Liquefied natural gas transport ship and liquefied natural gas transport system

A technology for liquefied natural gas and transport ships, which is used in transportation and packaging, ship accessories, hulls, etc., and can solve the problems of difficult construction of the sub-barrier support structure, difficult maintenance in the cabin, and heavy overall weight of the hull.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

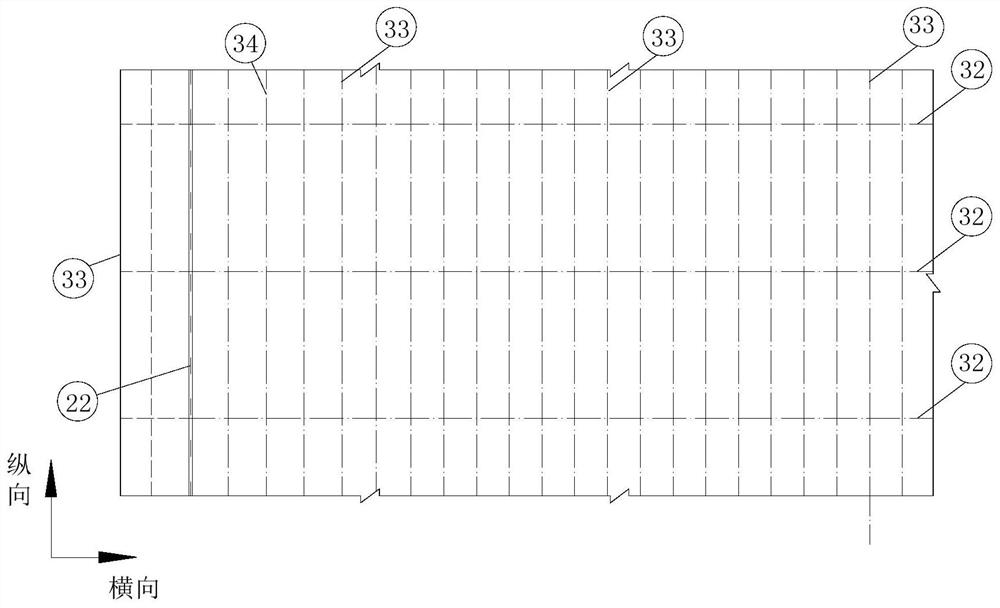

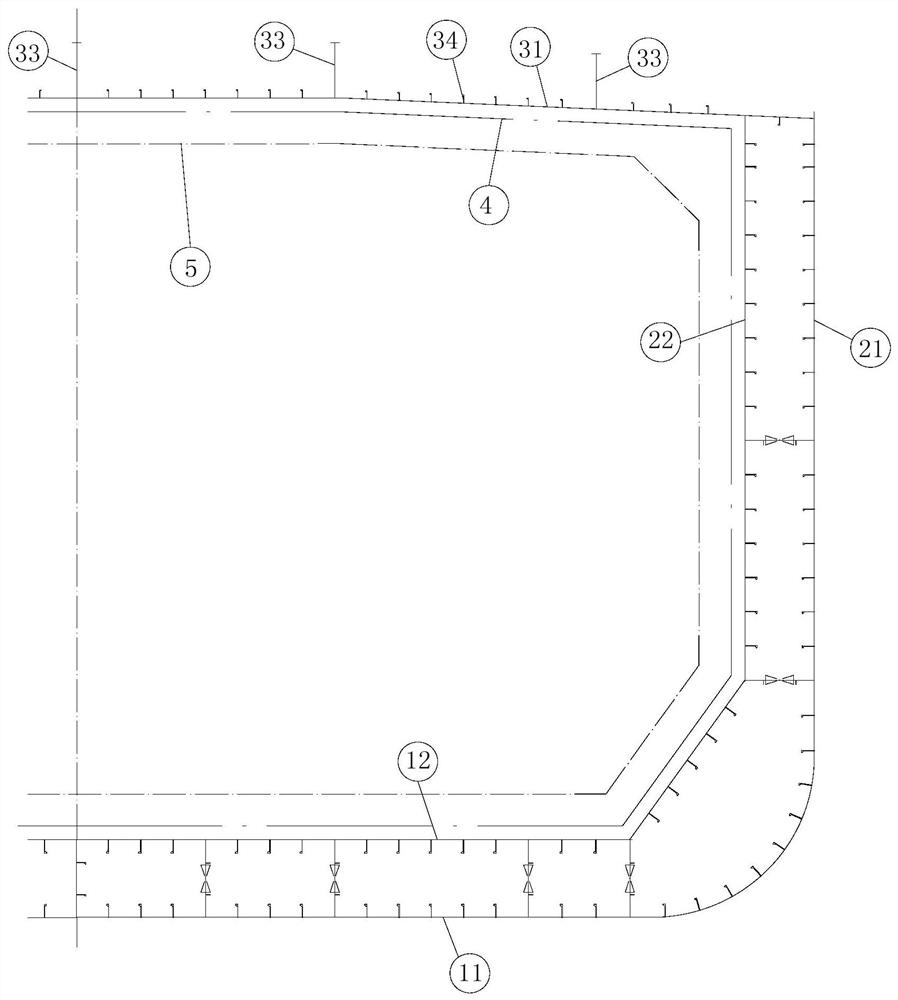

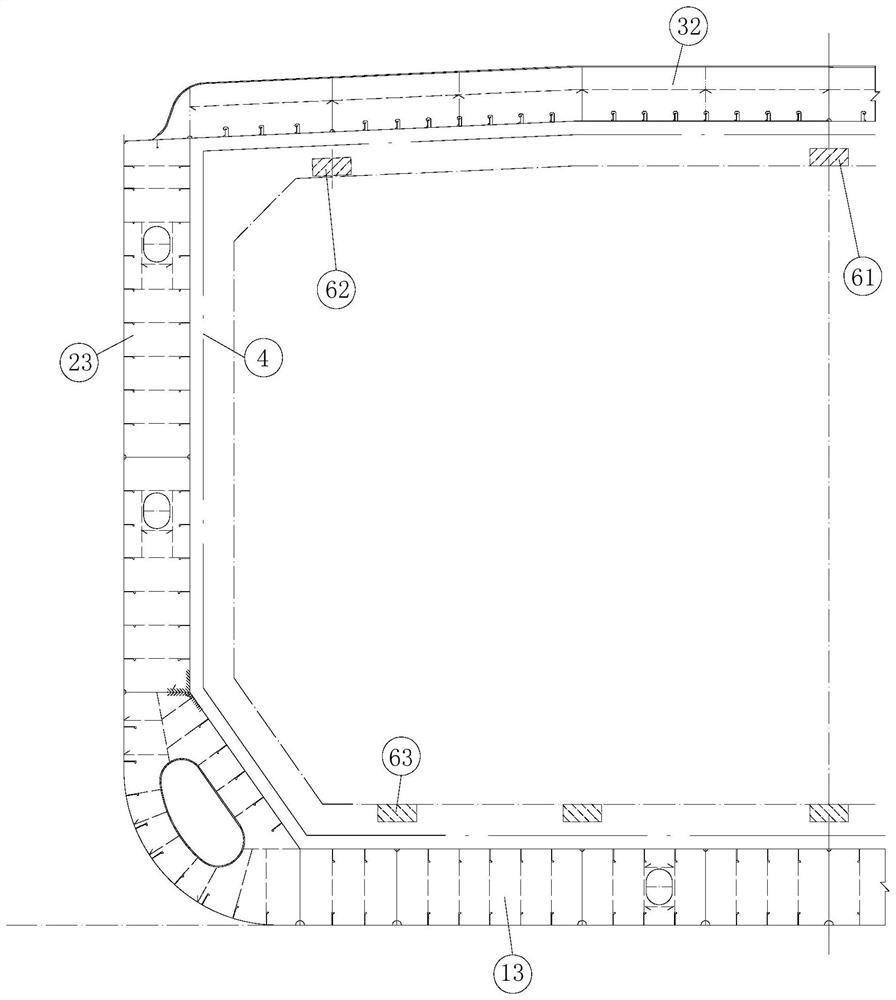

[0039] This embodiment provides a liquefied natural gas transport ship, refer to Figure 1 to Figure 3 , the hull of the liquefied natural gas carrier includes a double bottom, a double side skin and a single main deck. in, figure 2 and image 3 The strong frame and weak frame in refer to relatively speaking, the stronger and weaker frame structures in terms of structural strength.

[0040] Specifically, the above-mentioned double bottom plate includes a ship bottom outer plate 11, a ship bottom inner plate 12, and a ship bottom rib 13 connected between the ship bottom outer plate 11 and the ship bottom inner plate 12; the double-sided side plate includes a side outer plate 21, a side side The inner plate 22 and the side reinforcement frame plate 23 connected between the side outer plate 21 and the side inner plate 22; the single-layer main deck includes the deck body 31 and the deck reinforcement structure; the bottom inner plate 12 and the side inner plate 22 The liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com