Vessel provided with heat exchangers in the double bottom thereof

A heat exchanger and double-bottom technology, applied in the field of coolers and cooling water systems, can solve problems such as increased risk, space occupation, draft and fuel consumption, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

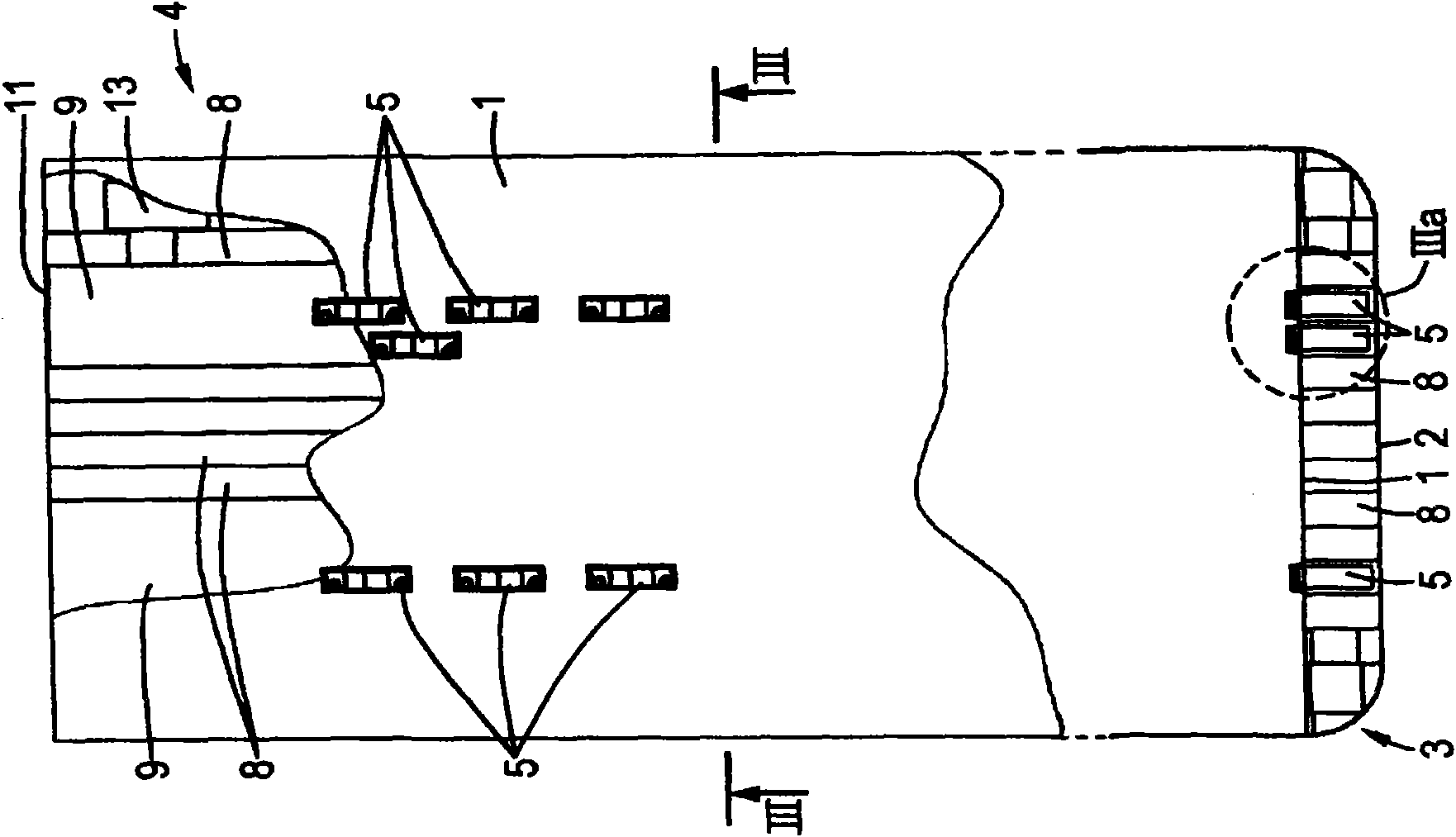

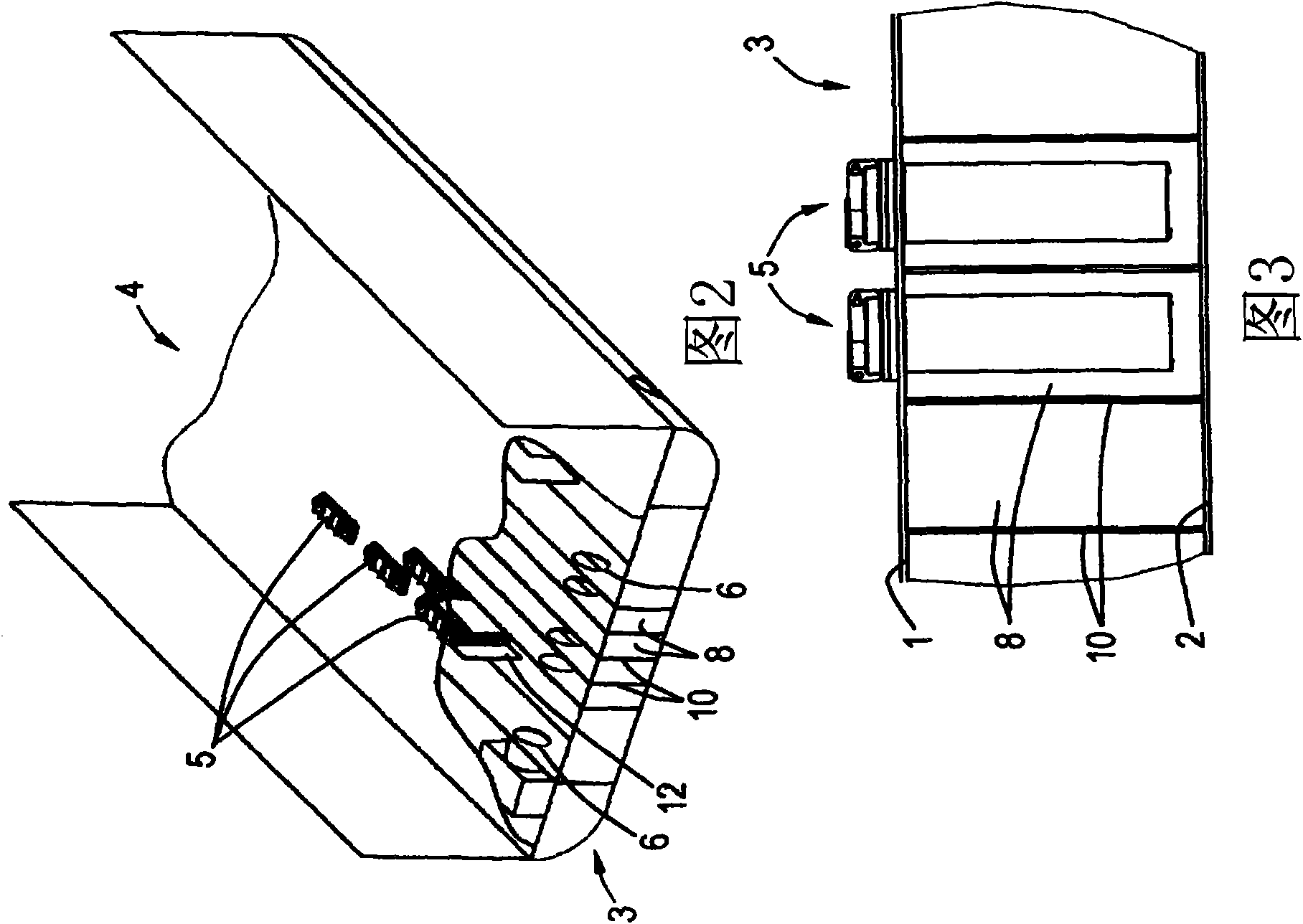

[0024] figure 1 Shell plating 1 and 2 are shown at a distance, forming a double bottom 3 of the whole (shown partially) of a vessel 4 (shown schematically). The vessel 4 is provided with one or more heat exchangers 5 arranged between the shell plating 1 and the shell plating 2 in the double bottom 3 however present.

[0025] Control members 6 (which can be closed or adjusted in the diameter or width of their passages) are usually provided in the forward hull plating or on the side of the double hull plating 1, 2, said control members acting as channels for cooling water (in particular is the inlet and channel member 6 of seawater). Furthermore, ducts (not shown in the figures) may form part of the channel member 6 which, like the channel member of the control member 6, extends to the heat exchanger 5 and from there to a channel not formed in the side hull of the vessel. One or more outlets 7 for discharge into the sea. The various control means 6 can be controlled, for exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com