A slag pumping device for cleaning holes in underground piles and walls

A technology for clearing holes and slag openings, which is applied to sheet pile walls, buildings, and foundation structure engineering. Disturbance, small lifting height, and the effect of preventing hole collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

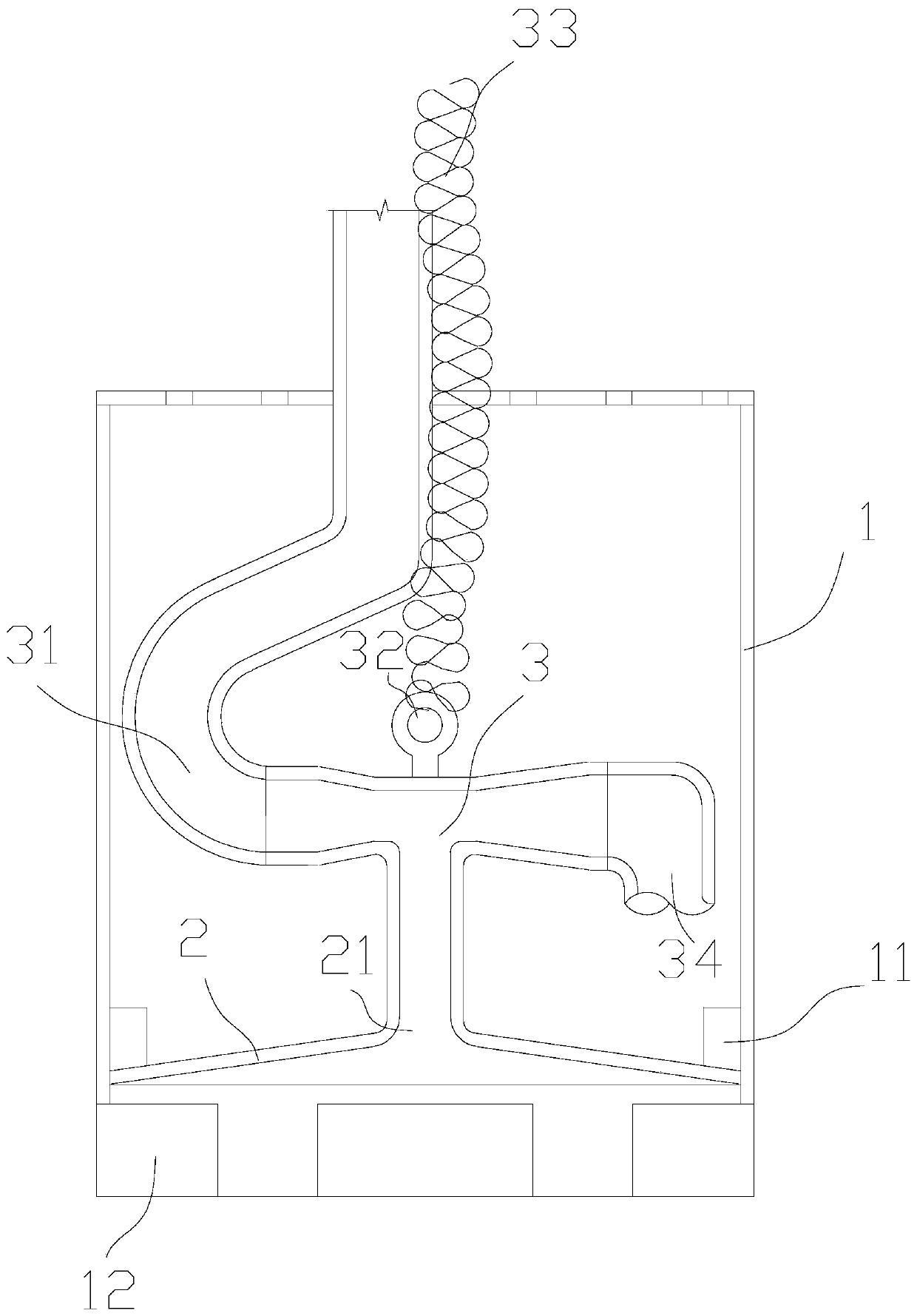

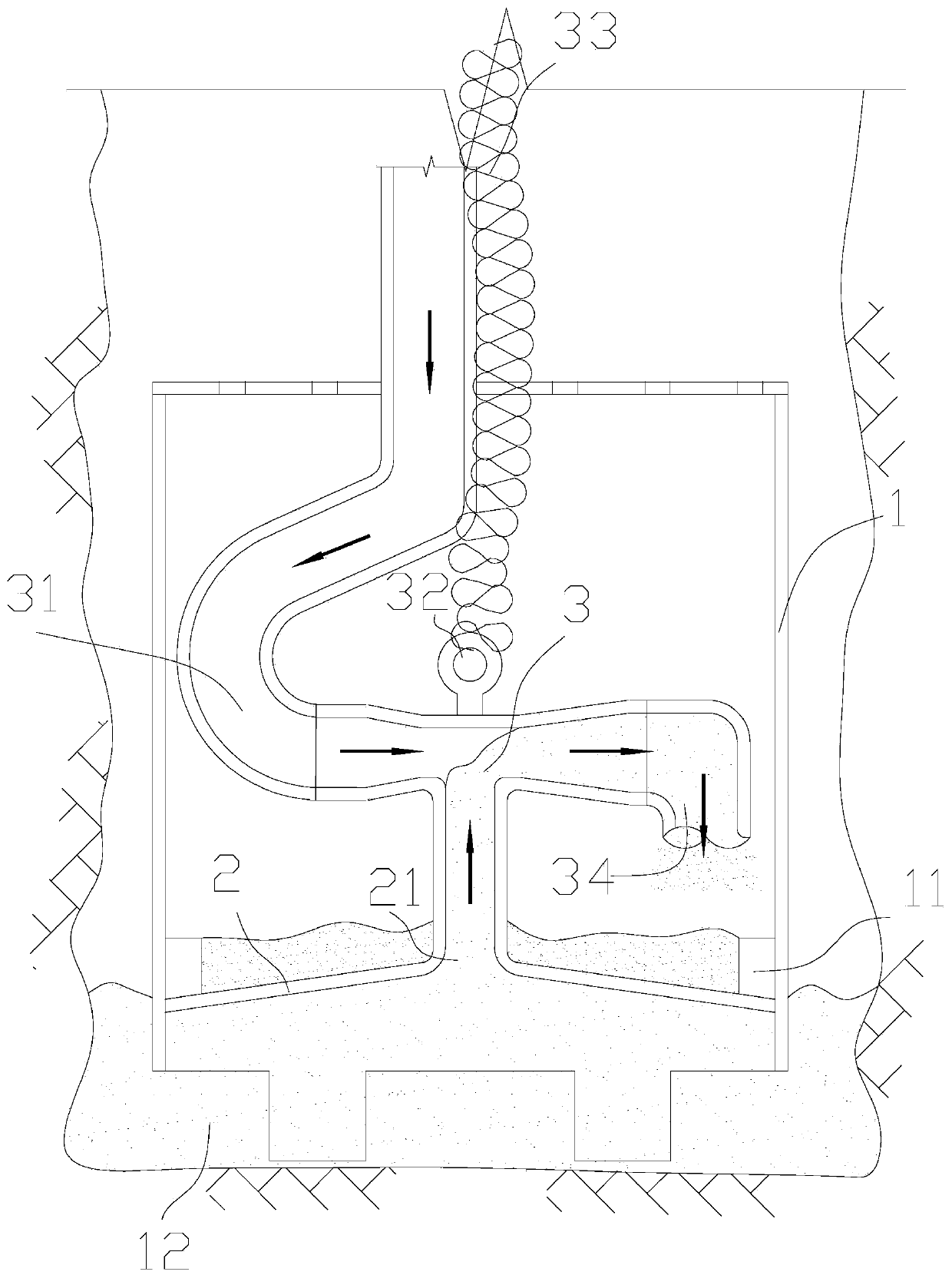

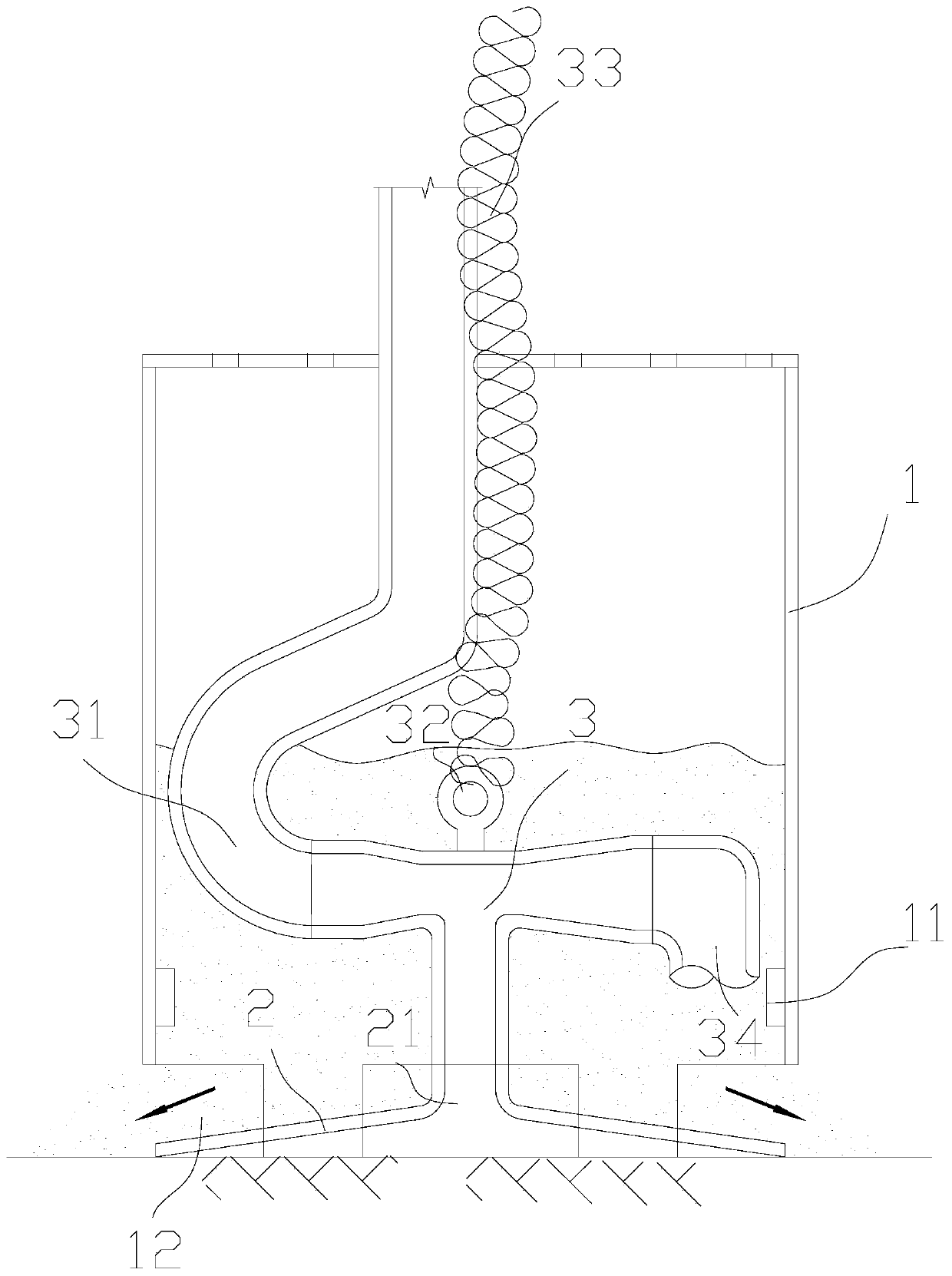

[0016] figure 1 The overall structure of the present invention is shown. like figure 1 As shown, a slag extraction device used for clearing holes in underground piles and walls includes a cylinder body 1. There is an inverted chamber in the cylinder body 1 that closely fits with the inner side wall of the cylinder body 1 and can move up and down along the inner side wall of the cylinder body 1. A funnel-shaped slag-absorbing tray 2, with a slag-absorbing port 21 in the middle of the slag-absorbing disc 2, and the slag-absorbing port 21 is fixedly connected to the T-shaped connecting pipe 3; a high-speed fluid port 31 is connected to the left side of the T-shaped connecting pipe 3 , the high-speed fluid inlet pipe 31 protrudes outside the top end cover of the cylinder 1, and the slag outlet 34 is on the right side of the T-shaped connecting pipe 3, and the high-speed fluid directly passes through the high-speed fluid pipe 31 outside and enters the T-shaped connecting pipe 3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com