Preparation method and device for preparing bio-organic fertilizer by utilizing crop straws

A technology of crop straw and bio-organic fertilizer, applied in fertilization equipment, agriculture, application, etc., can solve the problems of unfavorable multi-stage production and processing, crop straw is unfavorable for fertilizer production, and can not be produced, so as to achieve convenient granulation production Work, convenient linkage operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

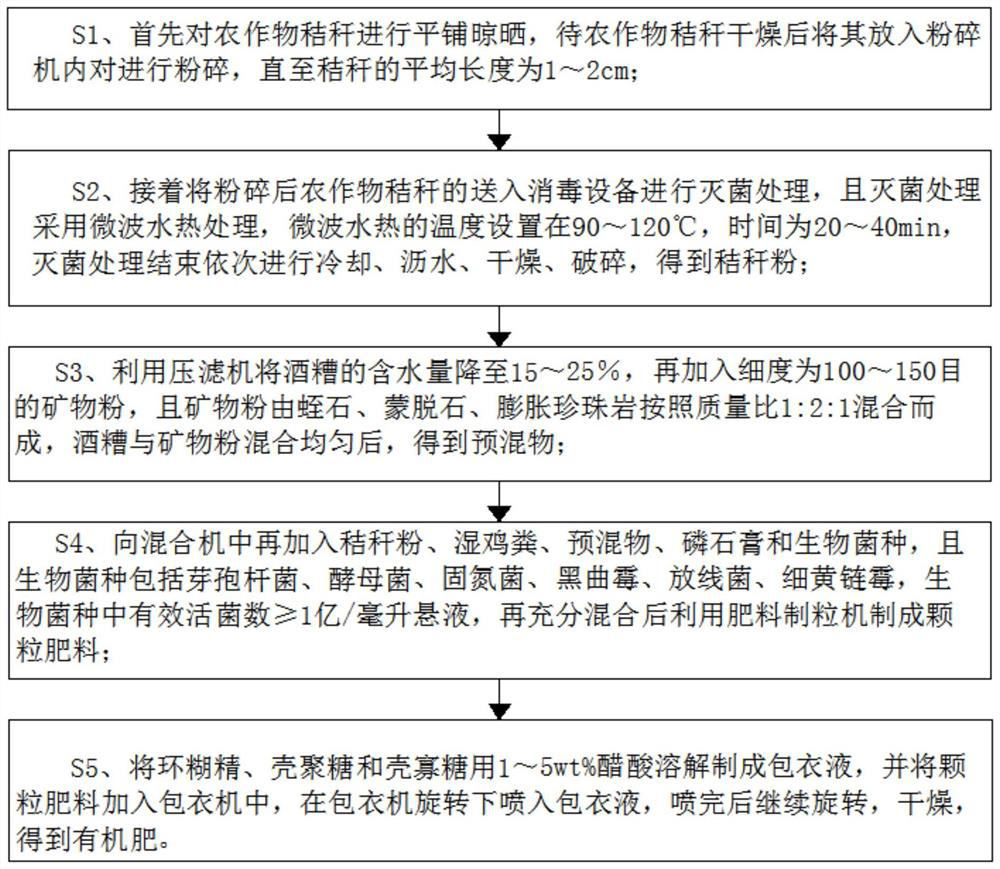

[0044] A preparation method and device for making bio-organic fertilizer from crop straws, refer to figure 1 , its preparation method comprises the following steps:

[0045] S1, firstly laying the crop straws for drying, and after drying the crop straws, put them into a pulverizer for pulverization, until the average length of the straws is 1cm;

[0046] S2, then send the pulverized crop straws into the sterilization equipment for sterilization treatment, and the sterilization treatment adopts microwave hydrothermal treatment, the temperature of the microwave hydrothermal treatment is set at 90 ° C, and the time is 20 min, and after the sterilization treatment is completed, cooling and draining are performed in turn. , drying and crushing to obtain straw powder;

[0047] S3. Use a filter press to reduce the water content of the distiller's grains to 15%, and then add mineral powder with a fineness of 100 mesh, and the mineral powder is mixed with vermiculite, montmorillonite,...

Embodiment 2

[0051] A preparation method and device for making bio-organic fertilizer from crop straws, refer to figure 1 , its preparation method comprises the following steps:

[0052] S1, firstly laying the crop straws for drying, and after drying the crop straws, put them into a pulverizer for pulverization, until the average length of the straws is 1.5cm;

[0053] S2, then send the pulverized crop straw into the disinfection equipment for sterilization treatment, and the sterilization treatment adopts microwave hydrothermal treatment, the temperature of the microwave hydrothermal treatment is set at 100 ° C, the time is 30min, and the sterilization treatment is completed. , drying and crushing to obtain straw powder;

[0054] S3. Use a filter press to reduce the water content of the distiller's grains to 17%, then add mineral powder with a fineness of 130 mesh, and the mineral powder is mixed with vermiculite, montmorillonite, and expanded perlite in a mass ratio of 1:2:1. After the...

Embodiment 3

[0058] A preparation method and device for making bio-organic fertilizer from crop straws, refer to figure 1 , its preparation method comprises the following steps:

[0059] S1, firstly laying the crop straws for drying, placing the crop straws into a pulverizer to pulverize them after drying, until the average length of the straws is 2cm;

[0060] S2, then send the pulverized crop straws into the sterilization equipment for sterilization treatment, and the sterilization treatment adopts microwave hydrothermal treatment, the temperature of the microwave hydrothermal treatment is set at 120 ° C, and the time is 40 min, and after the sterilization treatment is completed, cooling and draining are performed in sequence. , drying and crushing to obtain straw powder;

[0061] S3. Use a filter press to reduce the water content of the distiller's grains to 25%, then add mineral powder with a fineness of 150 mesh, and the mineral powder is mixed with vermiculite, montmorillonite, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com