Concrete double-hulled tank ship

a double-hulled, concrete technology, applied in the direction of hulls, armoured hulls, vessel construction, etc., can solve the problems of limited utility of concrete-hulled ships, hull arising from concrete-hulled ships sinking deeper in water than conventional ships, etc., to achieve high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Recent advances in materials and construction methods have made it possible to efficiently construct very large, strong, relatively lightweight, hollow, concrete structures. The present invention is directed to the application of this recent concrete technology in the construction of double-hulled tank vessels, especially double hulled tank ships. Modern methods for concrete fabrication allow a double-hulled concrete tanker to be optimized in order to minimize hull size and weight. Hull resistance is reduced (fuel efficiency is improved), and the tankers can safely navigate with fewer draft, beam and length restrictions.

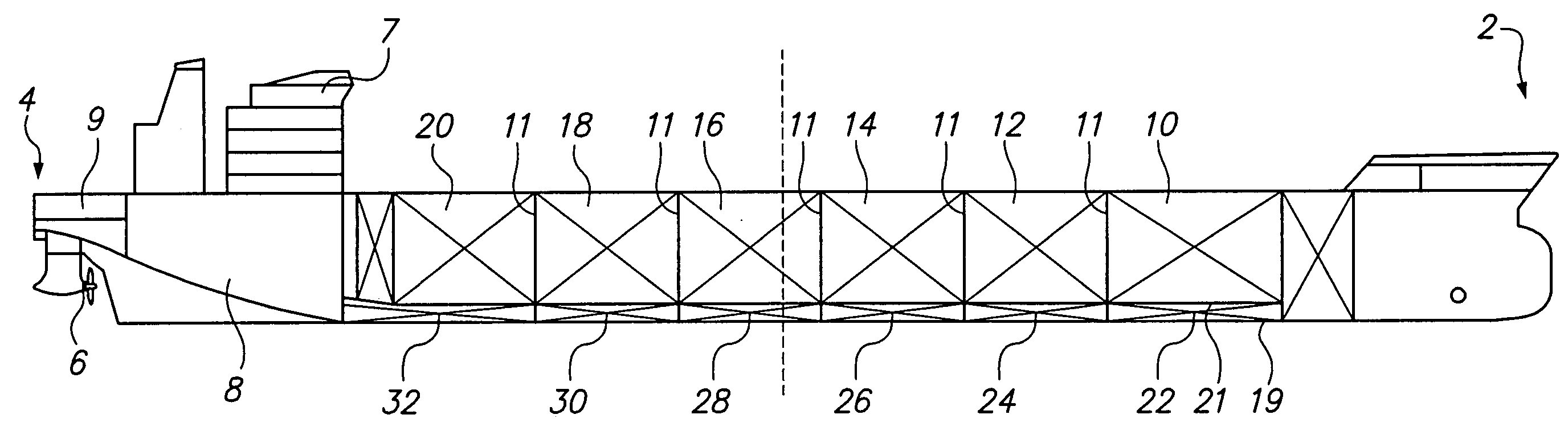

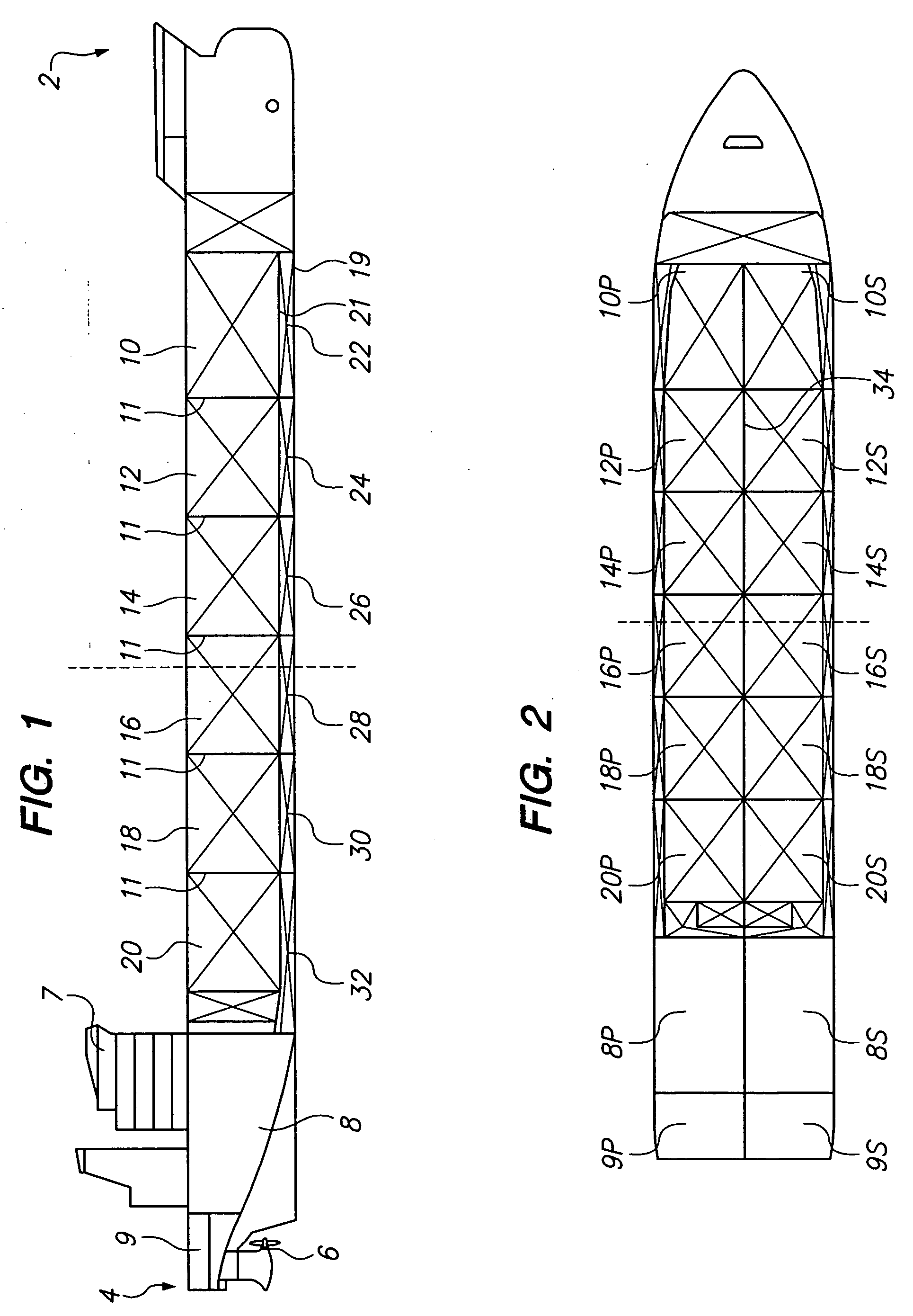

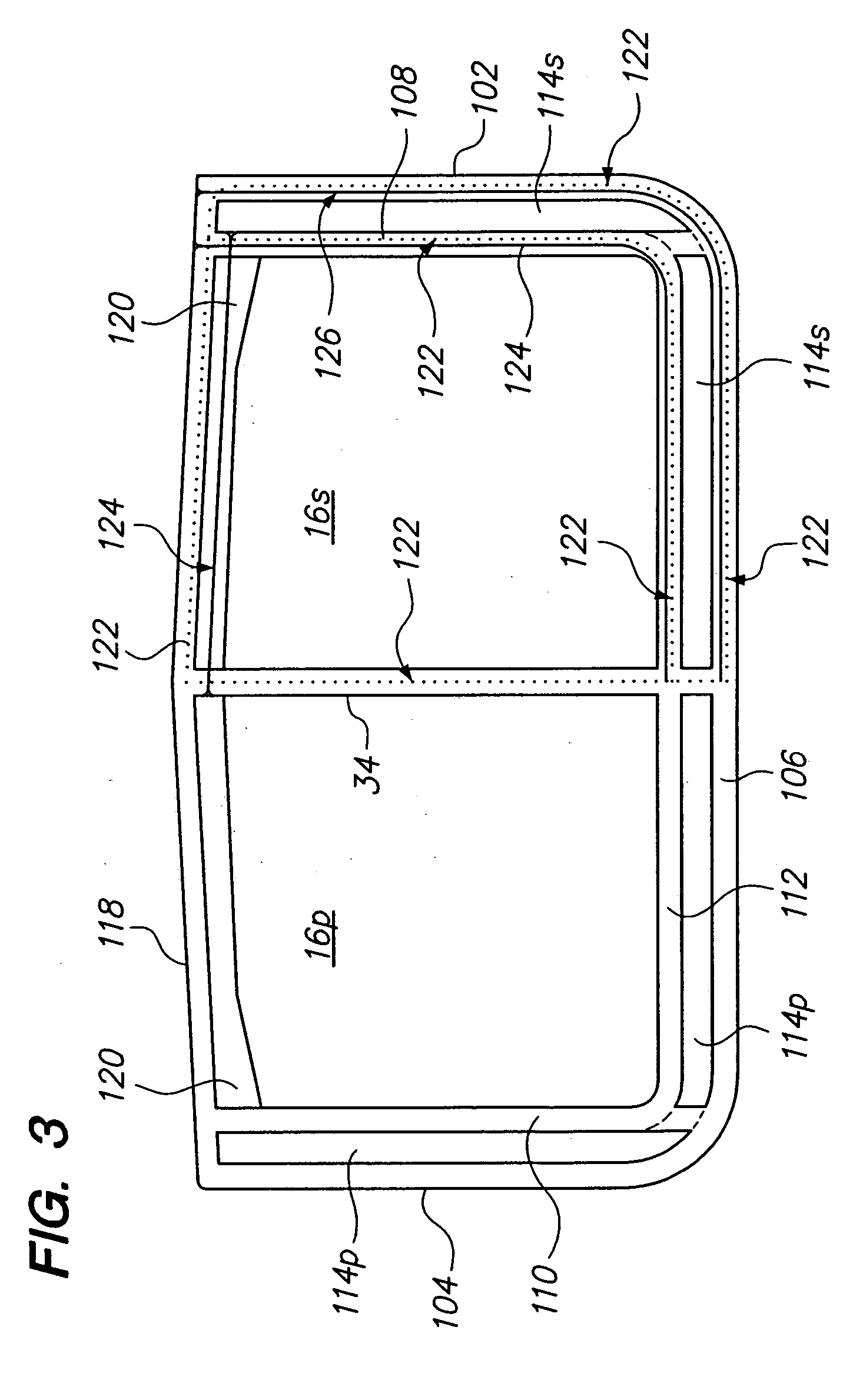

[0017] The present invention may be more clearly understood by reference to the drawings which illustrate a representative concrete double-hulled tank ship falling within the scope of the invention which is intended as a non-limiting embodiment of the invention. FIGS. 1, 2, and 3 show different views of a 632 foot long double-hulled concrete tank ship of abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com