Bottom structure of vertical corrugated bulkhead of ship

A bottom structure and trough-shaped bulkhead technology, which is applied to hull bulkheads, hull parts, and double-bottom hulls, can solve the problems of difficult construction and installation, increased empty ship weight, and high steel consumption, so as to increase ship loading. The effect of reducing the weight of the ship, reducing the weight of the ship, and increasing the capacity of the ship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

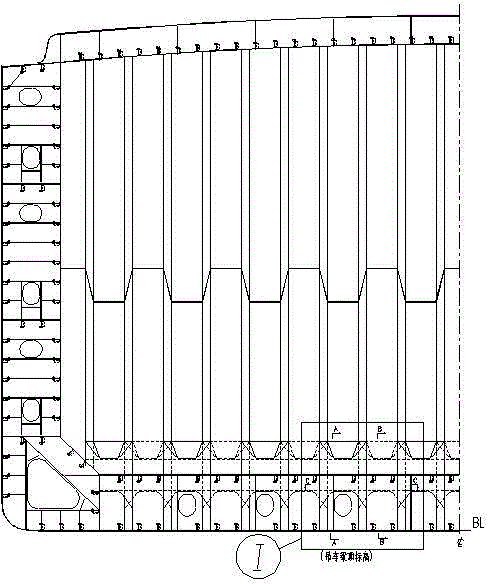

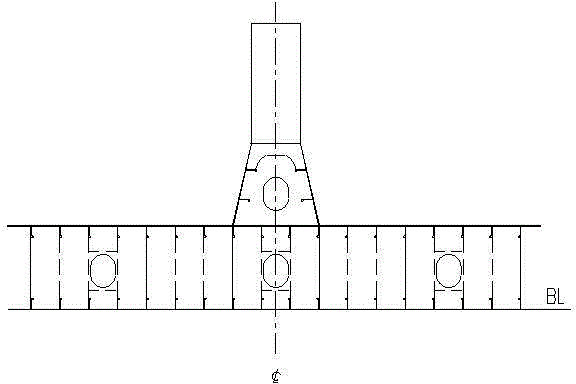

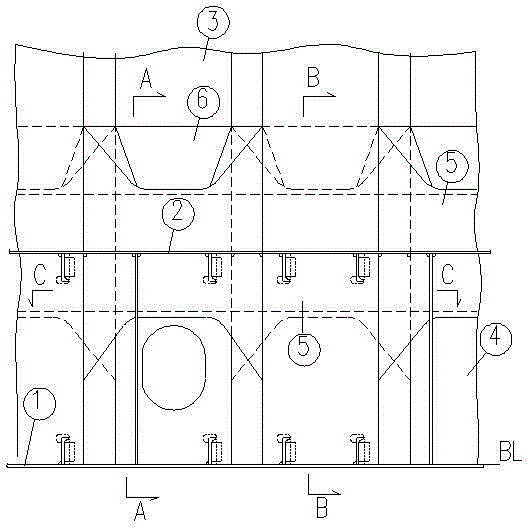

[0021] see Figure 1 to Figure 8 , a bottom structure of a vertical grooved bulkhead of a ship, comprising a bottom plate 1, an inner bottom plate 2, a vertical grooved bulkhead 3, a grooved rib 4, a U-shaped bracket 5, a grooved sealing plate 6, a short longitudinal girder 7, U-shaped plate reinforcement rib 8, inner bottom longitudinal bone 9, bottom plate longitudinal bone 10.

[0022] It is characterized in that a grooved rib 4 with the same cross-section as the vertical grooved bulkhead 3 is arranged between the bottom plate 1 and the inner bottom plate 2, and a U-shaped opening with a U-shaped mouth facing down is installed at the upper end of the grooved rib 4. The brackets 5, the inner bottom longitudinals 9 and the bottom plate longitudinals 10 are provided with matching passage holes, and the U-shaped brackets 5 with U-shaped openings facing upwards are installed at the grooved openings at the lower end of the vertical grooved bulkhead 3. The near U-shaped edge of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com