Drum type flying shears and gear pair return-clearance adjustment method

A flying shear and drum-type technology, which is applied to belts/chains/gears, shearing devices, mechanical equipment, etc., can solve problems such as difficult adjustments and poor shearing quality, and achieve simple equipment, high work efficiency, and reduced The effect of equipment weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

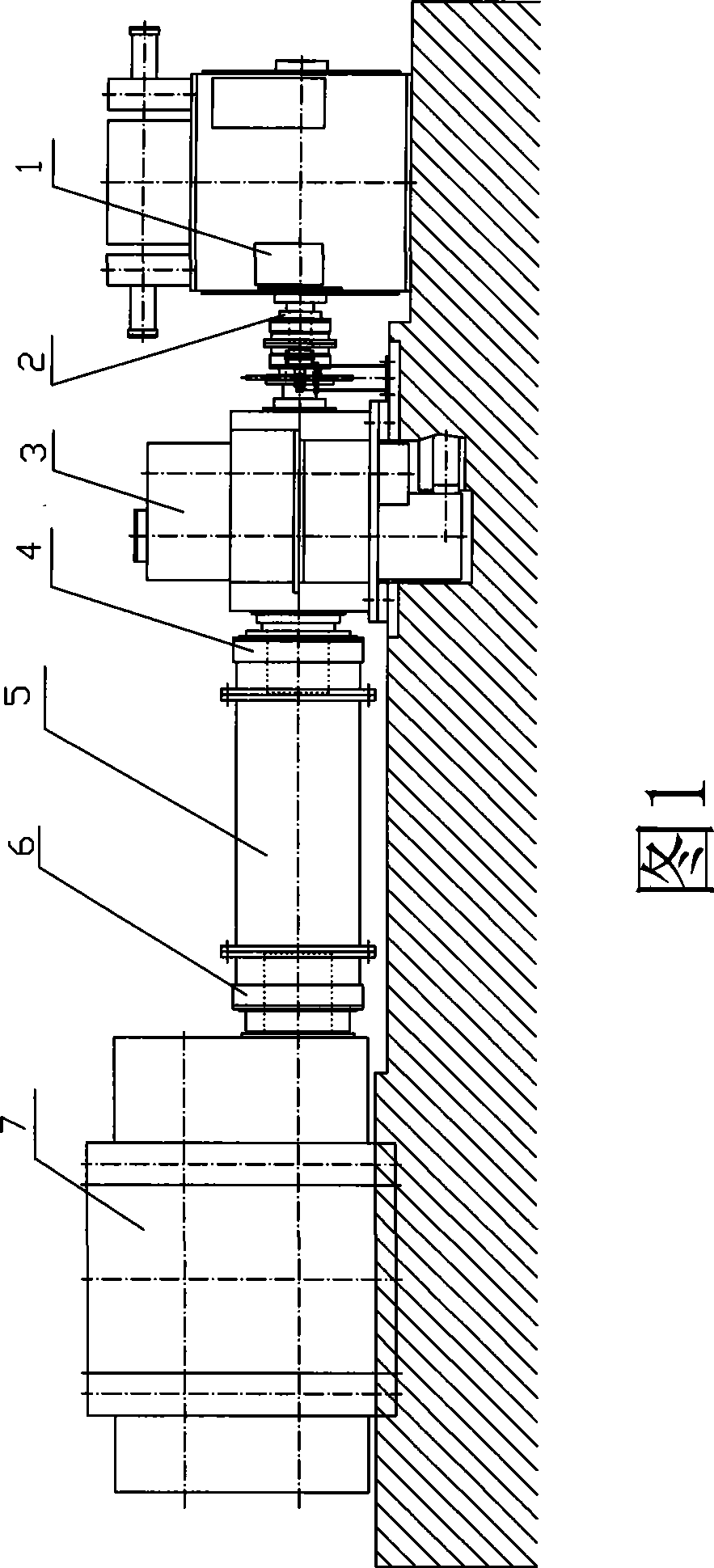

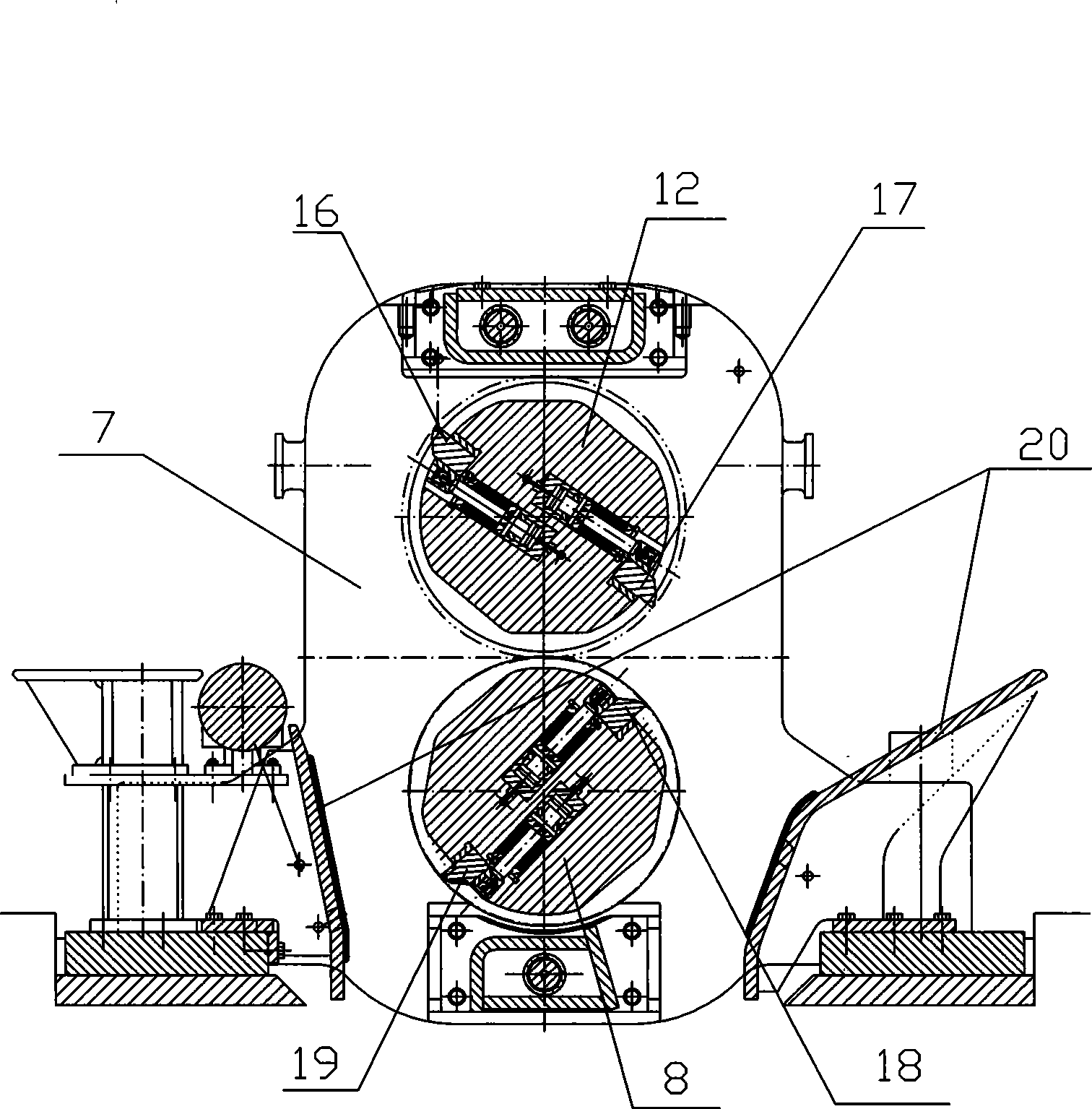

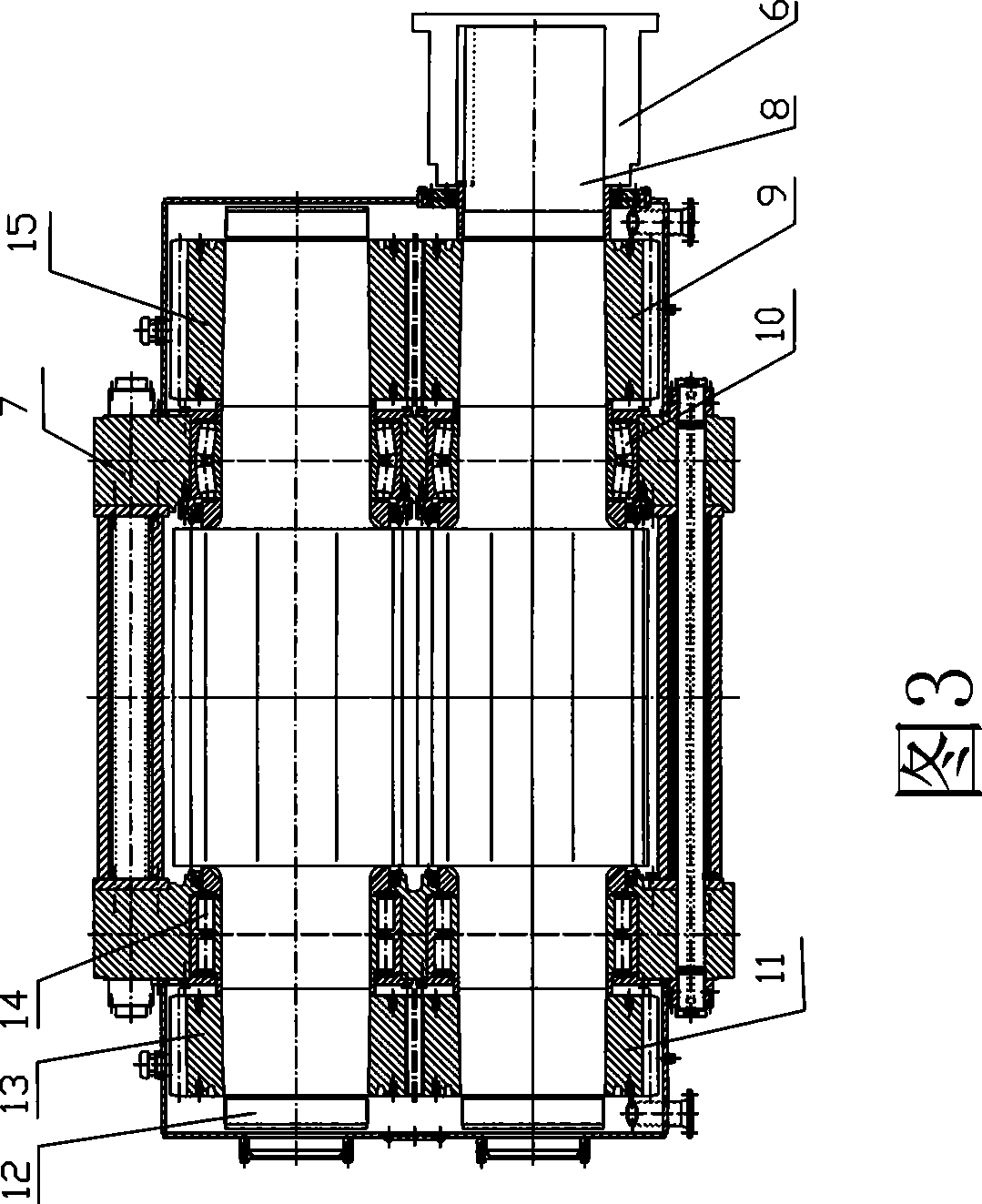

[0024] A drum-type flying shear machine as shown in Figures 1 to 3, including a motor 1, a coupling with a brake disc 2, a reducer 3, a coupling I 4, a transmission shaft 5, and a coupling II 6 , flying shear body 7, lower drum 8, gear I9, bearing I10, gear II 11, upper drum 12, gear III 13, bearing II 14, gear IV 15, cutting head upper cutting edge 16, cutting tail upper cutting edge 17 , cutting tail lower cutting edge 18, cutting head lower cutting edge 19 and baffle plate 20; the output shaft of motor 1 is fixedly connected with the input shaft of reducer 3 through coupling 2 with brake disc, and the output shaft of reducer 3 is through the coupling I 4 is fixedly connected with the transmission shaft 5, and the transmission shaft 5 is fixedly connected with the lower drum 8 through the coupling II 6; the lower drum 8 and the upper drum 12 are respectively supported on the flying shear body 7 by the bearing I 10 and the bearing II 14 The two ends of upper and lower drums 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com