Patents

Literature

77results about "Hull double bottoms" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

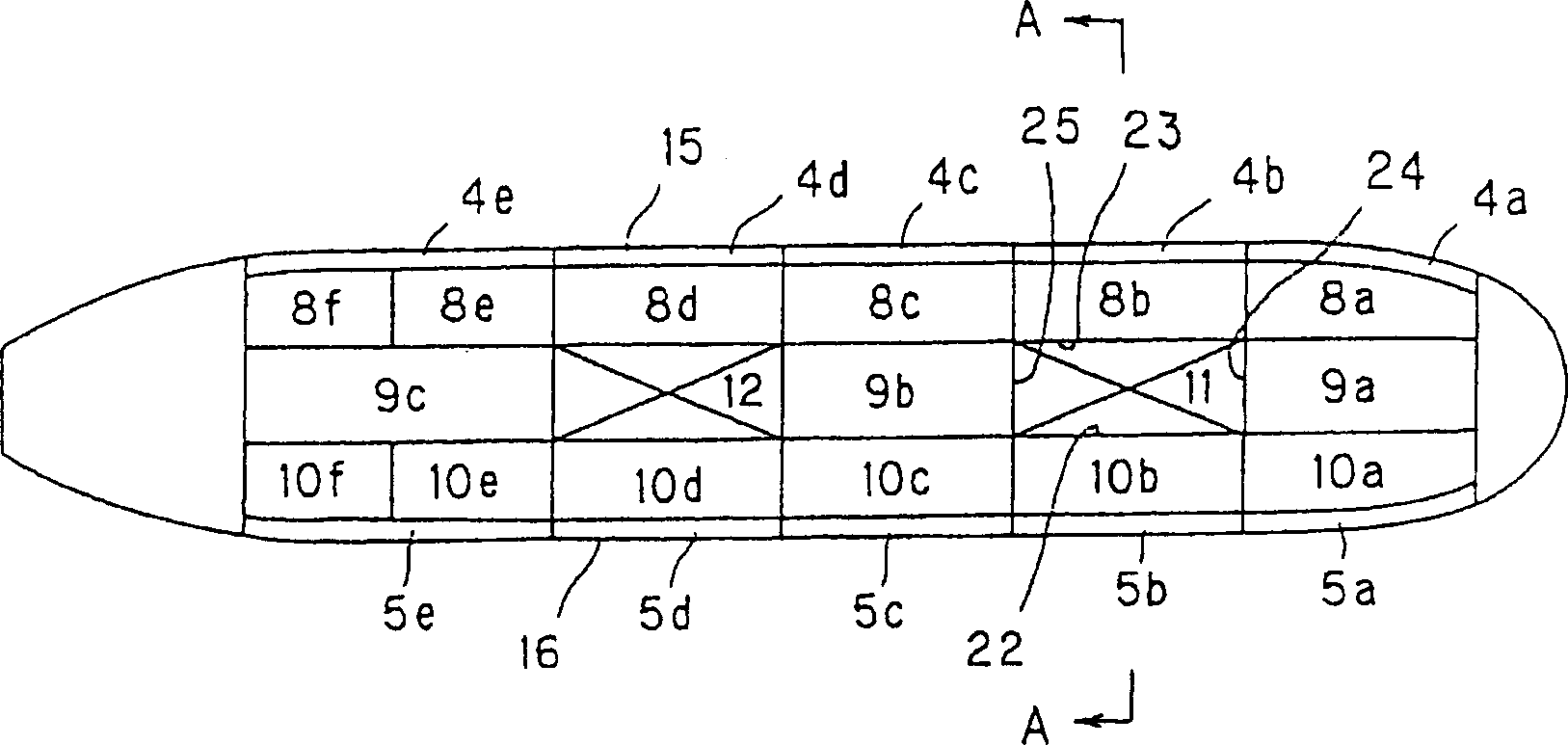

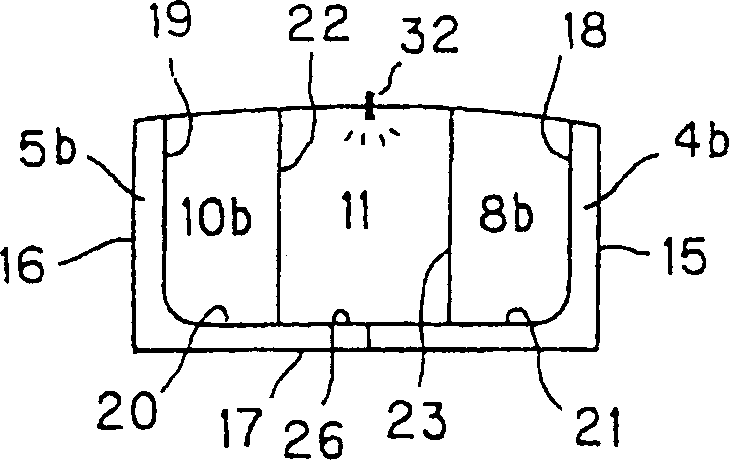

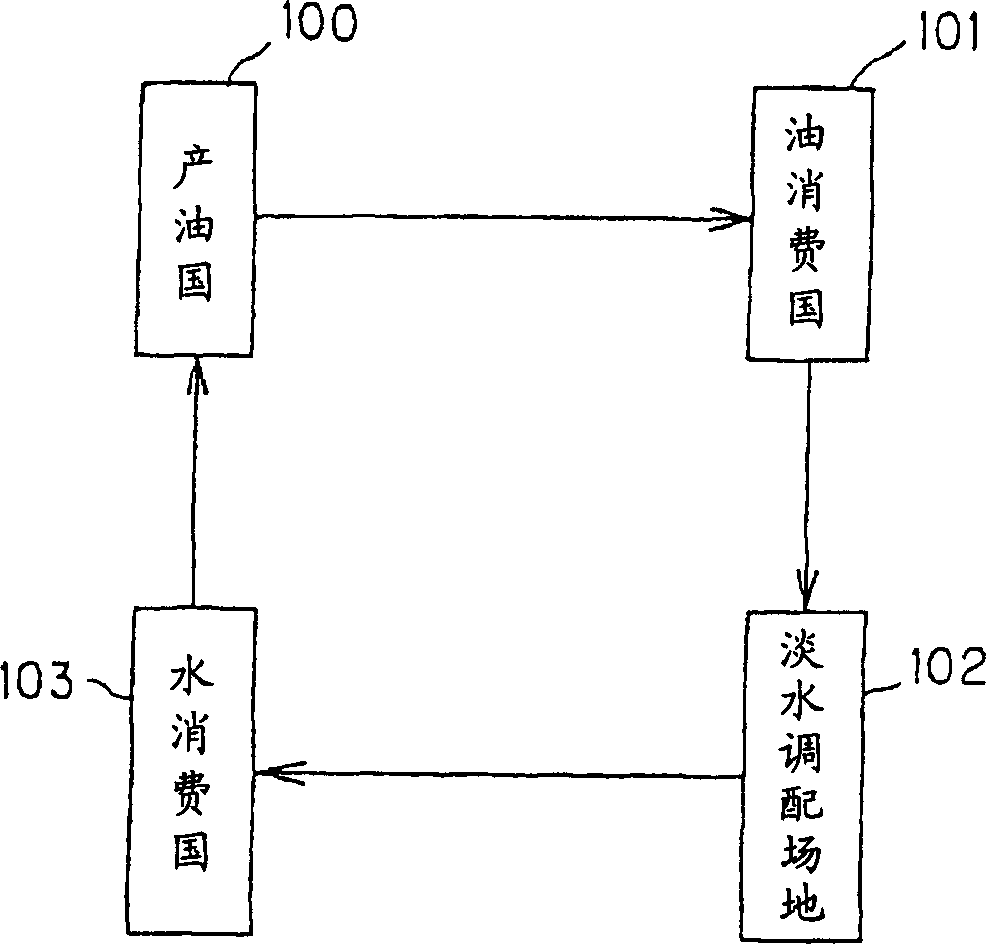

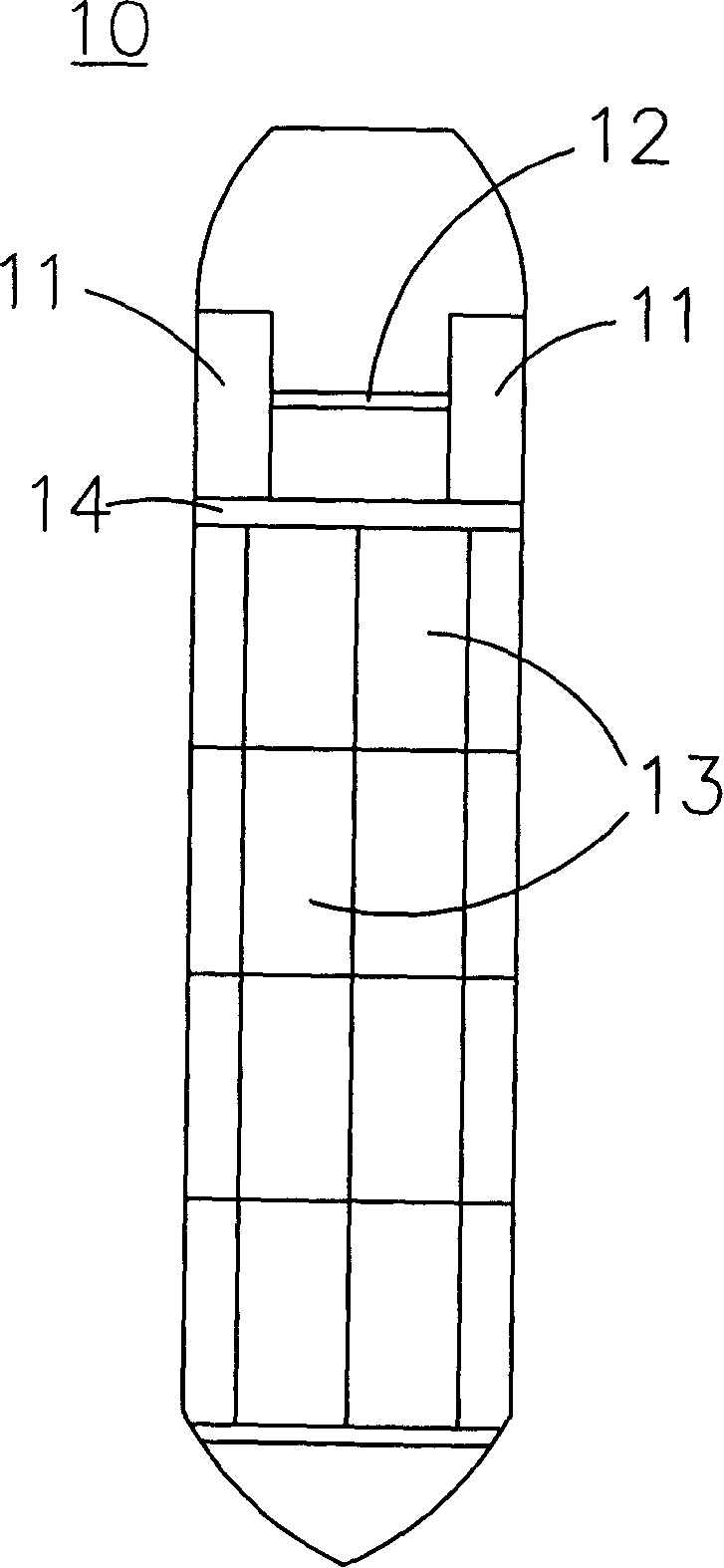

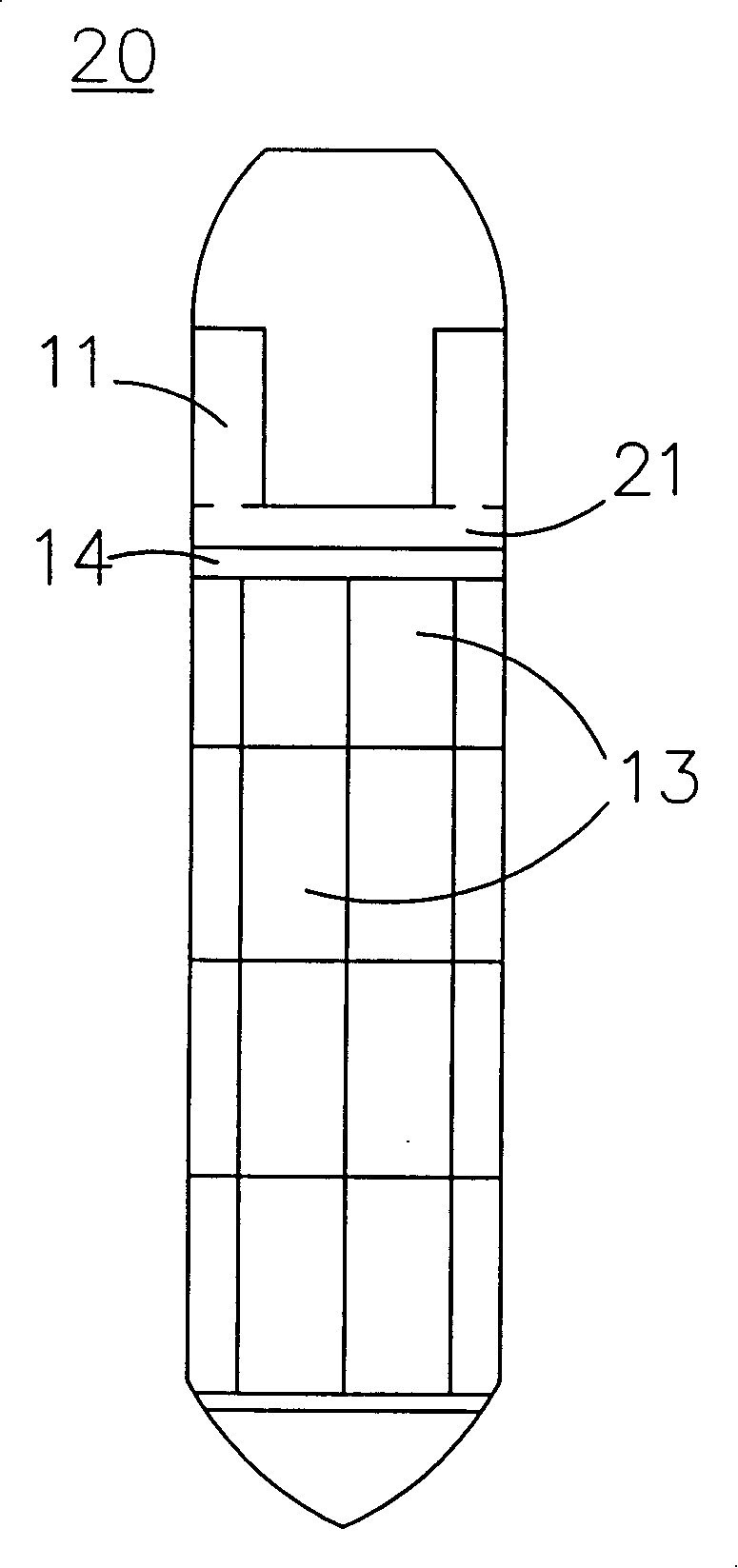

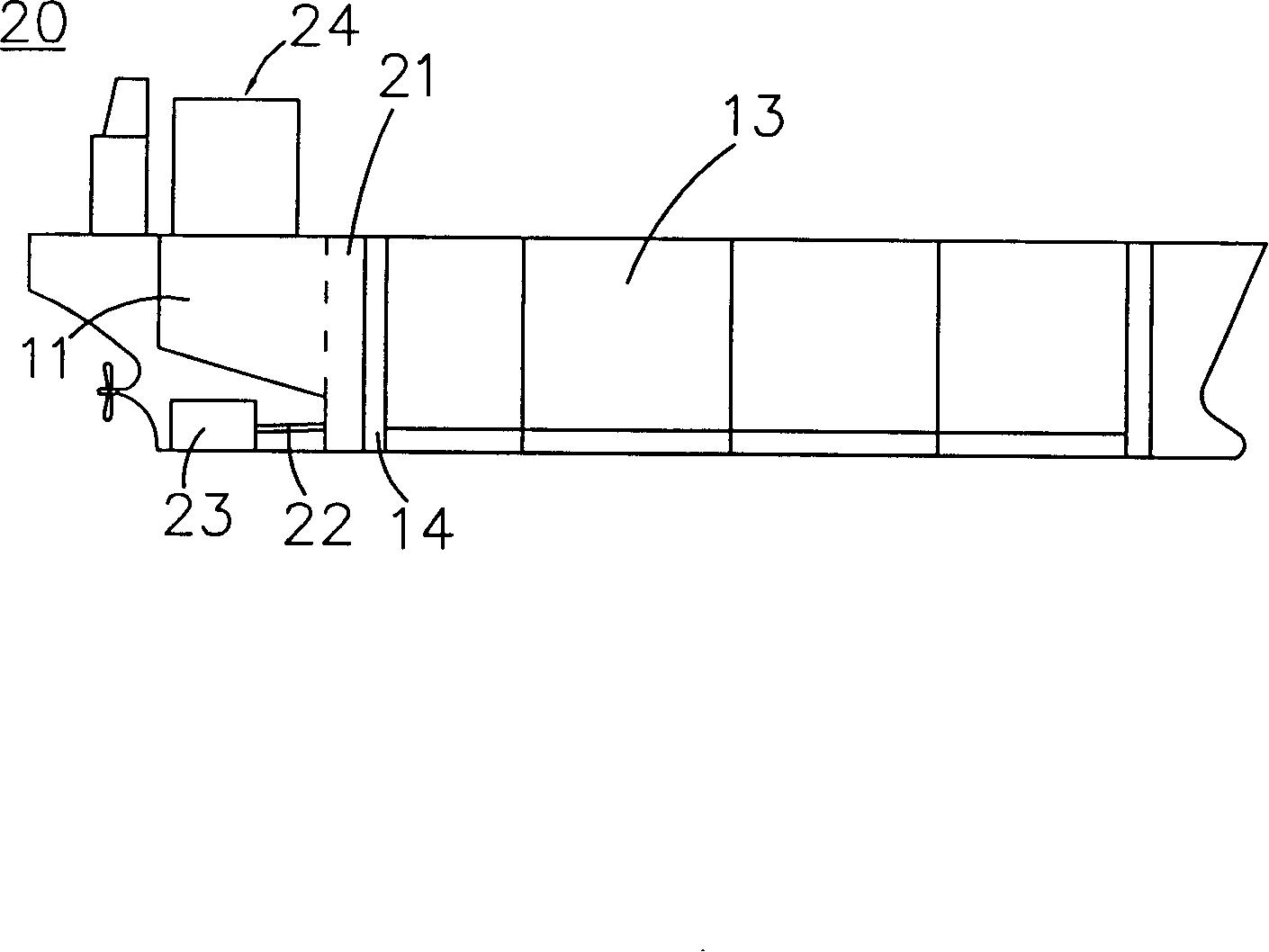

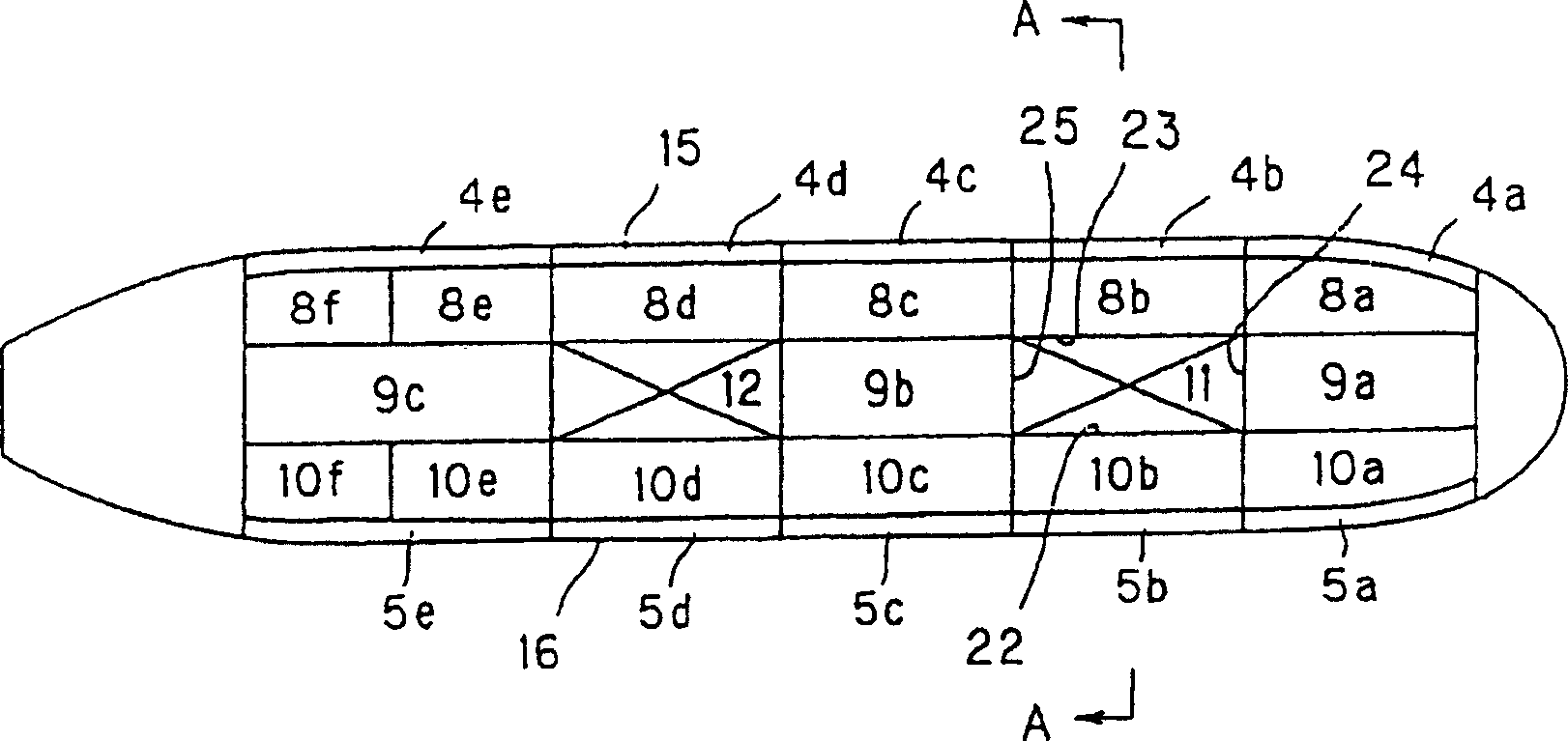

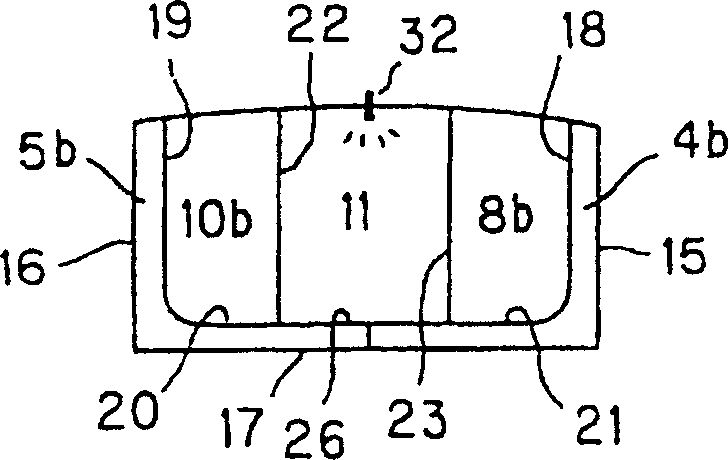

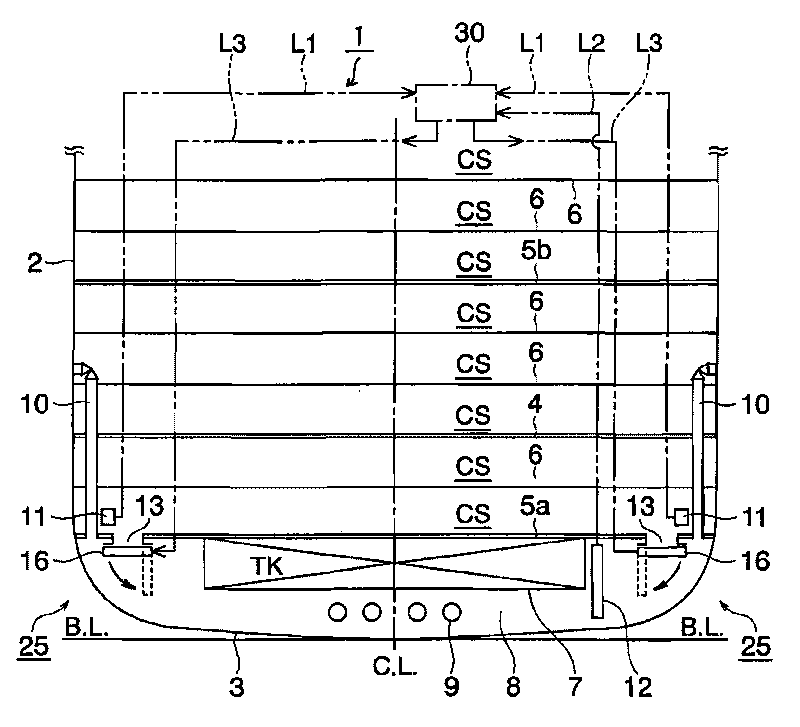

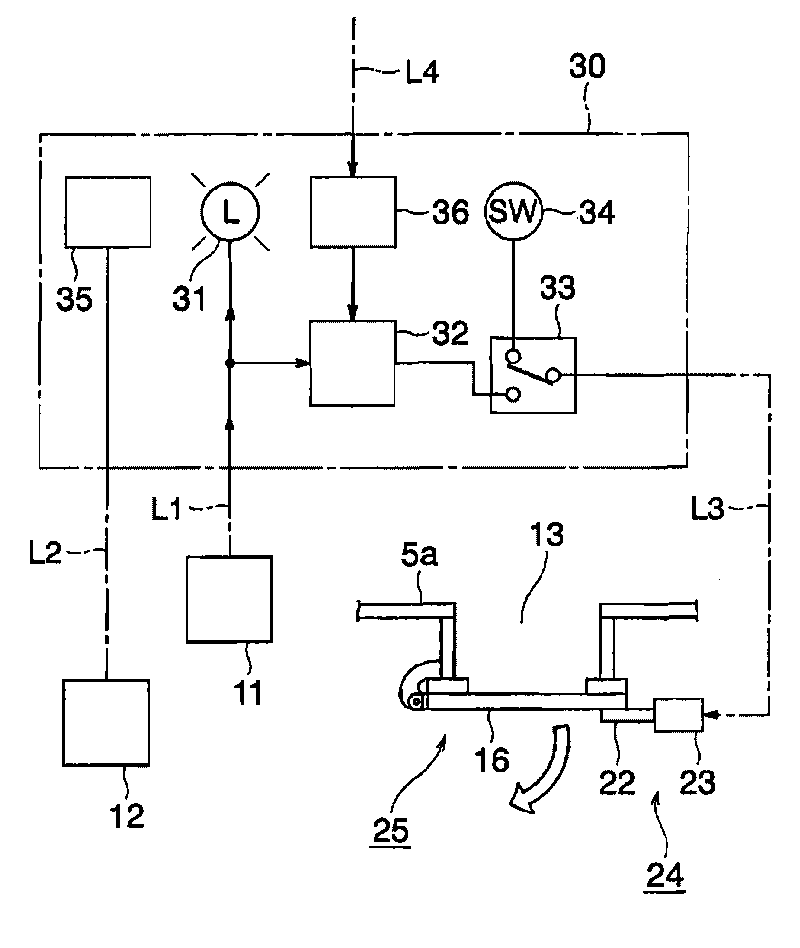

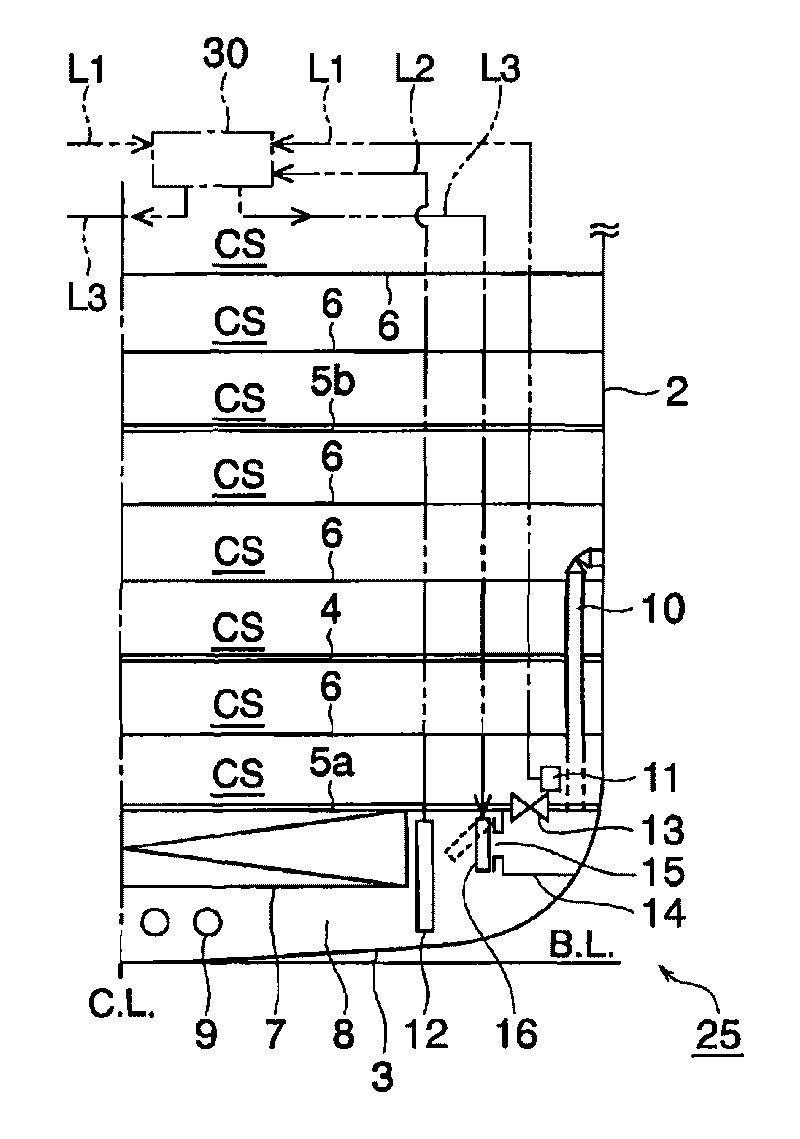

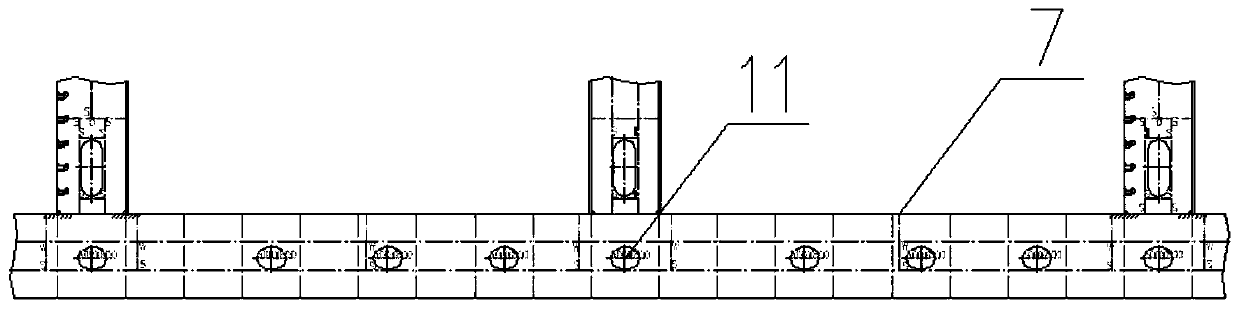

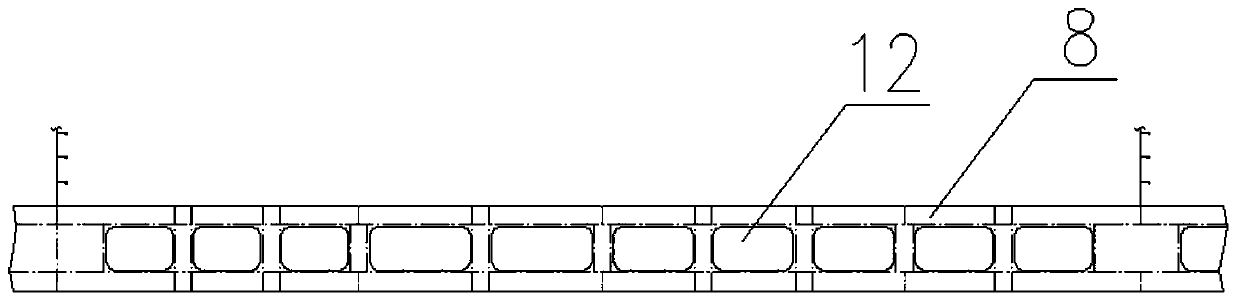

Ship structure for transporting oil and fresh water

InactiveCN1406812ANo empty sailingHull interior subdivisionSelf-bailing equipments/scuppersFresh waterBallast tank

The invention provides a hull construction of a oil tank for transporting oil and fresh water by using all ballast tanks formed in a double hull space as fresh water tanks 4a-4e and 5a-5e, and two combining tanks 11, 12 are provided at a central portion of a hull for combining a sea water ballast tank and a fresh water cargo tank. In this manner, non-wasteful sailing of an oil tanker can be realized by utilizing the tanker for transporting oil cargoes on a forward route and fresh water on a backward route.

Owner:约瑟夫·W·L·哈

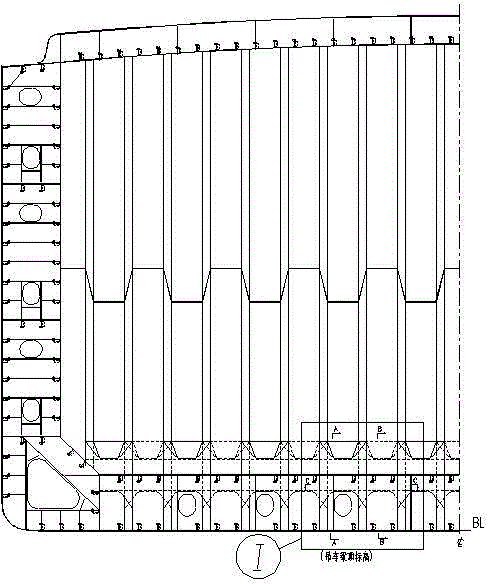

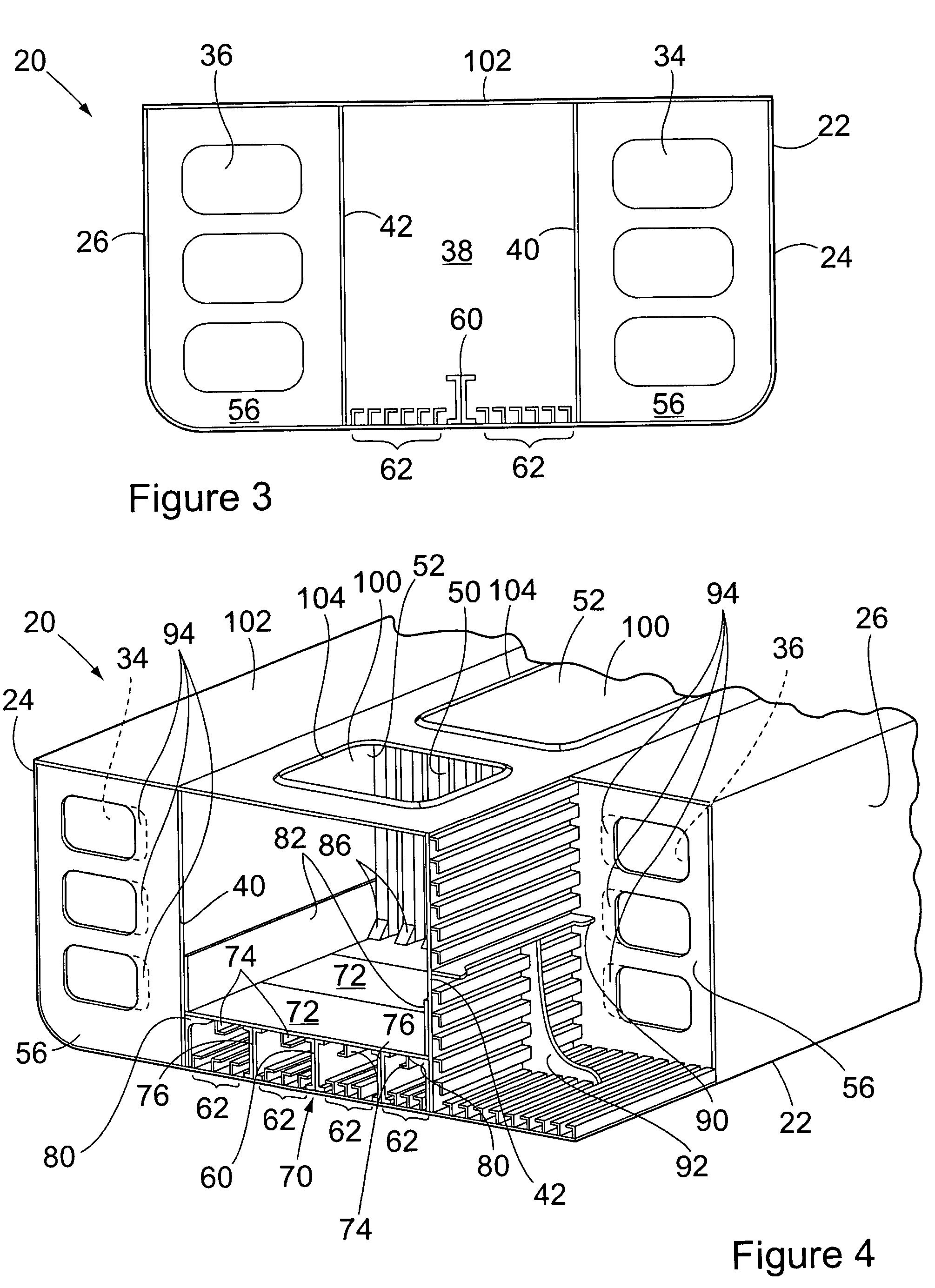

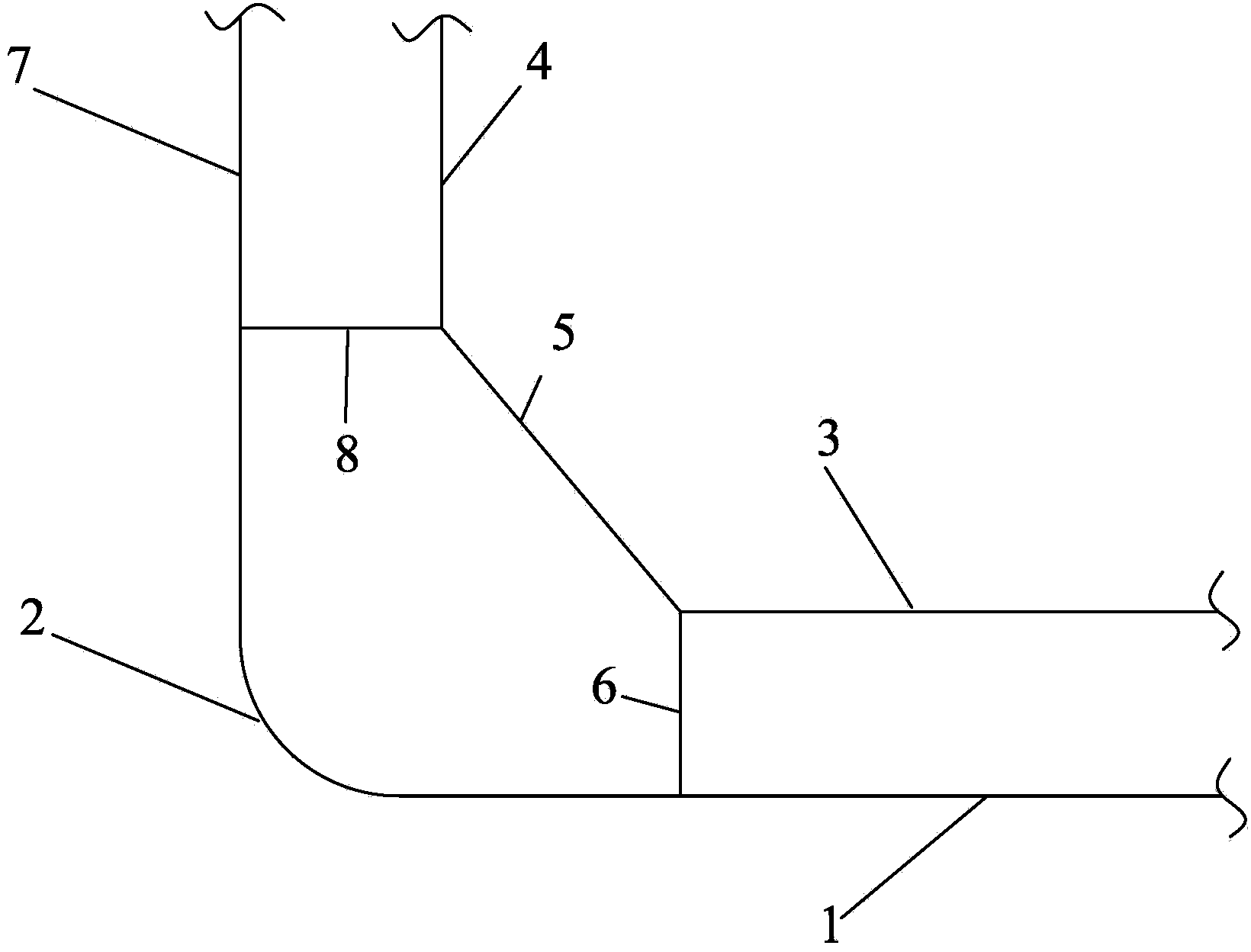

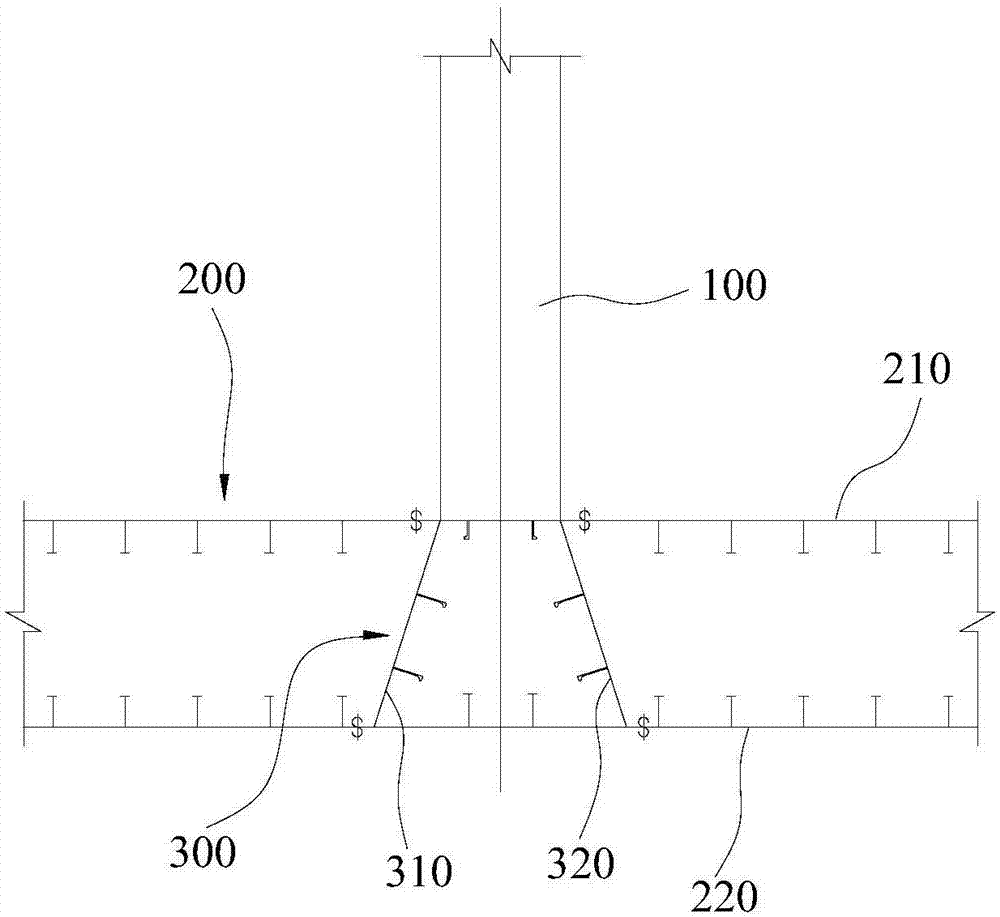

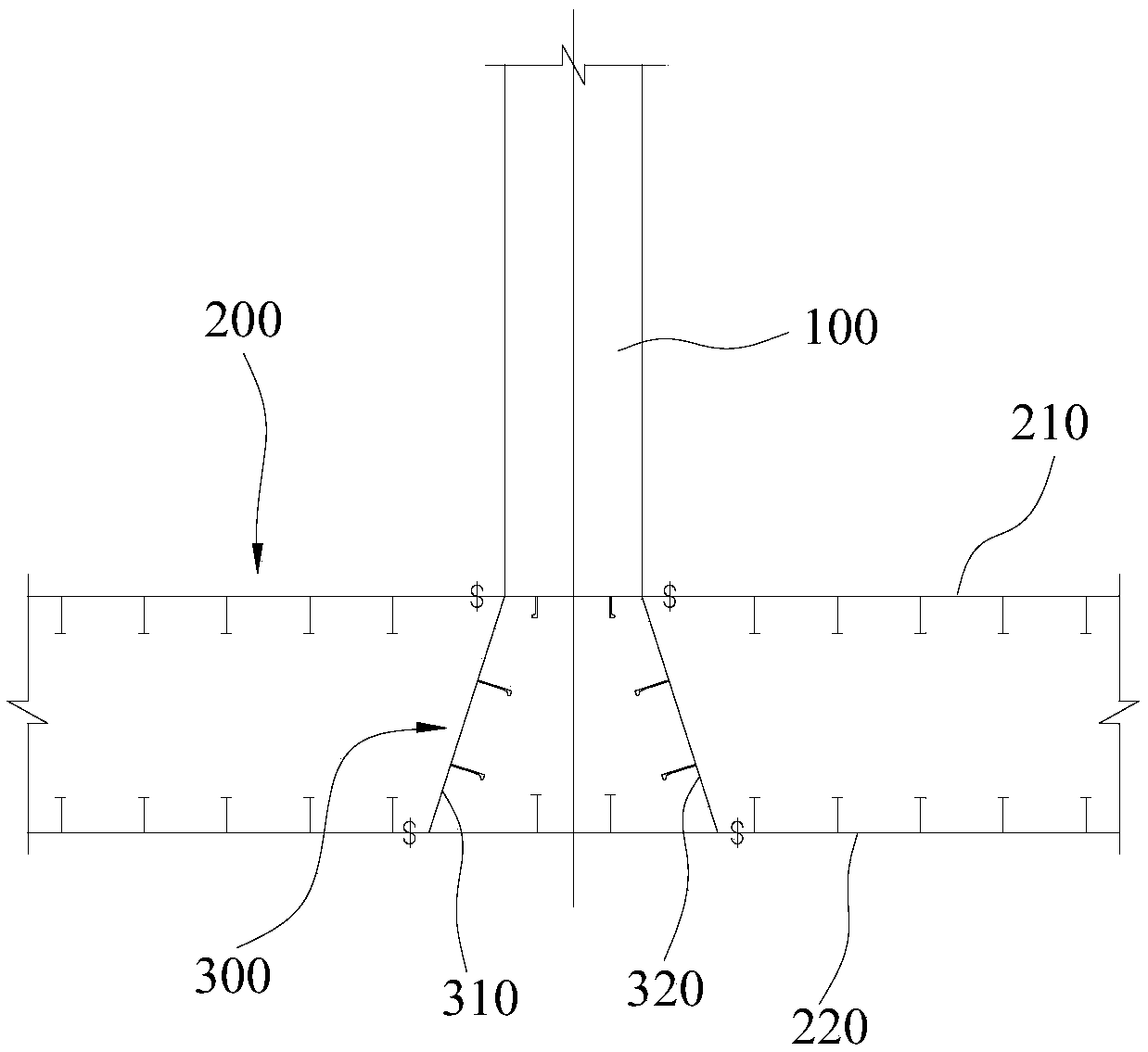

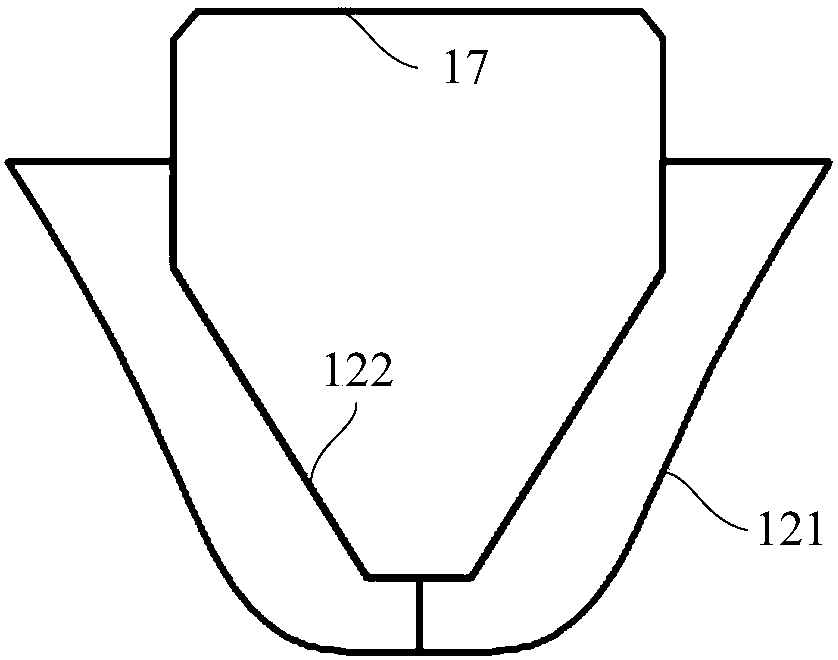

Bottom structure of vertical corrugated bulkhead of ship

InactiveCN103910027ALarge capacityIncrease loading capacityHull double bottomsHull bulkheadsStress concentrationMarine engineering

A bottom structure of a vertical corrugated bulkhead of a ship is characterized in that corrugated rib plates identical to the section of the corrugated bulkhead in shape are mounted and welded between a ship bottom plate and an inner bottom plate and at corresponding rib positions of the corrugated bulkhead to replace traditional planar solid rib plates, transitional reinforcement U-shaped toggle plates are mounted and welded at openings of notches at the upper ends of the corrugated rib plates and the lower end of the vertical corrugated bulkhead, U-shaped sides of the U-shaped toggle plates above the inner bottom plate are welded to a corrugated seal plate which functions in sealing the U-shaped toggle plates and facilitating cabin cleaning and serves as a discharging plate on a bulk freighter, U-shaped sides of the U-shaped toggle plates below the inner bottom plates are free sides, and horizontal reinforcement rib plates are welded close to the U-shaped sides of the U-shaped toggle plates. By mounting and welding the U-shaped toggle plates at the upper ends of the corrugated rib plates and the lower end of the vertical corrugated bulkhead, stress at the welding joint of the vertical corrugation bulkhead and the inner bottom plate is reduced while stress concentration is eliminated, and the corrugated rib plates can be thinned properly as compared with the corrugated bulkhead.

Owner:谢合清

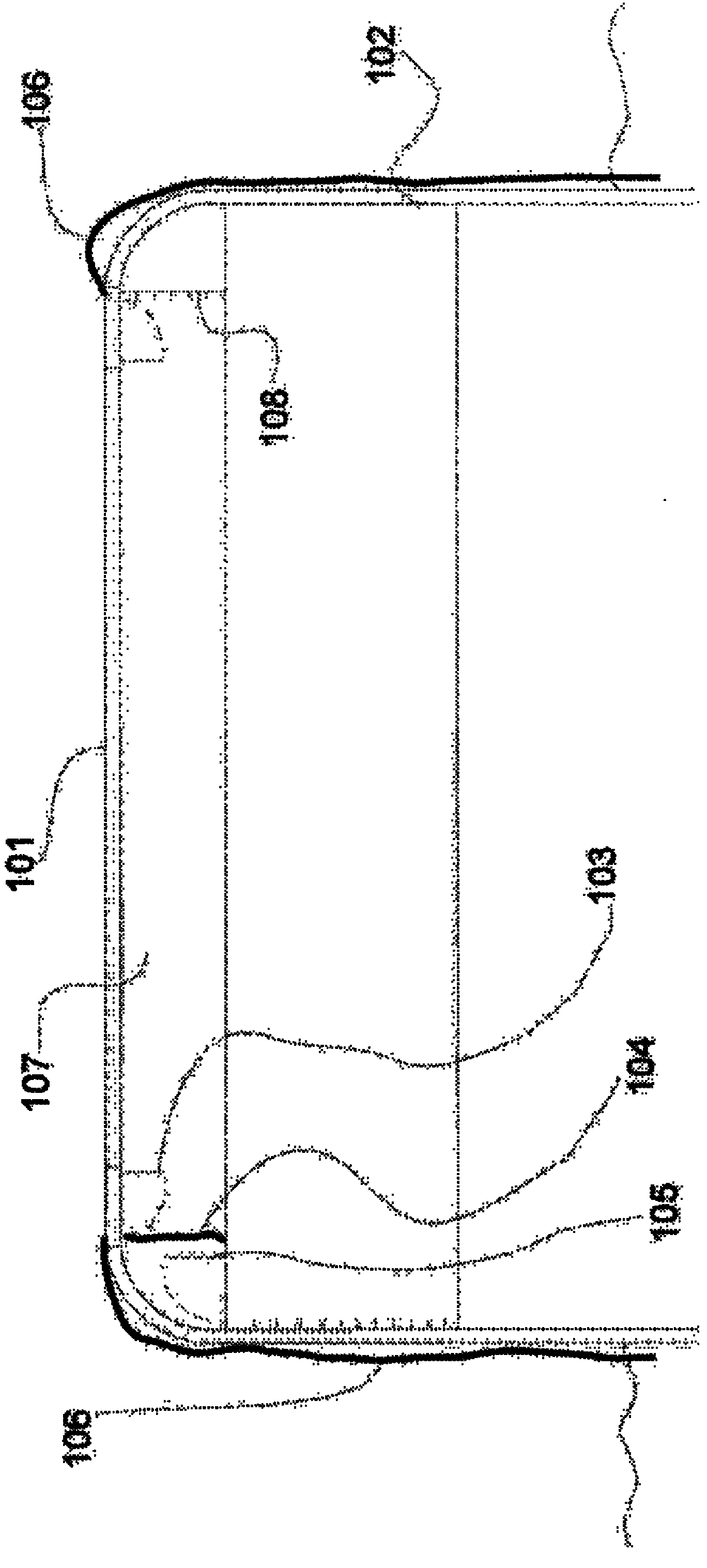

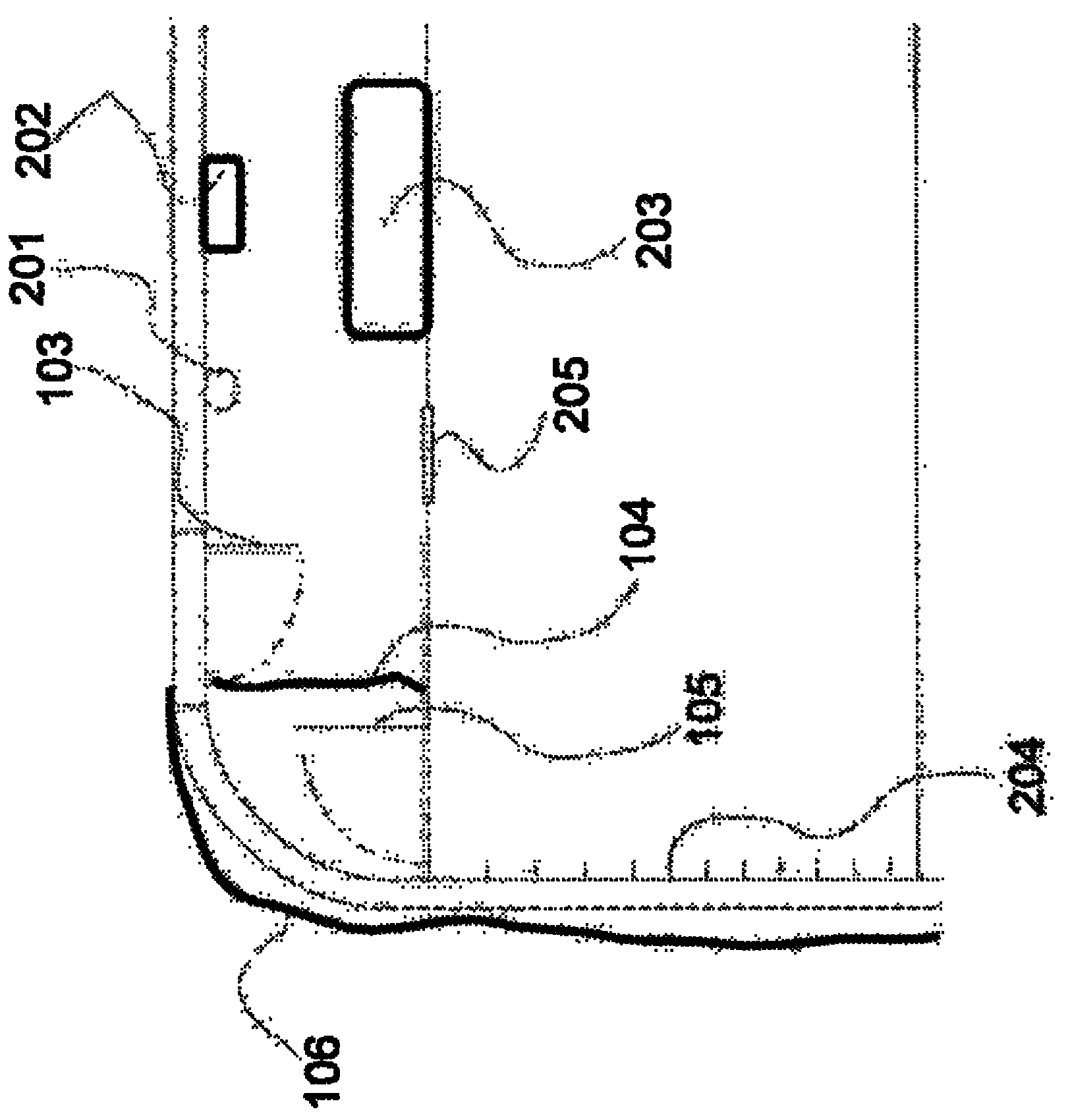

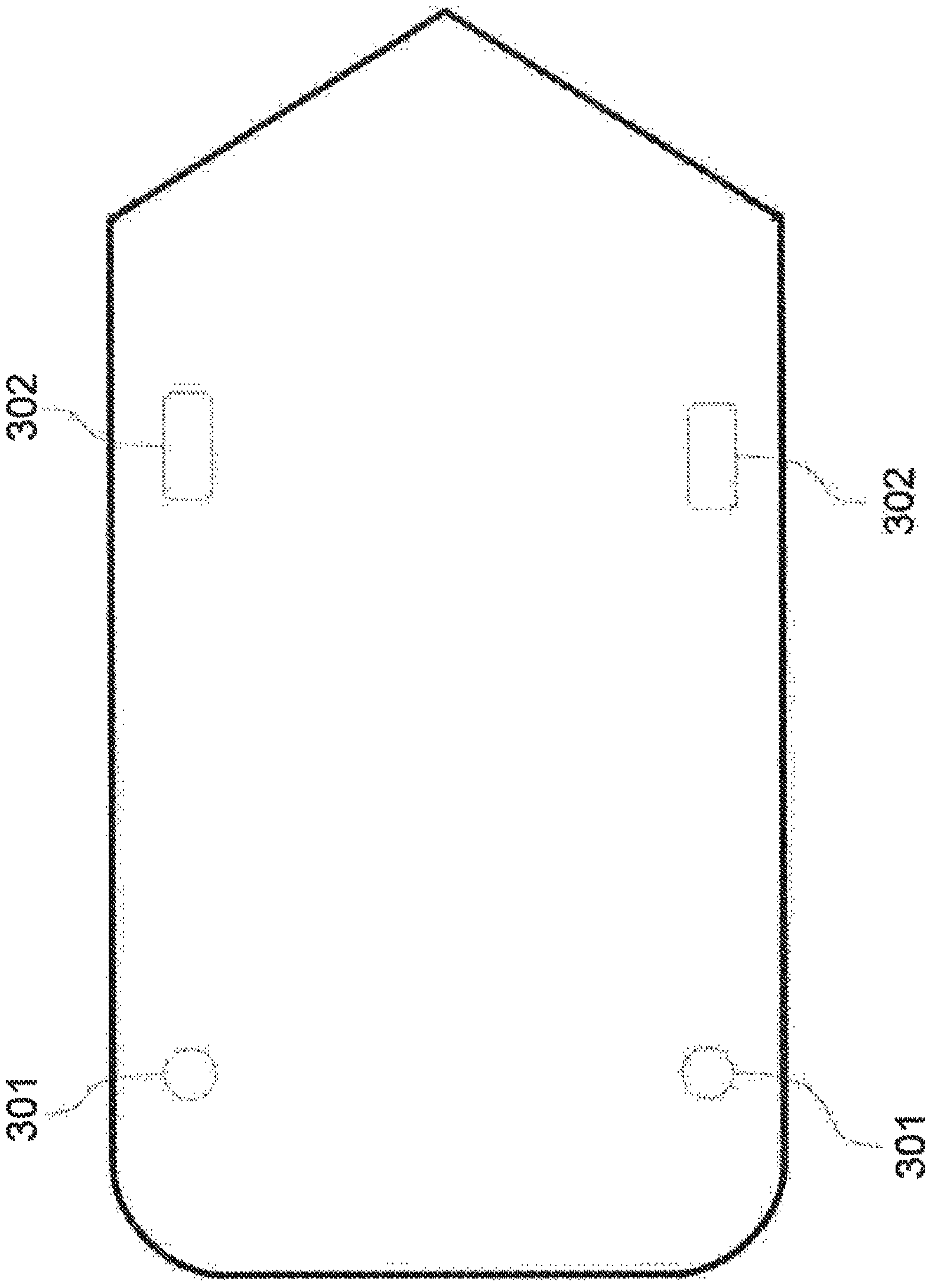

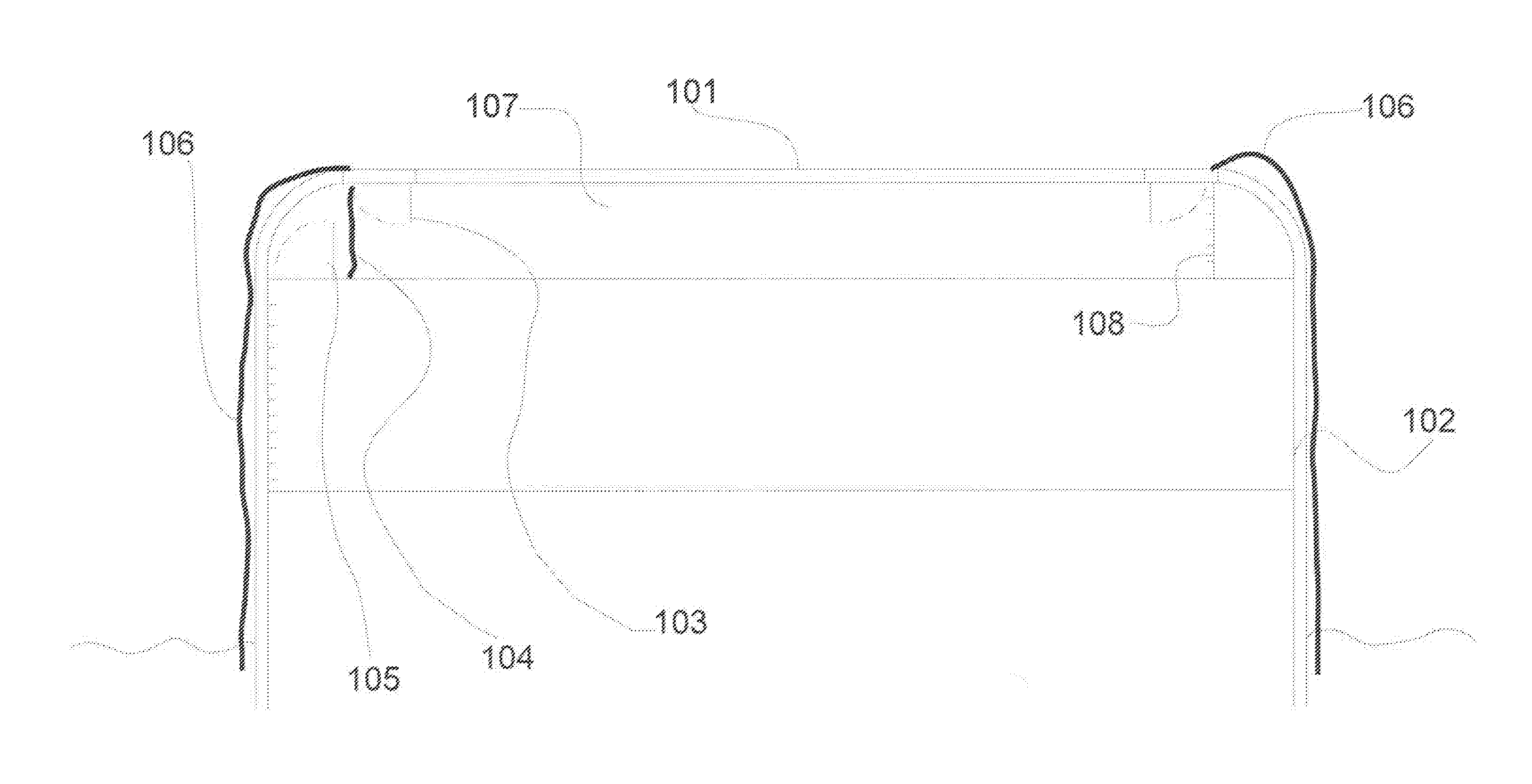

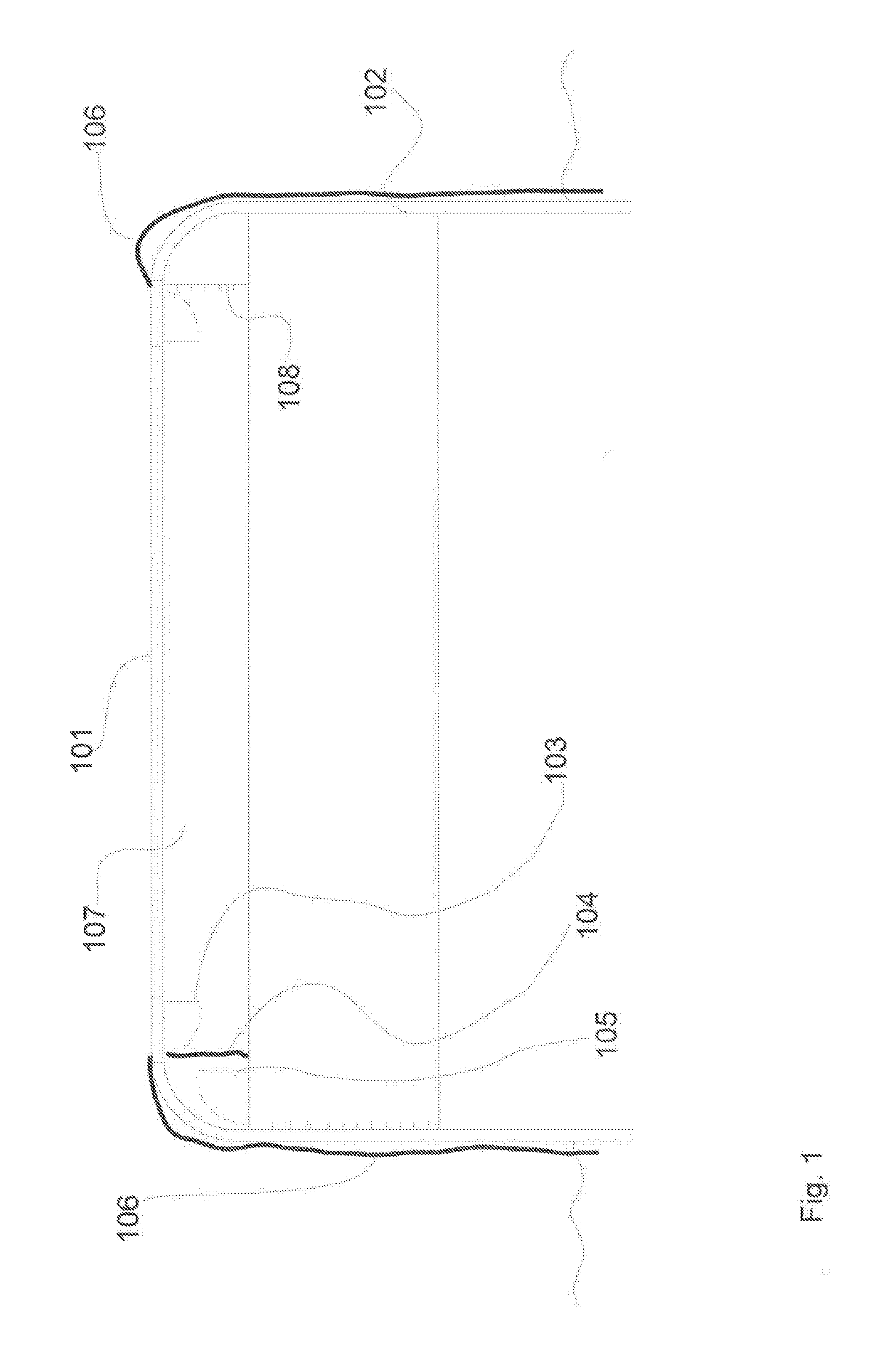

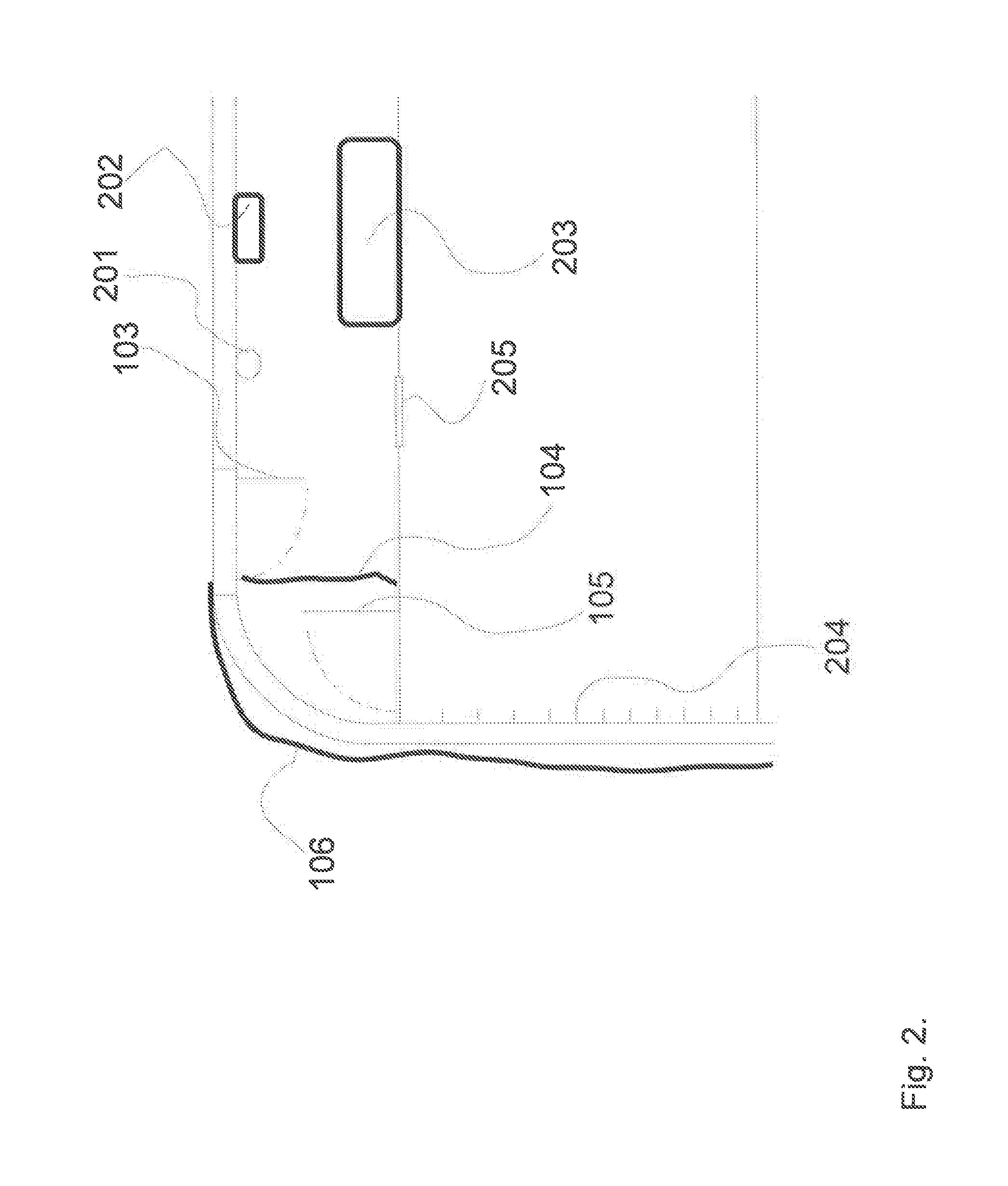

A system for evacuation of personnel from a capsized vessel

System for evacuation of personnel from a capsized vessel via a lockable escape hatch (103) in the bottom of said vessel, characterized in that the system comprises a first lockable escape hatch (105), said first lockable escape hatch(105) leads to an evacuation room (107), said room (107) is provided with a second lockable escape hatch (103), said room (107) is illuminated by lamps (201) receiving energy from a battery pack (202) not connected to the said vessel's energy system,said first and second lockable escape hatch (103, 105) cannot be opened simultaneously,in relation to said first lockable escape hatch (105), it is connected a device (106) for climbing, and said climbing device (106) unfolds when the said vessel has a lopsidedness in excess of a predetermined number of degrees.

Owner:DYB ASBJOERN BREVIK

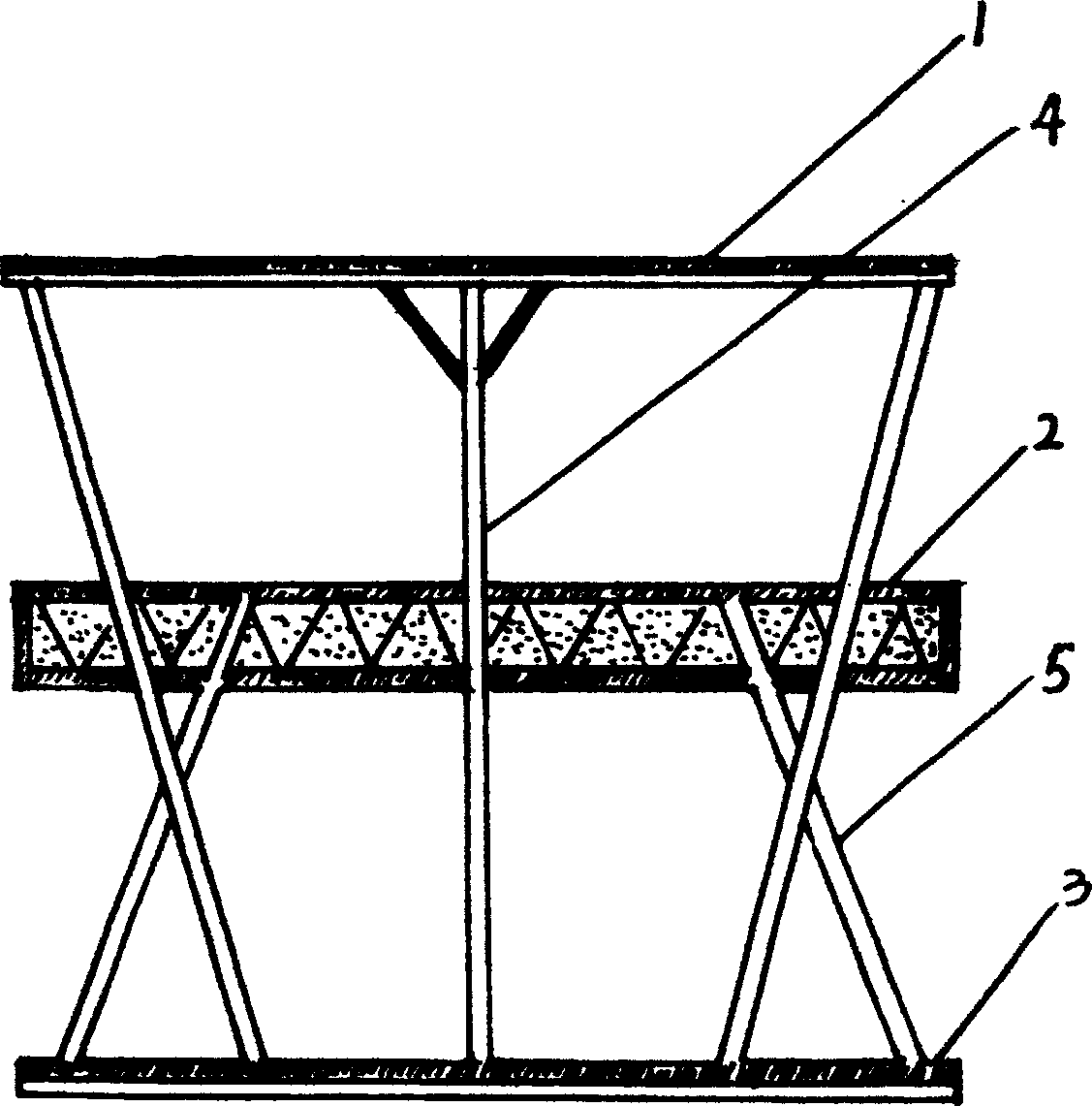

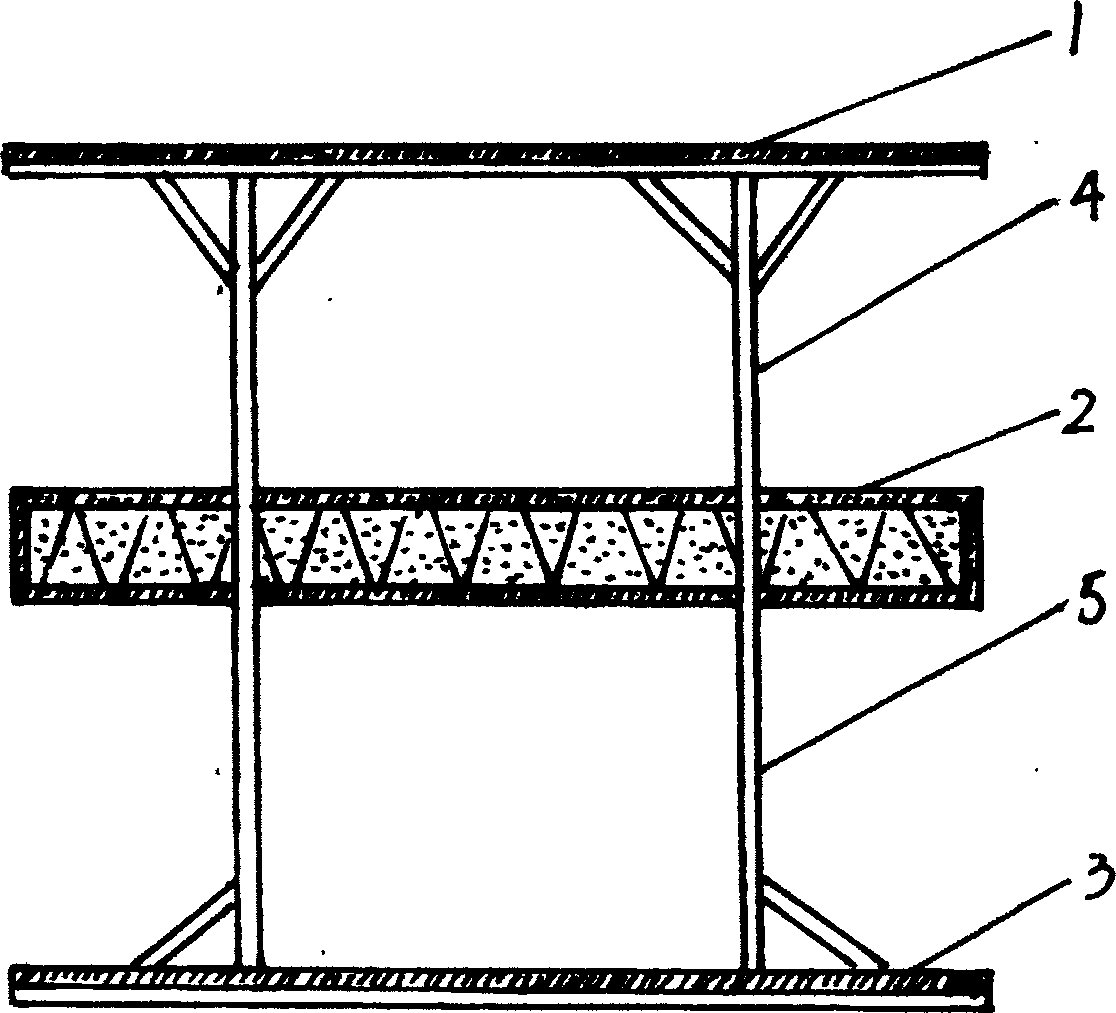

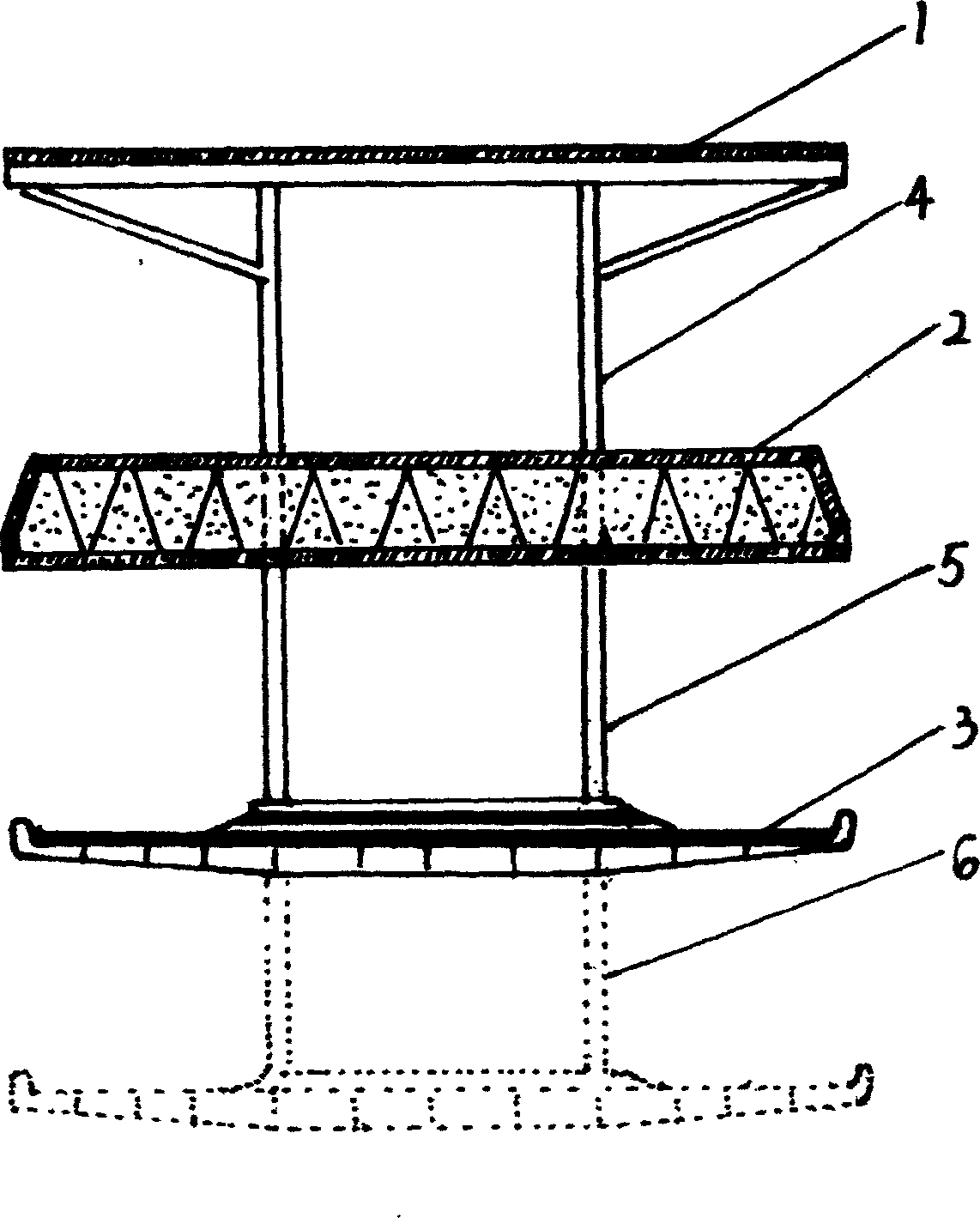

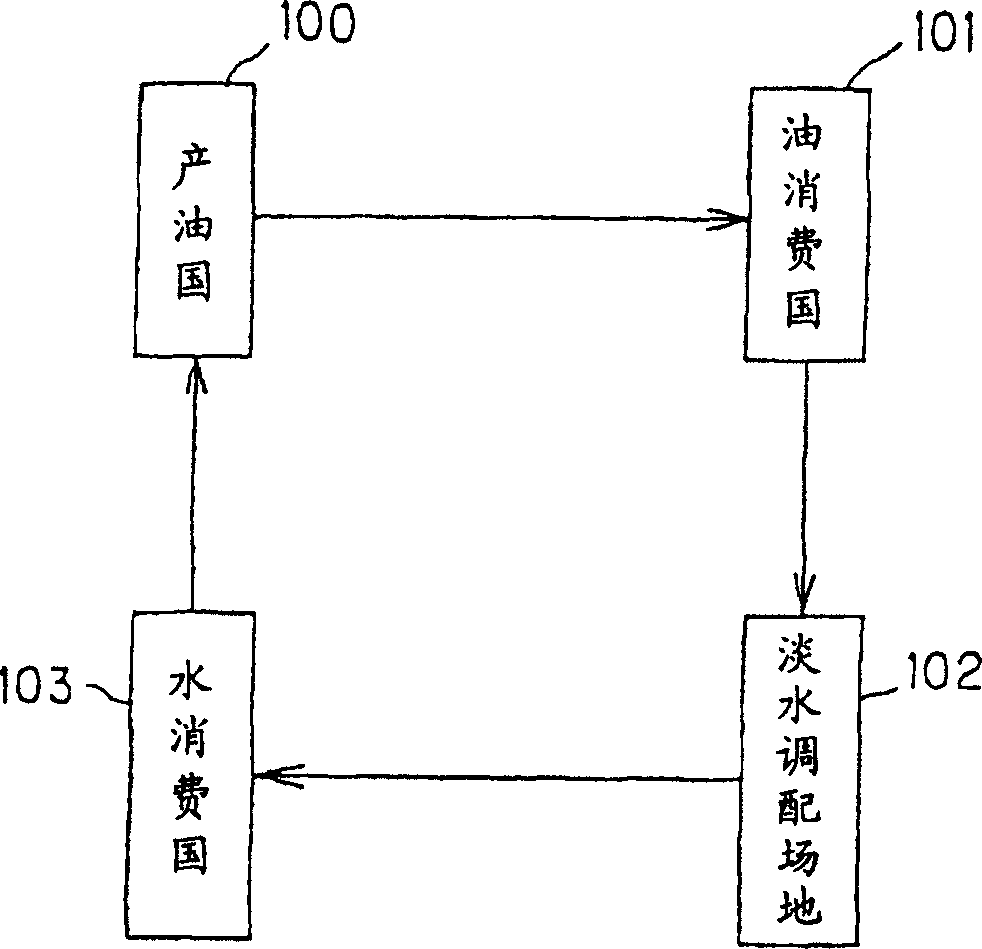

Floating structure with double bottoms

InactiveCN1631723AWide range of applicationsMeet long-term residenceNon-magnetic metal hullsHull double bottomsStormMarine engineering

The invention relates to a new bilaminar bed plate floating shipway. The ships now in use sway in the storm and sink, with single function which has become a difficult subject to overcome. The invention consists of a large float, bilaminar bed plate, and the hanging platform. The large float is plane framework structure which is built by enfolding with ferroglass or metal plank outside, filling with epispastic non-water-absorb material inside. The steel bilaminar bed plate is fixed by the connecting pole. The hanging platform is fixed by supporting stand. Bar slots can be set on the large float and the bilaminar bed plate so to fend off the wave. The depth the bilaminar goes by under the water can be pre-configured or adjusted by installing lifting pole inside the connecting pole. It can be built into both monomer structure and fitting structure. It is safe, reliable and of wide usage. It services stable and fast which meets the needs people live, work, entertain on the water for a long period of time. It is of cheap costs so to promote generally.

Owner:傅德俐

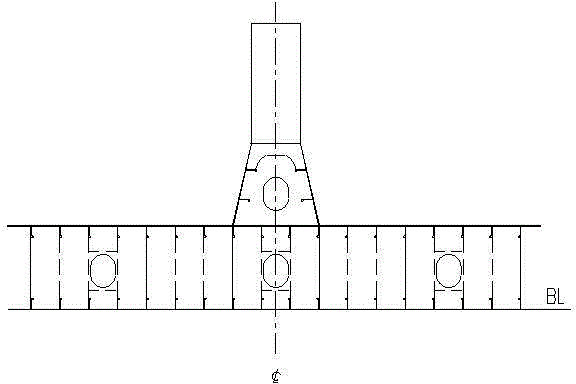

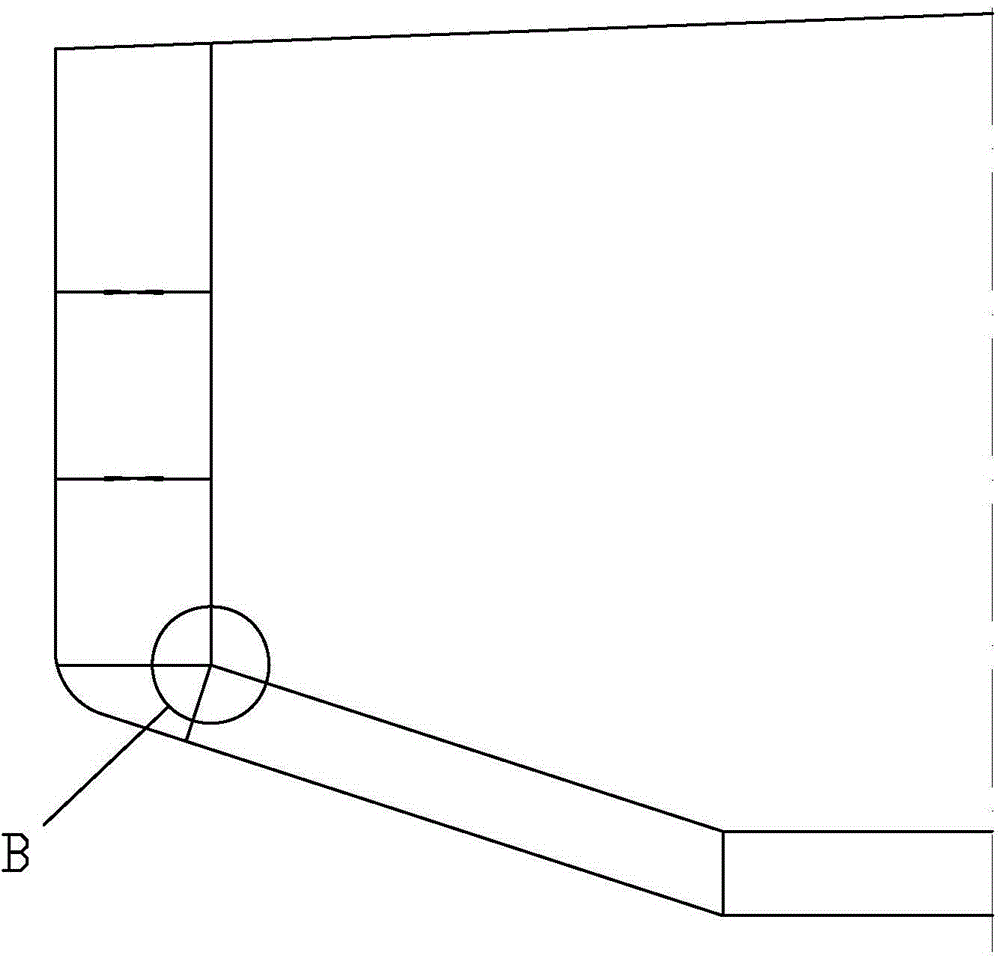

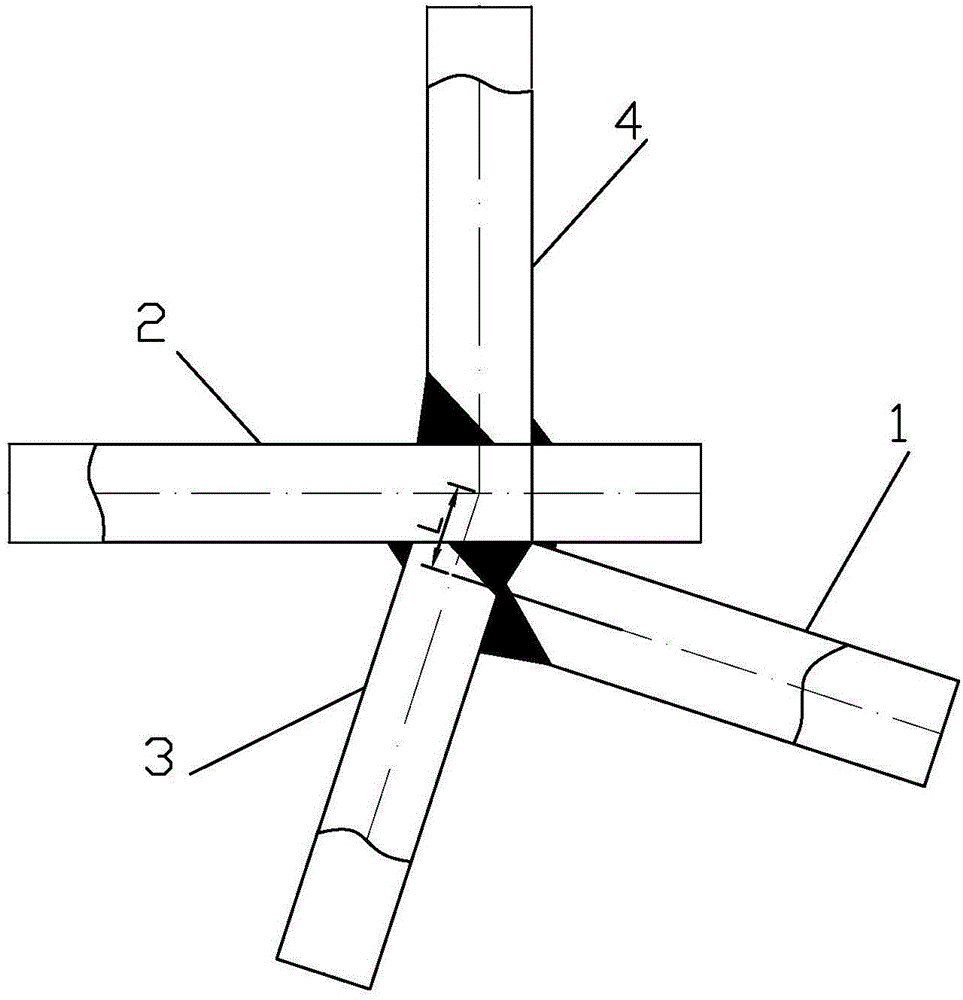

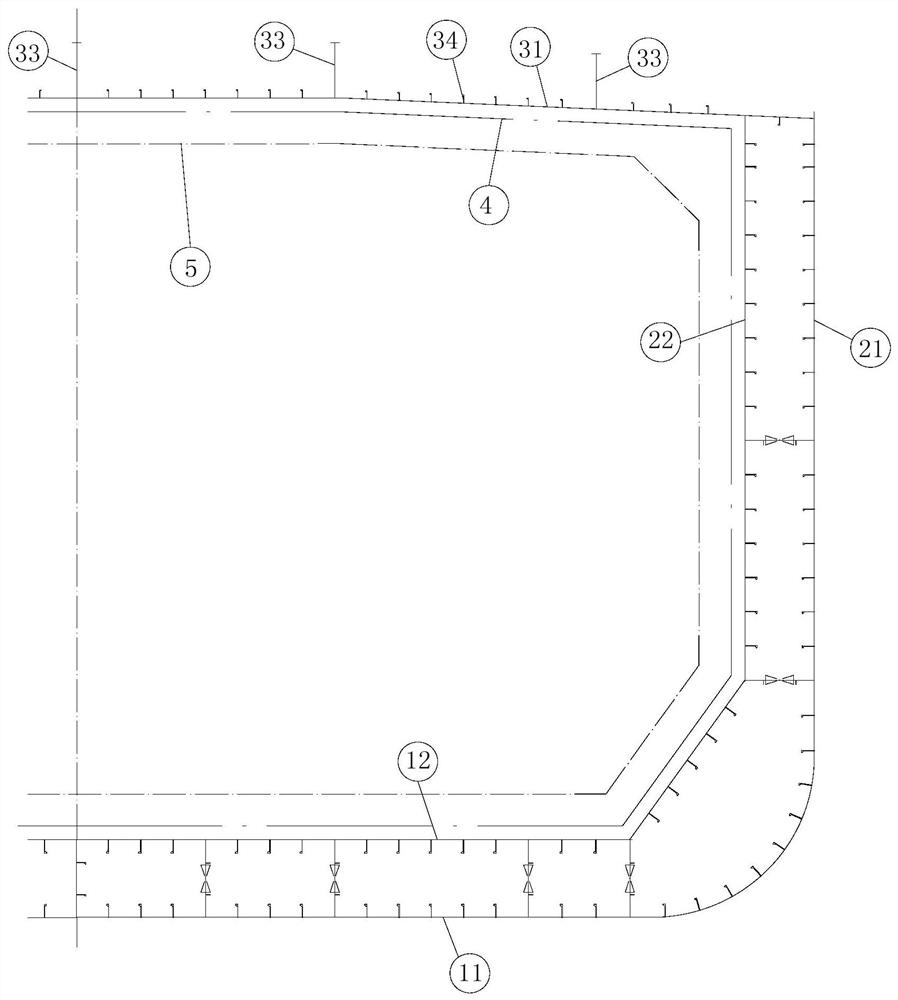

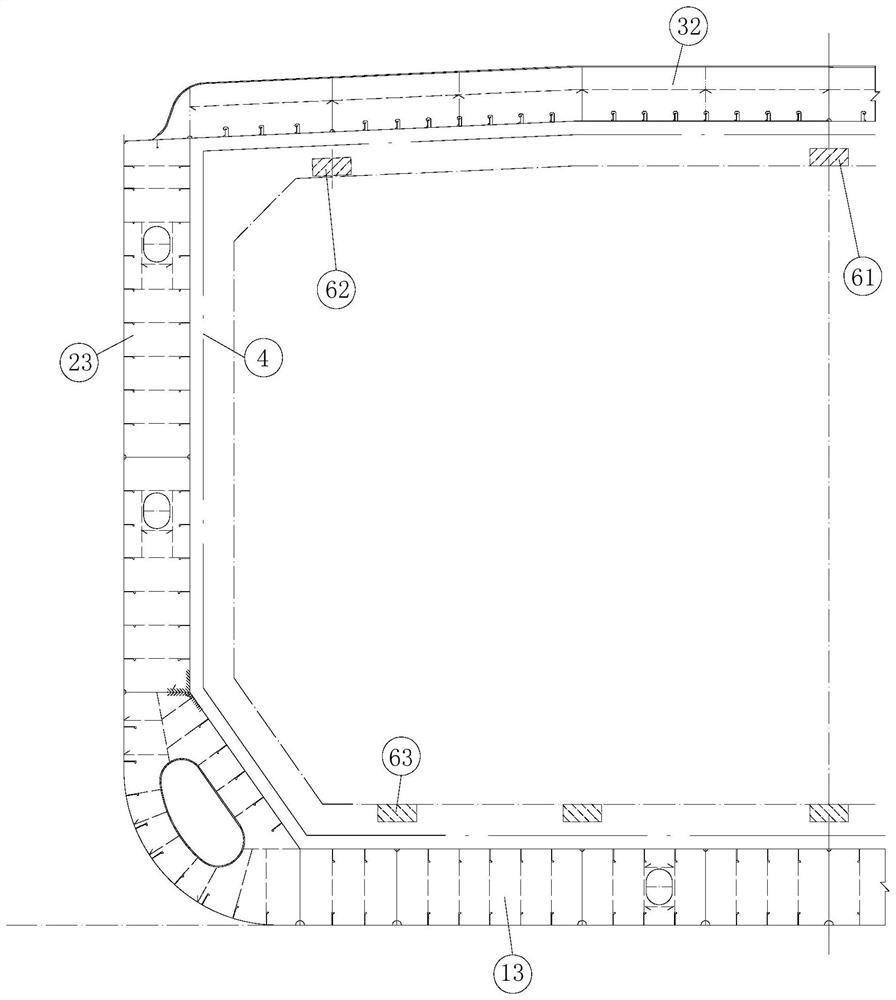

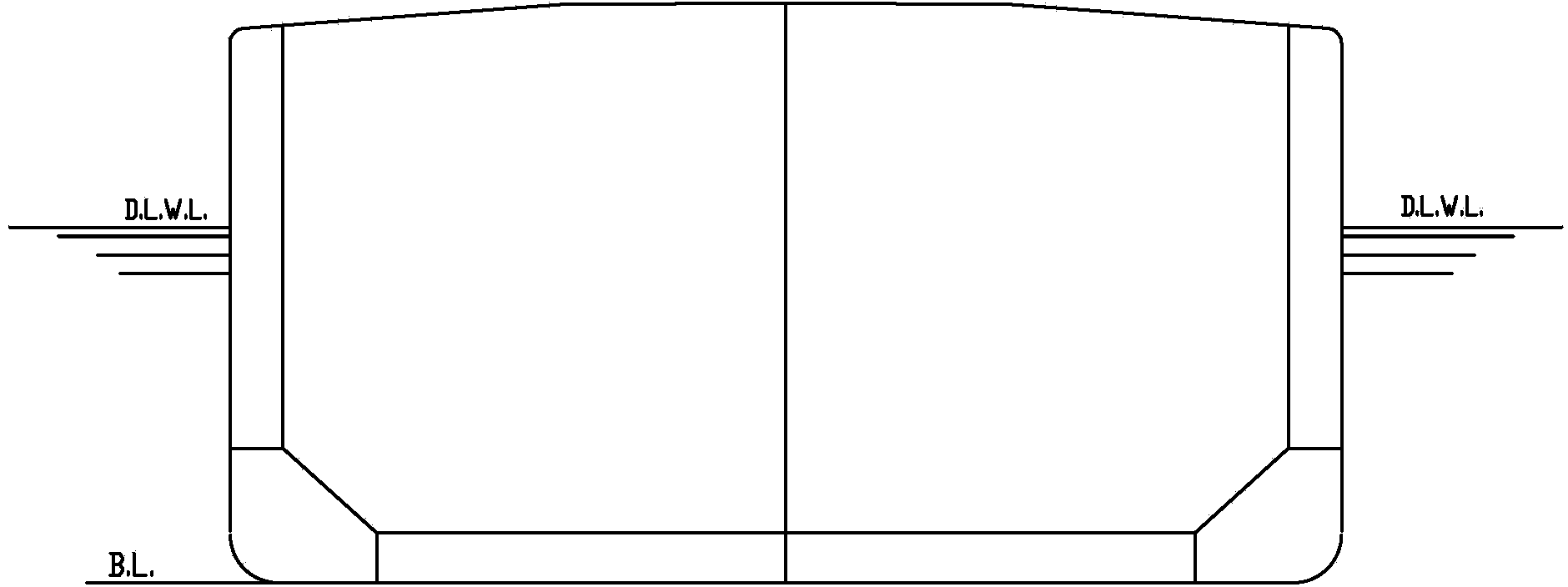

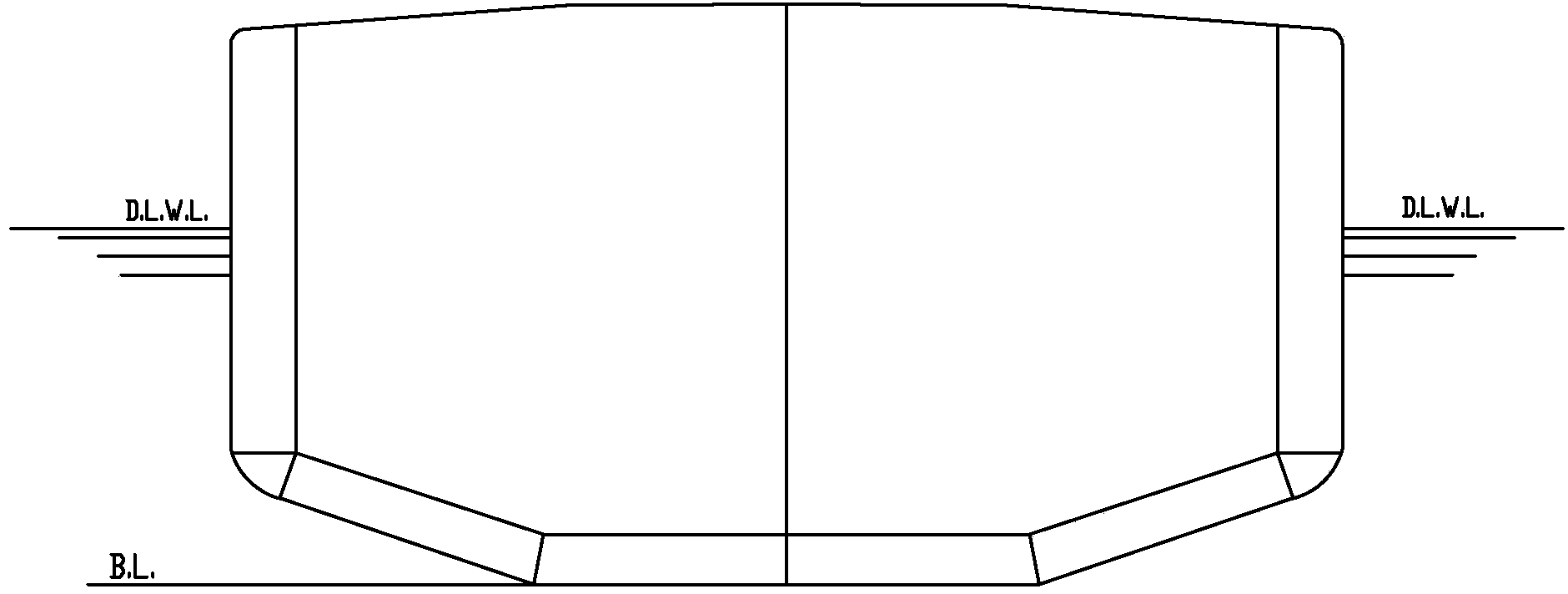

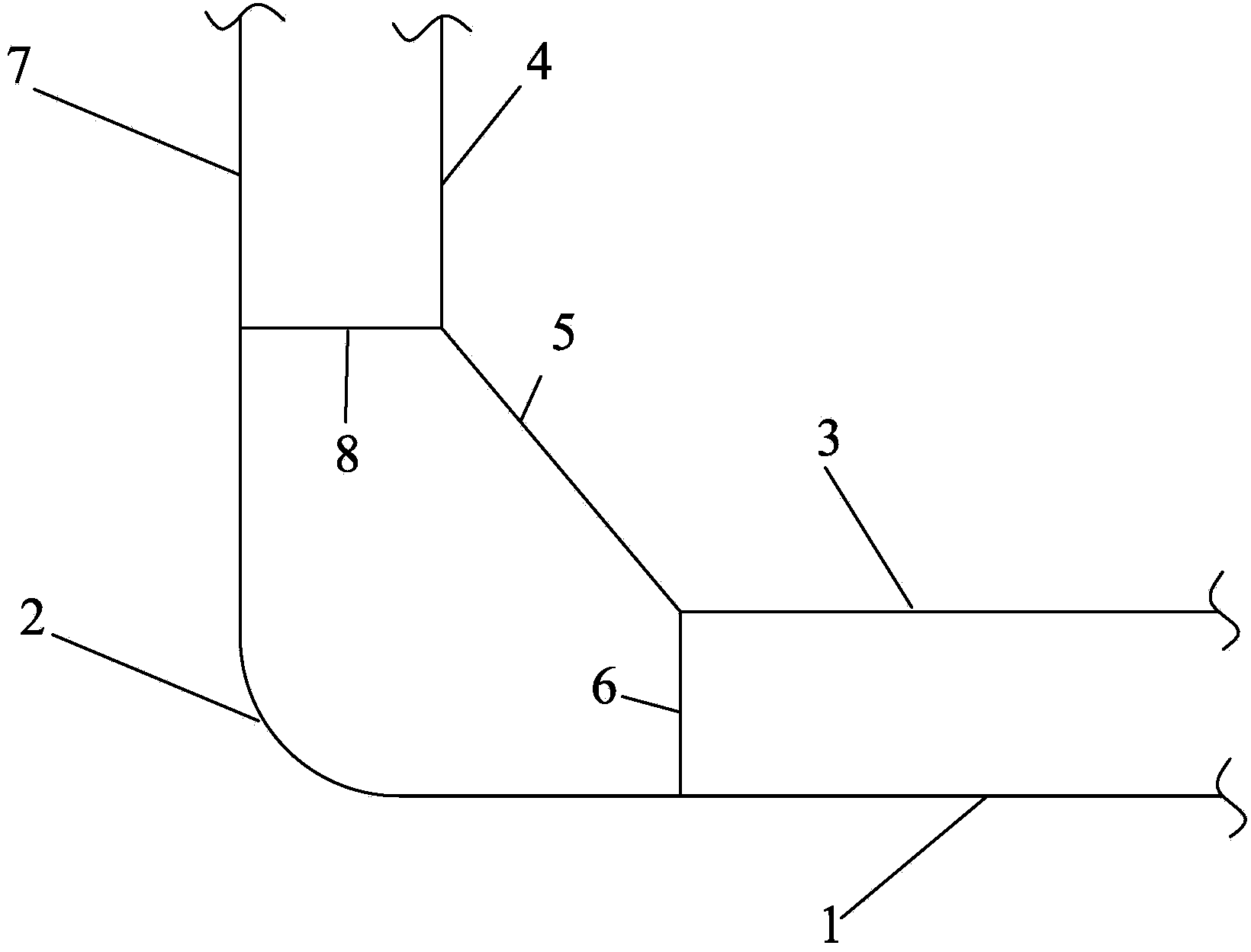

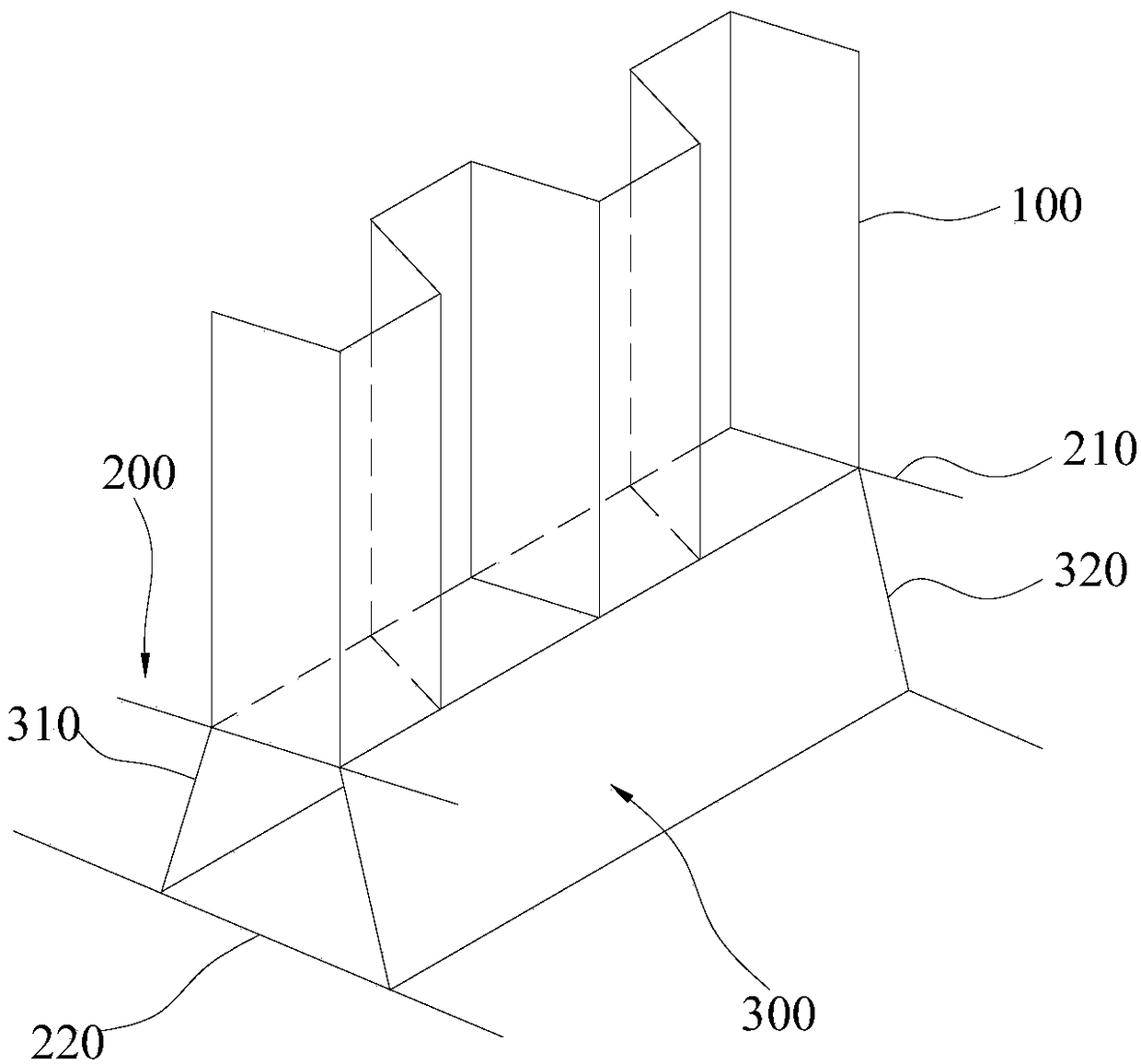

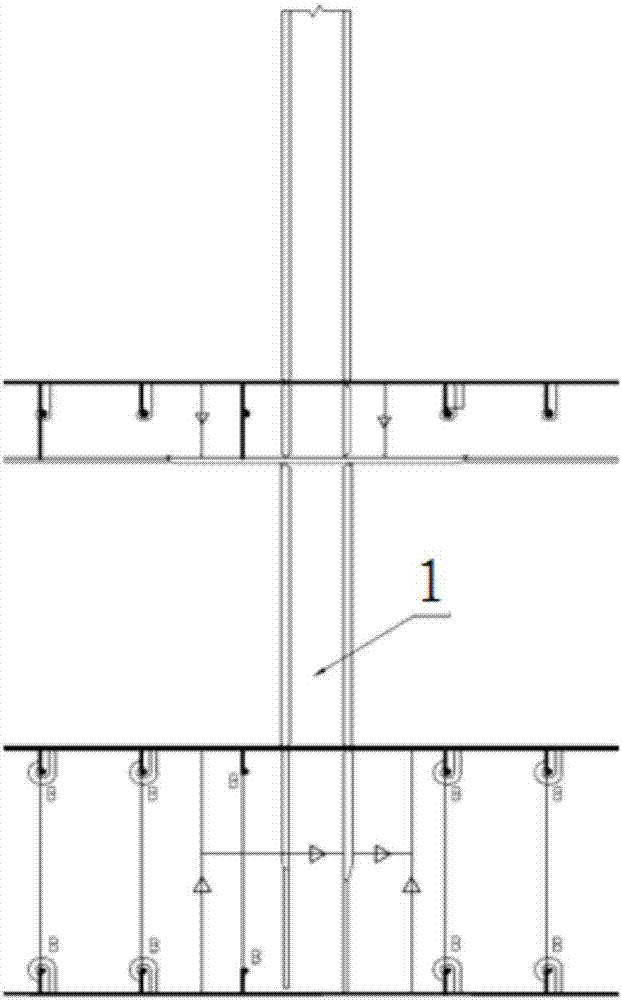

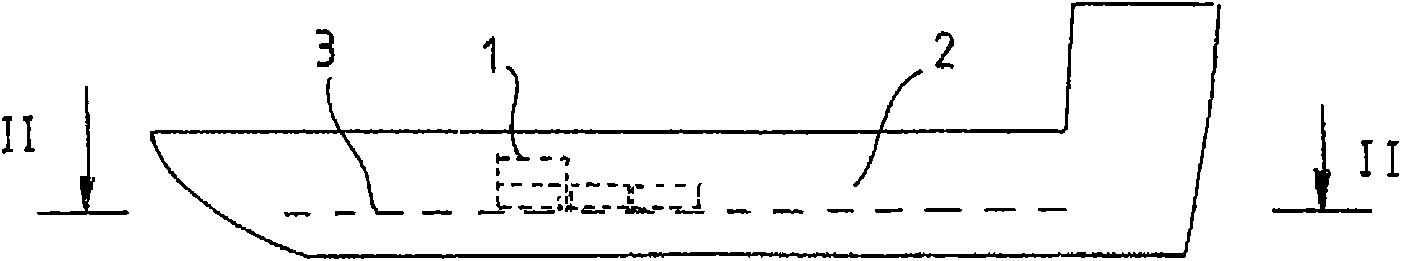

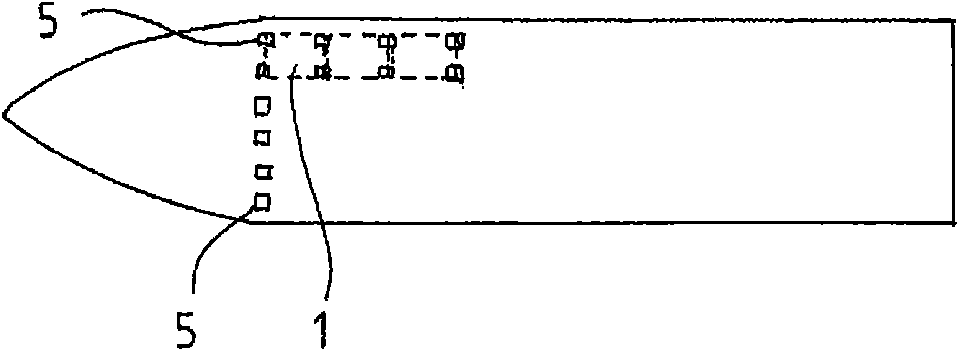

Inclined double-bottom ship based on four-center alignment connection of inner bottom plate and side horizontal girder

InactiveCN104554617AImprove stress concentrationEliminate additional bending momentsHull double bottomsEngineeringDouble bottom

The invention discloses an inclined double-bottom ship based on four-center alignment connection of an inner bottom plate and a side horizontal girder. The inclined double-bottom ship comprises a side and a bottom part, wherein the side and the bottom part are of a double-layer structure, the two sides of the bottom part are of inclined structures, the middle part of the bottom part is of a straight structure, an inclined inner bottom plate (1) and the side horizontal girder (2) are made of a whole bending plate, flat plate structures at the two sides of the bending part of the bending plate are respectively used as the inclined inner bottom plate (1) and the side horizontal girder (2), the inclined inner bottom plate (1) and the side horizontal girder (2) are respectively connected with a side inner shell plate (4) and an inner bottom edge stringer (3) at the upper part and lower part of the bending part, and then centerlines of the four plates are crossed into a point. The inclined double-bottom ship has the advantages that the anti-fatigue strength is effectively improved, the structure weight is reduced, the workload of welding and grinding is reduced, the construction and processing technology is simplified, the working efficiency is improved, the cost is low, and the strength is high.

Owner:DALIAN SHIPBUILDING IND

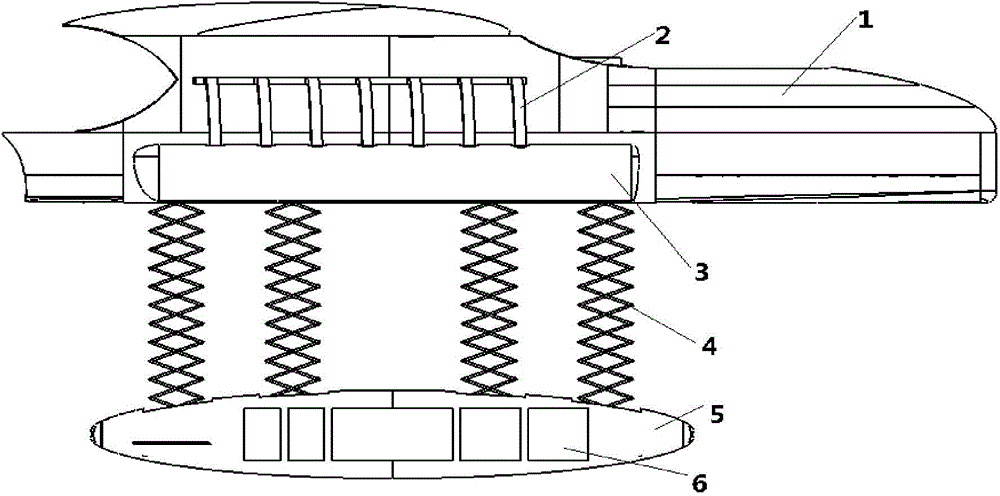

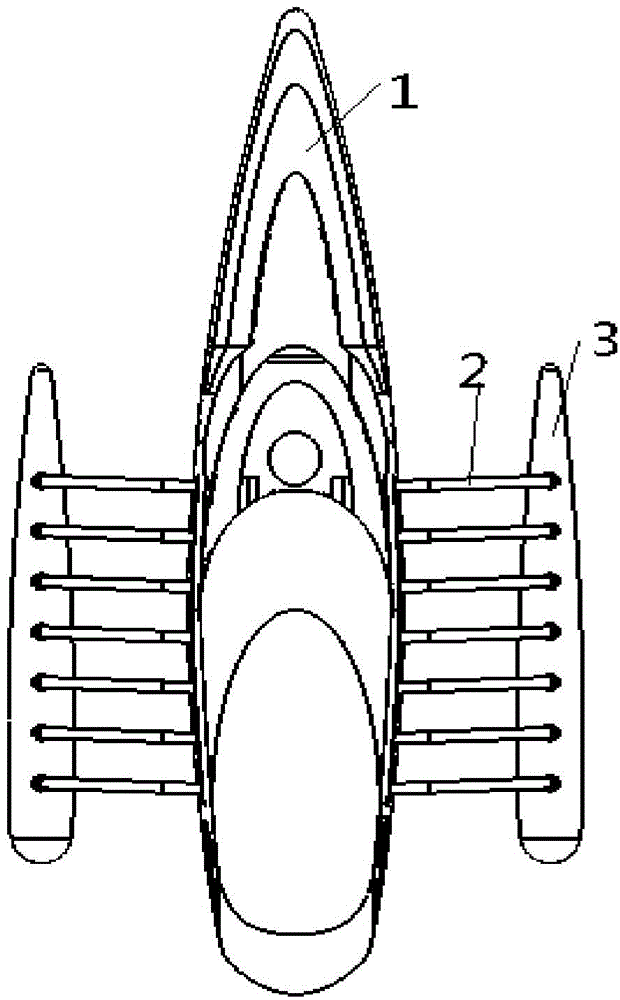

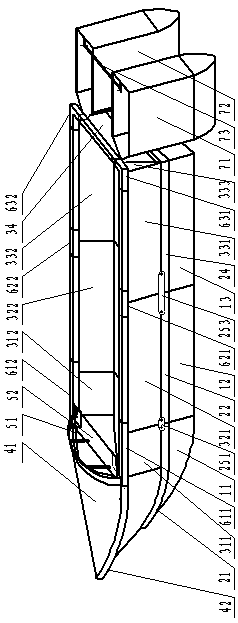

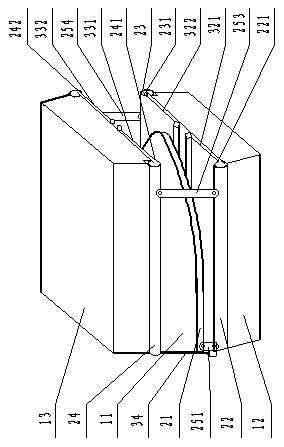

Low-noise separation type underwater sightseeing three-body yacht

ActiveCN104859805AReduce noiseReduce vibrationHull double bottomsSpecial purpose vesselsLow noiseMarine engineering

The invention discloses a low-noise separation type underwater sightseeing three-body yacht. The low-noise separation type underwater sightseeing three-body yacht comprises a yacht body, a depth-adjusted depth underwater sightseeing cabin and a width-adjusted side body and is characterized in that the depth-adjusted depth underwater sightseeing cabin is connected with a lifting control platform in a lifting control chamber in the yacht through a lifting mechanism, and the lifting mechanism drives the depth-adjusted depth underwater sightseeing cabin and the yacht body to be attached and separated through body lifting machine hydraulic mechanisms (13) at the two ends of the lifting mechanism; the body lifting machine hydraulic mechanisms are mounted at the attaching position below a deck on the bottommost layer of the yacht body; and the output ends of the mechanisms are connected with a computer through a data line. The low-noise separation type underwater sightseeing three-body yacht has the advantages of being low in noise, small in vibration, wide in navigation area, good in stability and the like.

Owner:WUHAN UNIV OF TECH

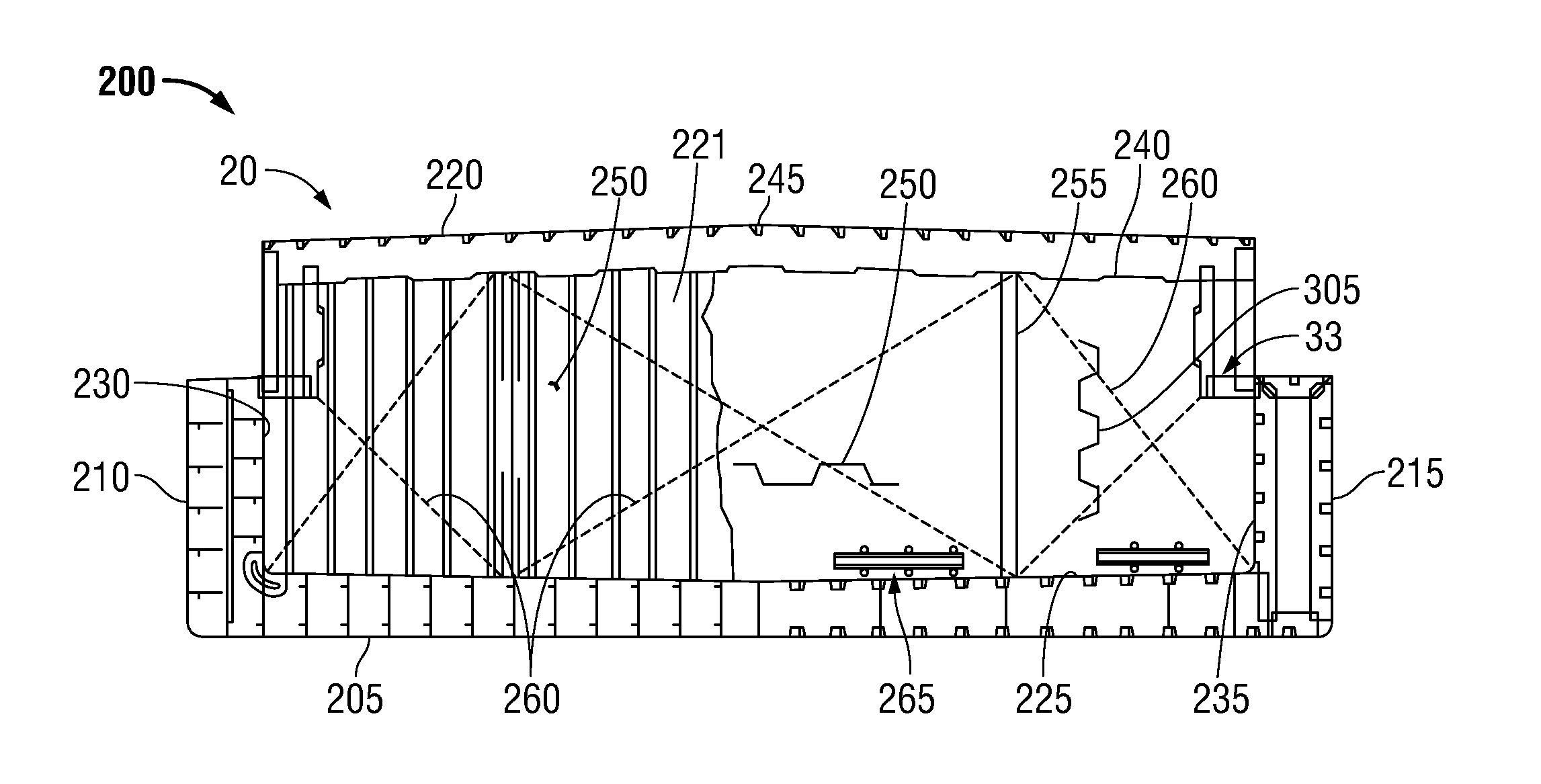

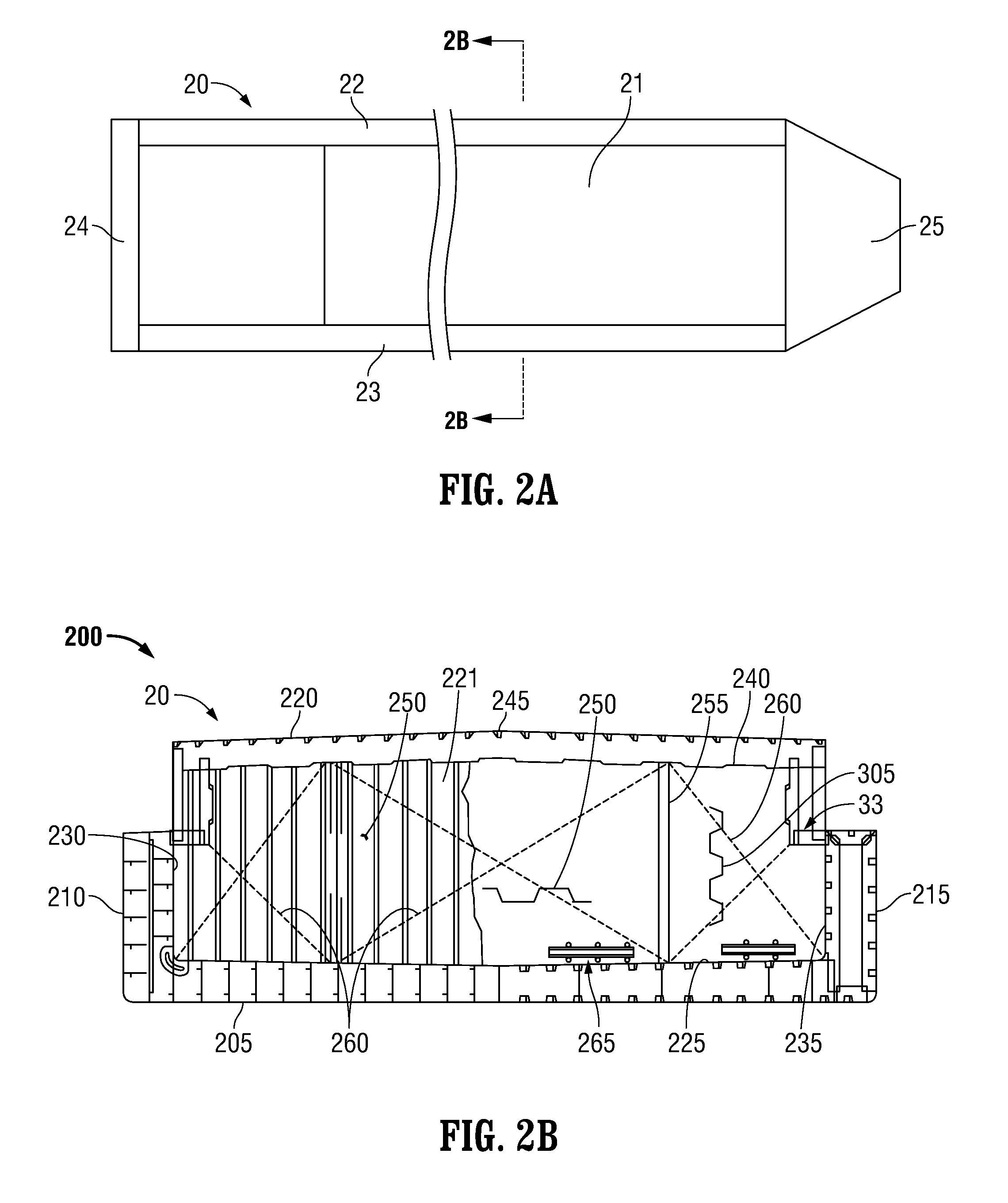

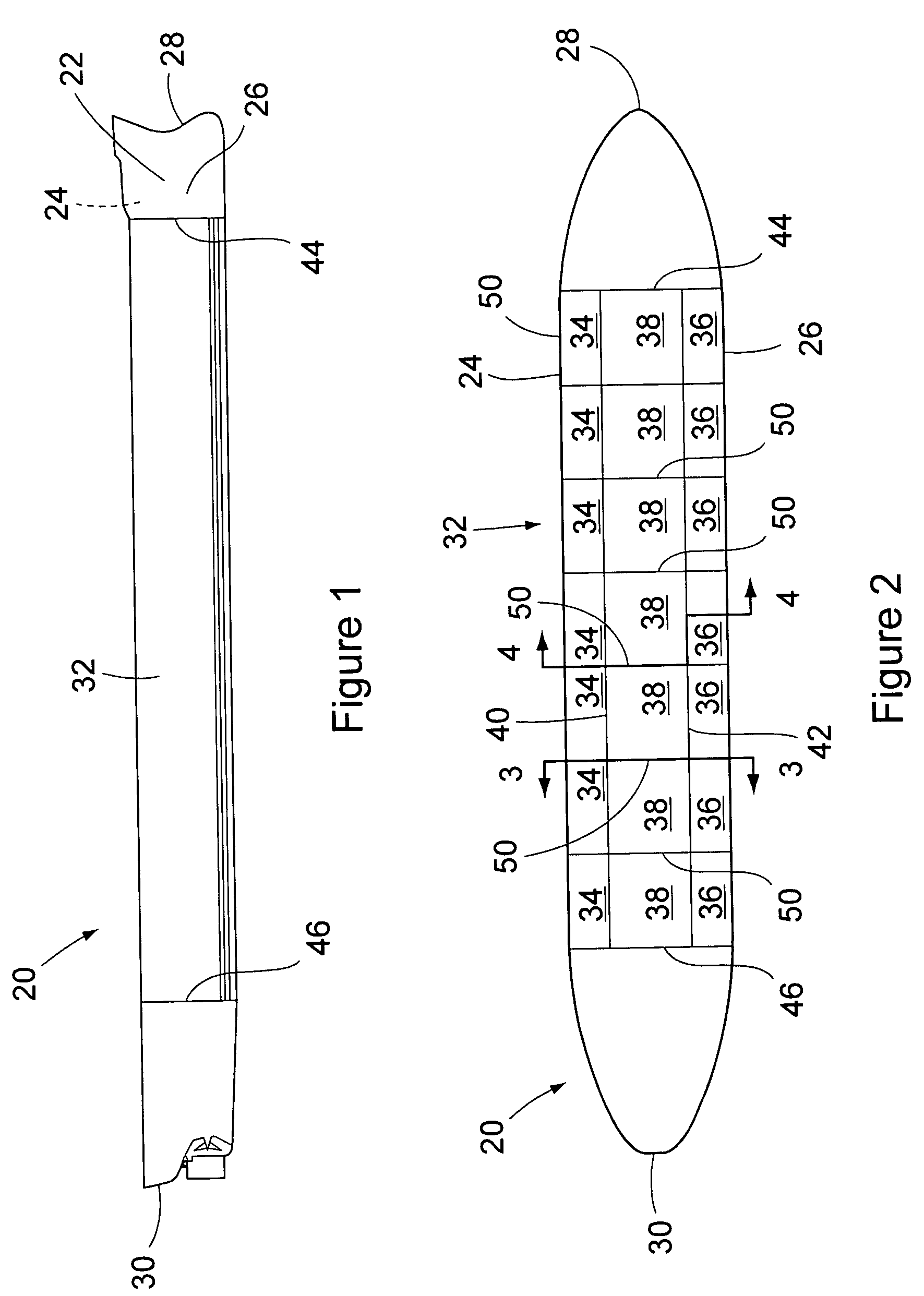

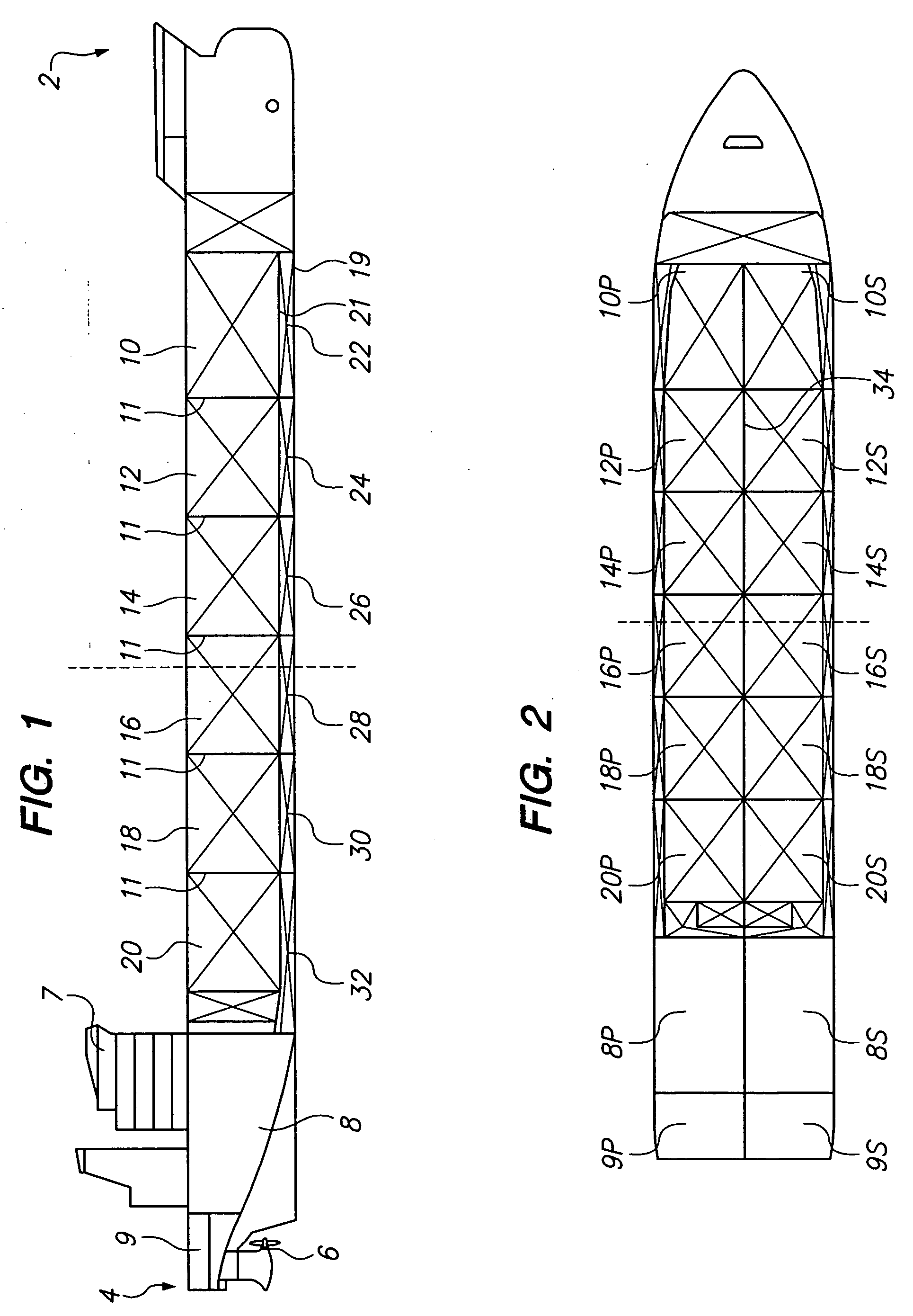

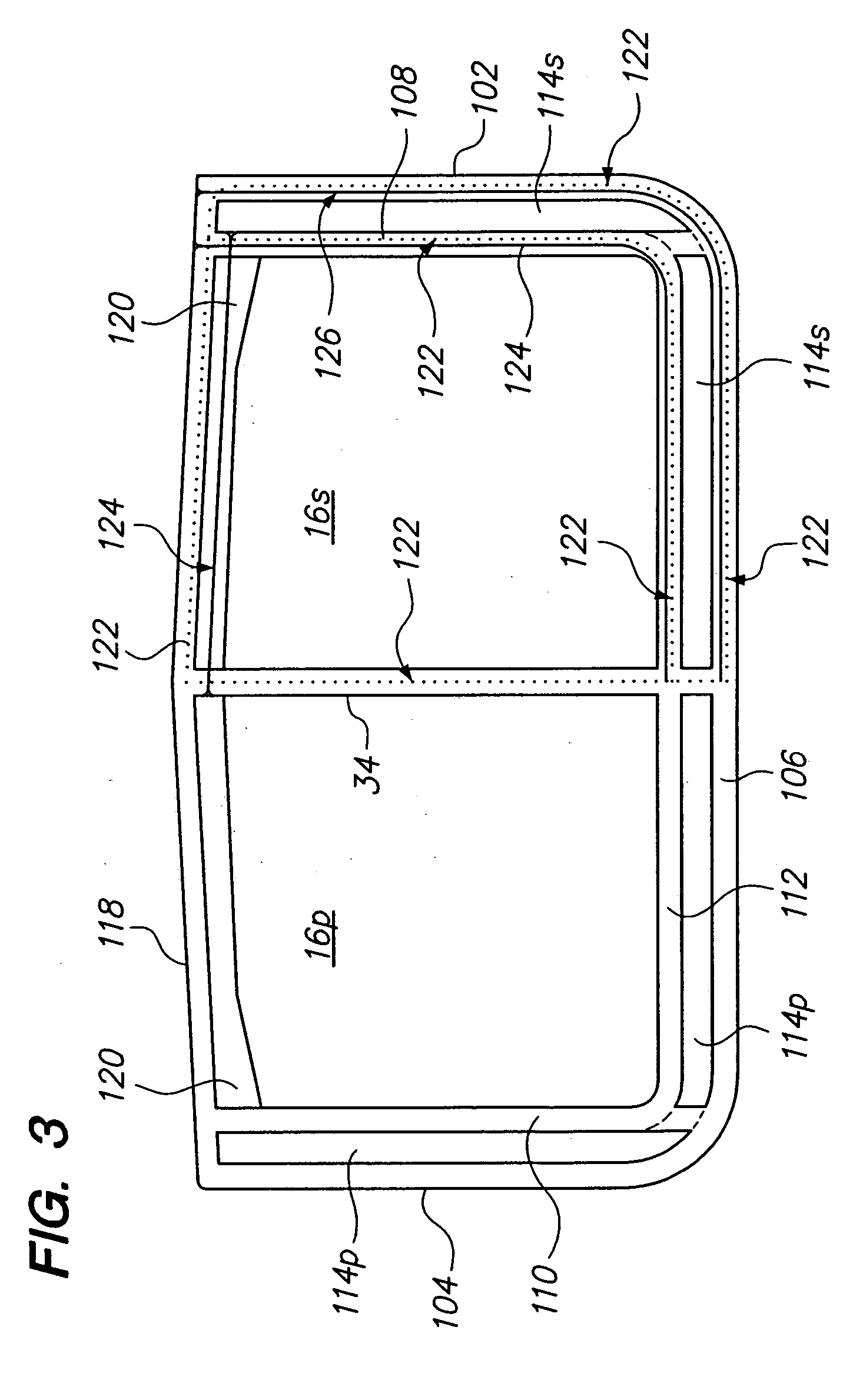

Complete integral tank double-hull cargo containment system vessel in maritime service

InactiveUS20140041566A1Provide structural integrityHull double bottomsVessel partsMarine engineeringOperating environment

A complete double-hull cargo containment vessel includes a primary hull and a secondary hull disposed within the primary hull. The primary hull includes a topside deck structural member. The secondary hull includes an interior cargo containment tank. The secondary hull includes a topside structural member configured to seal the cargo containment tank. The primary hull is configured to serve as a first boundary between an operating environment of the vessel and the cargo. The secondary hull is configured to serve as a second boundary between the operating environment of the vessel and the cargo. The topside deck member of the primary hull and the topside structural member of the secondary hull are configured to provide a double-hull on the topside of the cargo containment tank.

Owner:MARTIN OPERATING PARTNERSHIP

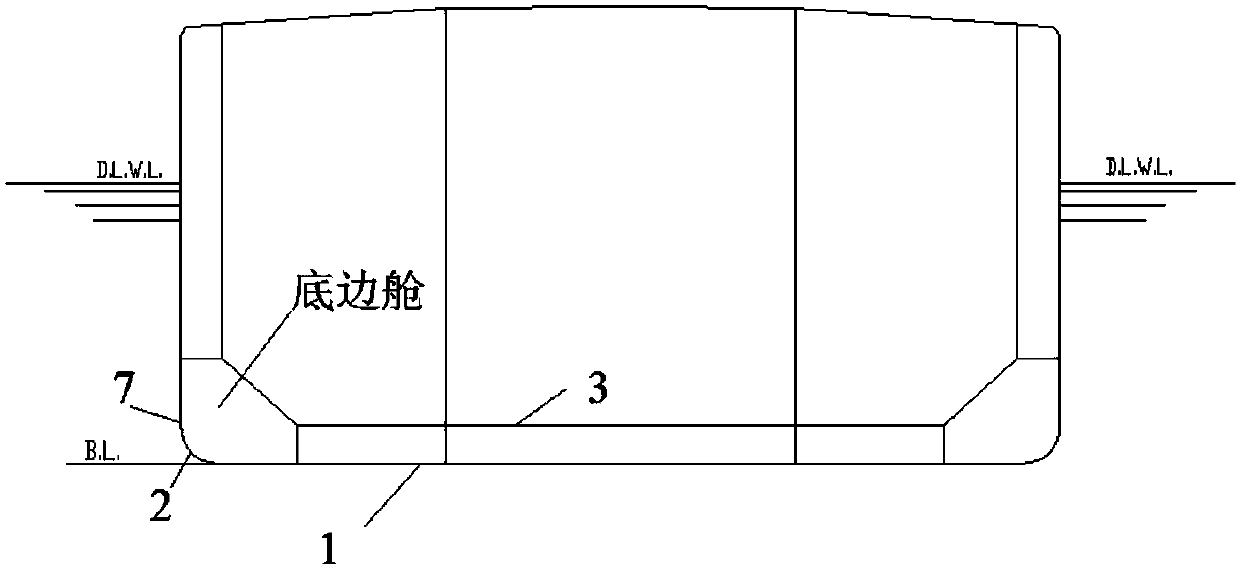

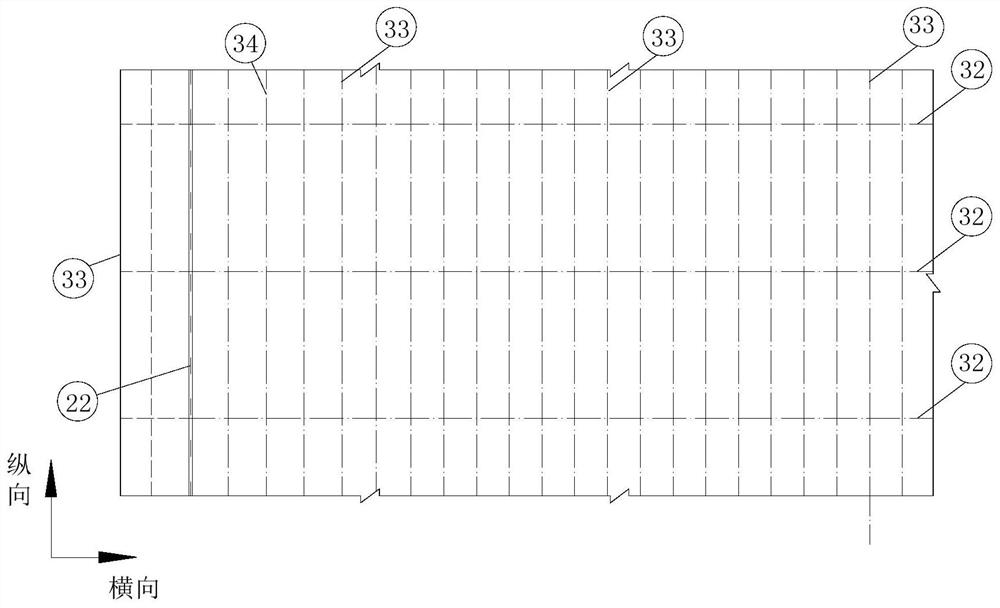

Method for designing overall-width flat-inner-bottom liquid cargo ship

InactiveCN107792294AHigh strengthEasy to removeHull interior subdivisionHull double bottomsStress concentrationBilge

The invention discloses a method for designing an overall-width flat-inner-bottom liquid cargo ship, belongs to the technical field of shipbuilding, and relates to a structural design method of an inner bottom in a double-bottom ship and a bottom side tank area of a bilge area. The method comprises the steps that a flat outer bottom, the bilge area, a side, a bottom side tank cantboard, an inner shell and a flat inner bottom are parallelly arranged at the bottom of the ship, the flat outer bottom is connected to the side through the bilge area, the flat inner bottom is connected to the bilge area or the side through an extension flat inner bottom, and the flat inner bottom is connected to the inner shell through the bottom side tank cantboard. According to the method for designing the overall-width flat-inner-bottom liquid cargo ship, the flat inner bottom is connected to the side through the extension flat inner bottom arranged in the bottom side tank, so that the flat inner bottom and an extended bottom area form a void space, the weight of ballast water for the ship reaches or is close to a minimum value of a dedicated ballast tank required by the MARPOL convention, so that energy consumption is reduced, and the purpose of energy conservation is achieved. Because the flat inner bottom serving as the bottom of the ballast tank is more beneficial for removing sediment, and theusing convenience is improved; and the structural continuity of the flat inner bottom can better transmit load, stress concentration is reduced, and the structural strength is improved.

Owner:CHINESE CLASSIFICATION SOC

Oiltank structure

InactiveCN101161543AExempt from settingIncrease profitHull interior subdivisionHull double bottomsFuel tankEngineering

Owner:TAWWAN MARITIME TRANSPORTATION

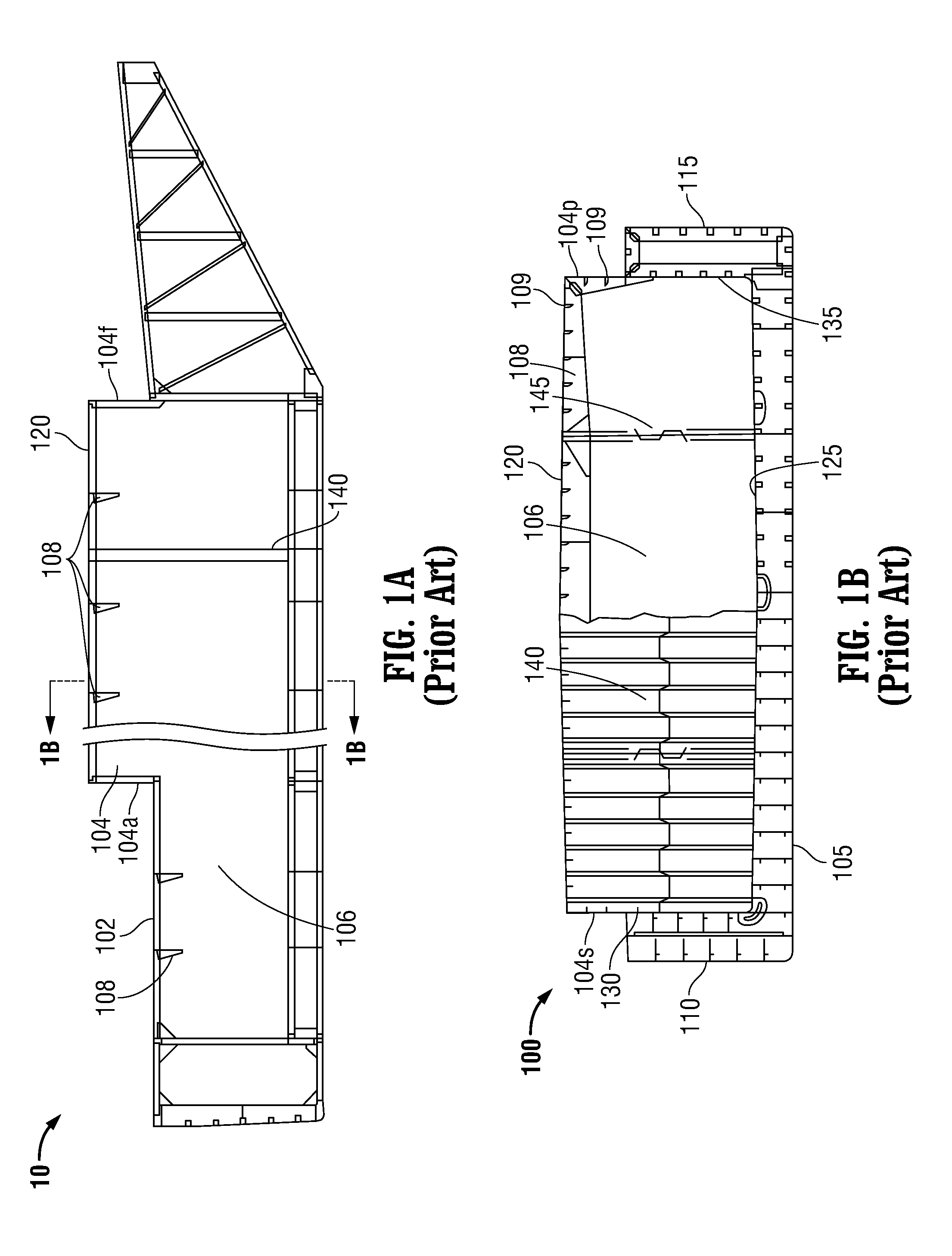

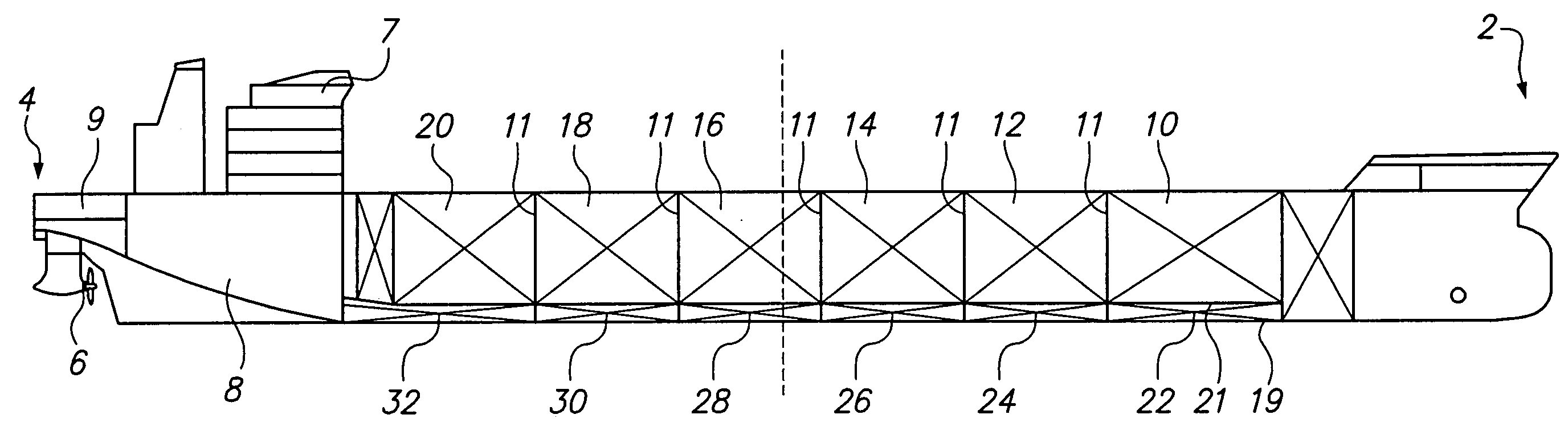

Double-hull ore carrying vessel conversion from single-hull oil tanker and method of performing the same

InactiveUS7077071B2High strengthEasy loading and unloadingNon-magnetic metal hullsHull double bottomsFuel tankOil tanker

A method for converting a single-hull vessel to a double hull vessel, and the converted double hull vessel, is disclosed. The single hull vessel to be converted has an outer hull surrounding a center cargo tank flanked by a port wing tank and a starboard wing tank, with spaced-apart transverse bulkheads extending between the port and starboard wing tanks to form one or more central tanks. An elevated floor is added to the central cargo tanks by installing new bottom plating spanning the transverse bulkheads and the sidewalls of the wing tanks. Support members are added to increase the strength of the elevated floor, the cargo tank, and the wing tanks, as needed. A sealed compartment is formed by the new elevated floor, the outer hull, and the sidewalls and bulkheads to protect the cargo from leaking out of the vessel should the integrity of the single hull be breached. The method achieves conversion of the single hull vessel to a double hull construction without breaching the integrity of the pre-existing single outer hull, and thus is faster and easier in converting single hull vessels to minimize cost of conversion and vessel outage.

Owner:NEU RICHARD W

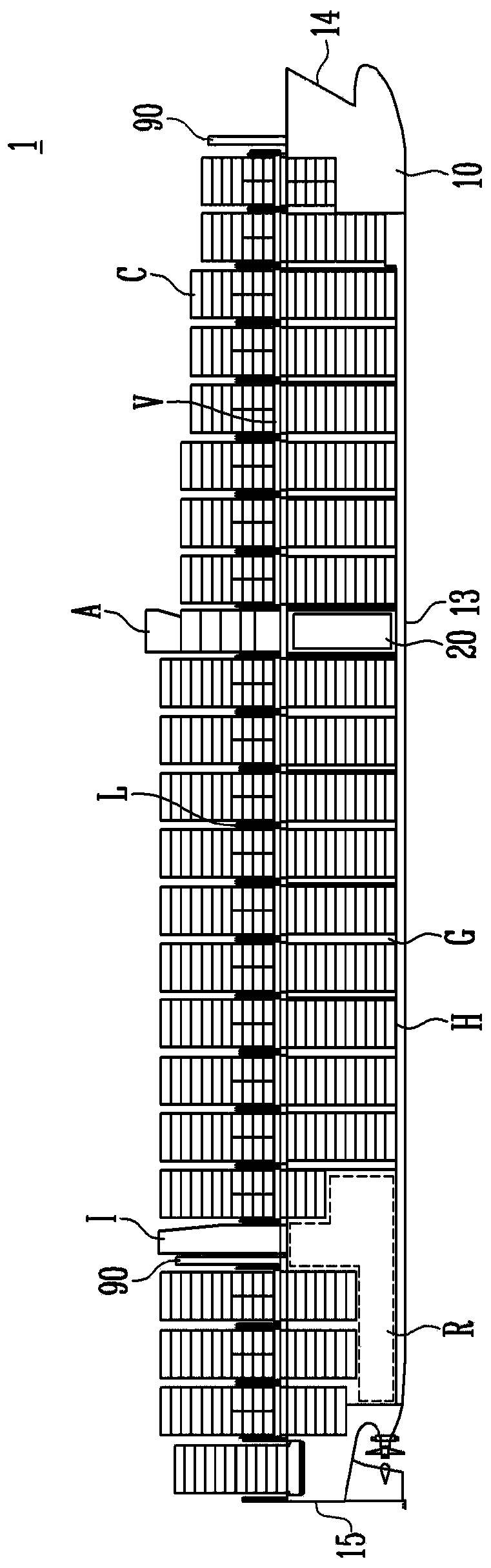

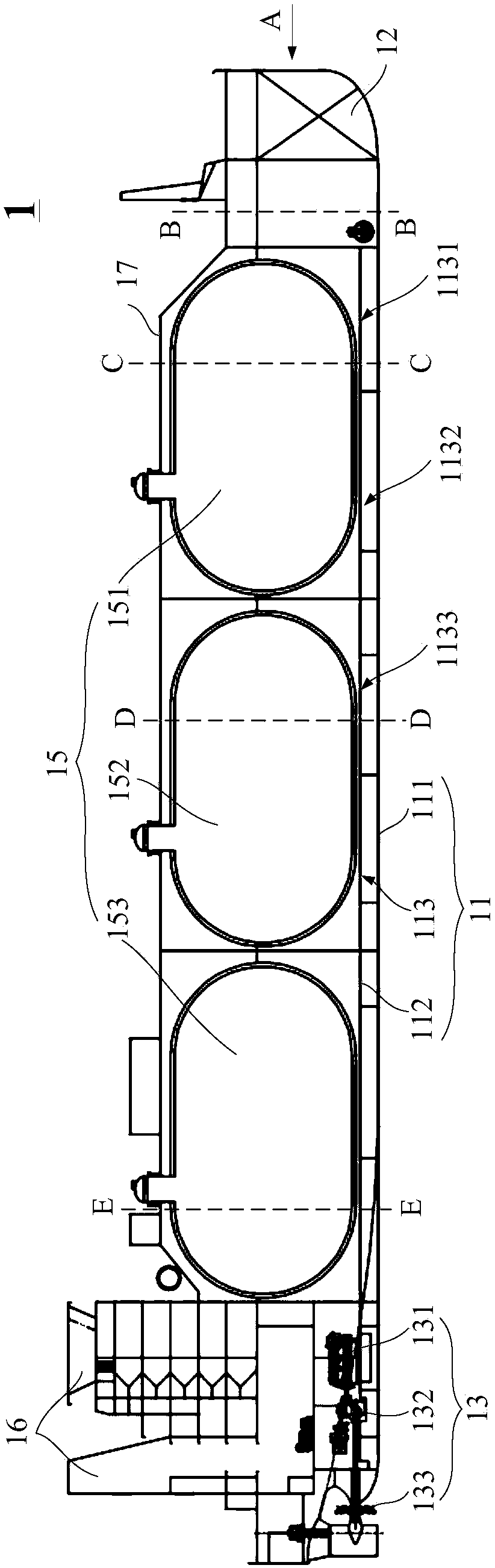

Liquefied natural gas transport ship and liquefied natural gas transport system

PendingCN112356972ALarge capacityImprove economyHull decksHull double bottomsHull structureTransport system

The invention provides a liquefied natural gas transport ship and a liquefied natural gas transport system, and relates to the technical field of oceans. The ship body comprises a double-layer bottomplate, a double-board side plate and a single-layer main deck; the double-layer bottom plate comprises a ship bottom outer plate, a ship bottom inner plate and a ship bottom rib plate; the double-board side plate comprises a board side outer plate, a board side inner plate and a board side reinforcing frame plate; the single-layer main deck comprises a deck body and a deck reinforcing structure; the ship bottom inner plate, the broad side inner plate and the deck body form a liquid tank cabin in a surrounding mode, and the deck reinforcing structure is arranged on the outer side face of the deck body. The liquefied natural gas transport system comprises the ship. The technical problems that in the prior art, the capacity of a ship body structure cabin of an LNT A-BOX type liquefied gas ship is small, the overall weight of the ship body is heavy, the top in the cabin is low, the laying of a secondary screen wall and the construction process of a supporting structure are difficult, the period is long, the cost is high, and the maintenance difficulty in the cabin is large are solved.

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

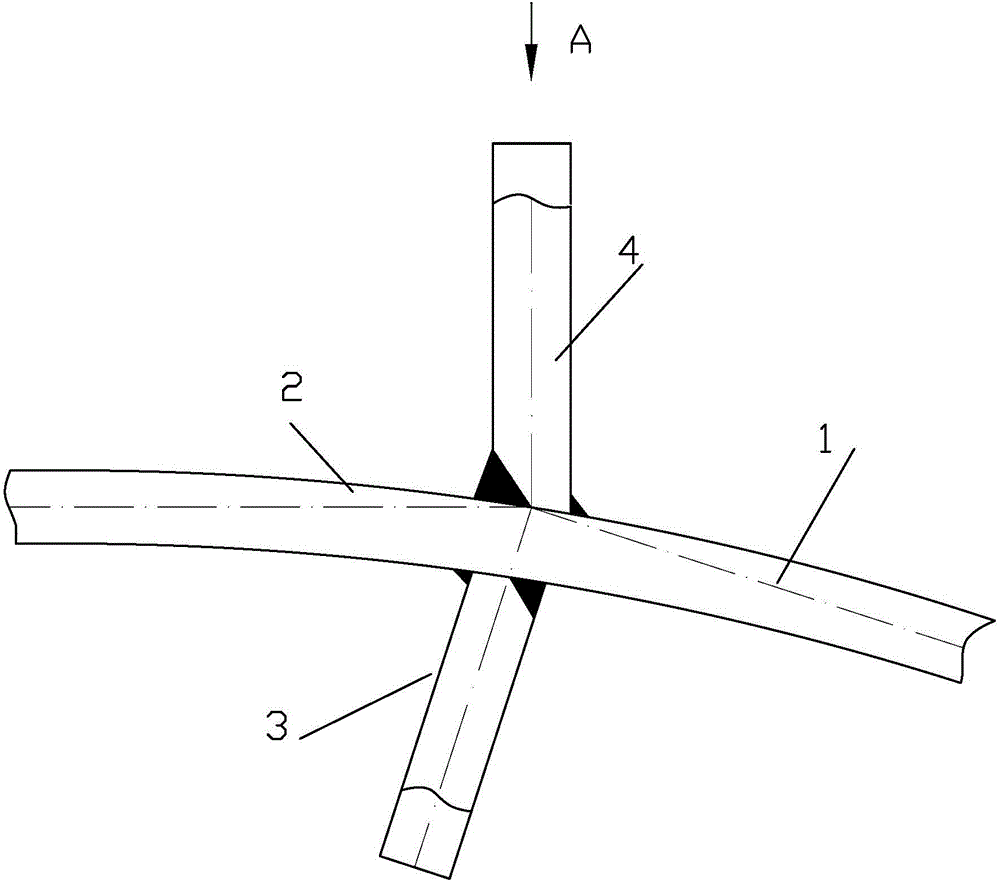

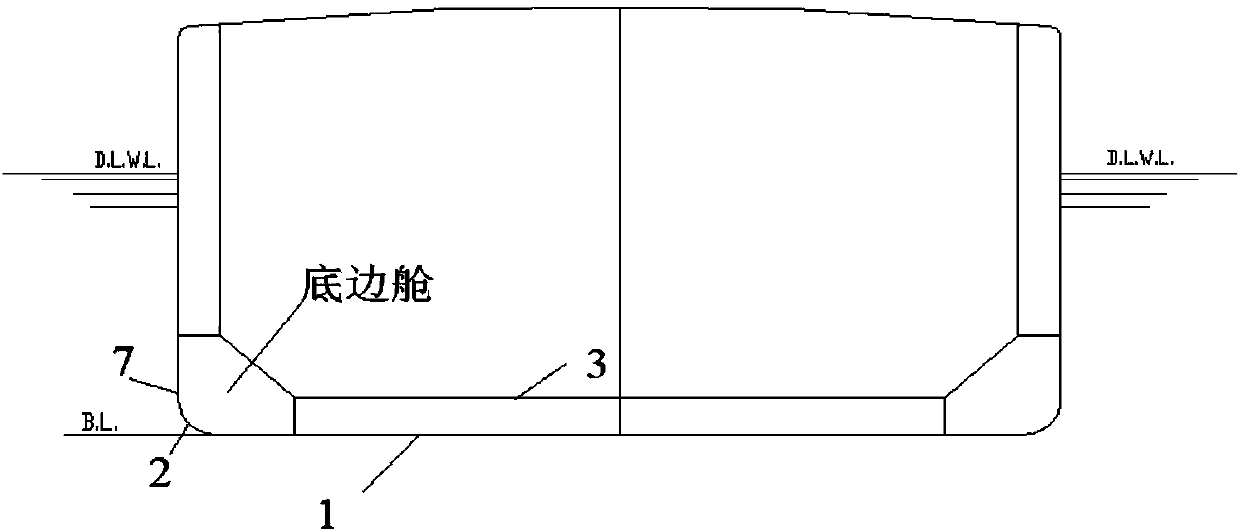

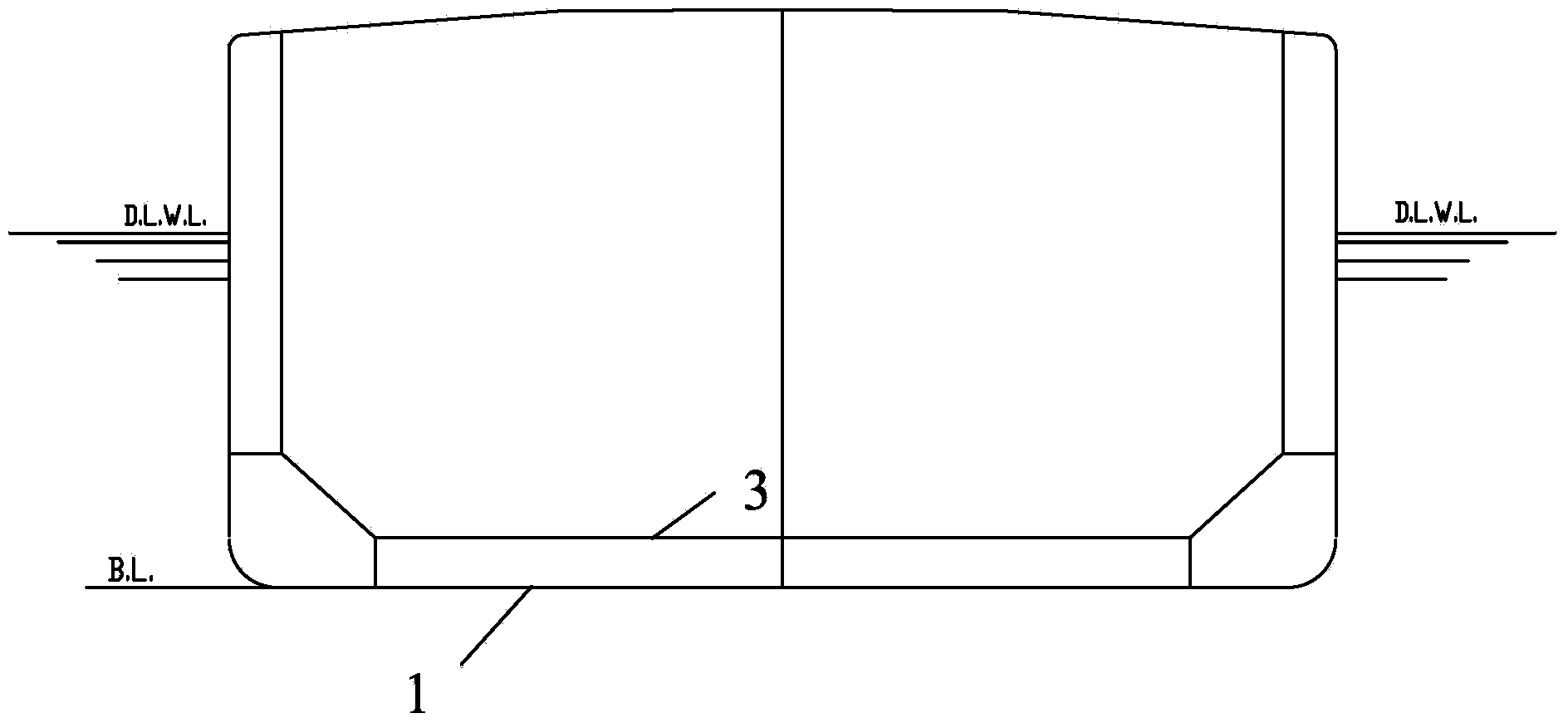

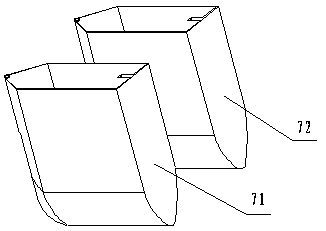

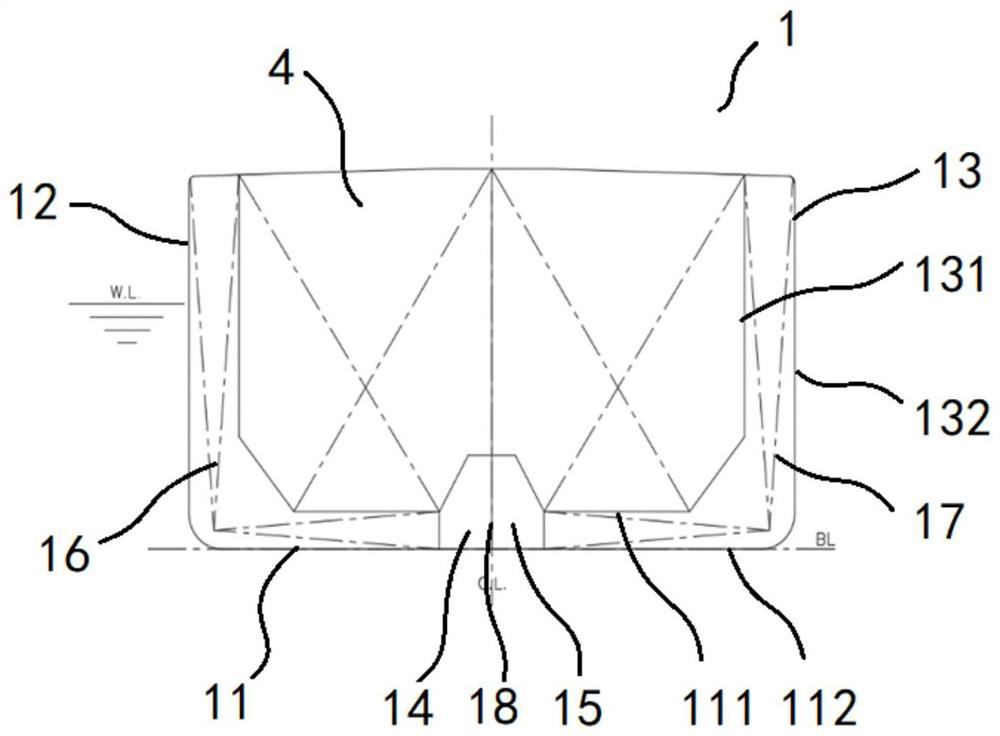

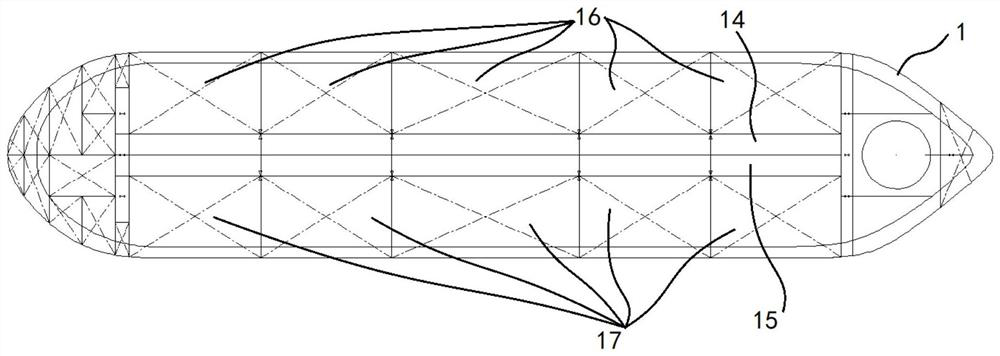

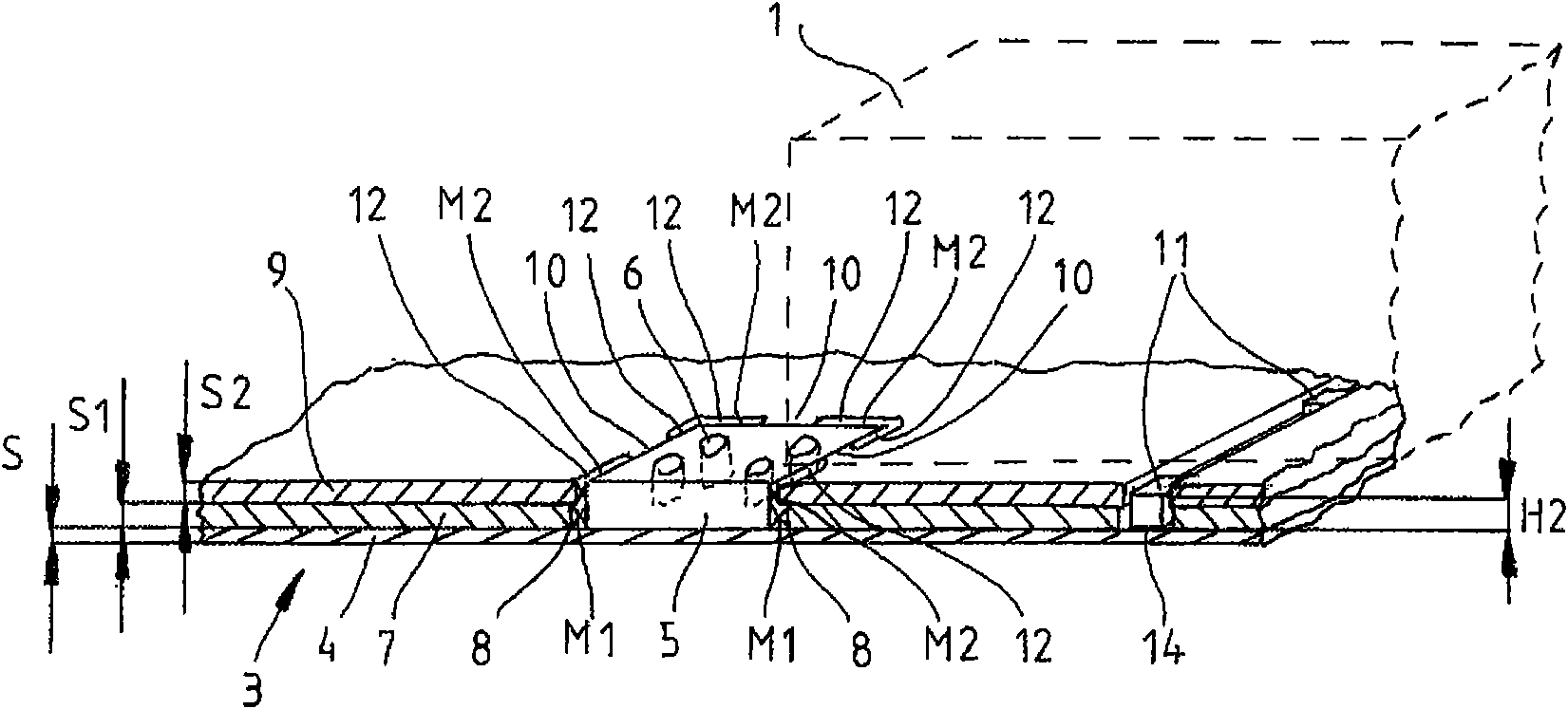

Ship with equant oblique double-layer bottoms

ActiveCN103661794AHigh strengthReduce stress concentrationHull double bottomsHull bulkheadsStress concentrationMarine engineering

The invention discloses a ship with equant oblique double-layer bottoms. The ship comprises flat outer bottoms (1) and flat inner bottoms (3). The flat outer bottoms (1) and the flat inner bottoms (3) are parallel to the bottom of the ship and are respectively connected with oblique outer bottoms (6) and oblique inner bottoms (5) so as to be connected to shipboards, and the oblique outer bottoms (6) are parallel to the oblique inner bottoms (5); bottom longitudinal girders (2) are arranged among folded corners of the flat outer bottoms (1) and the oblique outer bottoms (6) and folded corners of the flat inner bottoms (3) and the oblique inner bottoms (5). The bottom longitudinal girders (2) are aligned with a longitudinal bulkhead (4) (if the longitudinal bulkhead is available), the folded corners of the inner bottoms and the outer bottoms are equally divided by the bottom longitudinal girders (2), coordinates of the folded corners of the inner bottoms are consistent with coordinates of upper end points of the bottom longitudinal girders (2), and coordinates of the folded corners of the outer bottoms are consistent with coordinates of lower end points of the bottom longitudinal girders (2). The ship has the advantages that a method for arranging the bottom longitudinal girders at folded corner points is applied, various structural angles are reasonably arranged by the aid of an equant included angle principle, accordingly, loads can be effectively transmitted, stress concentration can be reduced, the structural strength of the ship can be improved, and a technology can be simplified.

Owner:DALIAN SHIPBUILDING IND

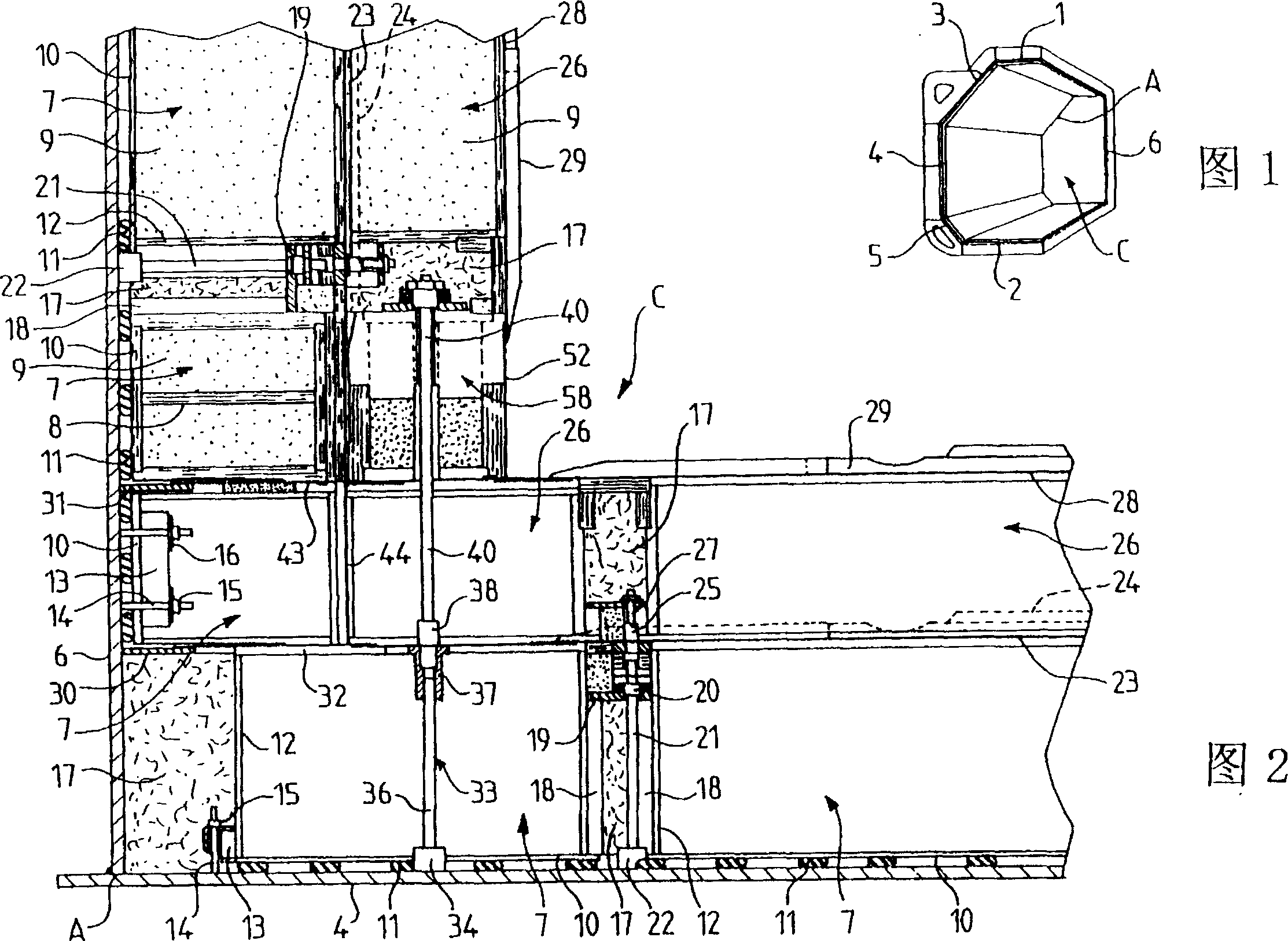

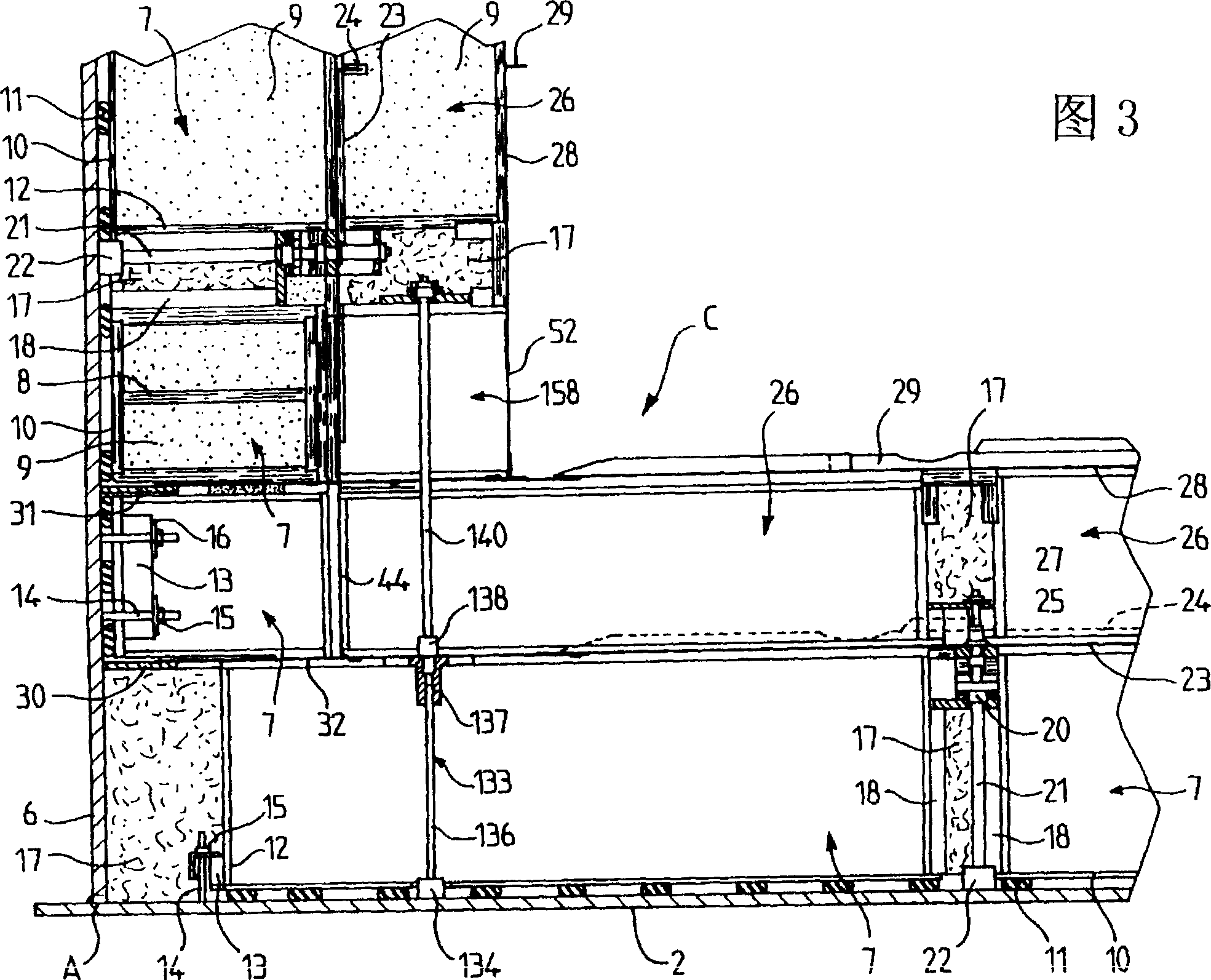

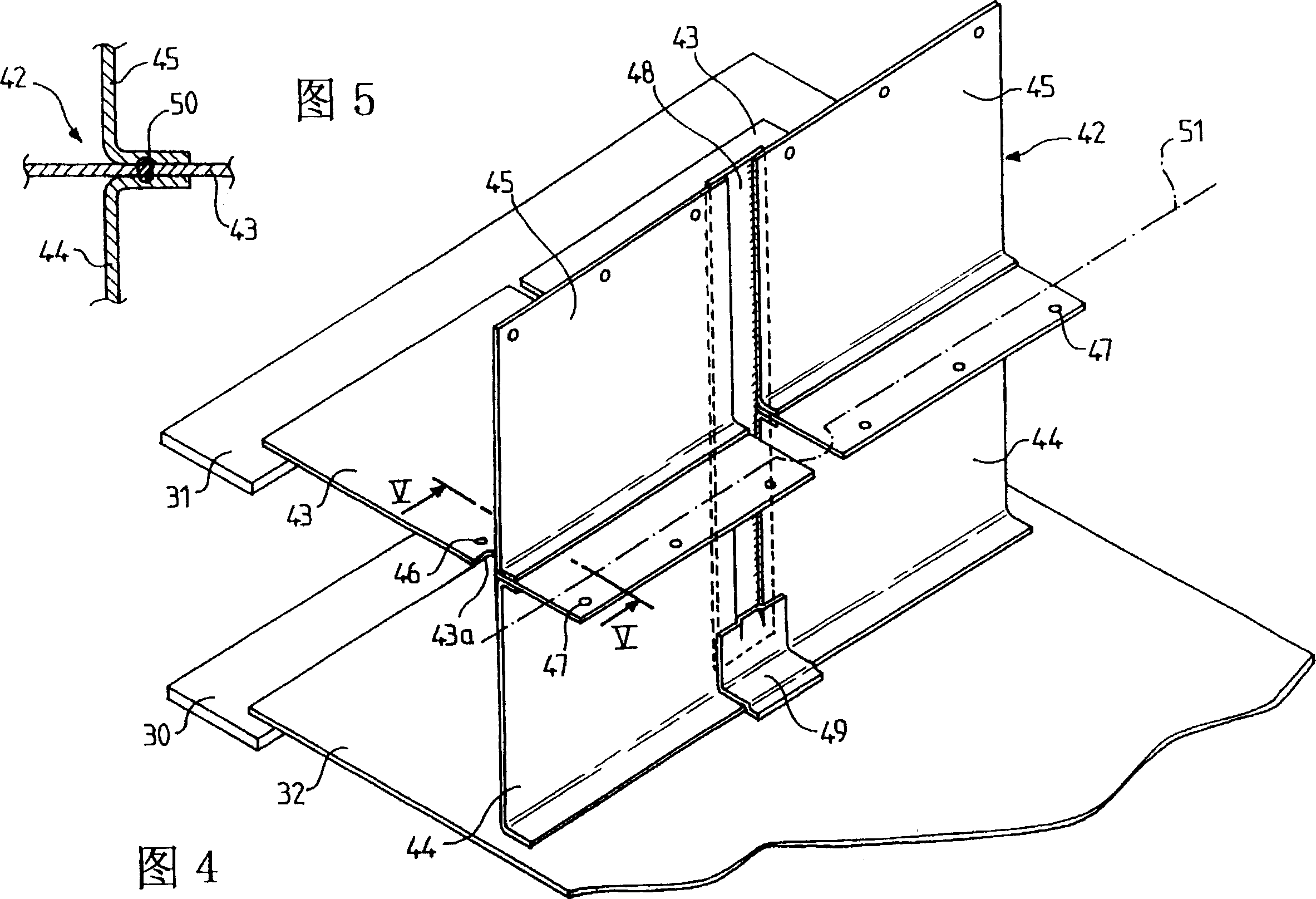

Water-proof heat-insulation cabin with simple corner structure in ship-supporting structure

A cabin C comprises both continuous watertight barriers and at least a heat-insulation barrier, which is built into a bearing structure comprising a longitudinal wall and a ransverse bulkhead. The connection between the corners of both watertight barriers is in the form of a connecting ring of a solid angle formed by the extending of the transverse bulkheads and the longitudinal walls. Each ransverse bulkhead comprises a pair of anchor plates, and each connecting ring has a metallic form. Both parallel longitudinal flanges extend in the continue part of both plates, the inner end of which is fixed on the longitudinal metallic plate of both watertight barriers. The connecting ring has a plurality of junction pieces in parallel to ransverse bulkheads, each junction piece hermetically drills through both flanges, the outer end of which is partially anchored on the longitudinal walls, and the inner end leans on an insulating girder so as to apply clamp force on the connecting ring.

Owner:GAZTRANSPORT & TECHNIGAZ SA

Concrete double-hulled tank ship

InactiveUS20070095266A1High strengthLight weightNon-magnetic metal hullsHull double bottomsHydrocotyle bowlesioidesPre stress

A double-hulled tanker of not less than of not less than about 2,000 metric tons deadweight in size which is suitable for the transportation of liquid hydrocarbons and meeting the requirements for the United States Pollution Act of 1990 and similar international regulations, said tanker comprising an inner hull and an outer hull separated by a void, said inner and outer hulls being constructed of high strength, light weight, reinforced and prestressed concrete.

Owner:CHEVROU USA INC

Floating type folding assembly ship

PendingCN110435811ACommonly available materialsSimple structureHull double bottomsVessel movement reduction by foilsHull structureButt joint

The invention provides a floating type folding assembling ship, which comprises a ship bottom, a ship structure beam, shipboards, shipboard butt joint fixing clamps, a soft material bow, a bow framework and a double-tail balance rudder. The ship bottom is a sealed double-layer ship bottom with a certain volume and is divided into three sections; the ship structure beam is divided into three sections corresponding to the ship bottom, the three sections are respectively fixed to the corresponding ship bottom, the three sections of structure beams are connected and combined through hinged connecting rods, and folding assembly and unfolding assembly of the whole ship can be realized; each shipboard and a handrail on the upper edge of the shipboard are integrated and are fixedly connected to the ship structure beam through a special hinge, wherein the left shipboard and the right shipboard of a stern are connected to triangular plates at the tail ends through the hinges and sealing strips,so that the ship body is trapezoid, and the rear shipboard of the stern is of an erected structure, is a fixing plate after triple folding when the whole ship is folded and is fixedly connected to themiddle bottom of the ship, so that the folded cube is not dispersed; the double-tail balance rudder is formed by two independent wedge-like bodies with a certain hollow volume and is provided with acommunication hole for communicating the internal water level with the outside, and the balance capability is achieved when the ship body fluctuates instantly.

Owner:李延成

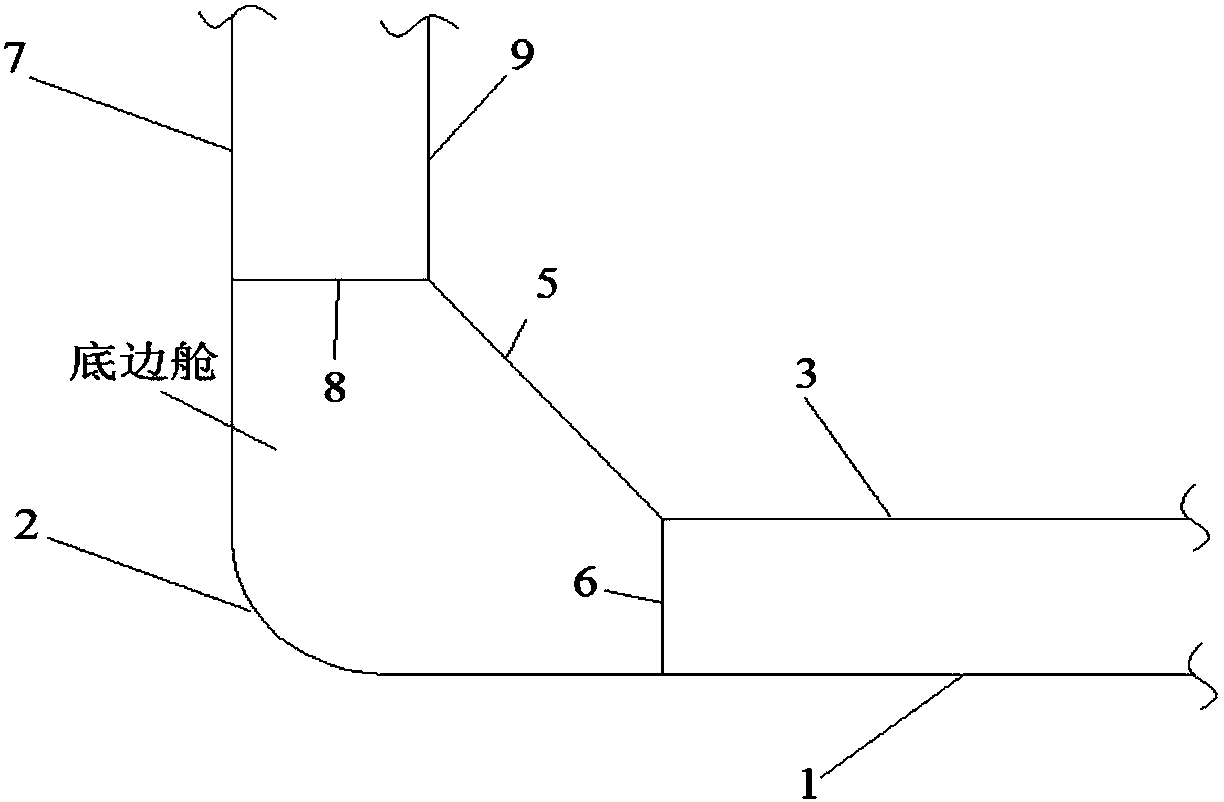

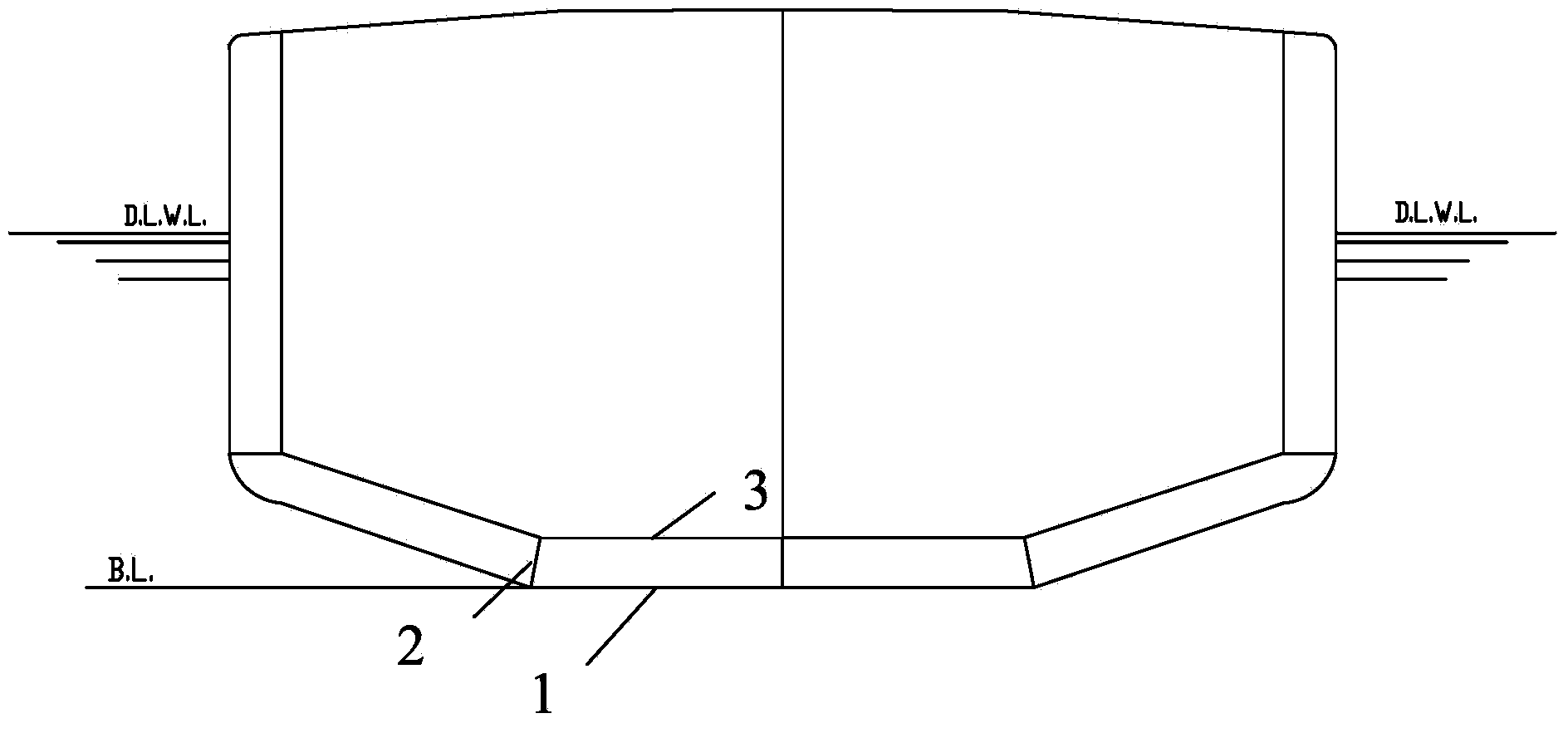

Ship based oblique double-bottom arc-shaped bilge

The invention discloses a ship based on an oblique double-bottom arc-shaped bilge. The ship comprises a flat outer bottom (1) and a flat inner bottom (3) which are arranged at the bottom of the ship in parallel. The flat outer bottom (1) and the flat inner bottom (3) are respectively connected with an oblique outer bottom (21) and an oblique inner bottom (23) which are arranged in parallel and extend towards a broadside (7). The inclination angles of the oblique outer bottom and the oblique inner bottom are larger than 5 degrees but smaller than 25 degrees. The oblique outer bottom (21) and the broadside (7) are in transition connection through the arc-shaped bilge (2) which is tangent to the oblique outer bottom (21) and the broadside (7) respectively. The oblique inner bottom (23) is connected to an inner shell on the inner side of the broadside (7) through an oblique baseplate (5) at an inclination angle B. The B satisfies the condition that (45+A) degrees < B< (65+A) degrees. Through transition connection of straight lines and arcs and reasonable design of ends, loads are effectively transmitted, stress concentration is reduced, and structural strength is improved.

Owner:DALIAN SHIPBUILDING IND

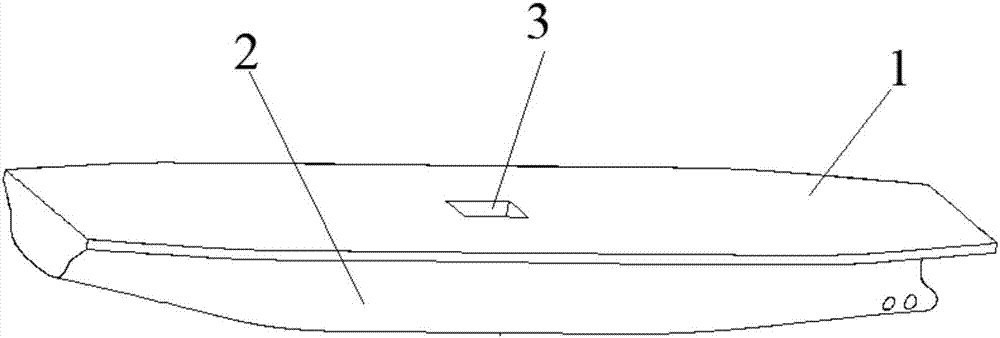

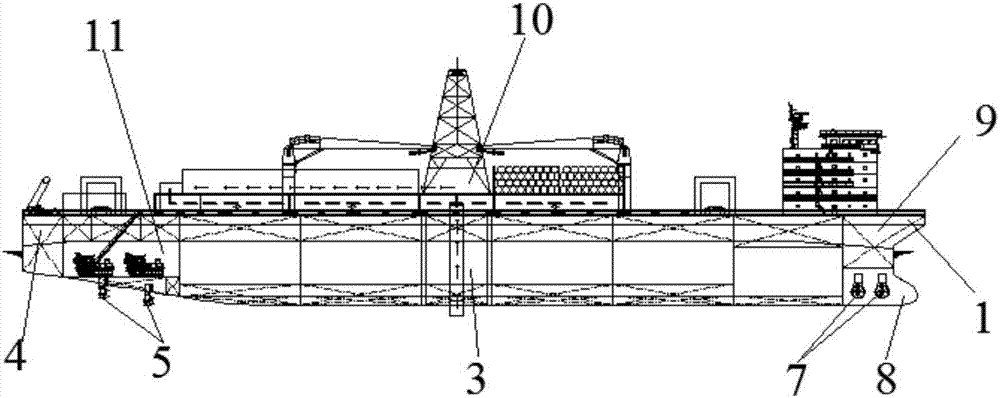

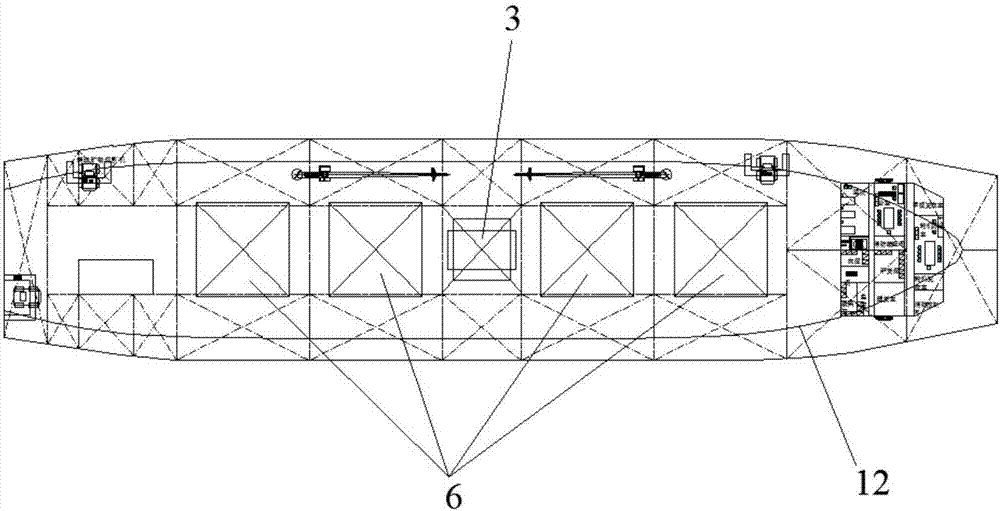

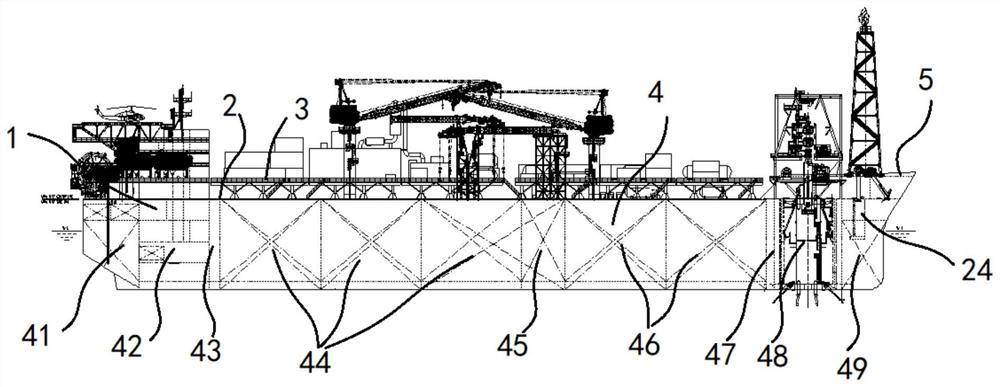

Convenient deep-sea mining ship type

InactiveCN106956752AImprove maneuverabilityGuaranteed structural strengthVessel cleaningHull decksDeep sea miningNacelle

The invention provides a flexible deep-sea mining ship type, which includes a main hull, a straight-through splint arranged on the main hull, and a moon pool that vertically penetrates the main hull for laying out mining equipment and recovering ores. The moon pool It is set in the middle of the main hull. The stern of the main hull is square and the bow is a flying shear type. There are three full-rotation thrusters in the stern engine room at the stern of the main hull and two in the bow propulsion cabin at the bow of the main hull. Lateral channel thrusters, and the superstructure is arranged at the bow of the main hull. The invention provides a flexible deep-sea mining ship type that can fully improve the utilization rate of cabin capacity, reduce the drainage volume, and has a wide deck area. At the same time, it can also meet the requirements of structural strength, general layout and performance.

Owner:HARBIN ENG UNIV

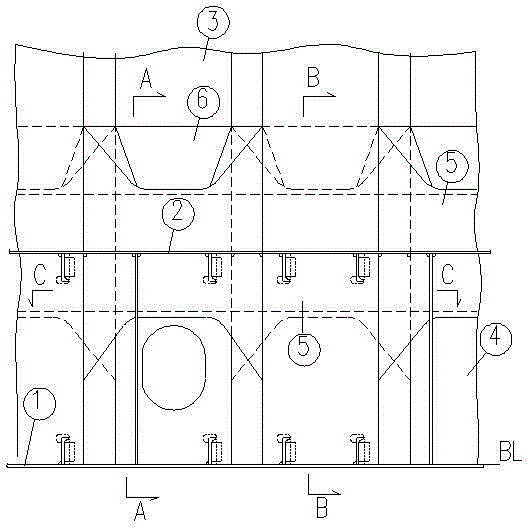

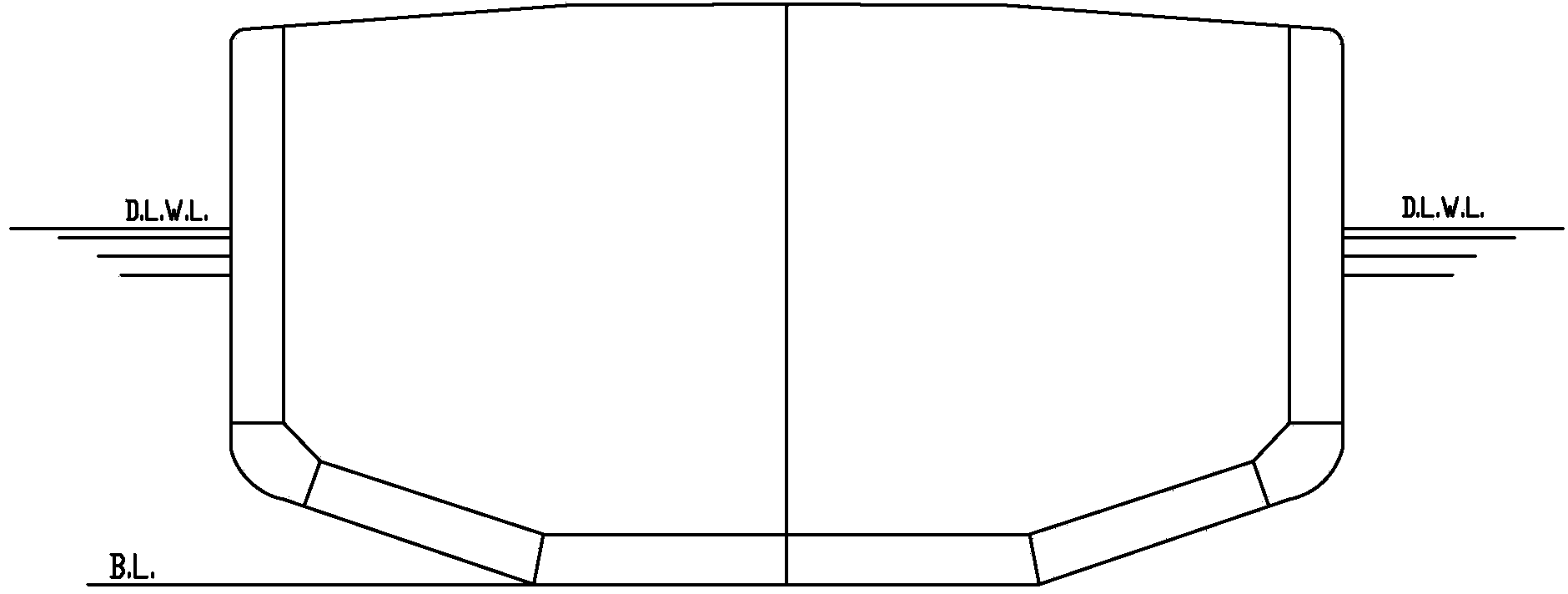

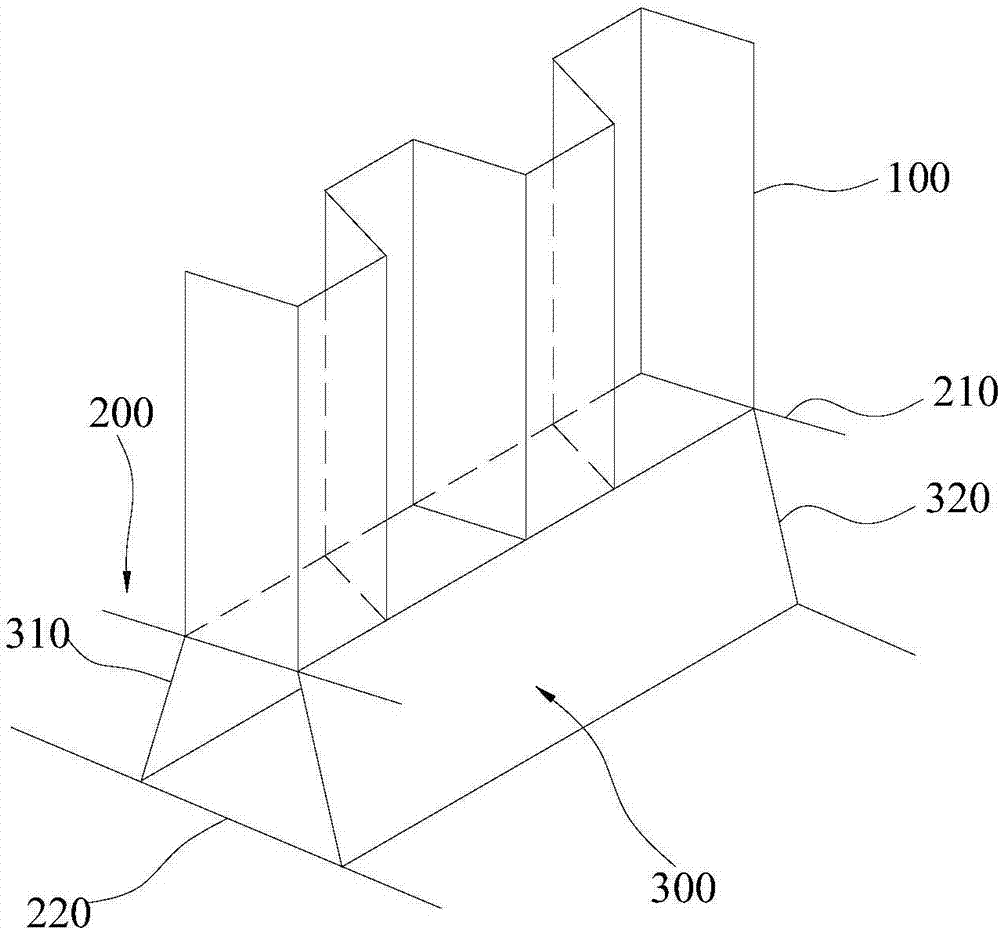

Groove-shaped bulkhead connecting assembly and ship comprising same

ActiveCN107323606AReduce stressDegree of reductionHull double bottomsHull bulkheadsHull structureMarine engineering

The invention discloses a groove-shaped bulkhead connecting assembly and a ship. The groove-shaped bulkhead connecting assembly comprises a groove-shaped bulkhead installed on a bottom plate of the ship, the bottom plate of the ship comprises an inner bottom plate and an outer bottom plate which are arranged in a spaced mode, and a bottom bench is arranged between the outer bottom plate and the inner bottom plate; the bottom bench comprises a first oblique plate and a second oblique plate which are arranged in a spaced mode, the upper ends of the first oblique plate and the second oblique plate are both connected with the inner bottom plate in a welded mode, and the lower ends of the first oblique plate and the second oblique plate are both connected with the outer bottom plate in a welded mode; and the distance between the upper end of the first oblique plate and the upper end of the second oblique plate is smaller than the distance between the lower end of the first oblique plate and the lower end of the second oblique plate, and the groove-shaped bulkhead is welded on the inner bottom plate and located between the first oblique plate and the second oblique plate. According to the groove-shaped bulkhead connecting assembly and the ship, compared with the prior art, the bottom bench can not occupy the hold capacity of a cabin, and the weight of a ship body structure is lightened, and the situation that a narrow construction space appears in the cabin is avoided.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Usage method of ship structure for transporting oil and fresh water

InactiveCN1263652CNo empty sailingHull interior subdivisionSelf-bailing equipments/scuppersFresh waterBallast tank

Owner:约瑟夫·W·L·哈

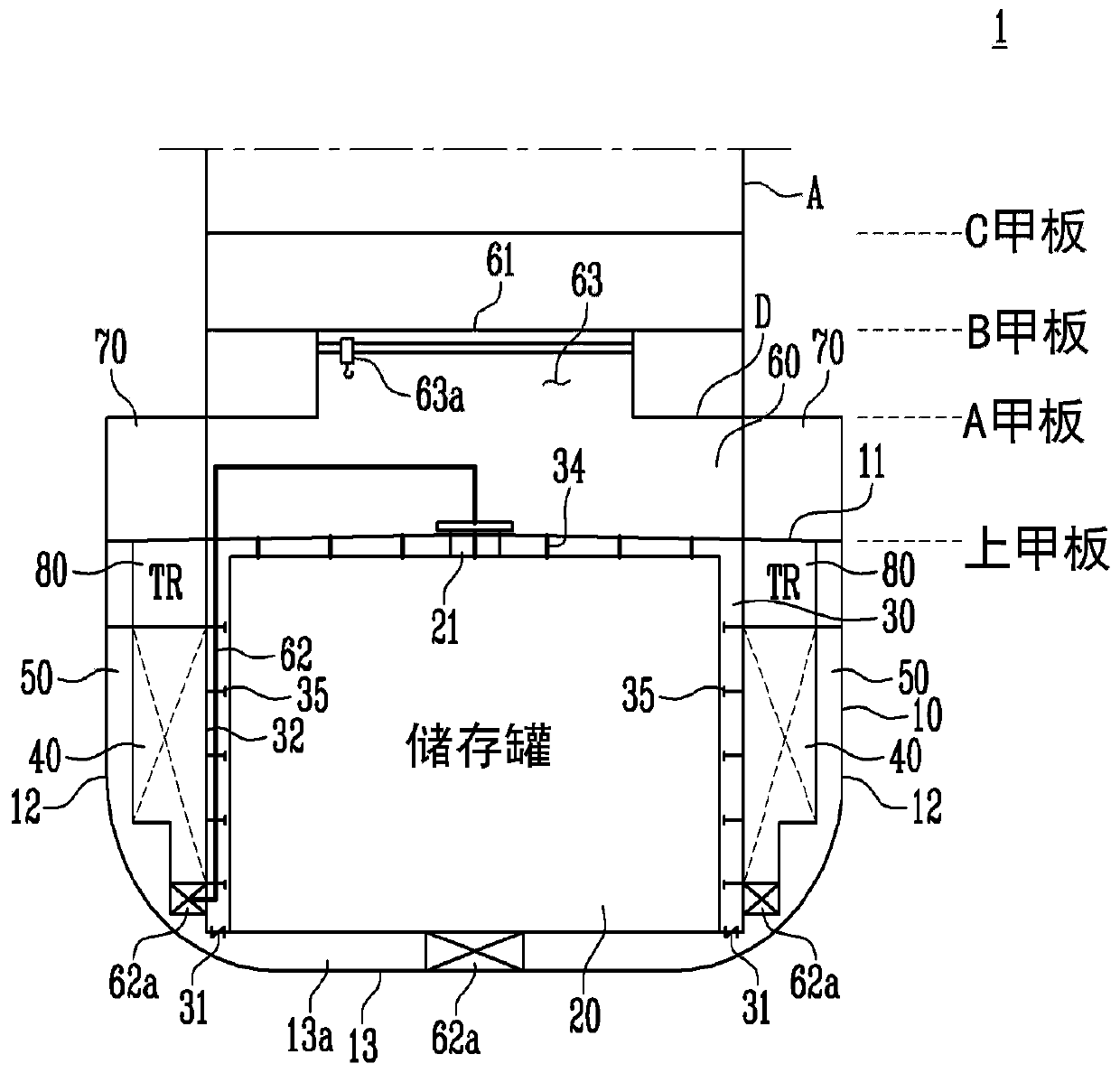

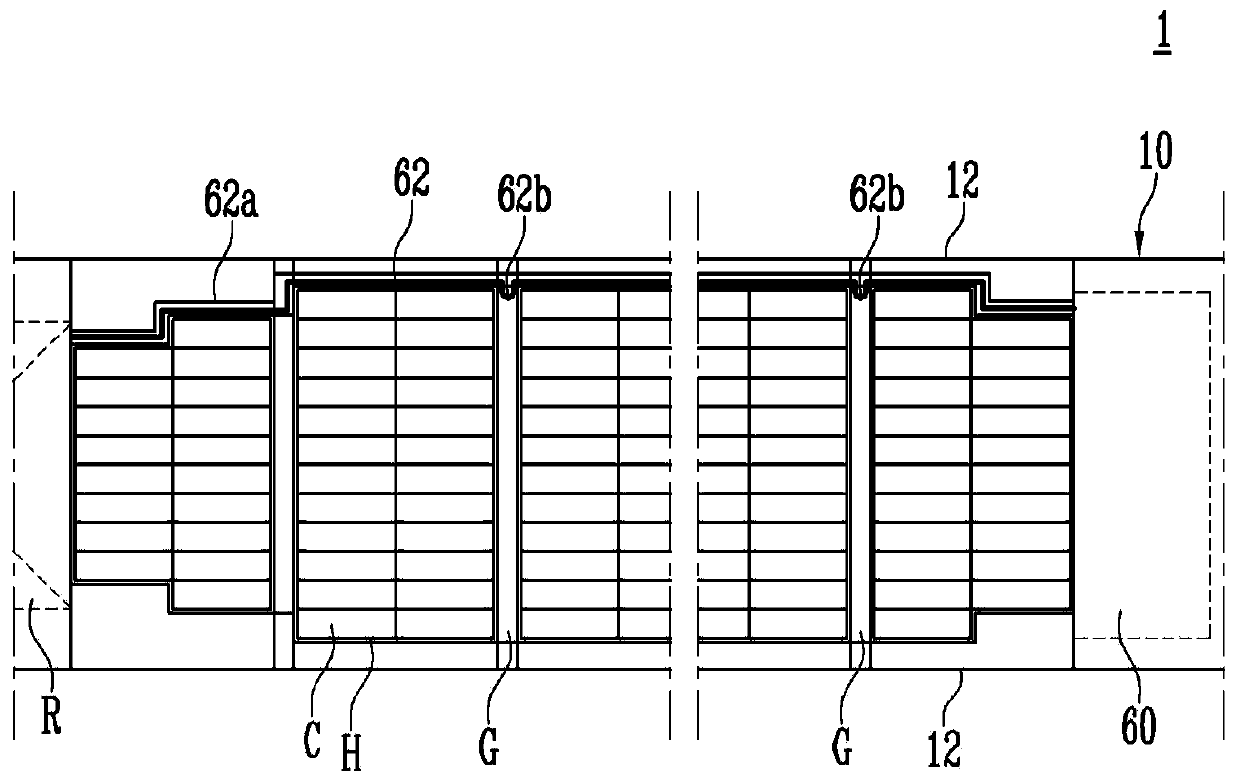

Gas fuel-propelled container carrier

ActiveCN110099842AImprove economyEmission reductionHull interior subdivisionWatercraft hull designLiquid gasPetroleum engineering

A gas fuel-propelled container carrier according to an embodiment of the present invention comprises: a liquefied gas storage tank provided under a cabin, for storing a liquefied gas; and a cofferdamprovided between the liquefied gas storage tank and a hull, wherein the cofferdam is provided between the upper wall of the liquefied gas storage tank and an upper deck, and between the side wall of the liquefied gas storage tank and a side shell plate, is spaced inwardly from the side shell plate, and is absent between the lower wall of the liquefied gas storage tank and a seacock.

Owner:HYUNDAI HEAVY IND CO LTD

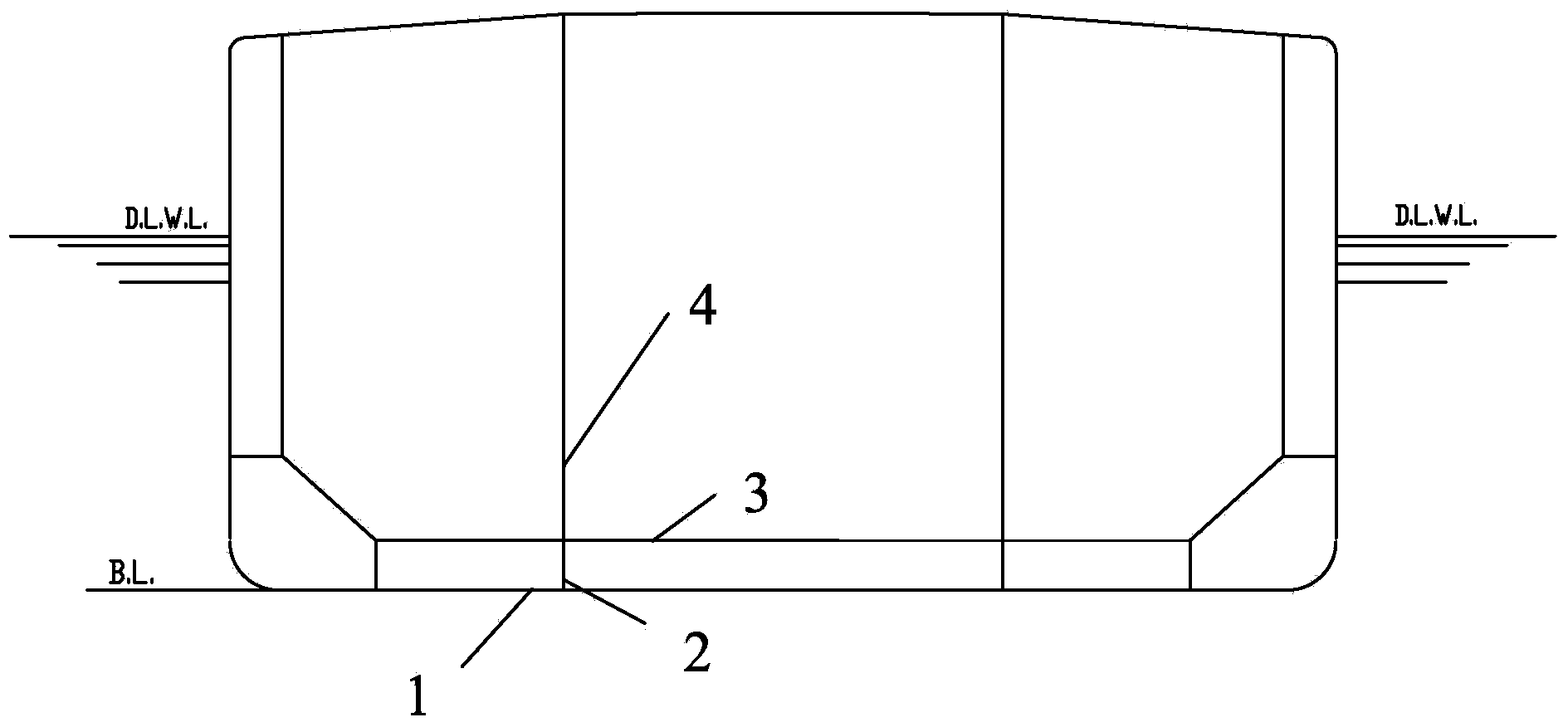

Slanted double-bottom and arc-bilge ship with inner bottoms aligned directly

InactiveCN103661795AHigh strengthEfficient deliveryHull double bottomsStress concentrationSlant angle

The invention discloses a slanted double-bottom and arc-bilge ship with inner bottoms aligned directly. The slanted double-bottom and arc-bilge ship comprises a flat outer bottom (1) and a flat inner bottom (3) arranged at the ship bottom in parallel. The flat outer bottom (1) and the flat inner bottom (3) are respectively linked with a slanted outer bottom (21) and a slanted inner bottom (23) which are arranged in parallel, have the slant angle A and both extend to a broadside (7); the slant angle A is larger than 5 degrees but smaller than 25 degrees. The slanted outer bottom (21) and the broadside (7) are in transitional connection through an arc bilge (2) which is tangent with the two respectively. The slanted inner bottom (23) is directly connected to an inner hull (4) on the inner side of the broadside (7). According to the direct alignment connection and the design of reasonable arrangement of various structural angles, load is transmitted effectively, stress concentration is decreased, and structural strength is improved.

Owner:DALIAN SHIPBUILDING IND

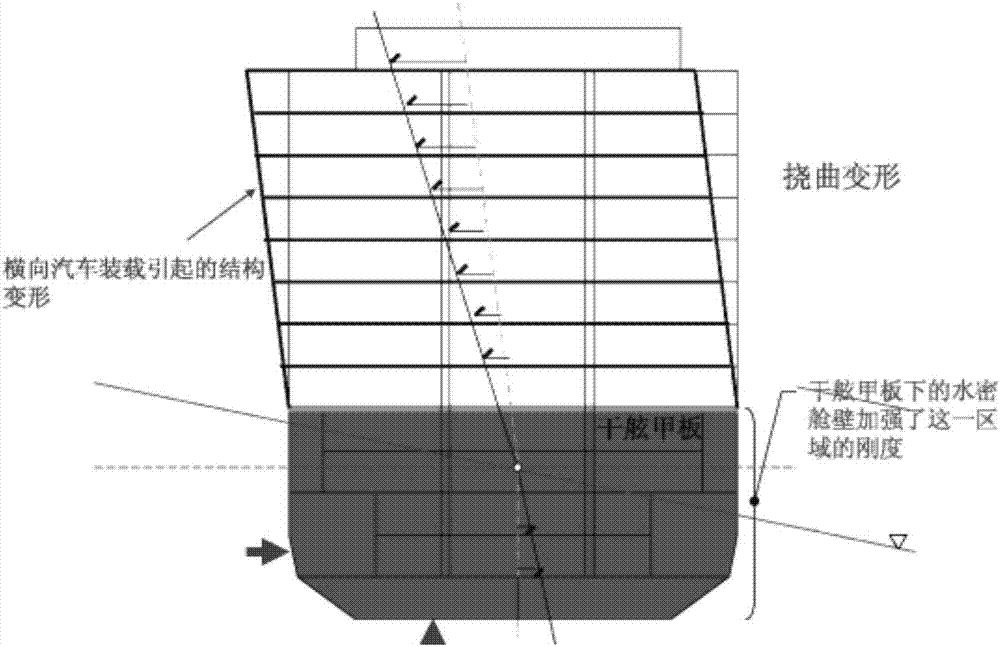

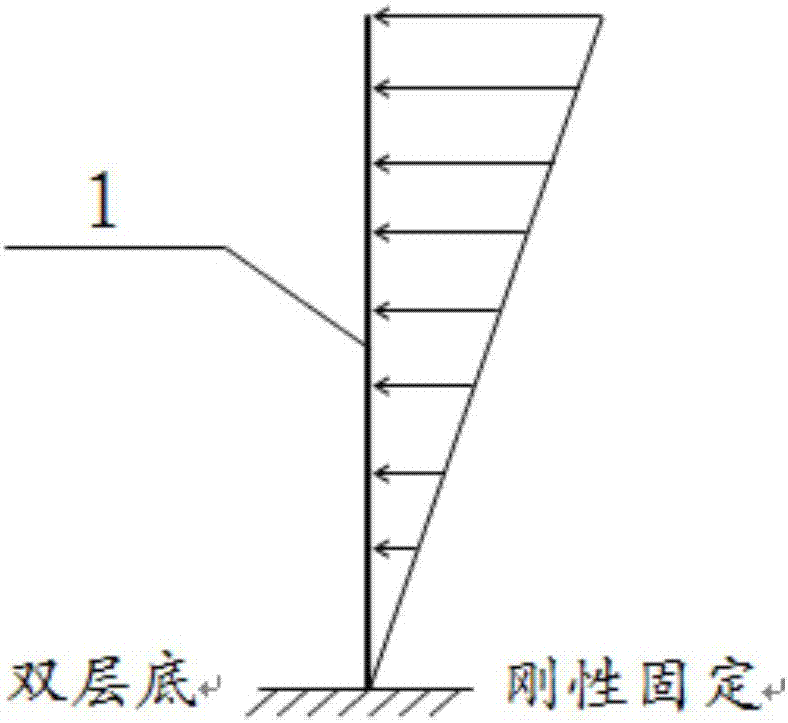

Ship recovery ability recovering apparatus and automobiles transporting ship having the apparatus

The invention provides a ship recovery ability recovering apparatus and automobiles transporting ship having the apparatus. The ship recovery ability recovering apparatus is characterized in that: a seawater guiding apparatus capable of being opened remotely is disposed on the watertight deck for forming a void compartment on the ship bottom. Thereby, if the outside plate of the ship is broken and seawater enters into the ship, the seawater guiding apparatus on the lowest watertight deck can be opened, the seawater entered into the ship can be guided into the void compartment, thus, the void compartment generally used as a huge standby buoyancy can be used as a seawater pressure chamber, and can recovery the recover ability of the ship.

Owner:MITSUBISHI SHIPBUILDING CO LTD

Corrugated bulkhead connection assembly and ships containing it

ActiveCN107323606BReduce stressDegree of reductionHull double bottomsHull bulkheadsHull structureStructural engineering

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

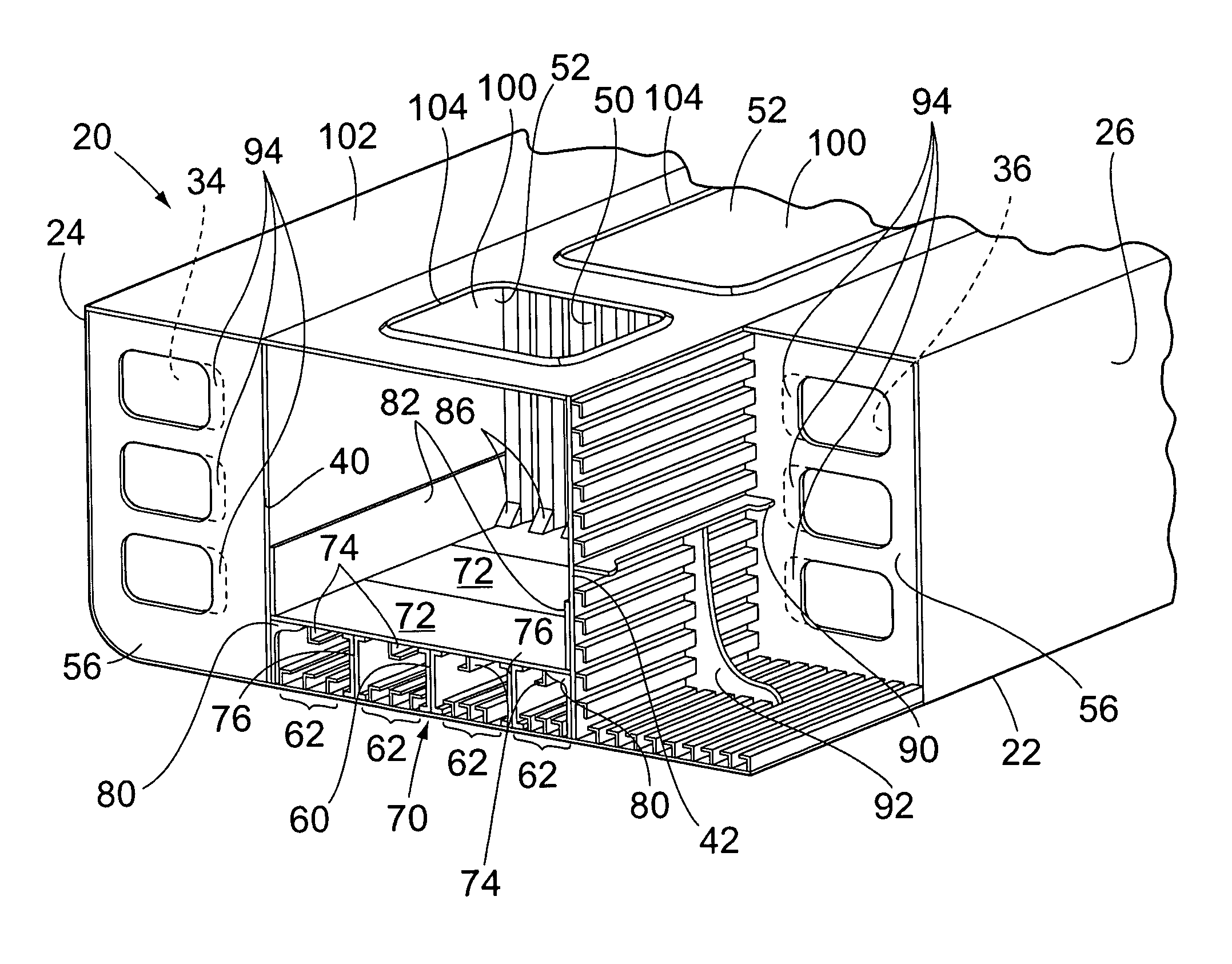

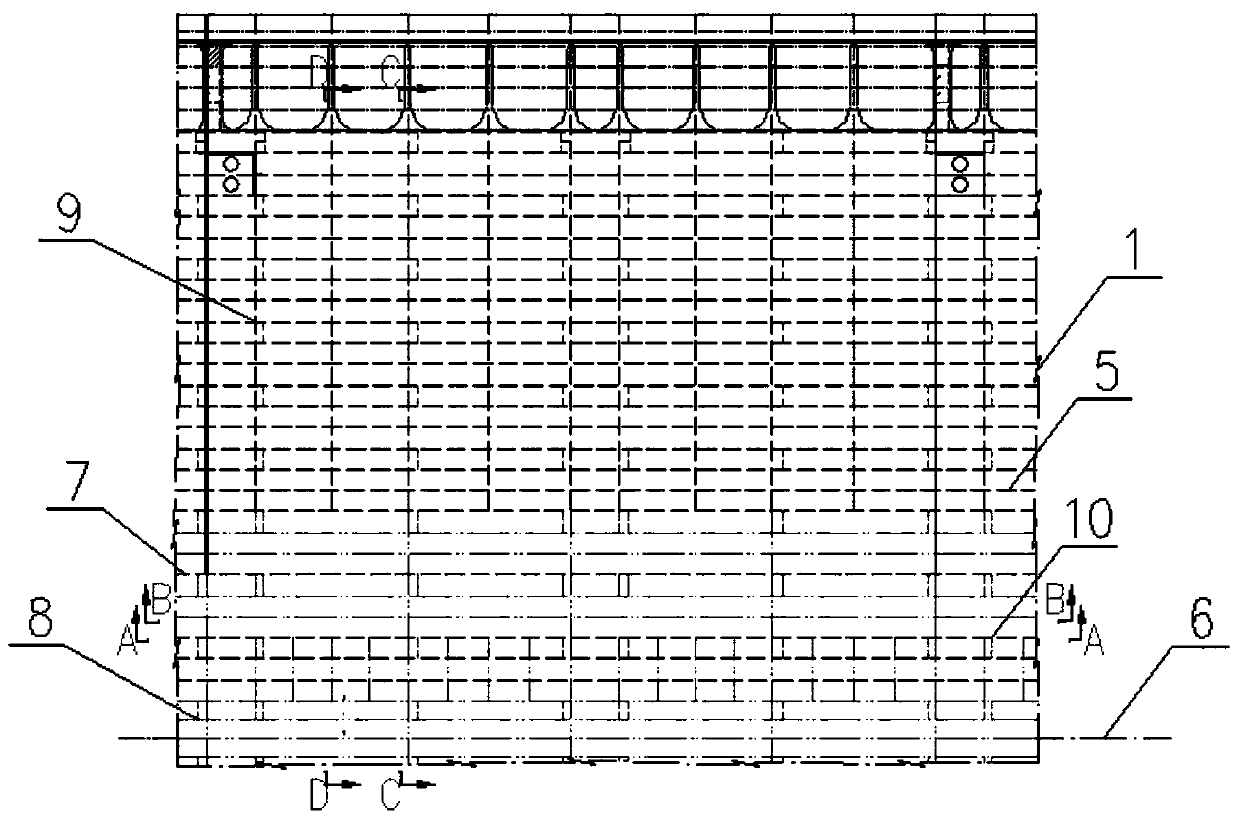

Bottom structure of container ship with bottom longitudinal girders centrally arranged

ActiveCN110027671AIncrease modulus marginIncrease stiffnessHull double bottomsSpecial purpose vesselsEngineeringMechanical engineering

The invention discloses a bottom structure of a container ship with bottom longitudinal girders centrally arranged. The bottom structure comprises an outer bottom plate and an inner bottom plate whichare arranged from bottom to top. A plurality of containers are arranged on the upper end surface of the inner bottom plate, and the multiple containers are fixed to the inner bottom plate through a plurality of box legs arranged on the inner bottom plate in a penereating mode at equal intervals, longitudinal ribs are arranged at the multiple box legs on the lower end surface of the inner bottom plate at equal intervals, the outer bottom plate is provided with a plurality of longitudinal ribs with upper positions and lower positions corresponding to the longitudinal ribs disposed on the lowerend surface of the inner bottom plate, and the multiple longitudinal ribs are arranged in parallel with the center line of the breadth; a plurality of heavy-type bottom longitudinal girders are arranged on the upper end surface of the outer bottom plate laterally; a plurality of light-weight bottom longitudinal girders are arranged between the heavy-type bottom longitudinal girders parallelly; anda plurality of solid rib plates are arranged on the upper end surface of the outer bottom plate longitudinally. The bottom structure for the container ship can increase bottom modulus margin and enhance bottom stiffness through the longitudinal girders disposed near a midship area at intervals and the solid rib plates arranged near a shipboard area, and has the advantages that the cost is cost and the strength is high.

Owner:708TH RES INST OF CSSC

Opening anti-fatigue arrangement structure and method of ship double bottoms

ActiveCN106892053ARealize flexible connectionAvoid excessive local stressHull double bottomsMarine engineeringDouble bottom

Owner:SHANGHAI MERCHANT SHIP DESIGN & RES INST

System for evacuation of personnel from a capsized vessel

System for evacuation of personnel from a capsized vessel via a lockable escape hatch (103) in the bottom of said vessel, characterized in that the system comprises a first lockable escape hatch (105), said first lockable escape hatch (105) leads to an evacuation room (107), said room (107) is provided with a second lockable escape hatch (103), said room (107) is illuminated by lamps (201) receiving energy from a battery pack (202) not connected to the said vessel's energy system, said first and second lockable escape hatch (103, 105) cannot be opened simultaneously, in relation to said first lockable escape hatch (105) it is connected a device (106) for climbing, said climbing device (106) unfolds when the said vessel has a lopsidedness in excess of a pre-determined number of degrees.

Owner:DYB ASBJORN BREVIK

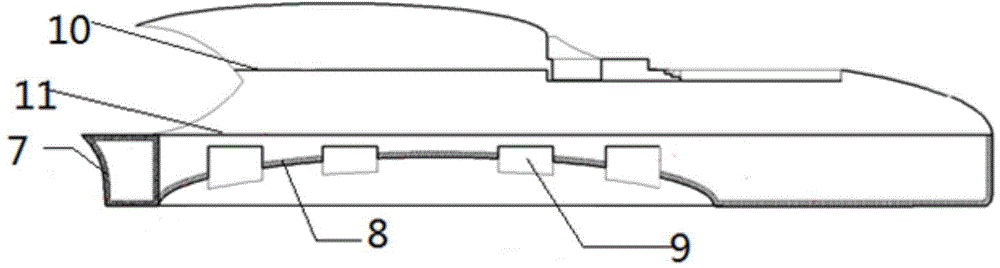

Vessel provided with heat exchangers in the double bottom thereof

InactiveCN101654148AEfficient use ofNot vulnerable to damagePower plants using condensersAuxillariesPlate heat exchangerMarine engineering

There is disclosed a vessel having a double bottom, in which double bottom cooling water passage means are provided and in which heat exchangers coupled to said cooling water passage means are disposed. In particular, the heat exchangers are disposed in channels extending in the longitudinal direction in the double-walled bottom of the vessel. Selective closure of certain channels makes it possible to carry out maintenance and repairs, at sea, on the heat exchanger(s) present therein during normal operation of the vessel based on a forced flow.

Owner:BLOKSMA

Cargo transport ship

PendingCN107776827AReduce construction costsLower center of gravityHull interior subdivisionHull double bottomsMarine engineeringBallast

The invention relates to the technical field of ships, in particular to a cargo transport ship. The cargo transport ship comprises a ship bottom, ship sides fixedly connected to the ship bottom and apropelling device for providing driving force, wherein the ship bottom and the ship sides define a cabin. The cargo transport ship is characterized in that the ship bottom adopts a double-layer structure and comprises an inner ship bottom and an outer ship bottom arranged in parallel at an interval; a plurality of sealed cavities are formed in the inner ship bottom and the outer ship bottom. The cargo transport ship requires no ballast water and thus the building cost can be reduced.

Owner:SHANGHAI ENN NEW ENERGY TECH CO LTD

Floating production oil storage device with dry ballast piping system

ActiveCN113386919AImprove friendlinessEasy to walkHull interior subdivisionSelf-bailing equipments/scuppersBallast tankHull

The invention relates to a floating type production oil storage device with a dry type ballast piping system. The floating type production oil storage device comprises a ship body, the ship body comprises a larboard side, a starboard side, a double-layer bottom connected with the bottom of the larboard side and the bottom of the starboard side and a main deck connected with the top of the larboard side and the top of the starboard side; a process deck is arranged on the main deck; A cabin is formed among the larboard side, the starboard side, the double-layer bottom and the main deck, the larboard side, the starboard side and the double-layer bottom are each of a double-layer shell structure, the two sides of the double-layer bottom communicate with the larboard side and the starboard side correspondingly to form a ballast tank, and the double-layer bottom is provided with a ballast pipe tunnel in the length direction of a ship body; and the ballast tank is divided into a larboard ballast tank body and a starboard ballast tank body by the ballast pipe tunnel. When the floating production oil storage device is overhauled, the interior of the ballast tank does not need to be emptied, and a maintainer only needs to enter the ballast pipe tunnel for overhauling, so that the complexity of overhauling operation is reduced, and walking of the maintainer is facilitated.

Owner:CHINA NAT OFFSHORE OIL CORP +1

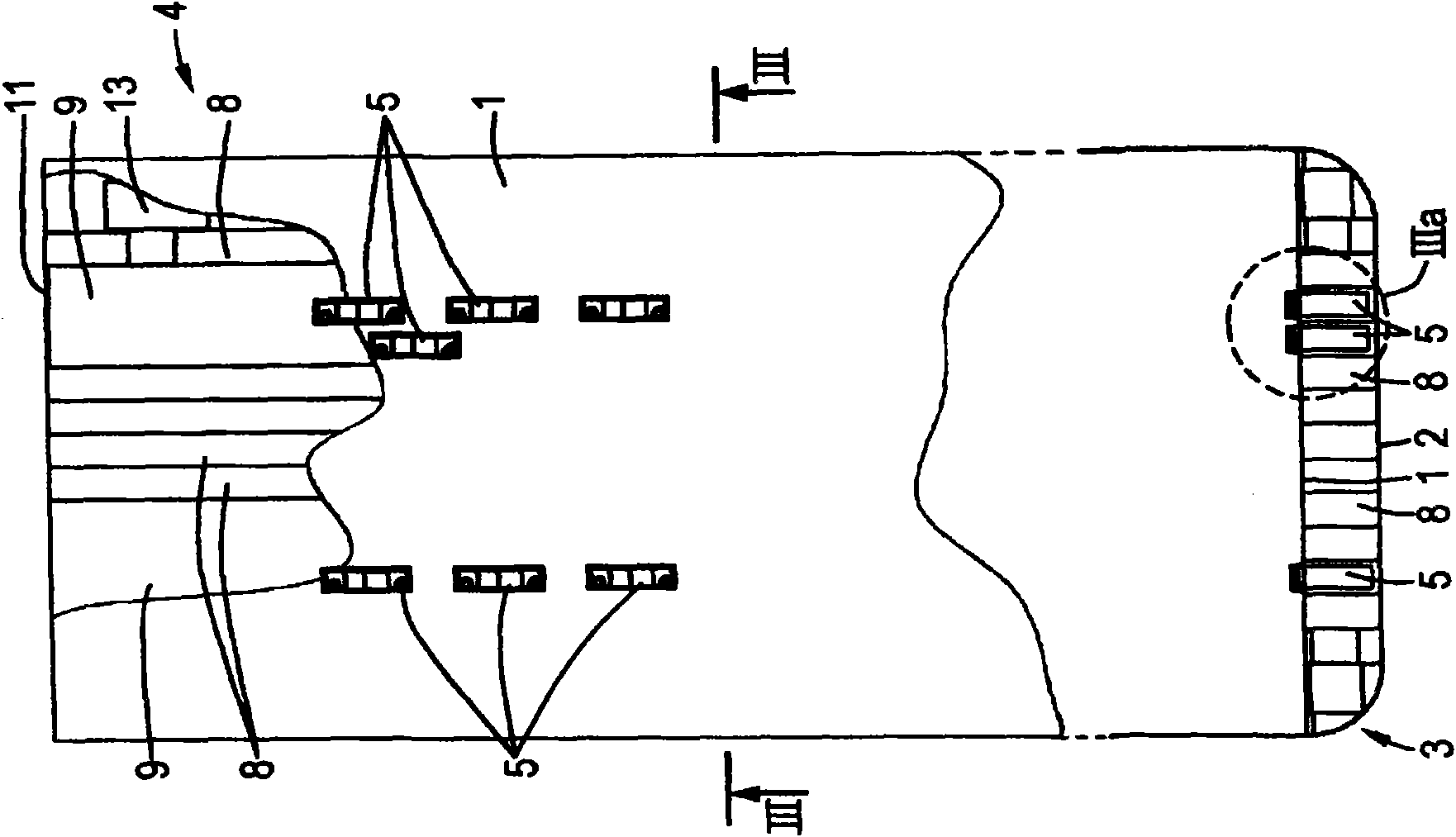

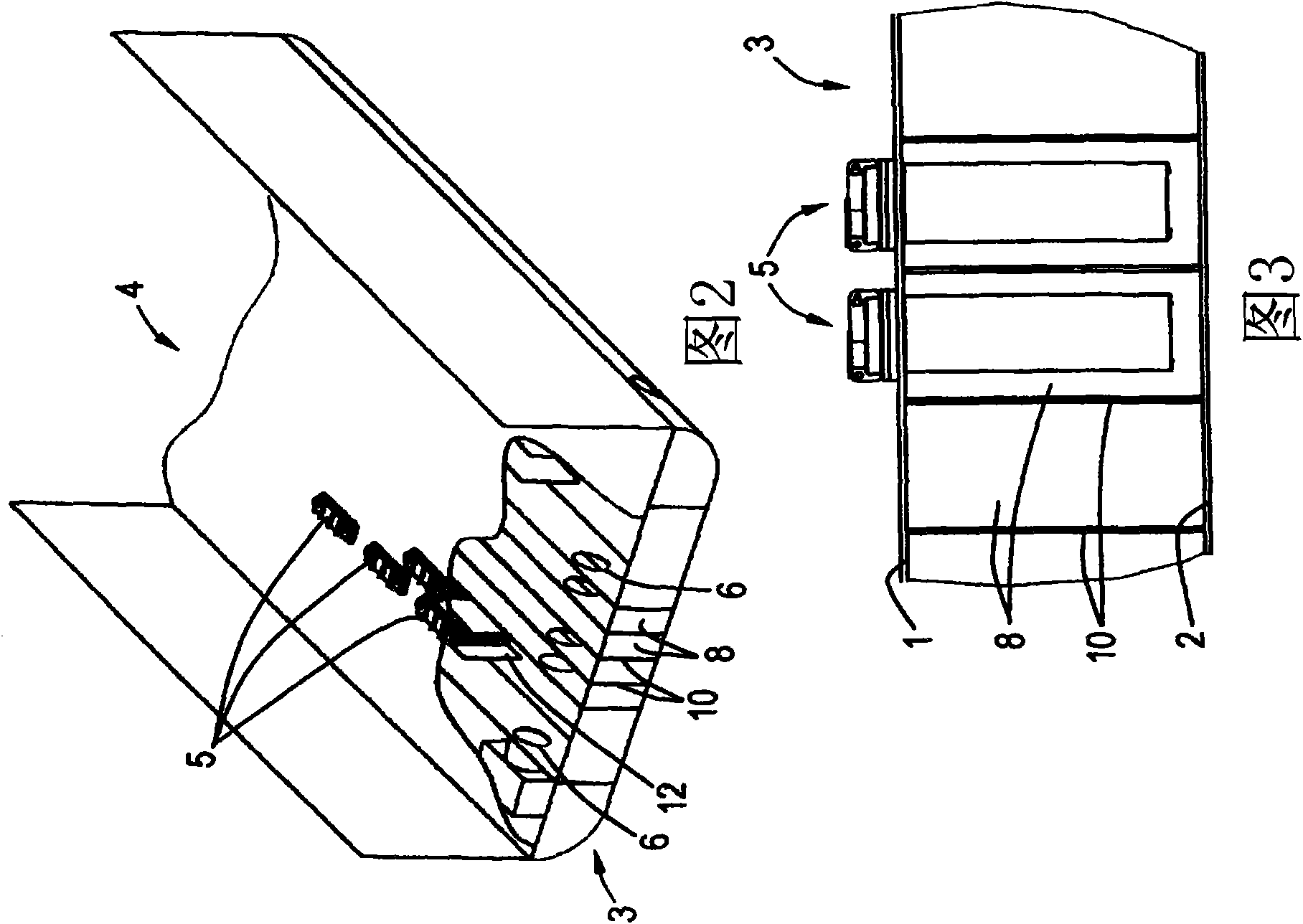

Ship

InactiveCN101808888AEasy to provideHull interior subdivisionAccommodation for deck loadsEngineeringMechanical engineering

The invention relates to a ship comprising a cargo space on the bottom (3) of which there is a bottom plate (4), whereby above the level formed by the bottom plate there are a plurality of container supports (5) for receiving and securing containers and cargo transportation stands to the cargo space, the upper end of the container supports being at a distance equal to the height of the container supports from the bottom plate. In order that the ship could be employed for transporting bulk goods, in addition to containers and various goods transportation stands, on top of the bottom plate (4) of the cargo space there is arranged a levelling construction (7) on top of which there is arranged a protective plate (9) provided with lead-through points (12) for container supports such that the container supports are surrounded by the levelling plate (7) and the protective plate (9) and the upper level of the protective plate is at a level with the upper end of the container supports (5).

Owner:OY LANGH SHIP AB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com