Motor, oil bearing and manufacturing method thereof

A manufacturing method and bearing technology, which is applied in the manufacture of motor generators, casings/covers/supports, electrical components, etc., can solve the problems of limited oil content, increased frictional resistance, and affecting the service life of motors, and achieves obvious results , increase the oil storage capacity, and improve the life of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

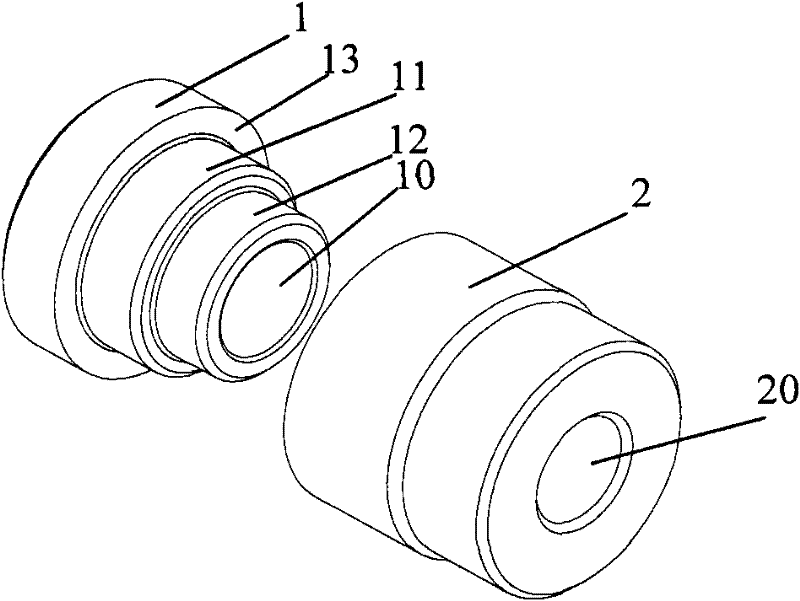

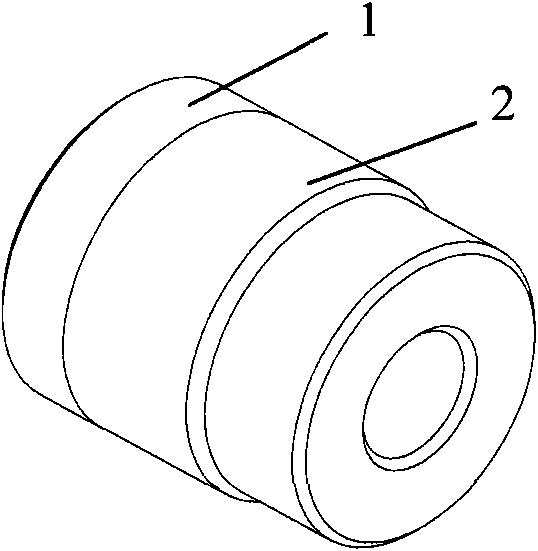

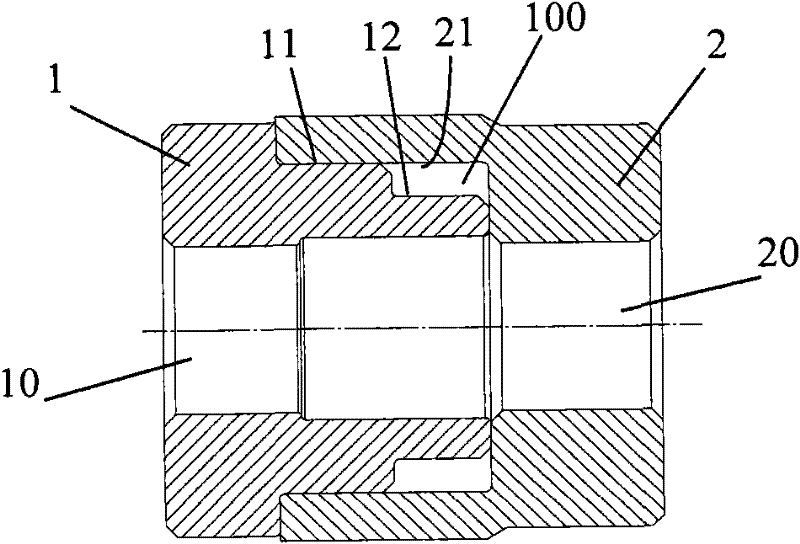

[0017] Such as figure 1 As shown, one end of the bearing segment 1 axially protrudes from a first flange 11 , and a second flange 12 axially protrudes from the first flange. The bearing segment 1 has a central hole 10 which runs through the entire bearing segment 1 .

[0018] Such as image 3 As shown, one end of the bearing segment 2 is recessed to form a groove 21 . The bearing segment 2 has a central hole 20 which runs through the entire bearing segment 2 .

[0019] The outer diameter of the first flange 11 is larger than the outer diameter of the second flange 12 . The inner diameter of the groove portion 21 is greater than the outer diameter of the second flange, and is close to or equal to the outer diameter of the first flange 11 . A shaft shoulder 13 is formed at the root of the first flange 11 of the bearing segment 11 due to a sudden change in the outer diameter. The first flange 11 and the second flange 12 form a flange coupling. The groove portion 21 forms a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com