Noodle rod putting conveying mechanism

A rack transfer and noodle bar technology, applied in the field of noodle bar upper rack transfer mechanism, to achieve simple equipment, reduce mechanical equipment failures, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

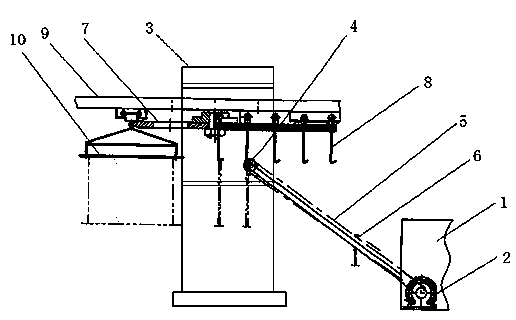

[0018] as attached figure 1 As shown, the noodle rod upper frame transmission mechanism of this embodiment includes a power output sprocket 2 installed on the noodle rolling and cutting main machine 1, and also includes a bracket 3 and a top sprocket 4 installed on the top of the bracket 3. The power output chain The wheel 2 is connected with the top sprocket 4 by a noodle bar upper rack conveying chain 5, and the noodle pin upper rack conveying chain 5 is provided with a noodle pin upper rack pushing claw 6.

[0019] The conveying mechanism for noodle sticks in this embodiment is located between the main machine 1 of the noodle rolling and cutting machine and the conveying chain 7 for noodle sticks, and the noodle sticks 10 hung with wet noodles can crawl to the highest point through the noodle stick conveying chain 5 for mixing noodles. The noodle bar hook 8 heights on the bar walking conveyor chain 5 are consistent. The specific working principle of the noodle stick racki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com