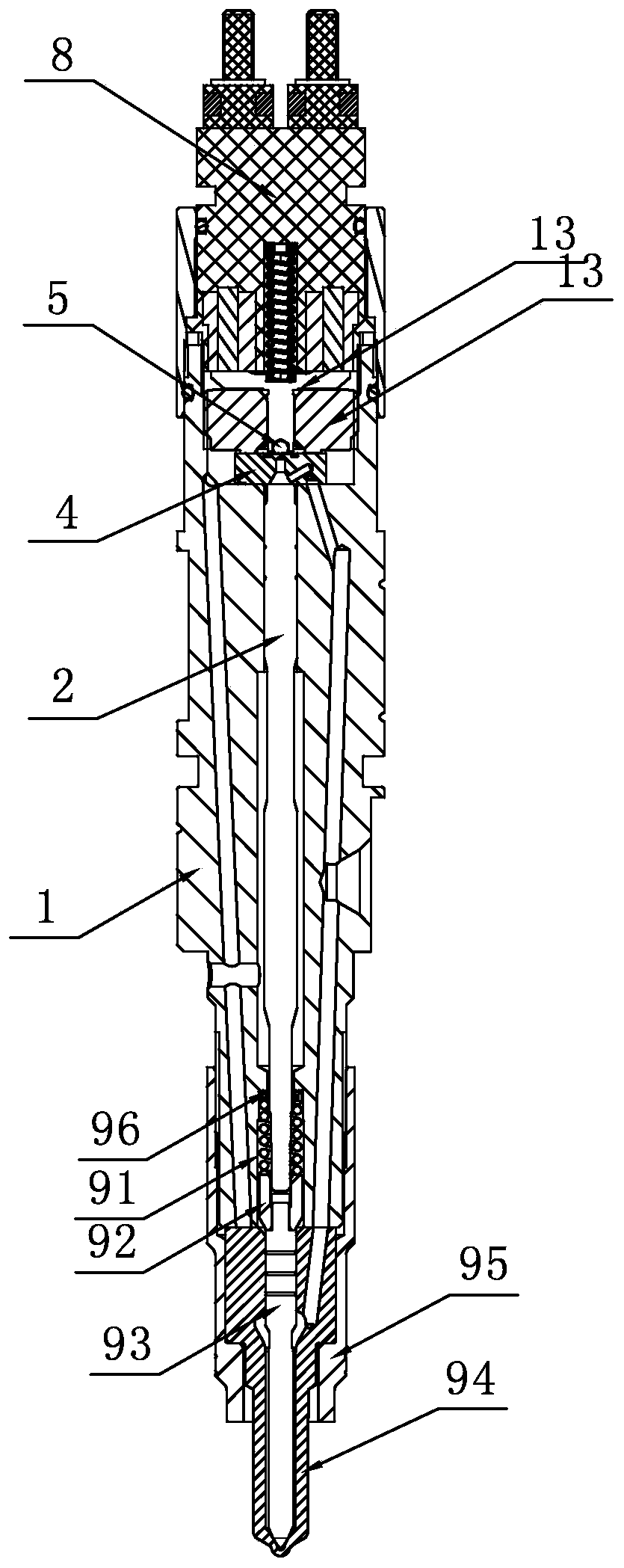

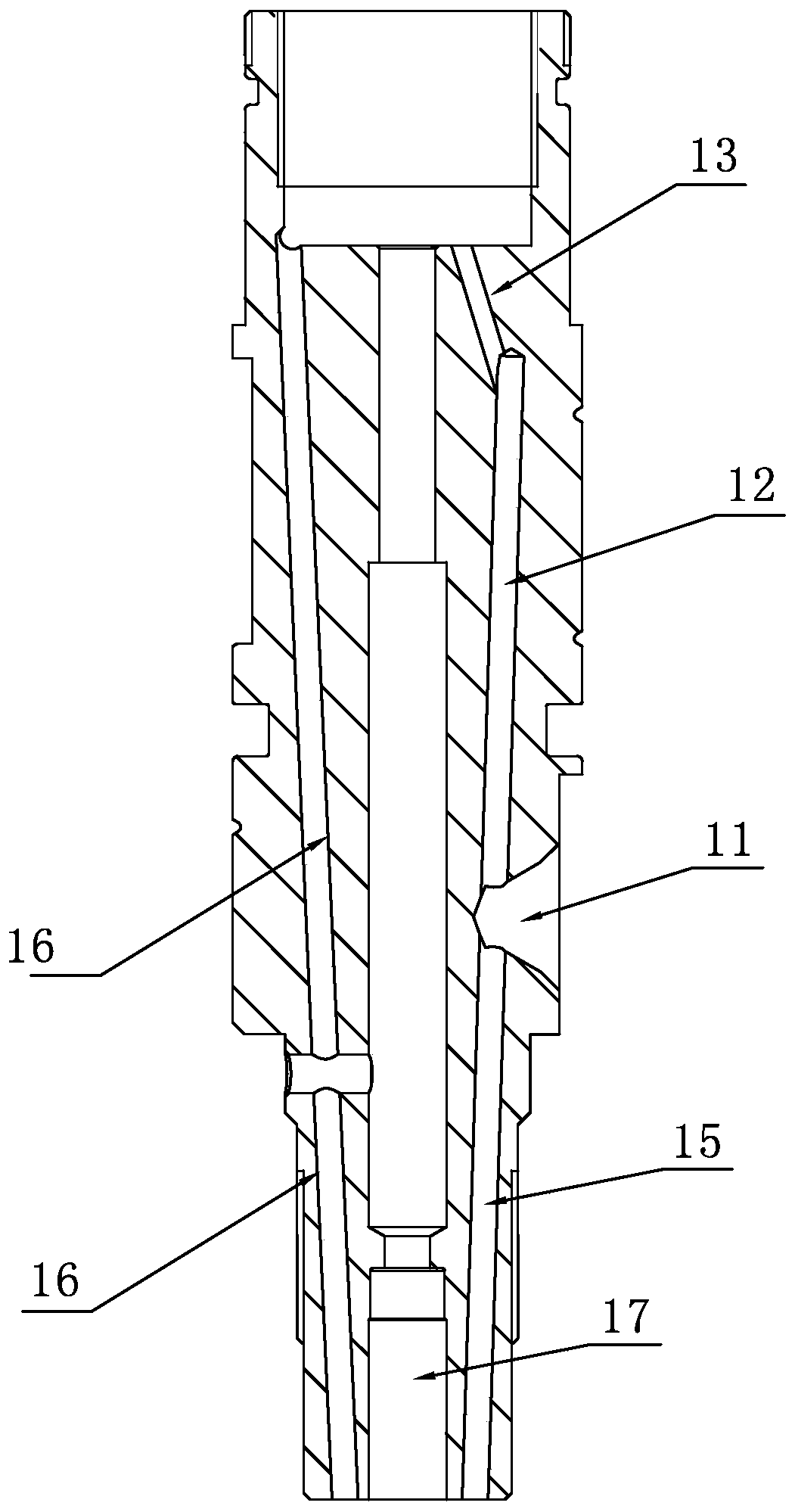

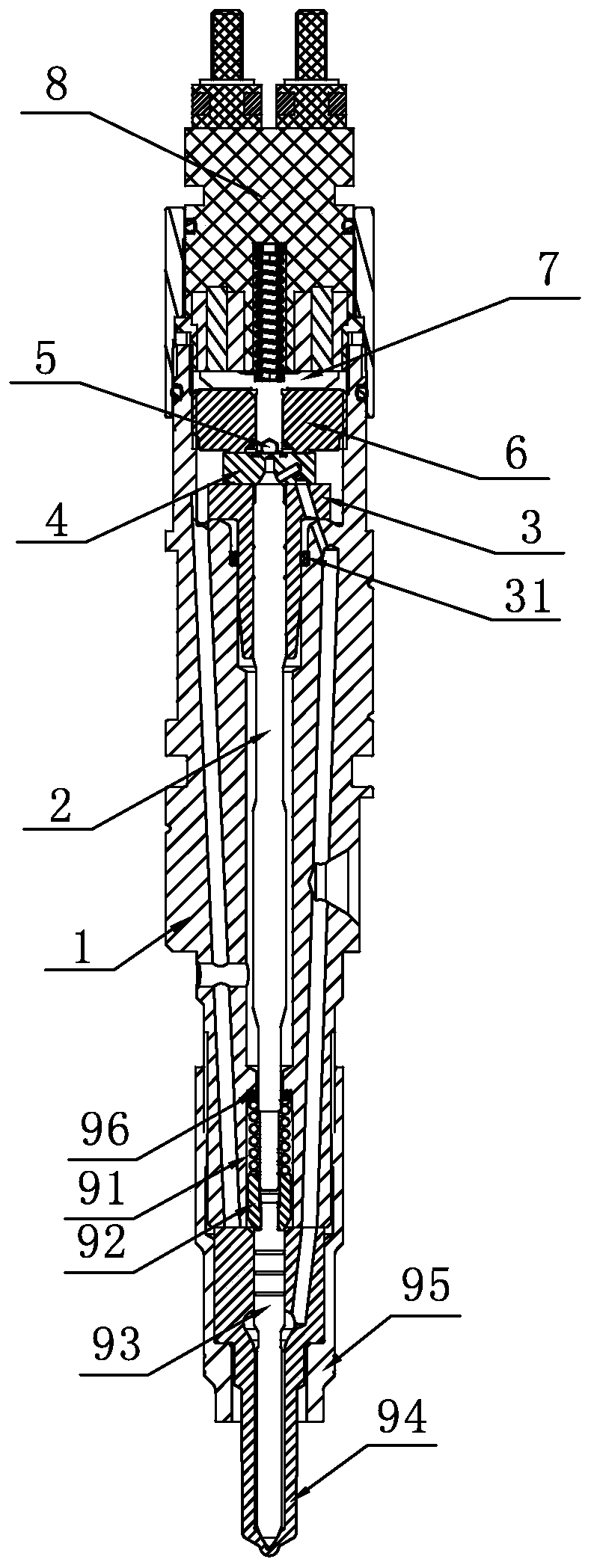

[0022] A high-pressure common rail fuel injector with valve stem coupling, Figure 3-Figure 5 As shown, it includes valve body 1, valve stem 2, valve stem sleeve 3, throttle body 4, sealing ball 5, iron-absorbing seat 6, iron-absorbing rod 7, solenoid valve parts 8, needle compression spring 91, double guide sleeve 92, The fuel injection valve needle 93, the fuel injection coupler sleeve 94 and the locking cap 95 are provided with an oil inlet hole 11, an upper and outer oil inlet passage 12, an oblique oil outlet hole 13, a lower outer oil inlet passage 15, Pressure relief oil passage 16, lower guide hole 17, pressure balance hole 18, valve stem sleeve seat hole 19, the valve stem sleeve 3 includes a shaft shoulder seat 31, a matching sleeve 32 and an oil inlet hole 33, and the valve stem sleeve 3 is matched by The sleeve 32 is installed in the valve stem sleeve seat hole 19, and there is a clearance fit between the two. The shoulder seat 31 is in contact with the upper end s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com