Ship with equant oblique double-layer bottoms

A double bottom and ship technology, applied in the direction of the double bottom of the hull, hull, hull bulkhead, etc., to achieve the effects of simplifying the process, reducing stress concentration, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

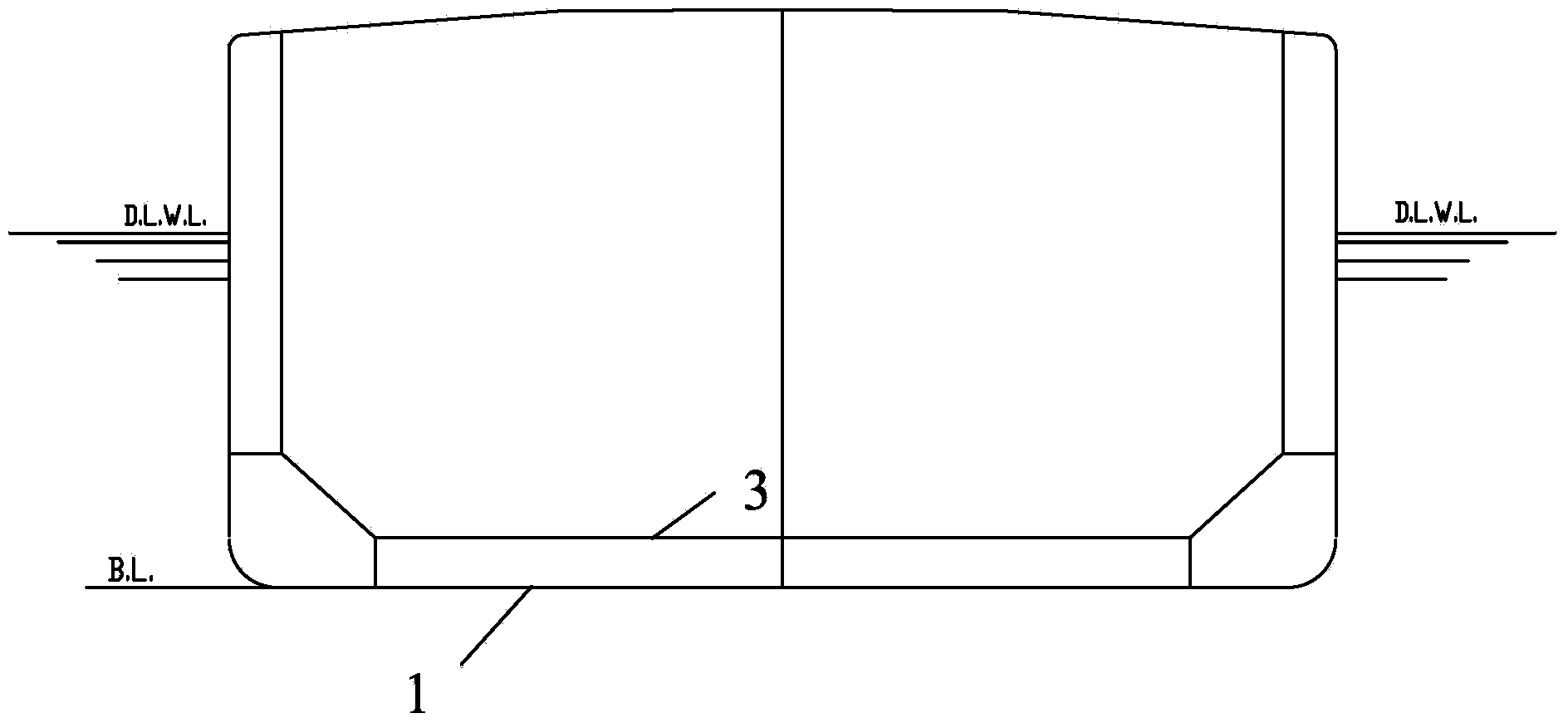

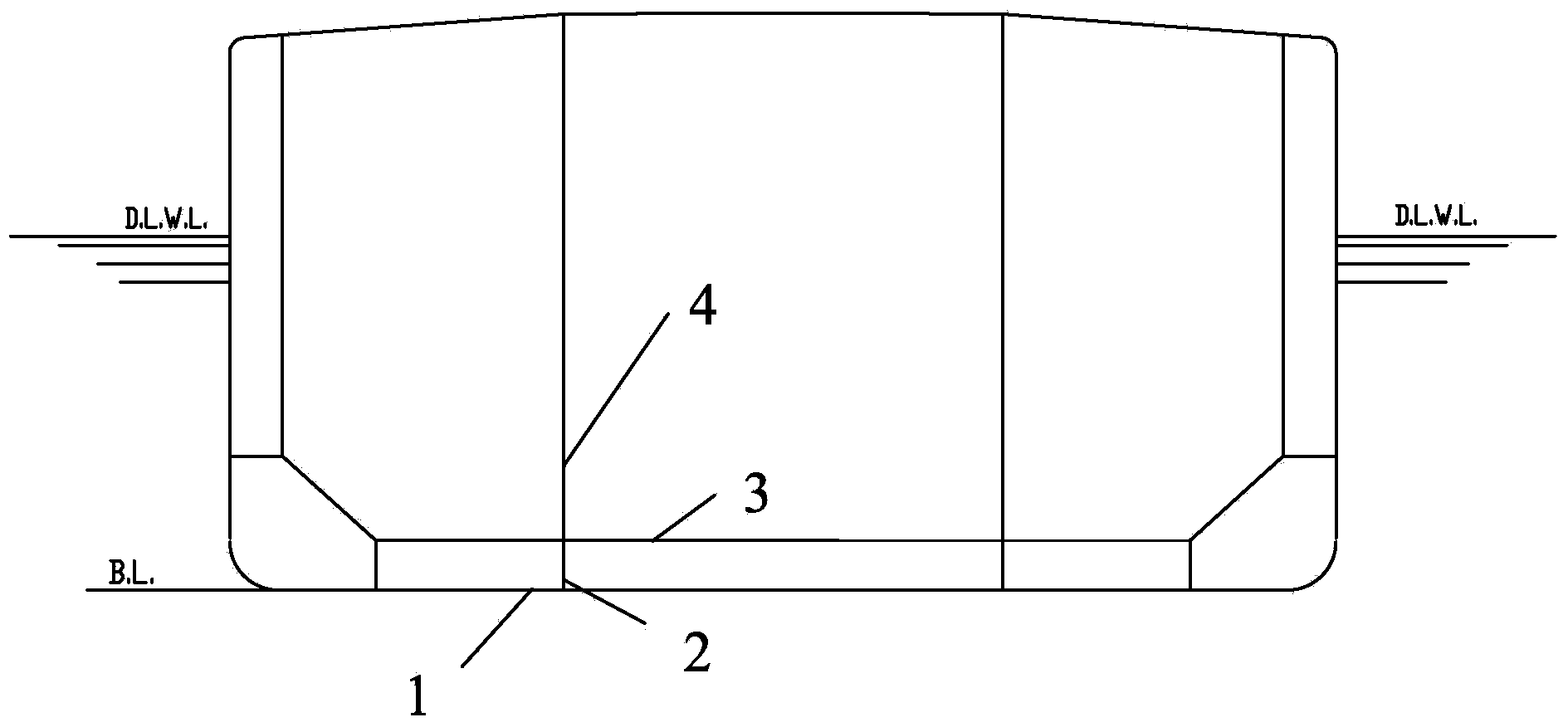

[0012] In order to meet certain functional requirements, the outer bottom of the ship design adopts an inclined design. If the inner bottom still adopts the conventional designed horizontal layout, the inner and outer bottoms will not be parallel, and the determination of the construction coordinates of the inner and outer bottoms is very complicated. The connecting plates between them are all trapezoidal plates. Since the plates ordered by the steel mill are all rectangular plates, several more cutting processes are required. Moreover, the cut side plates cannot be reused, and the construction cost will be greatly increased.

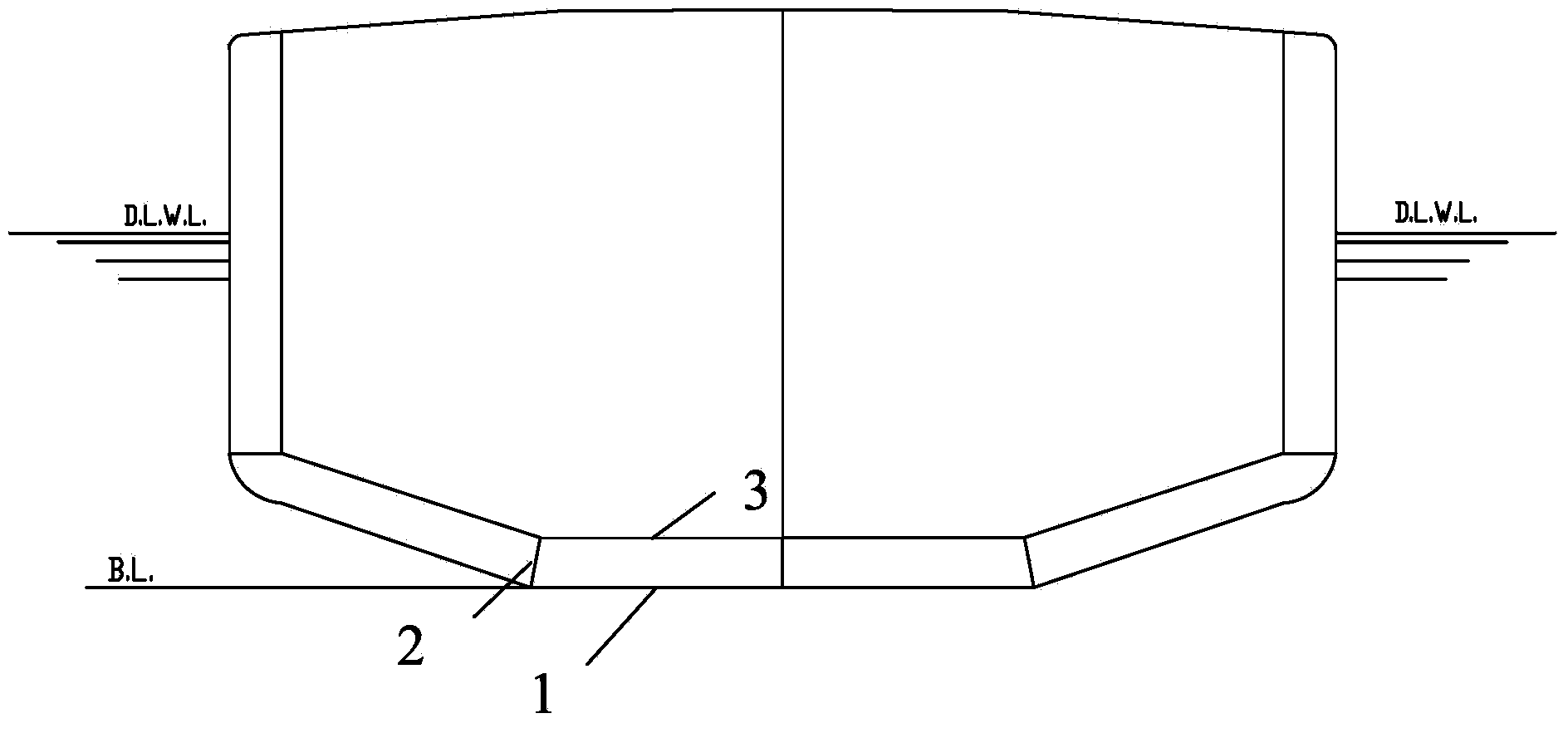

[0013] The present invention as image 3 , 4 , 6, the flat outsole 1 and the flat insole 3 respectively extend to the side by connecting the sloping outsole 6 and the sloping insole 5 through knuckles. The advantage of the parallel design of the outsole and the insole is that it is convenient to arrange the structure and facilitate the on-site construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com