Patents

Literature

34results about How to "Avoid excessive local stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

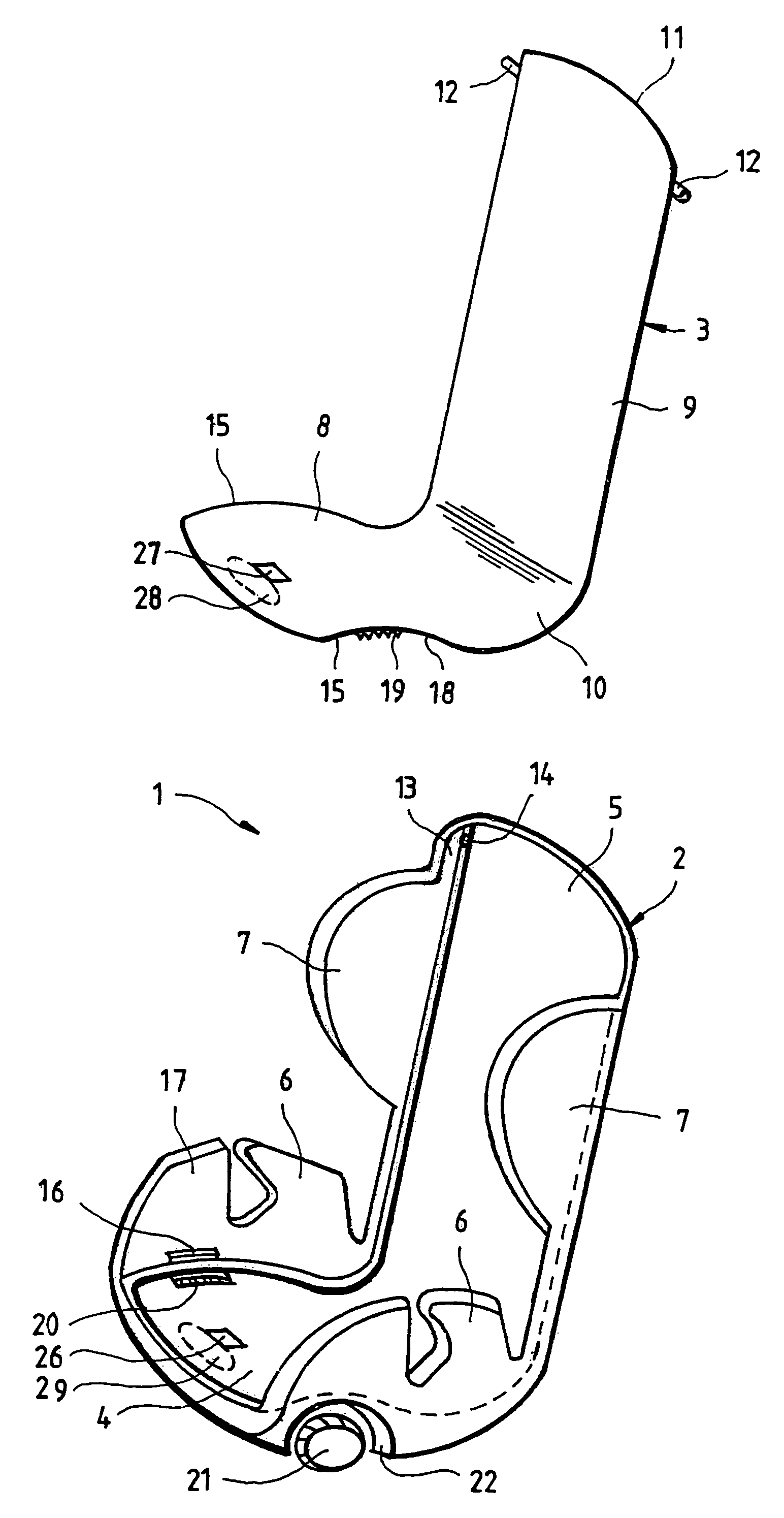

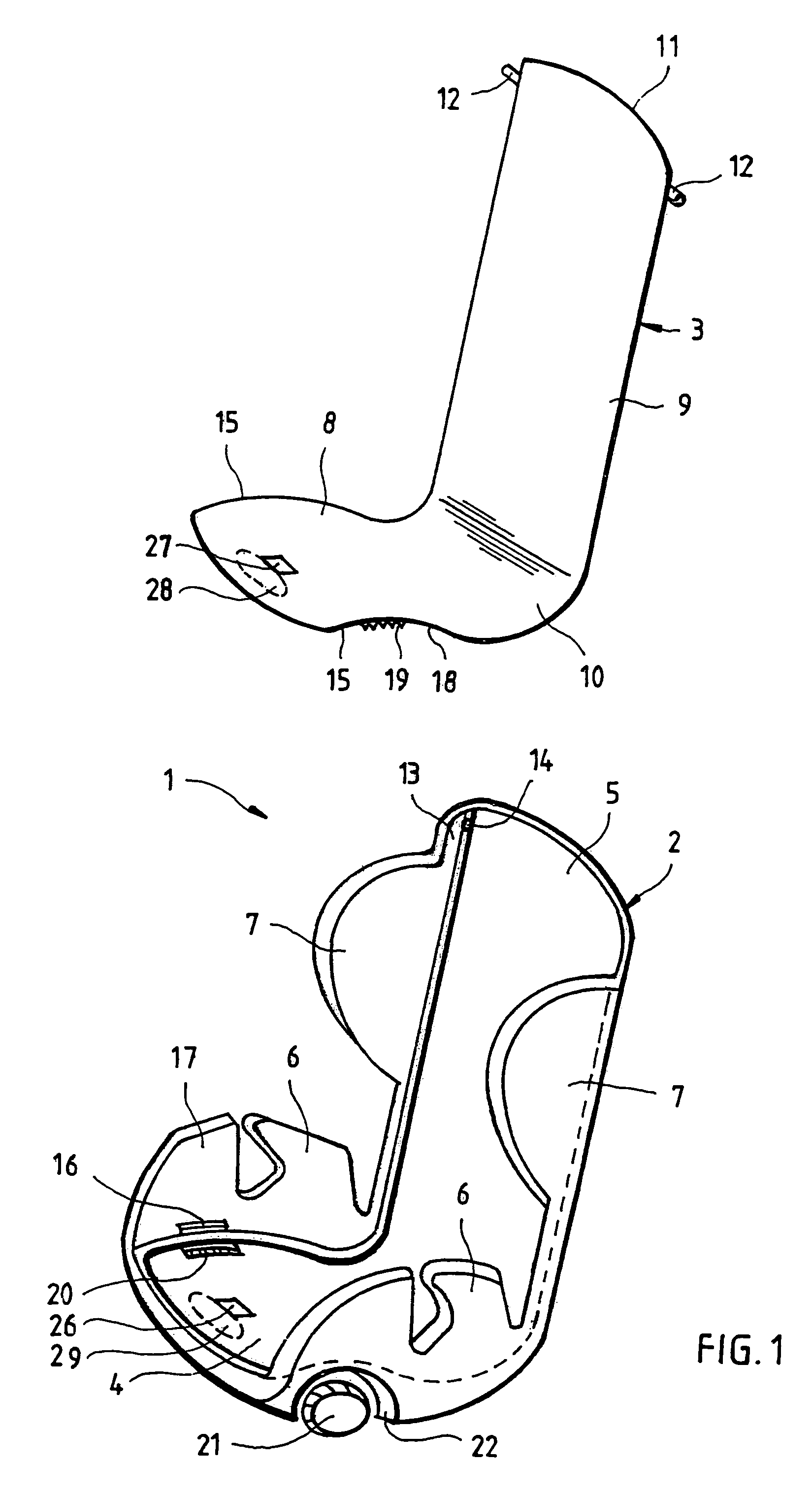

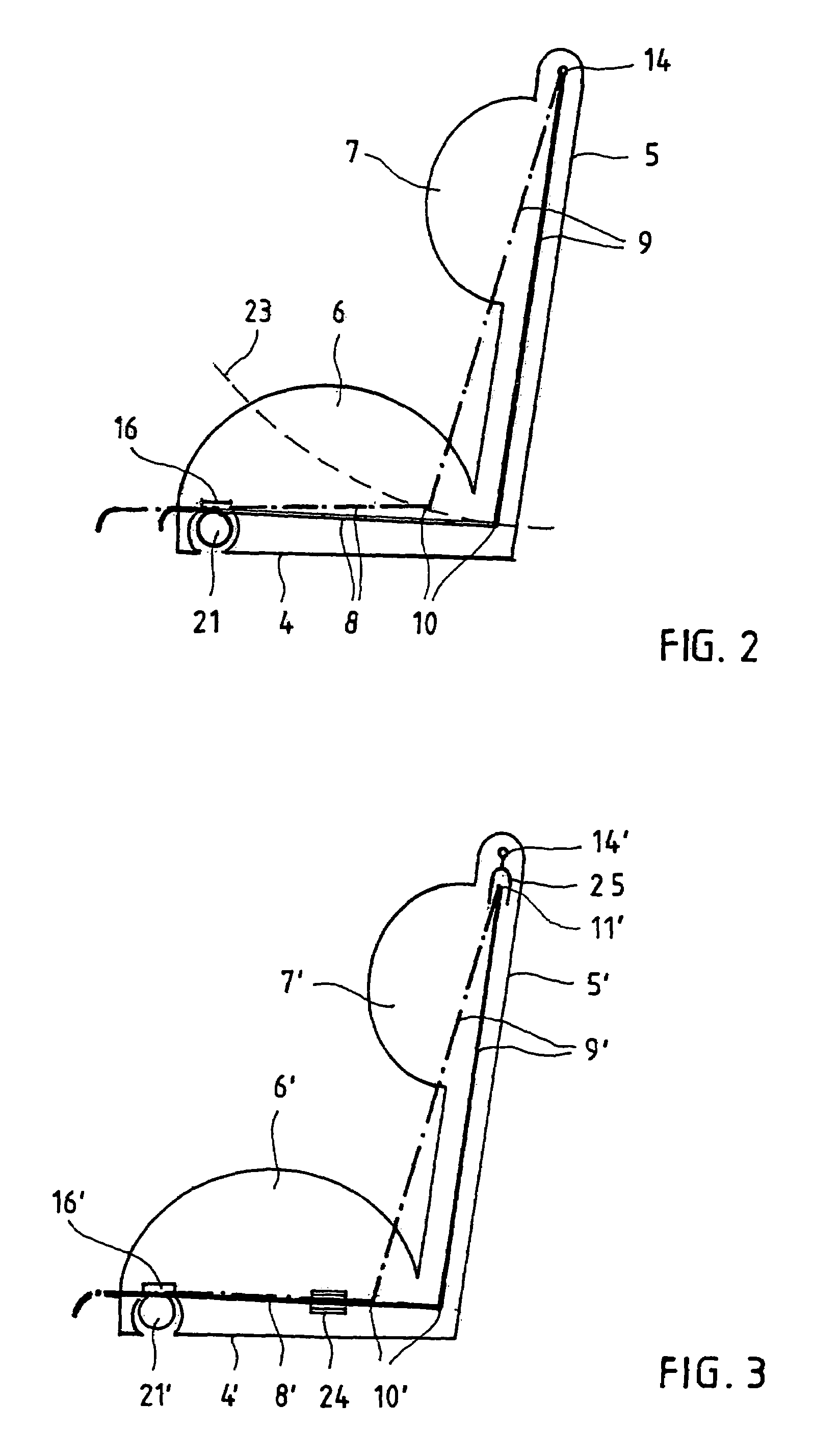

Child car seat

InactiveUS7344192B2Structural expenditure be minimalImprove stabilityVehicle seatsStoolsHandrailAutomobile safety

The invention is directed to a child car seat, composed ofa) a seat shell, comprising a bottom sitting region with at least one bottom stand surface to be stood on a seat of a vehicle, a backrest region extending upwardly from the sitting region and having at least one outer surface to be leaned against the backrest of the vehicle seat, and lateral surfaces, for example lateral armrests, shoulder supports and / or head supports, for limiting the lateral range of movement of a child, at least that portion of the backrest region that comprises a rear leaning surface being rigidly connected to the sitting region comprising a bottom stand surface, andb) a rather two-dimensional seat element, comprising a sitting surface and / or backrest that is / are disposed on the inner side, turned toward the child, of the seat shell and is / are adjustable with respect thereto in terms of inclination and position and is / are lockable in a plurality of different inclinations and / or positions by means of a manually operable device on the seat having a coupling to the adjustable, rather two-dimensional seat element on the one hand and to the seat shell on the other.

Owner:RECARO CHILD SAFETY

Biological tendon repairing material and preparation method thereof

ActiveCN107854727APromote growthEasy to climbTissue regenerationProsthesisCell-Extracellular MatrixCellular infiltration

The invention provides a biological tendon repairing material and a preparation method thereof. The biological tendon repairing material comprises an extracellular matrix body subjected to immunogen removal, wherein the extracellular matrix body consists of one or more layers and comprises a first surface and a second surface; the first surface comprises a first area and a second area; the mechanical strength of the first area is lower than that the second area. During preparation of an extracellular matrix subjected to immunogen removal, layering is avoided. As the biological tendon repairingmaterial is provided with the surface which consists of the first area and the second area, cellular infiltration of defective tissues is facilitated, tissue repairing is accomplished, stress born bythe repairing material can be uniformly distributed, and local stress cannot be excessively large. Besides, the surface has a high suture retention force and can serve as the second surface of a suture area of the repairing material, and the strength of the repairing material can be guaranteed while repairing of the defective tissues is facilitated.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

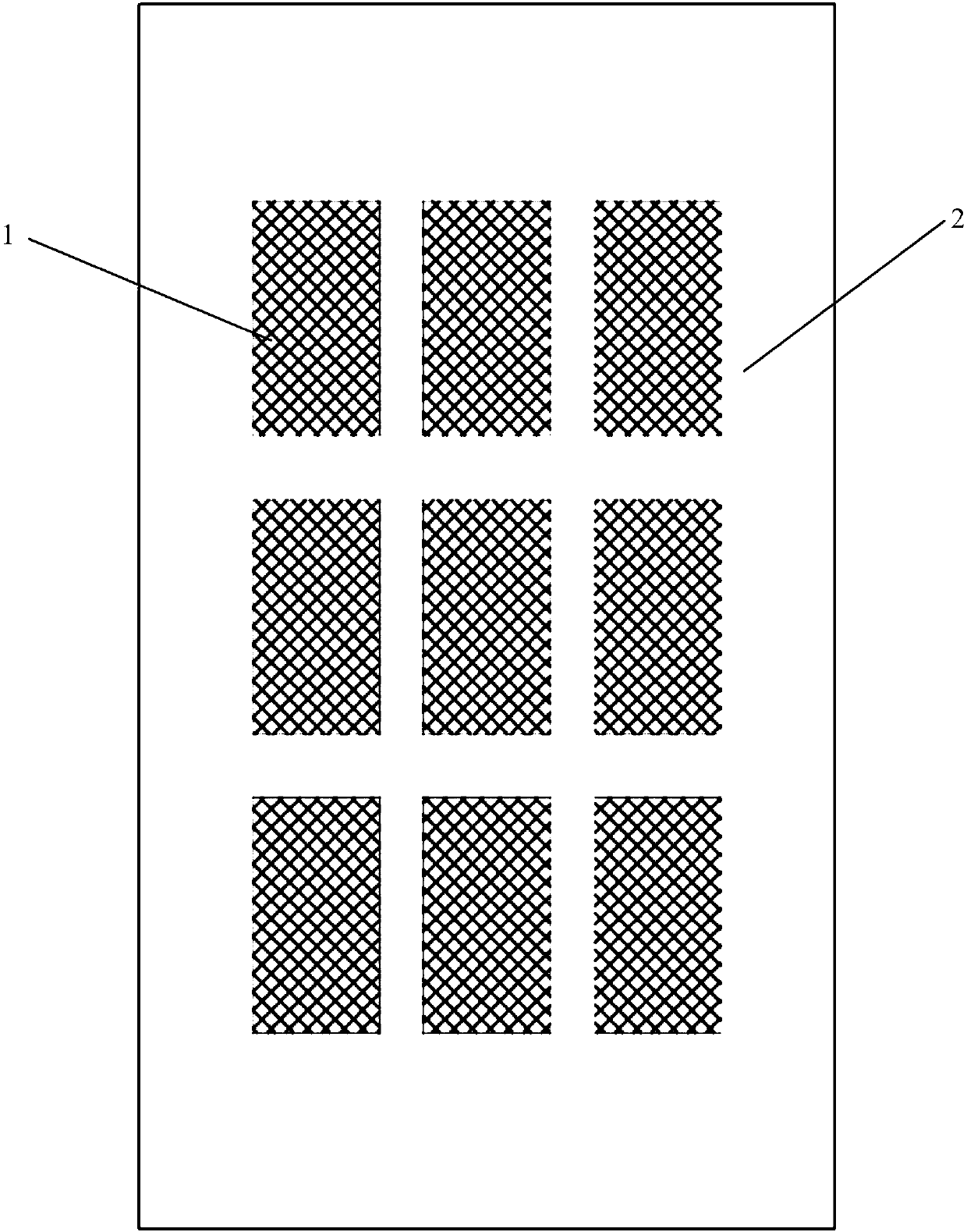

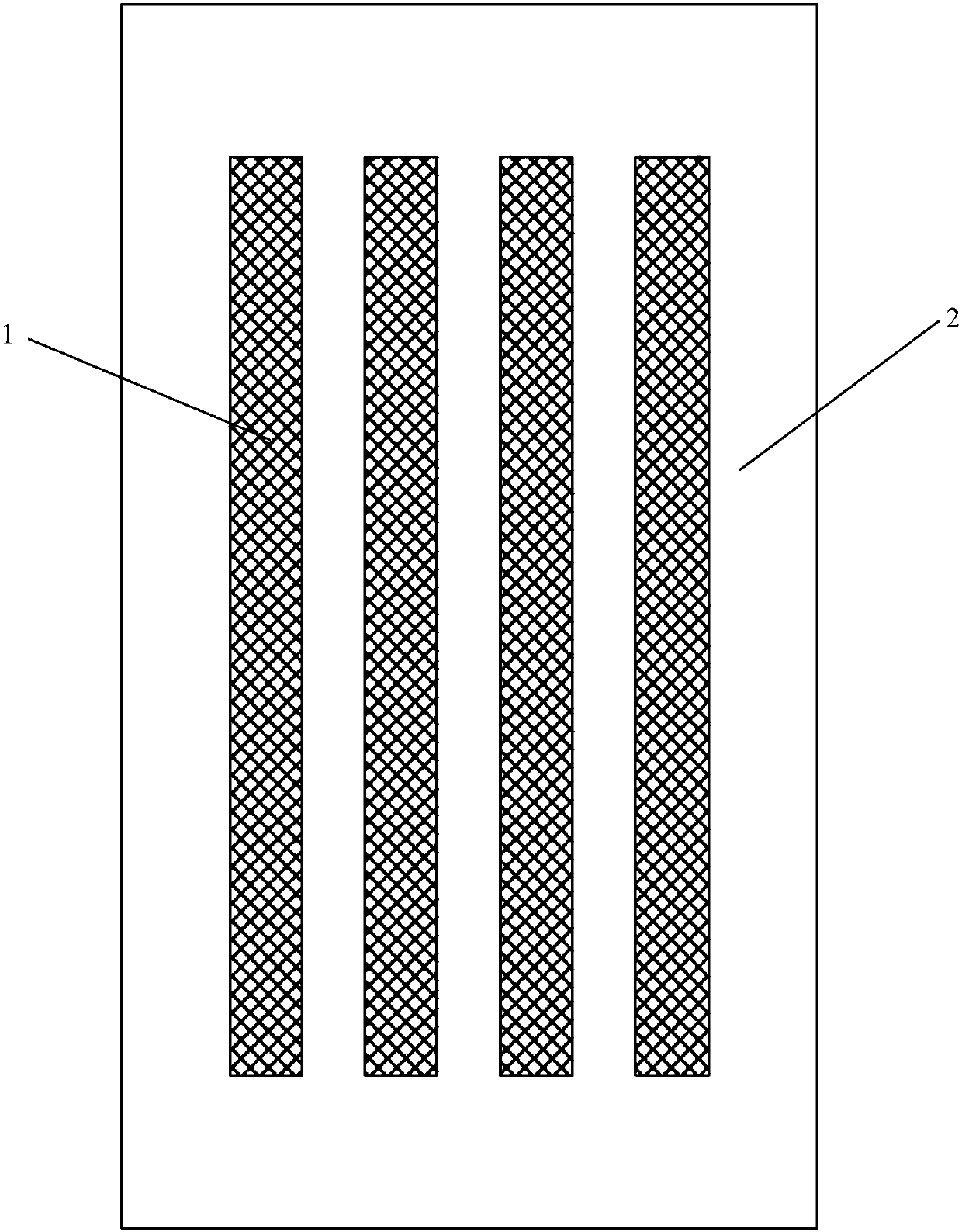

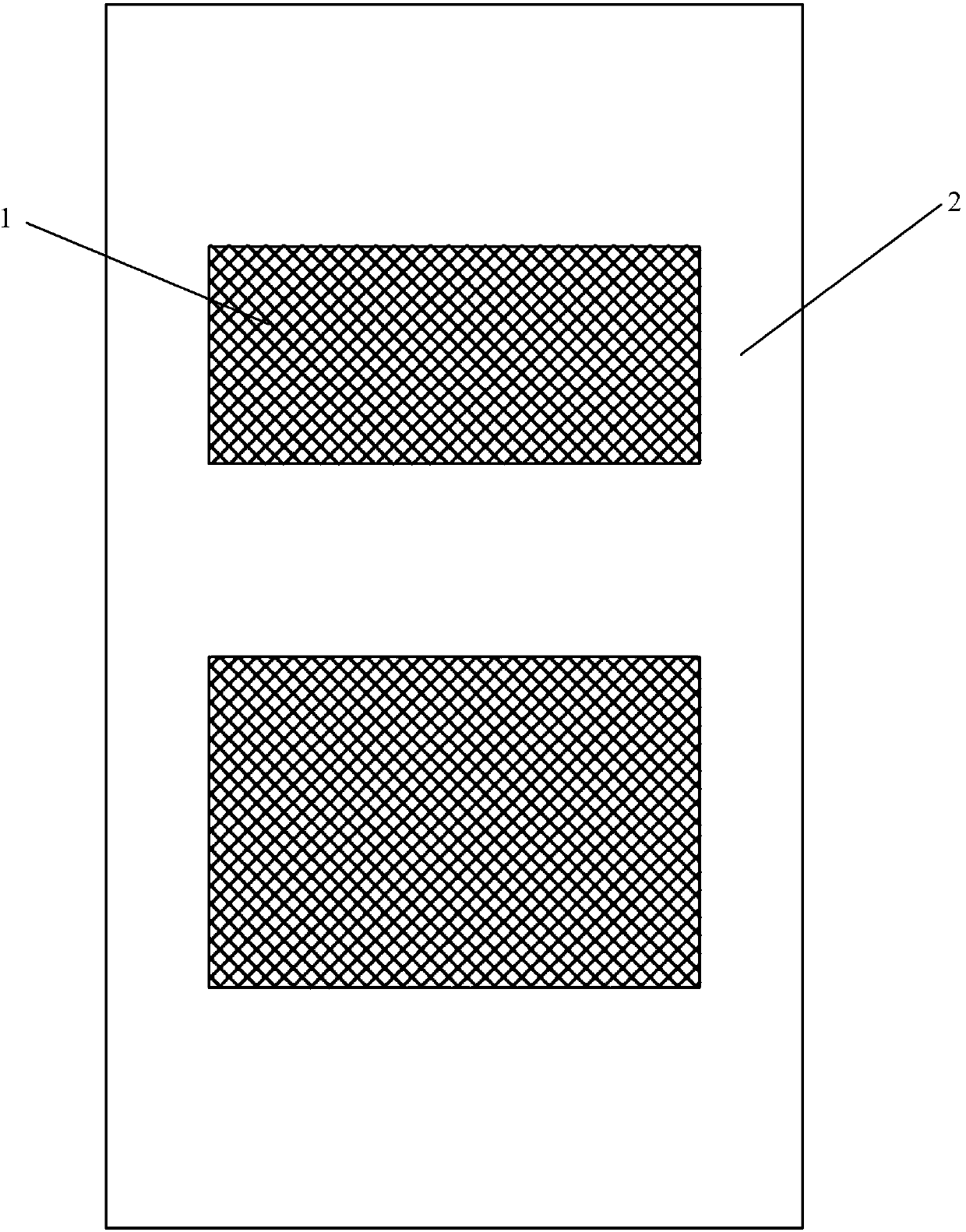

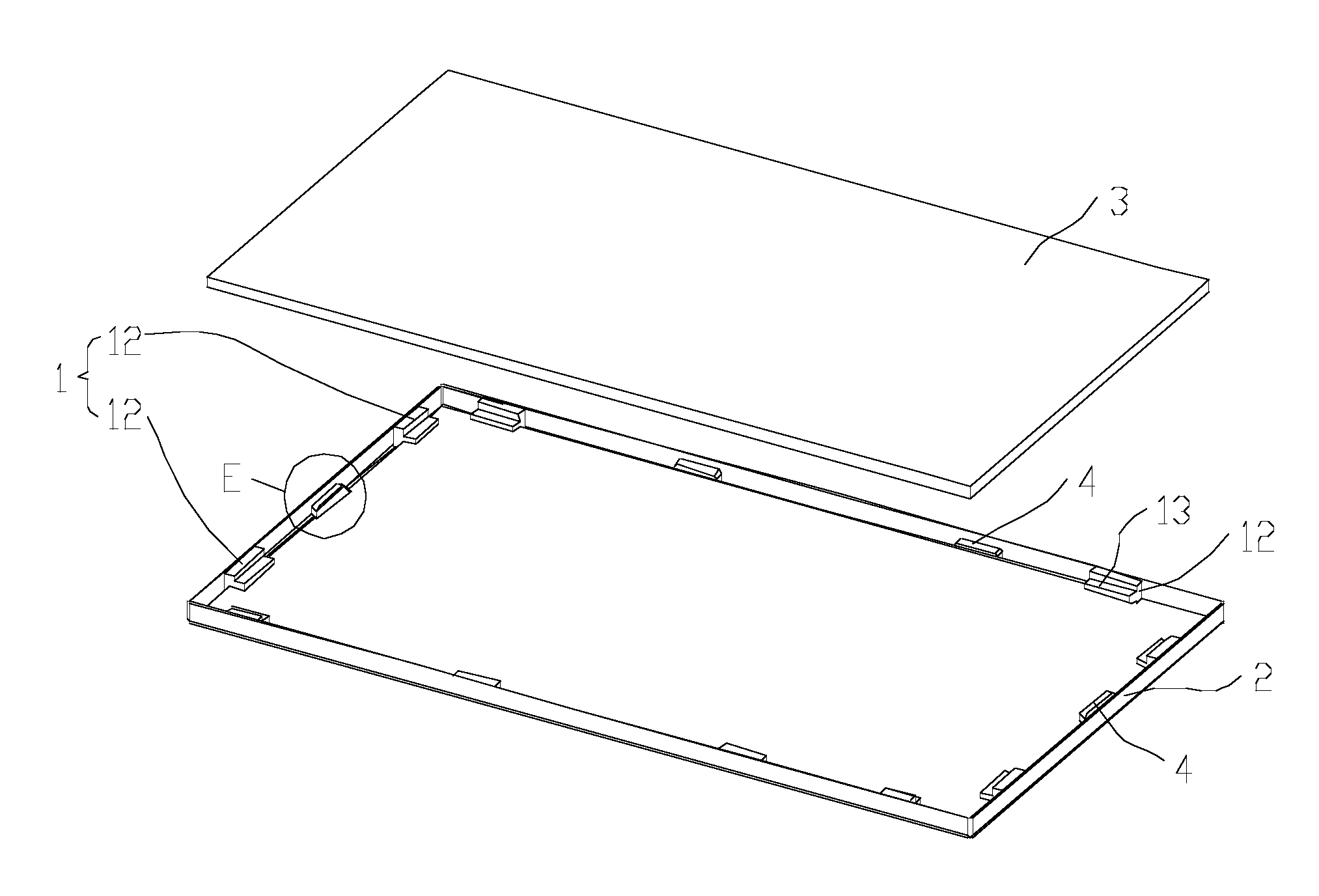

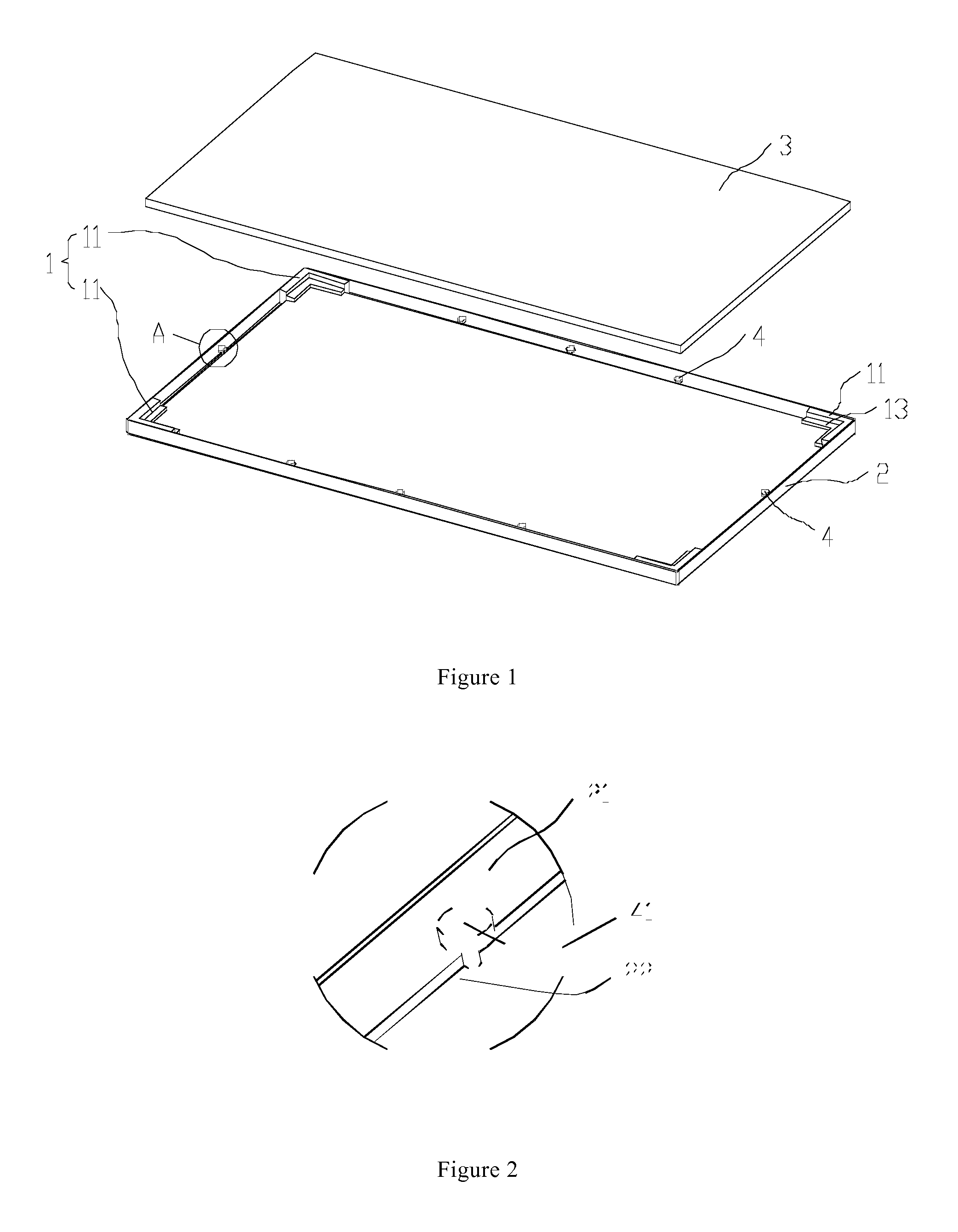

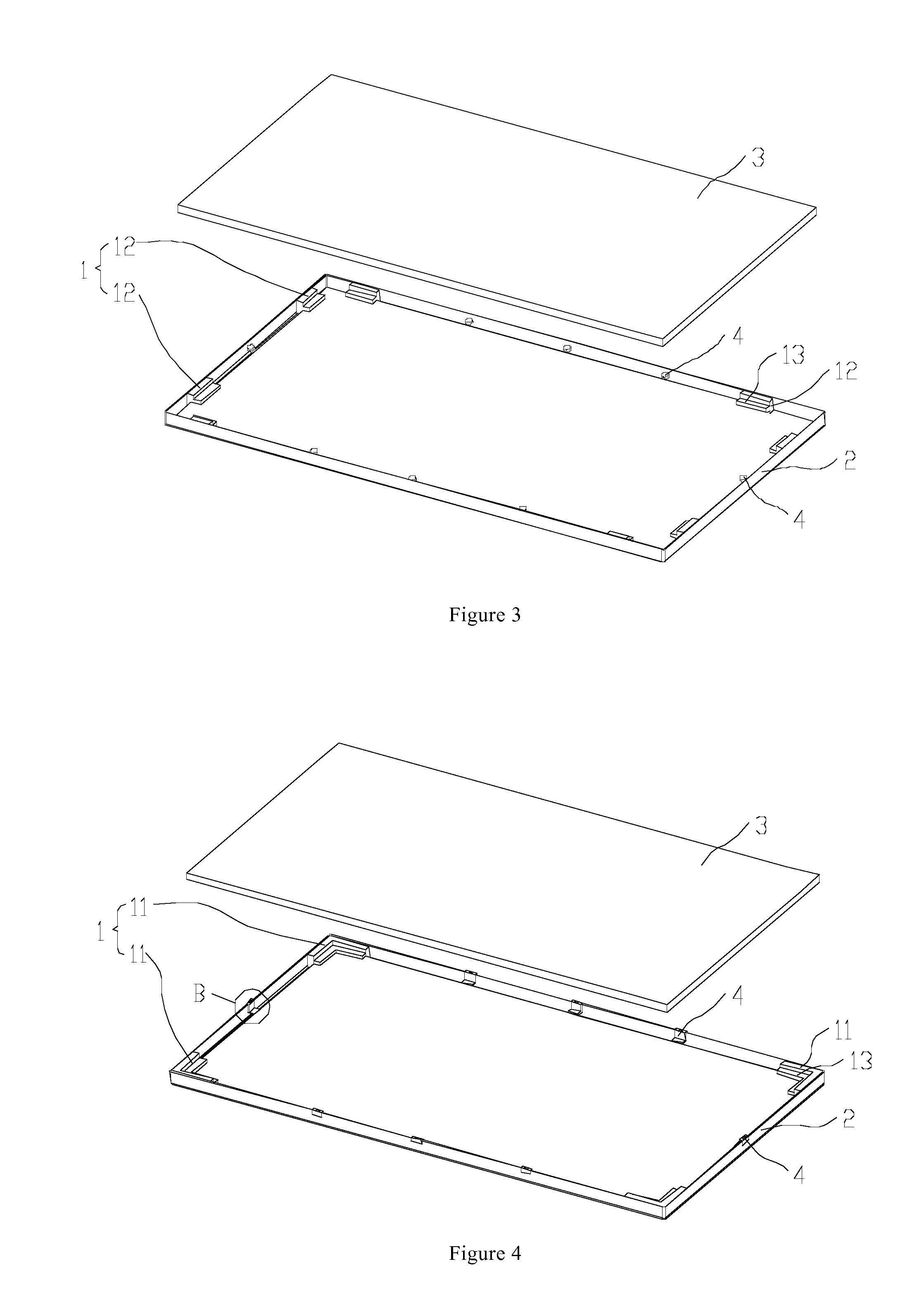

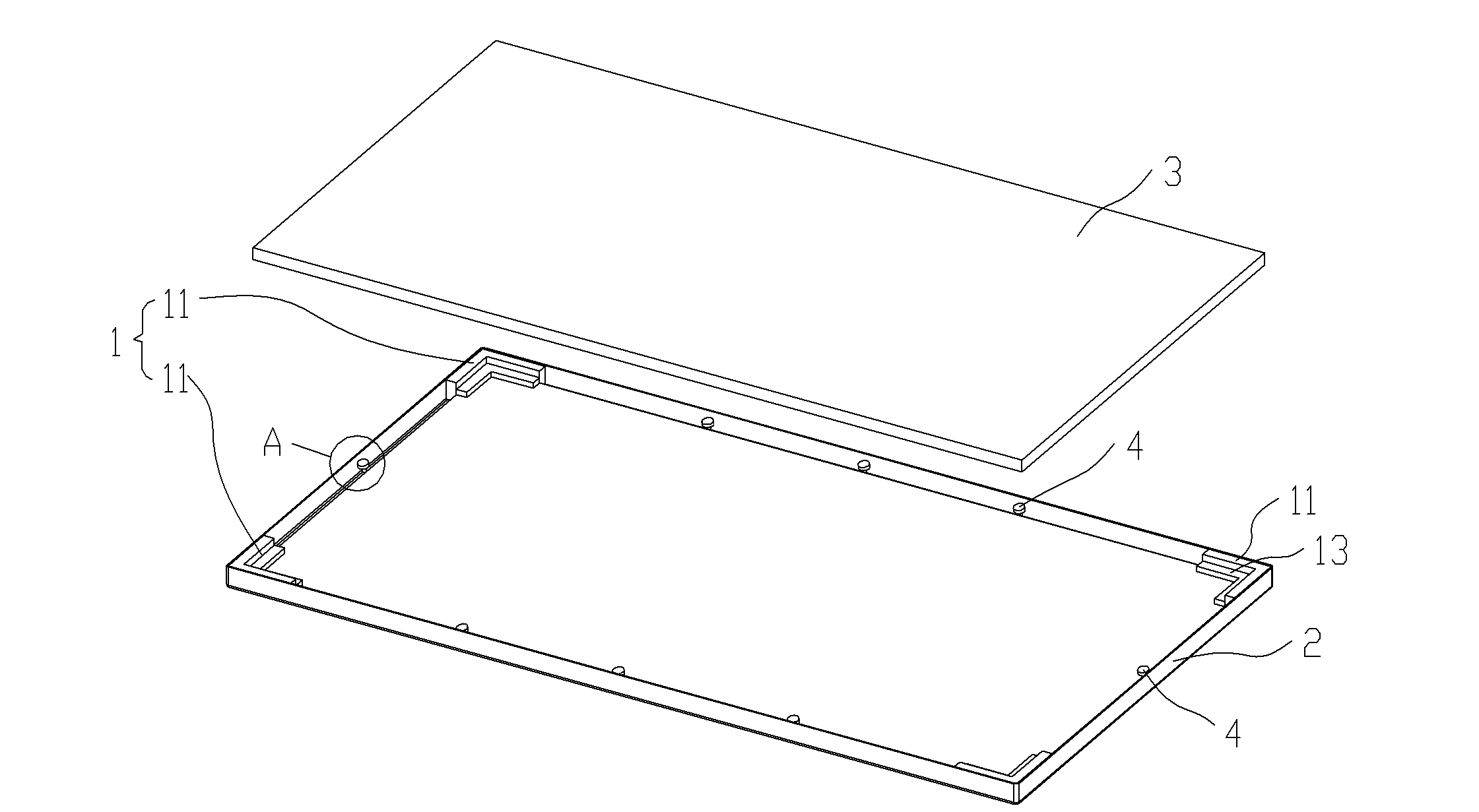

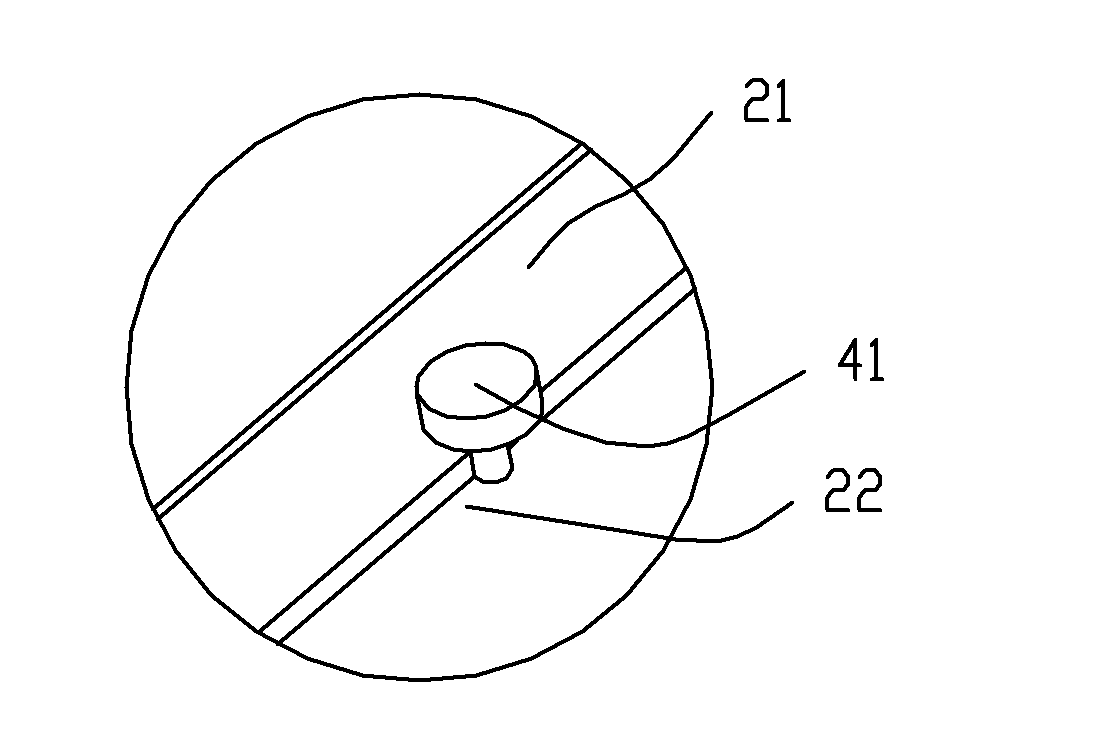

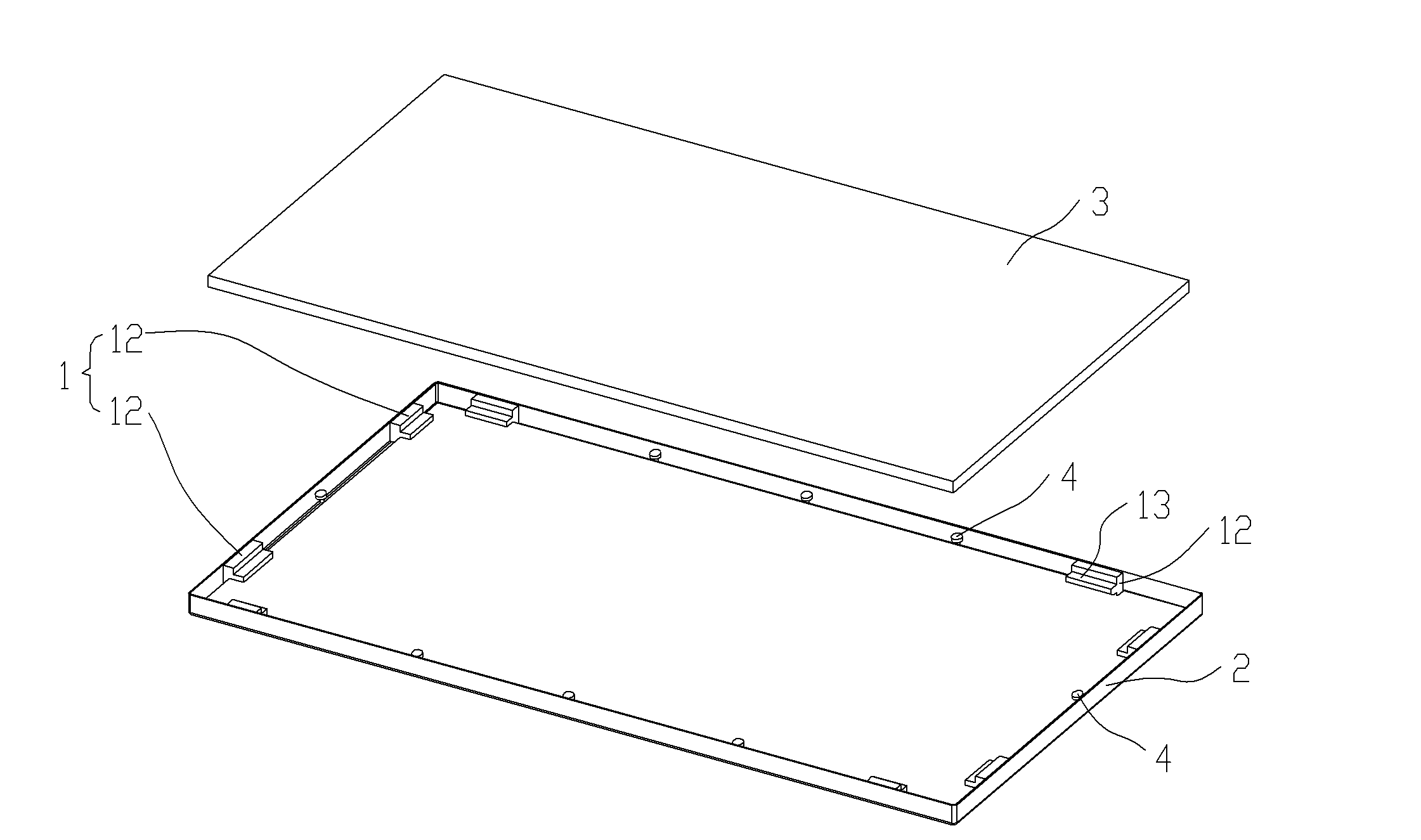

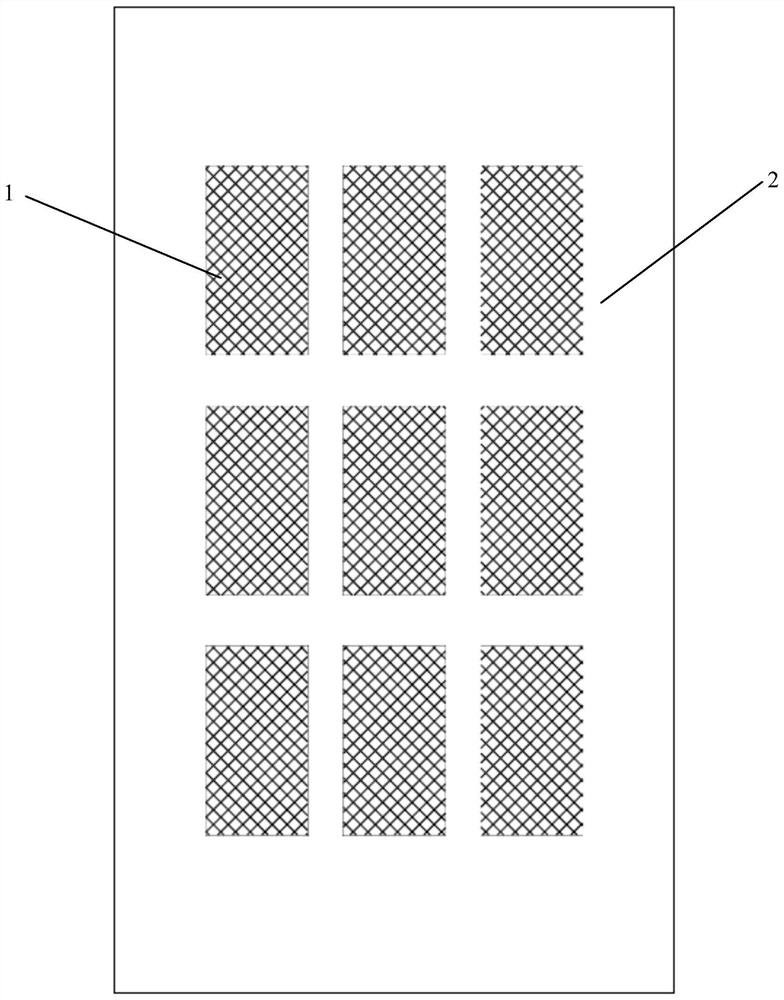

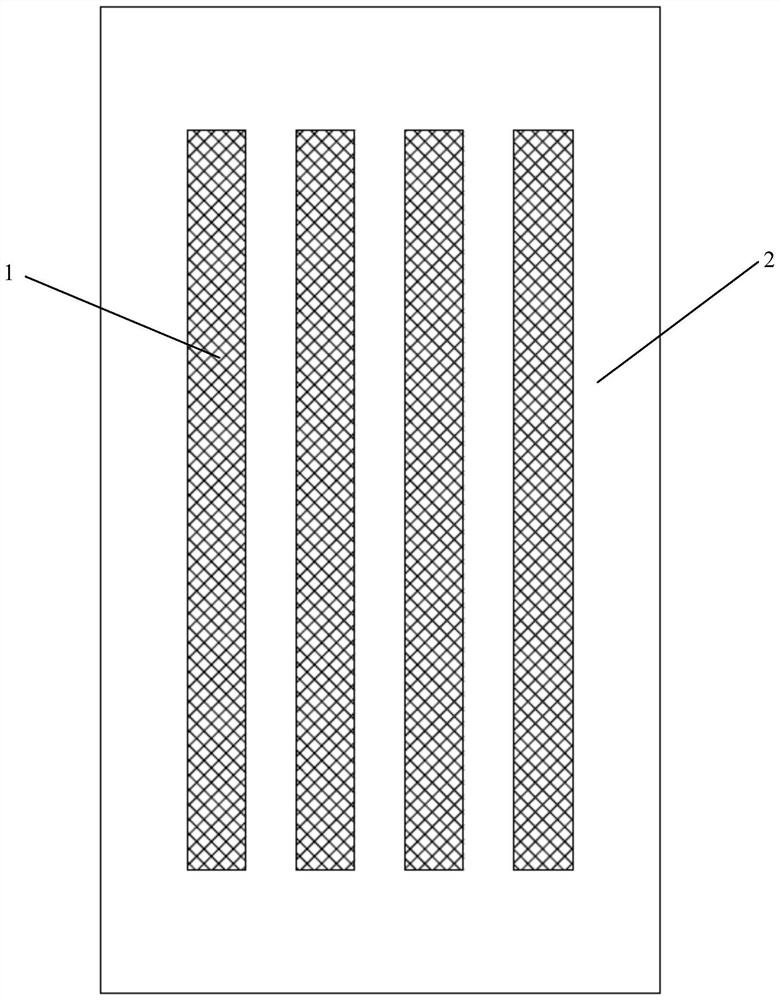

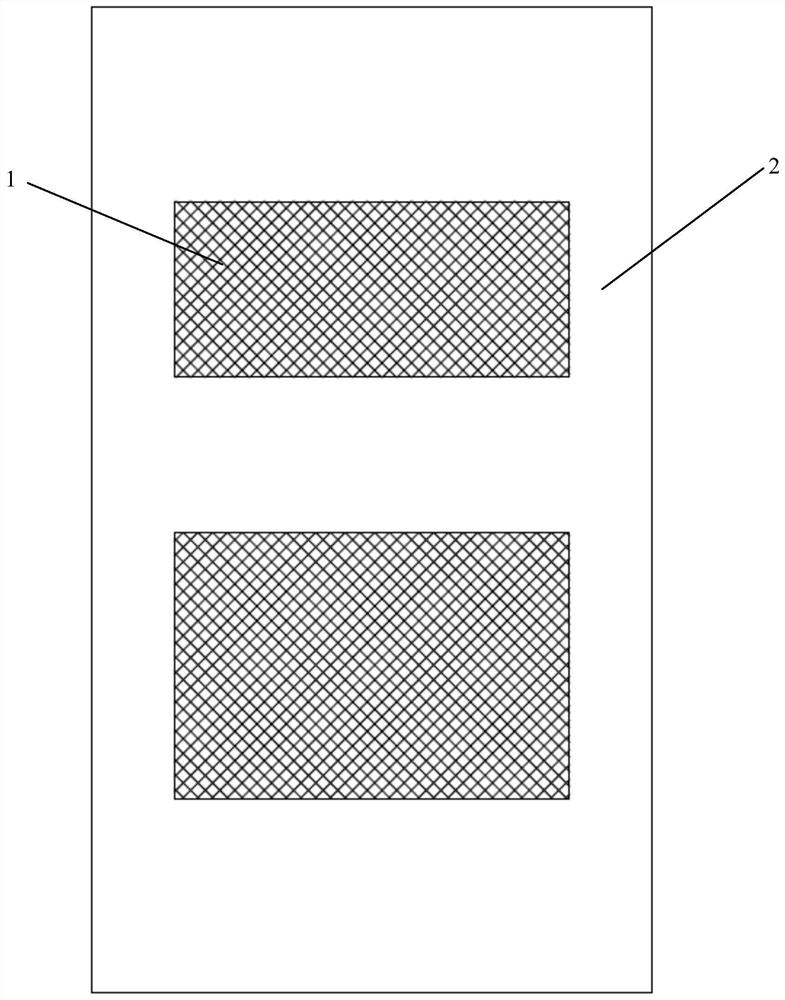

LCD Device and Backlight Module

InactiveUS20130286321A1Avoid excessive local stressUniform supportFurniture partsCabinetsLiquid-crystal displayEngineering

The invention relates to the field of LCDs, and more particularly to an LCD device and a backlight module. The LCD device includes a middle frame, a backplane, and an LCD panel; the LCD panel is arranged on a support surface of the middle frame; the middle frame includes a plurality of member units, and a distance is reserved between two adjacent member units. The LCD device further comprises a support member(s) used for assistantly supporting the LCD panel; the support member(s) is fixedly arranged on the backplane, and the support member is positioned between adjacent member units; the support surface of the support member is flush with the support surface of the middle frame. The support member(s) of the LCD panel is additionally arranged on the LCD device of the invention; the support member(s) is arranged between two member units when the distance between two adjacent member units is long to provide intermediate support force, so as to enable the support force obtained by the LCD panel is more uniform, and prevent excessive local stress.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display device and backlight module

InactiveCN102621727AUniform supportAvoid excessive local stressLighting support devicesNon-linear opticsLiquid-crystal displayBackplane

The invention belongs to the field of liquid crystal display and in particular relates to a liquid crystal display device and a backlight module. The liquid crystal display device comprises a middle frame, a backplate and a liquid crystal display panel, wherein the liquid crystal display panel is arranged on a supporting surface of the middle frame; the middle frame comprises multiple member units; a distance is arranged between the adjacent member units; the liquid crystal display device further comprises a supporting piece used for providing assistance in supporting the liquid crystal display panel; the supporting piece is fixedly arranged on the backplate and positioned between the two adjacent member units; and the supporting surface of the supporting piece is aligned with the supporting surface of the middle frame. According to the invention, because the supporting piece of the liquid crystal display panel is additionally arranged on the liquid crystal display device, the supporting piece can be placed between the two member units to provide middle supporting force when the distance between the two adjacent member units is larger so that the supporting force obtained by the liquid crystal display panel is more uniform and the local stress is prevented from being overlarge.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

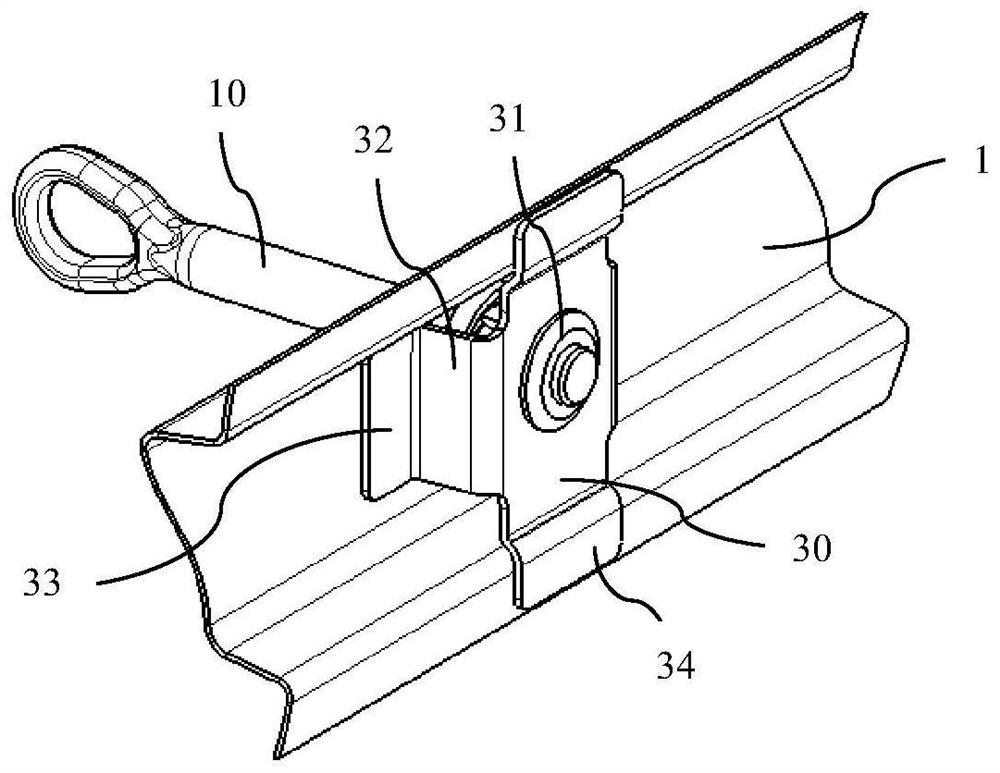

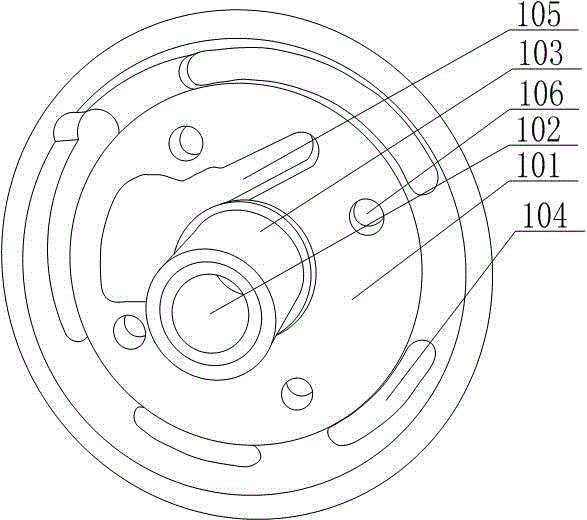

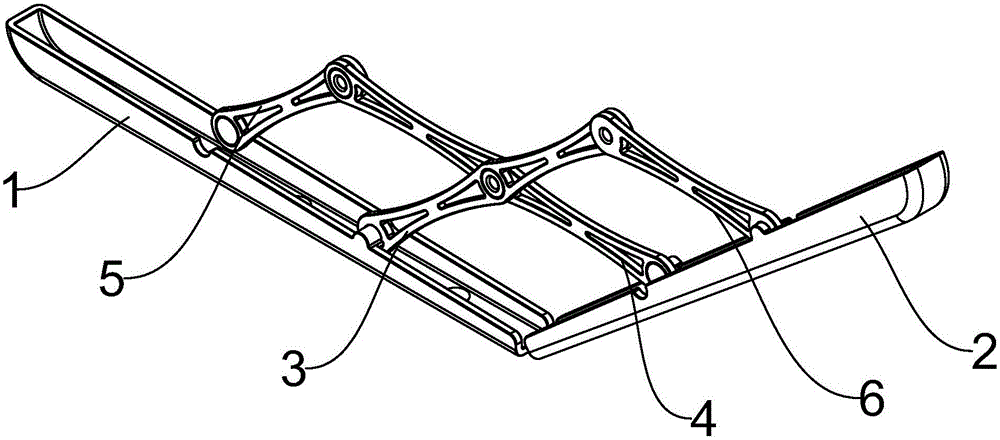

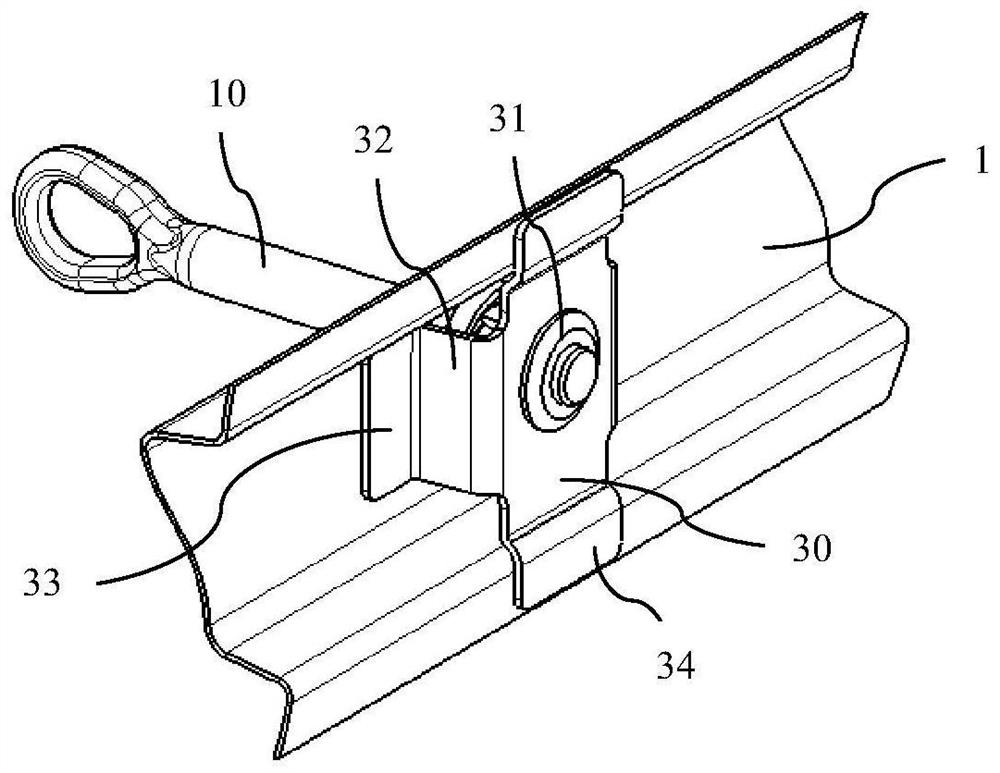

Connecting device of wave glider water surface floating body and umbilical cable

ActiveCN110341887AEasy to disassembleAvoid excessive local stressTowing/pushing equipmentNaval architectureEngineering

The invention discloses a connecting device of a wave glider water surface floating body and an umbilical cable, and relates to the field of naval architecture and ocean engineering. The device includes a device shell, a first backing plate, a second backing plate, first clamping strips, a latch, second clamping strips and a knob; the device shell is connected to the first backing plate and the second backing plate; the first backing plate is located at the upper part of the second backing plate; the first clamping strips, the latch, the second clamping strips and the knob are arranged at theinternal of the device shell; the first clamping strips fix an umbilical cable joint; the latch and the first clamping strips are in butt joint; the second clamping strips fix the latch; and the knobcontrols the opening and closing of the second clamping strips. An applied method of the device includes inserting the umbilical cable joint into the first clamping strips; inserting the latch into the device shell from top to lock the first clamping strips; and rotating the knob to push the second clamping strips into the groove of the latch so that the latch can be fixed. The device is safe andreliable in structure and convenient in dismounting, and therefore, the navigation safety of a wave glider under severe sea conditions can be guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

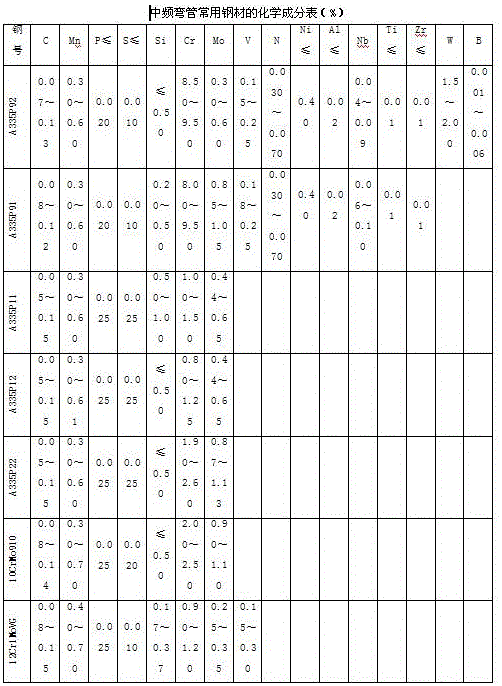

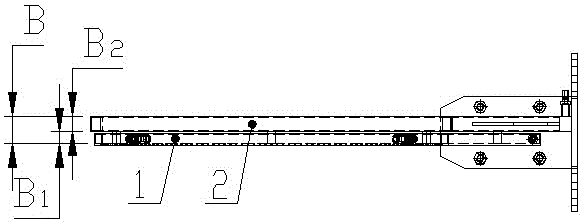

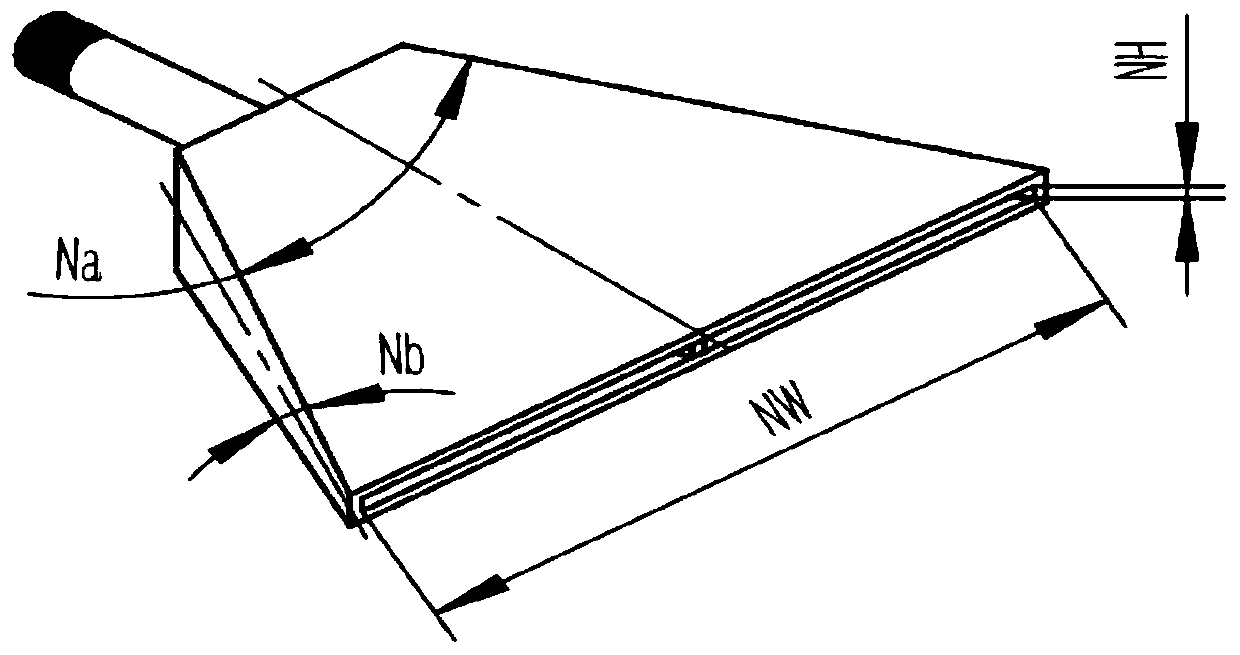

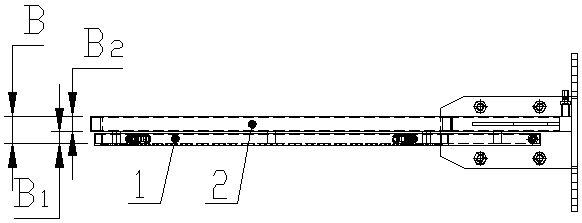

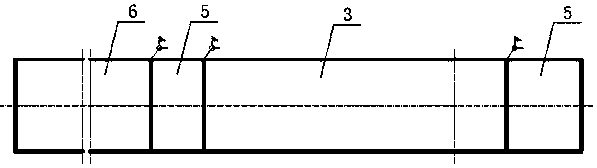

Medium-frequency simmering technology for A335P92 material bend pipe

The invention provides a medium-frequency simmering technology for an A335P92 material bend pipe. The simmering technology is characterized by comprising the following steps of 1) determining a width (B) of an induction heating ring, 2) determining promoting speed during bend pipe medium-frequency simmering, 3) determining a technology section, 4) conducting medium-frequency simmering, 5) determining cooling temperature, 6)taking heat-insulating measures after formation of medium-frequency simmering, and 7) conducting thermal processing after formation of medium-frequency simmering. In the 1) step, induction heating coil width (B)=(2T1 to 50)mm is provided for a thick-wall bend pipe while simmering a main steam pipeline, so wrinkles in an arc position can be prevented when the bend pipe comes out of the induction ring during medium-frequency simmering. In the 2) step, prompting speed during medium-frequency bend pipe simmering is controlled between 10 to 15mm / min, so local excessive stress produced during the medium-frequency simmering can be controlled. In the 3) step, the technology section is formed by a transition section and top material; the transition section is made from low-chromium-molybdenum steel and the length L is no more than 500mm; the transition section can be re-used; and the top material is a carbon steel pipe.

Owner:吉林昊宇电气股份有限公司

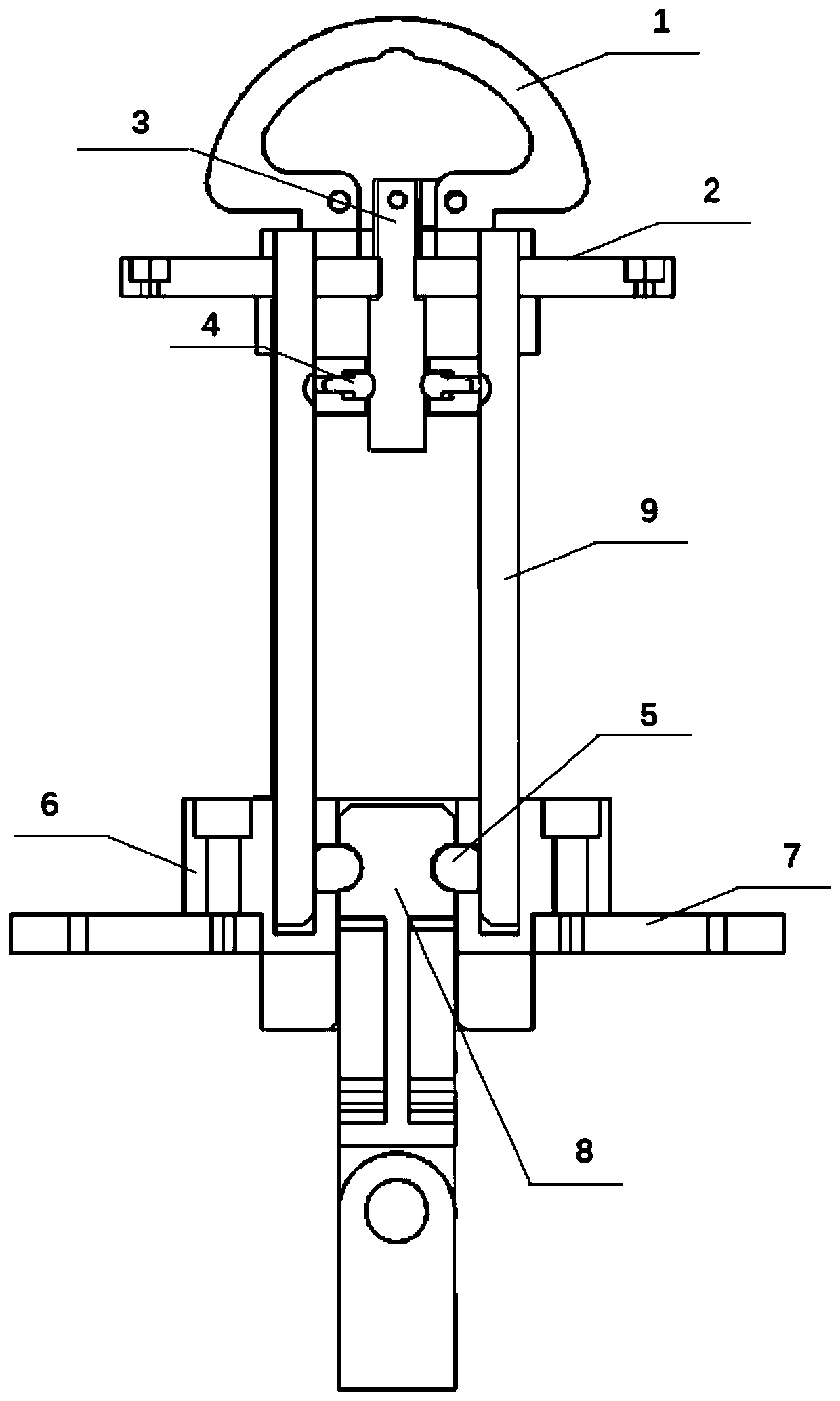

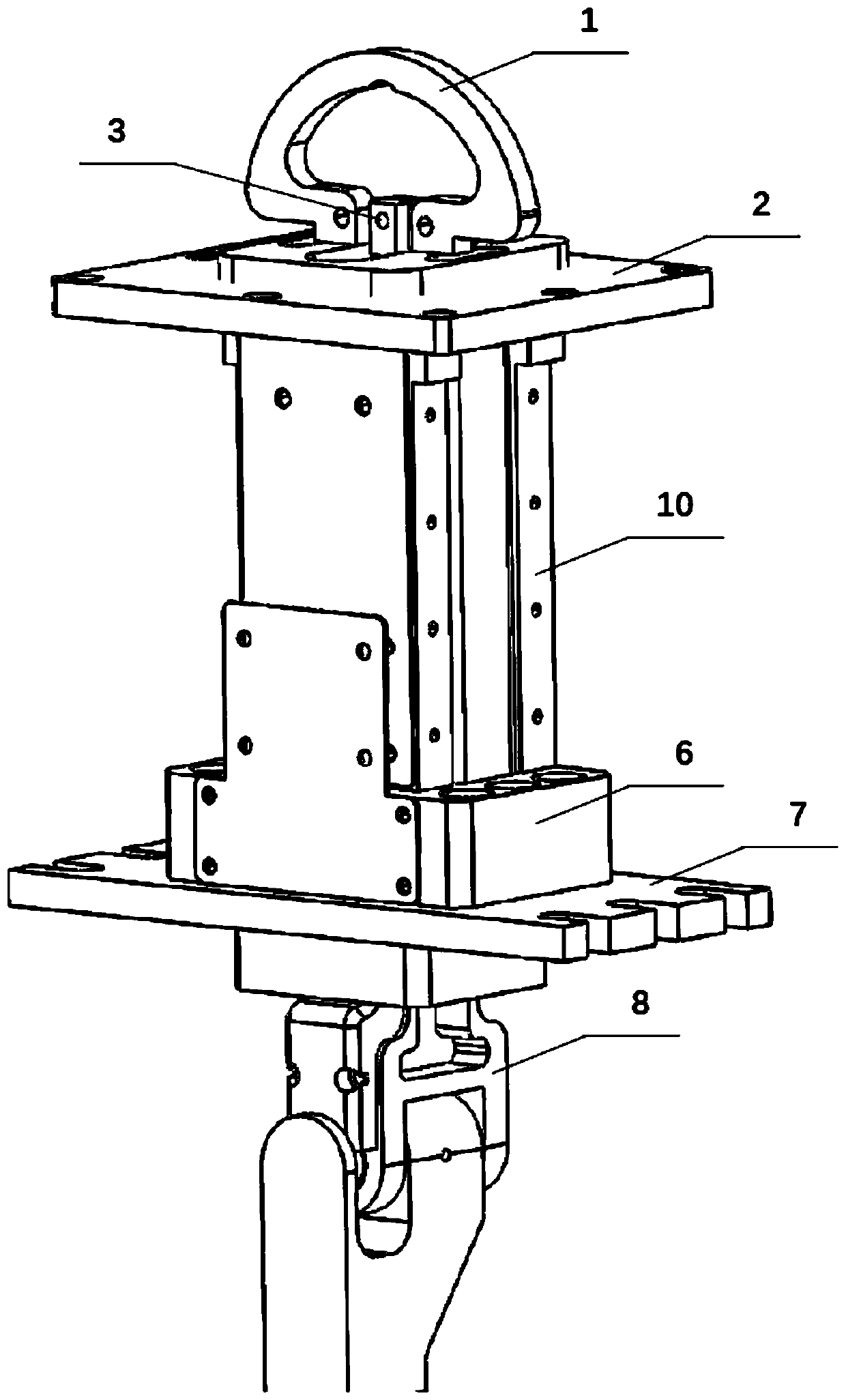

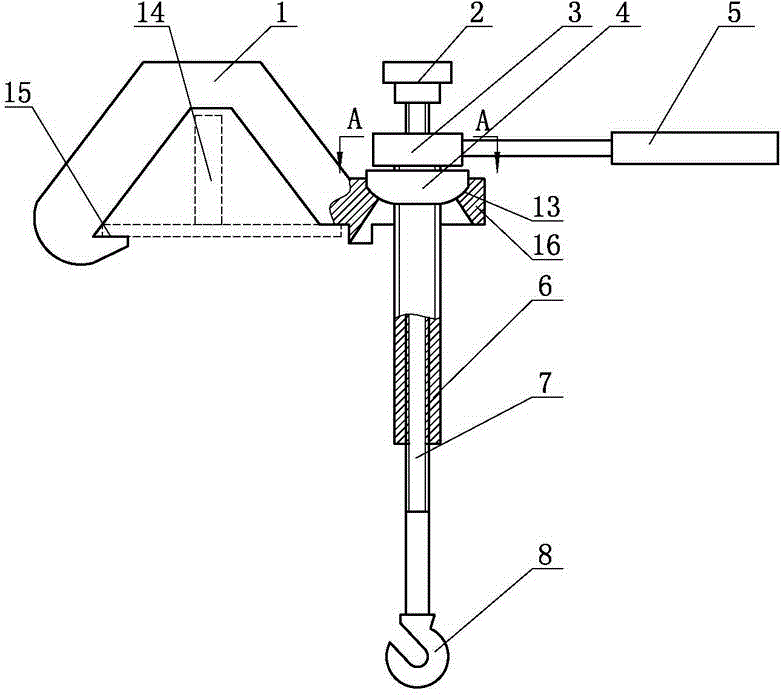

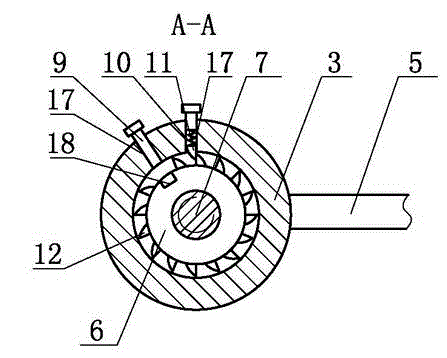

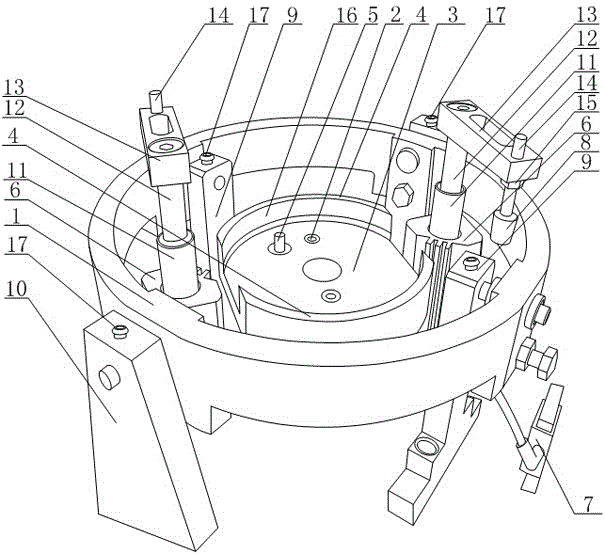

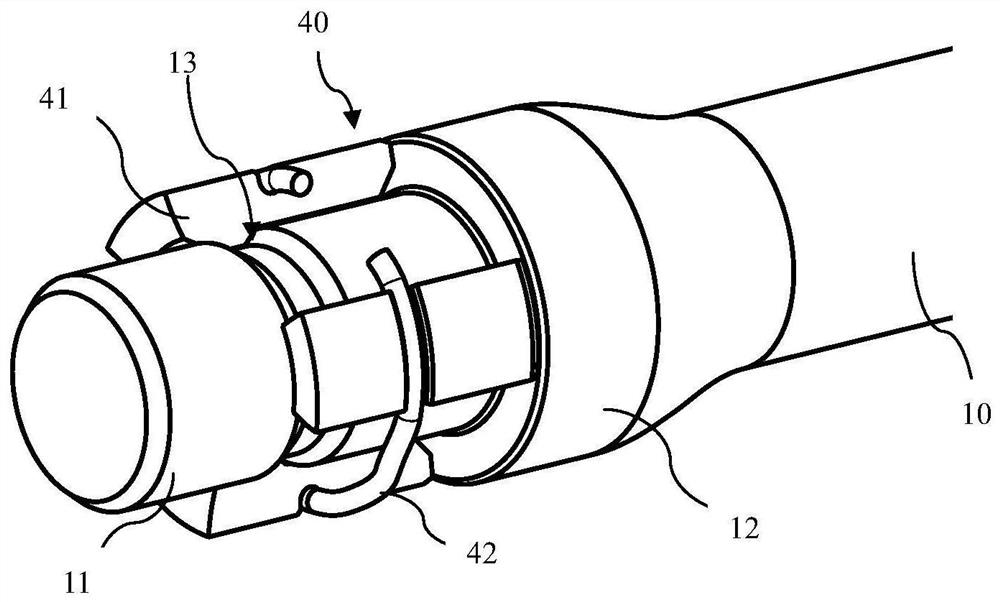

Riding type threading wire-suspending device for 500 kV overhead ground wires

ActiveCN104659727AReduce torqueAvoid deformationSuspension arrangements for electric cablesApparatus for overhead lines/cablesEngineeringScrew thread

The invention discloses a riding type threading wire-suspending device for 500 kV overhead ground wires. The riding type threading wire-suspending device comprises an inverted V-shaped support, wherein a horizontal plate facing to the inner side is arranged at one end of the support, and a horizontal base is arranged at the other end of the support; a through hole is formed in the horizontal base, and a cambered surface is arranged at the upper part of the through hole; a ball head nut is arranged in the through hole, and the ball head of the ball head nut is matched with the cambered surface of the through hole; a threaded bushing is arranged on the ball head nut in a matching manner, and a rotary sleeve is arranged on the threaded bushing; a handle is mounted at the outer part of the rotary sleeve, and a hook is arranged at the lower part of the threaded bushing. The riding type threading wire-suspending device is directly buckled on a cross arm through the support and is close to the cross arm, so that the moment is reduced, and deformation is prevented. As the ball head nut can be matched with the cambered surface of the through hole in a swinging manner, the riding type threading wire-suspending device can swing in any direction, avoids deflection caused by heavy wind, and is effectively protected.

Owner:STATE GRID CORP OF CHINA +1

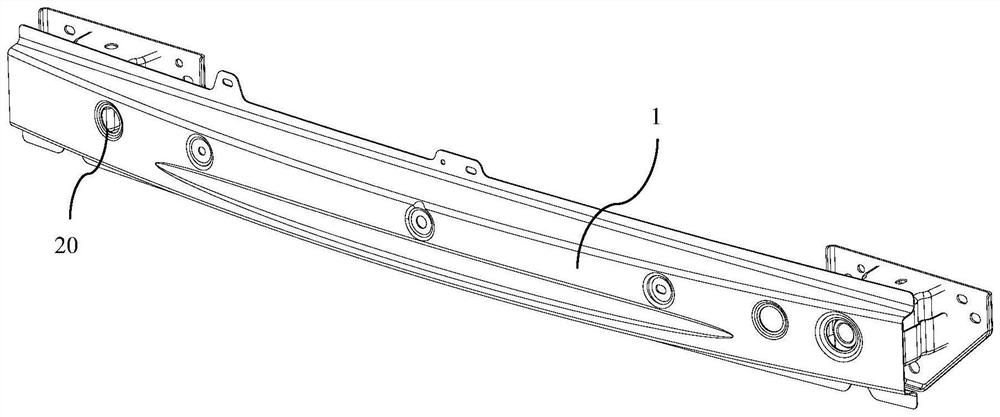

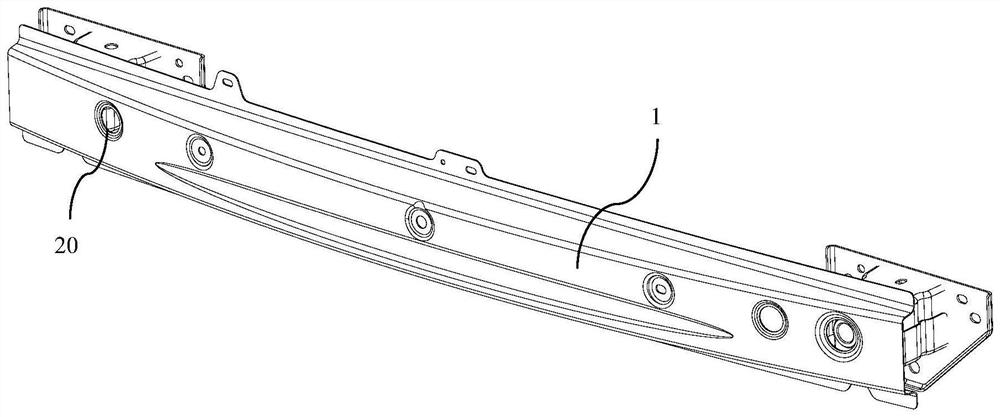

Tow hook mounting structure

ActiveCN111873730AAvoid mutual interferenceOccupy compressed spaceTowing devicesThreaded pipeEnergy absorption

The invention provides a tow hook mounting structure, and the structure comprises a through hole formed in the groove bottom of a groove-shaped front anti-collision beam and used for a tow bar to penetrate through; a nut seat is arranged behind the through hole, an expanding unit is adjacently arranged in front of the threaded section of the tow bar in the length direction of a vehicle, and the threaded section of the tow bar is screwed into the nut seat; the rear end of the expanding unit and the nut seat extrude to drive the front end of the expanding unit to open, and the front end of the expanding unit and the groove bottom of the front anti-collision beam form limiting fit for limiting forward displacement of the tow bar relative to the front anti-collision beam after the front end ofthe expanding unit is opened. A common threaded pipe mounting structure is canceled, so the compression space of the energy absorption box is prevented from being occupied by an overlong rigid threaded pipe structure, and meanwhile, one nut seat is reduced on the basis of the previous application scheme of the applicant, so only one nut seat needs to be aligned when the tow hook is mounted, so the situation of mutual interference when a plurality of nut seats are mounted in a matched manner is avoided.

Owner:CHERY AUTOMOBILE CO LTD

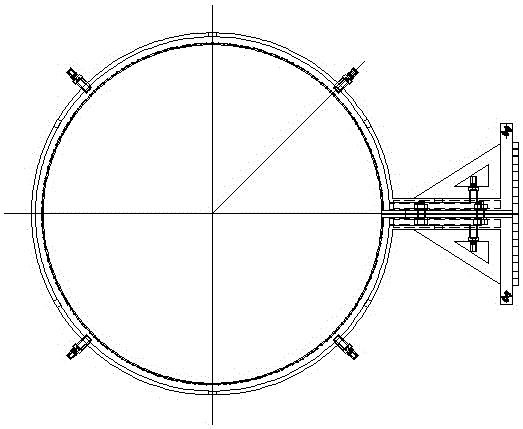

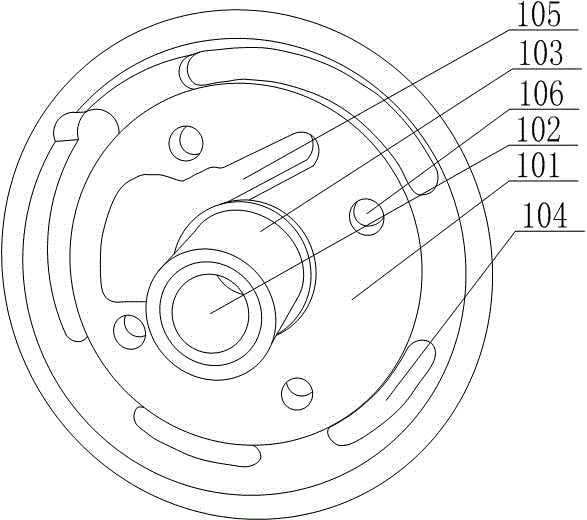

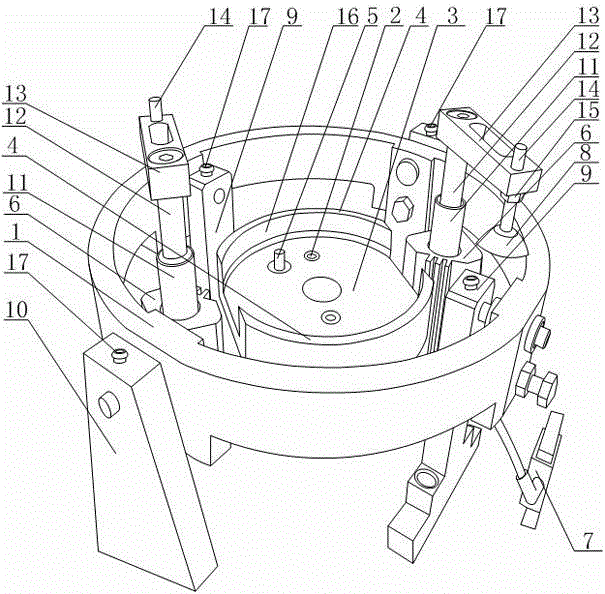

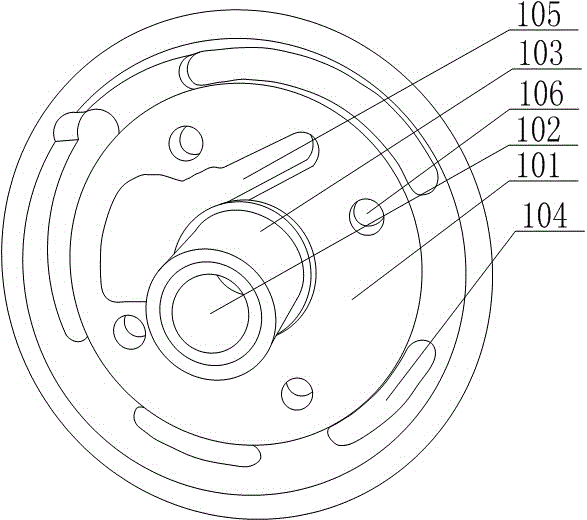

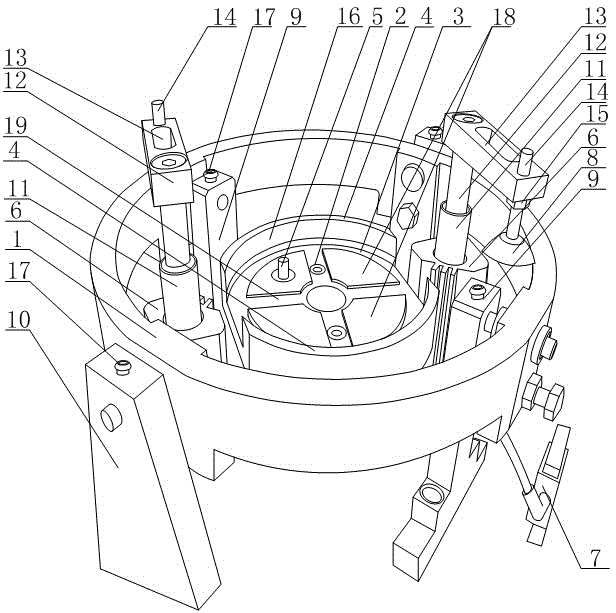

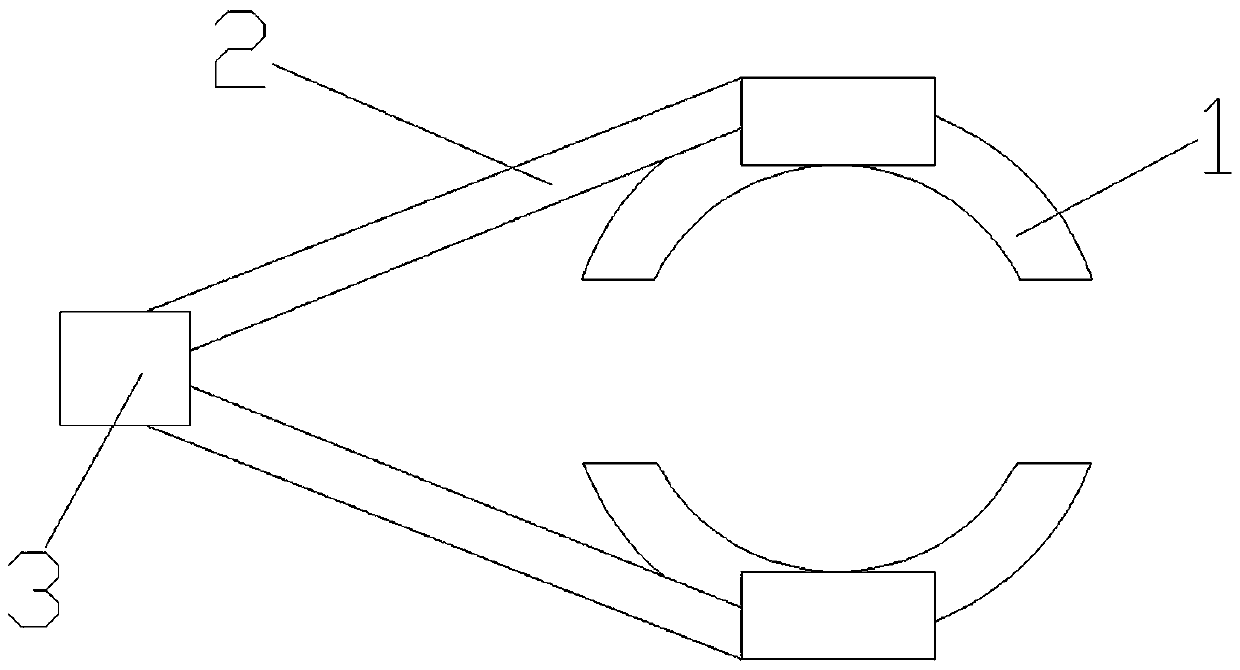

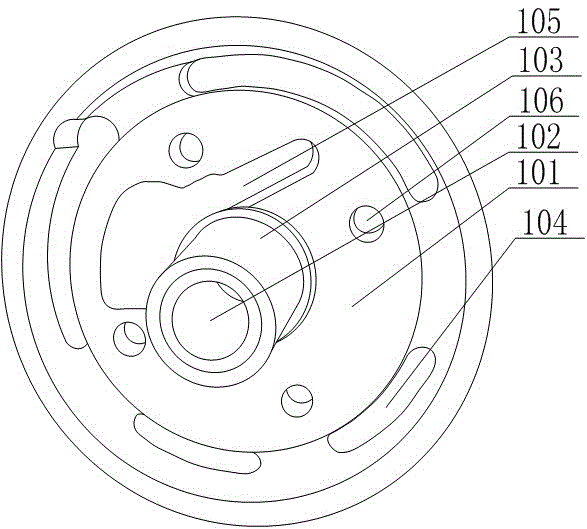

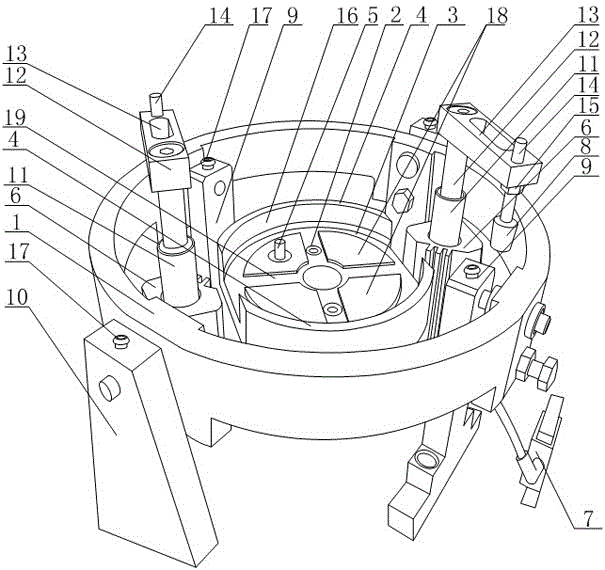

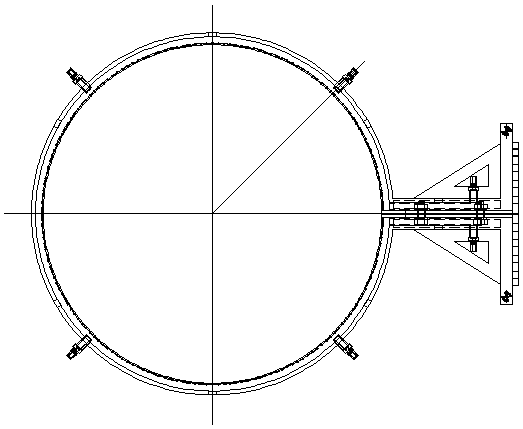

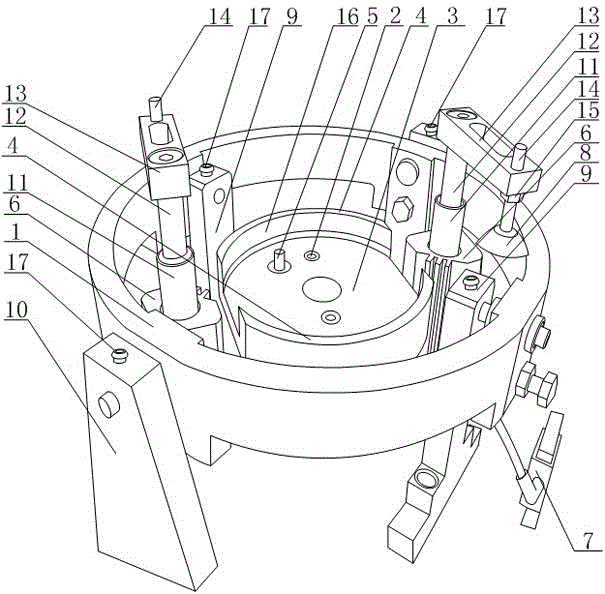

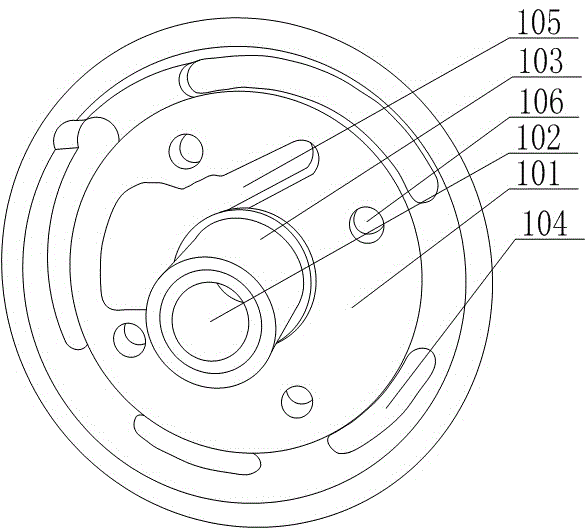

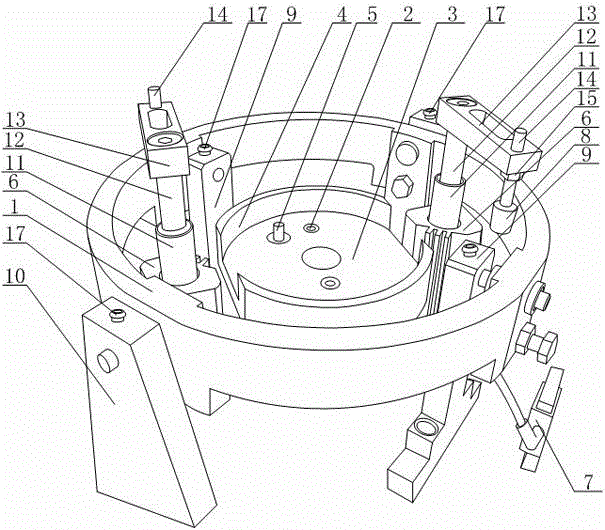

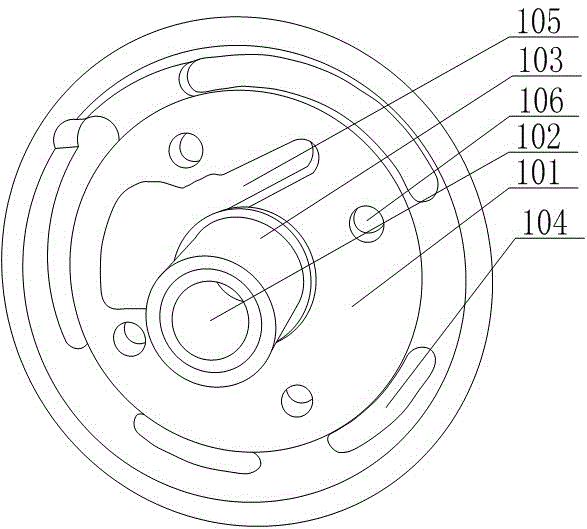

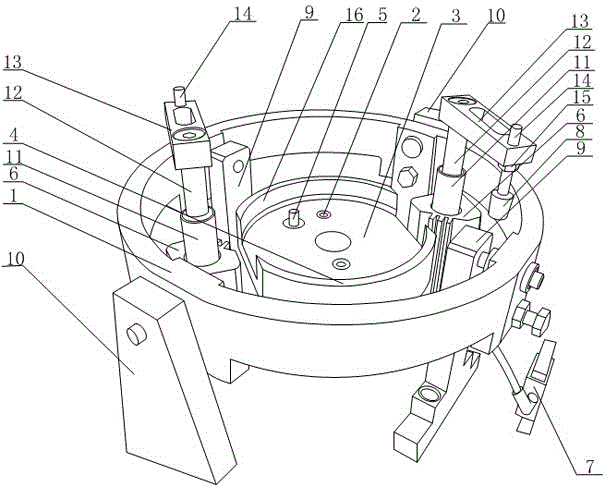

Hole-milling quick positioning tool for eccentric upper sealing head flange

InactiveCN104148968AAccelerateImprove processing efficiencyWork clamping meansPositioning apparatusEngineeringElectromagnetic valve

The invention discloses a hole-milling quick positioning tool for an eccentric upper sealing head flange. The hole-milling quick positioning tool comprises a positioning ring, a positioning disc, air cylinders, electromagnetic valves and pressing heads, a set of circular-arc-shaped side walls and an eccentric positioning pin are arranged on the positioning disc, the circular-arc-shaped side walls form a cylindrical excircle, the inner-side surface of each circular-arc-shaped side wall and an end-portion plane are connected through a bevel, two bevels form a conical face, the air cylinders extend and contract to drive the pressing heads to press or release a workpiece, a cooling liquid pipeline is arranged inside each of inner columns and outer columns, and a quick plug communicated with the corresponding cooling liquid pipeline is mounted on each of the inner columns and the outer columns. The conical face is formed by the two bevels and plays a role in guiding putting-in of a sealing plate, and convenience is brought to quick putting-in of the sealing plate, so that clamping speed is increased; by means of arranging cooling pipelines inside supporting columns, the cooling pipelines are contained in the supporting columns, so that no space is occupied, structure is simplified, and the objectives of compactness and high efficiency are achieved.

Owner:四川富临集团成都机床有限责任公司

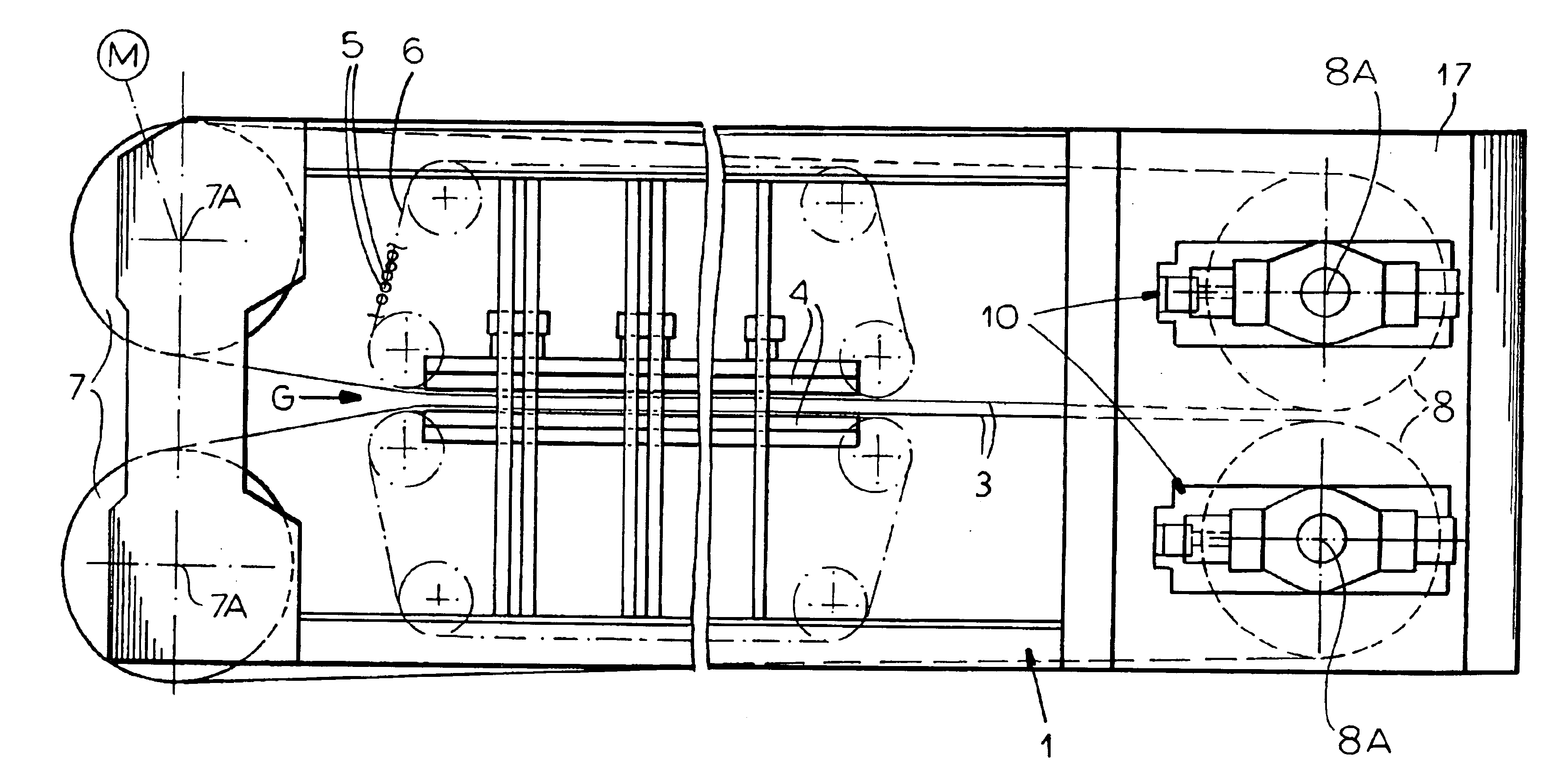

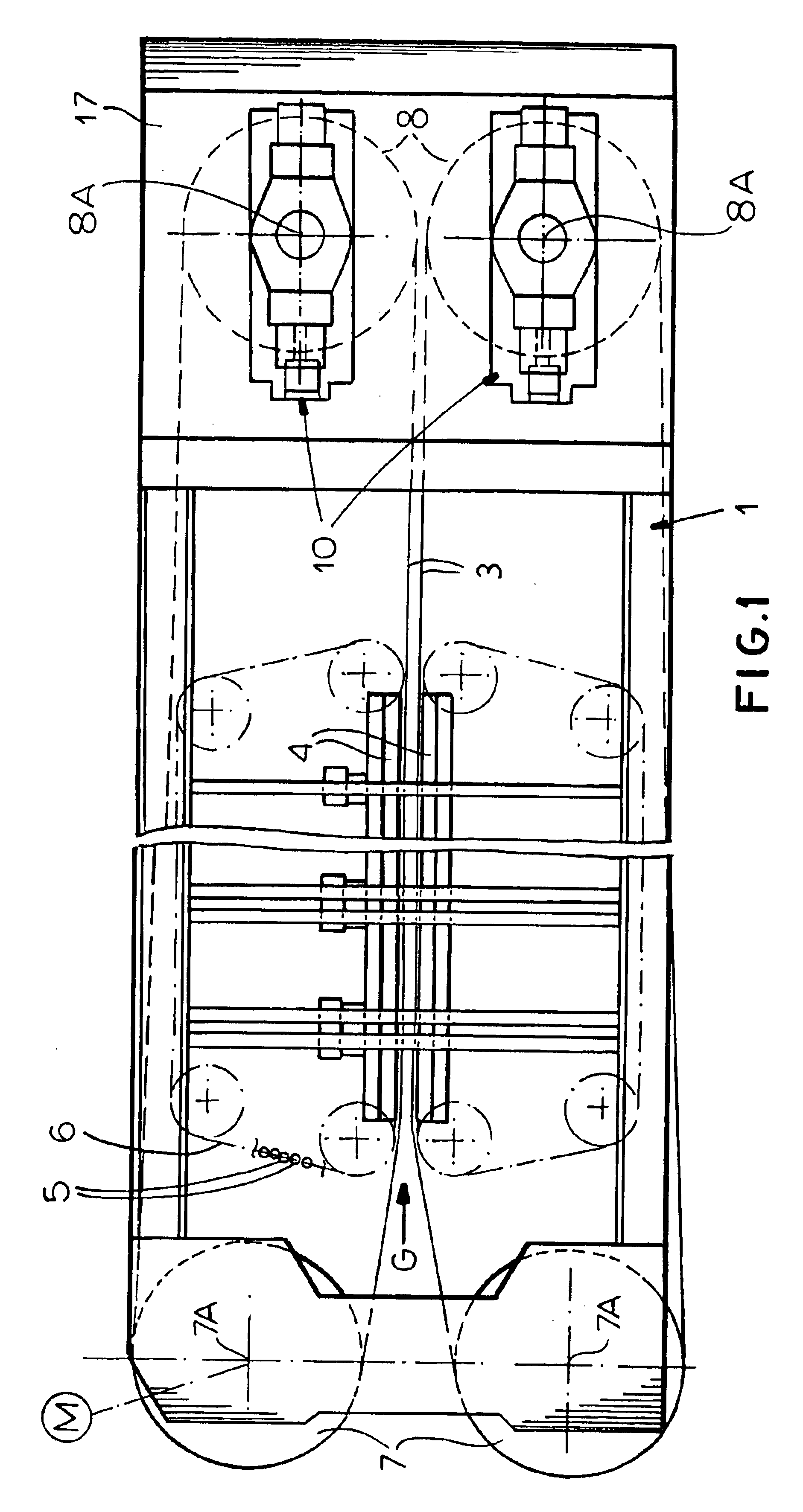

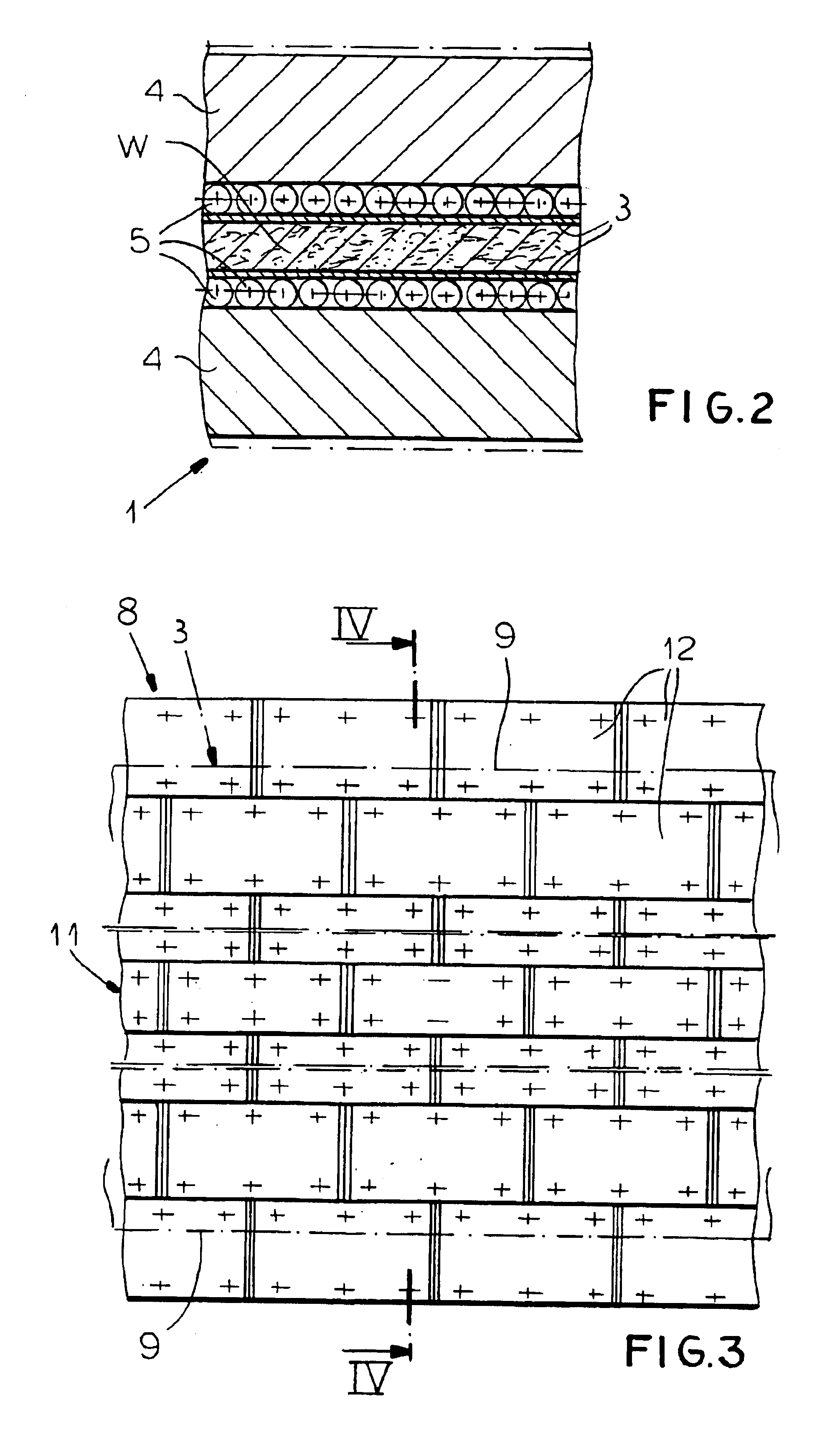

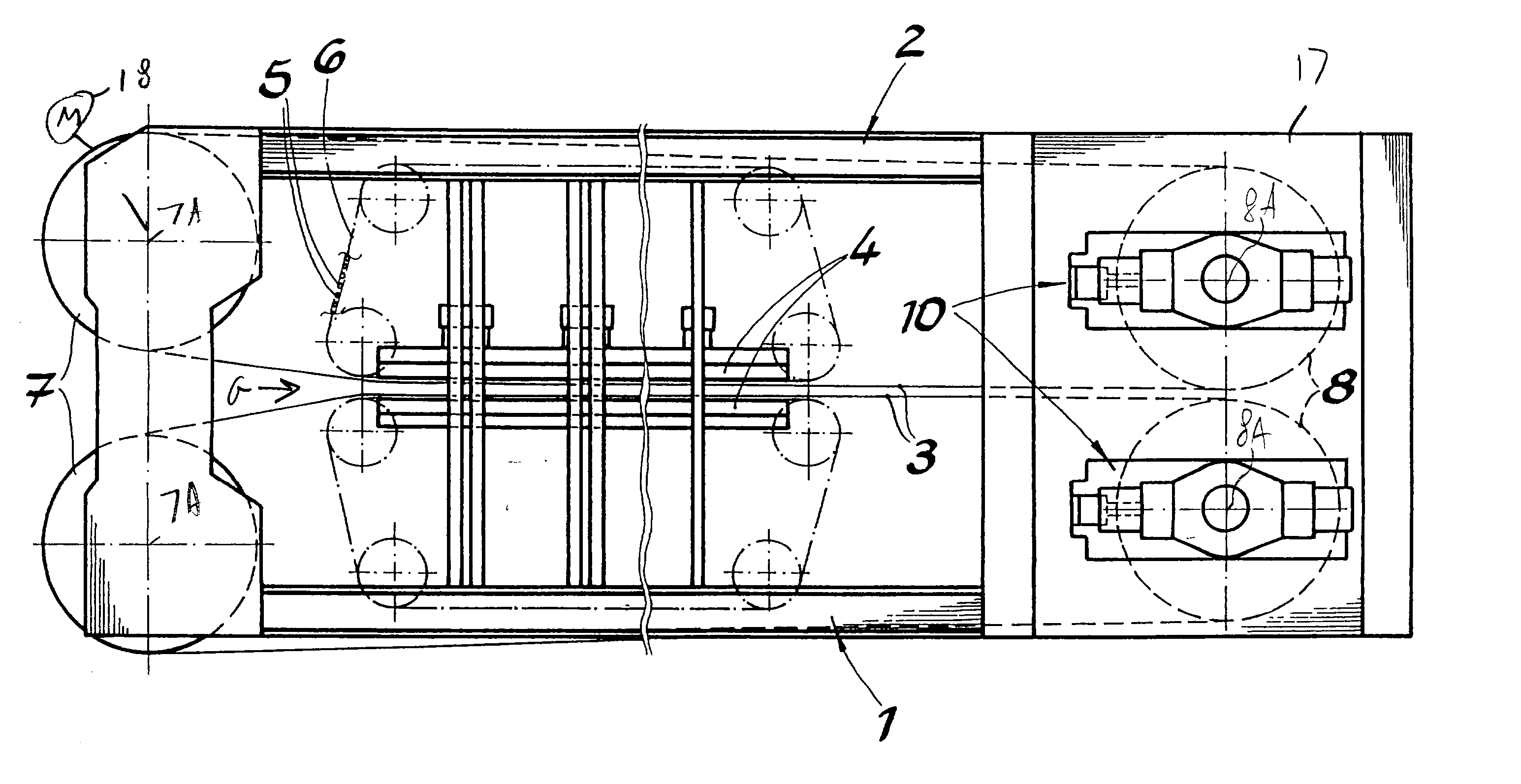

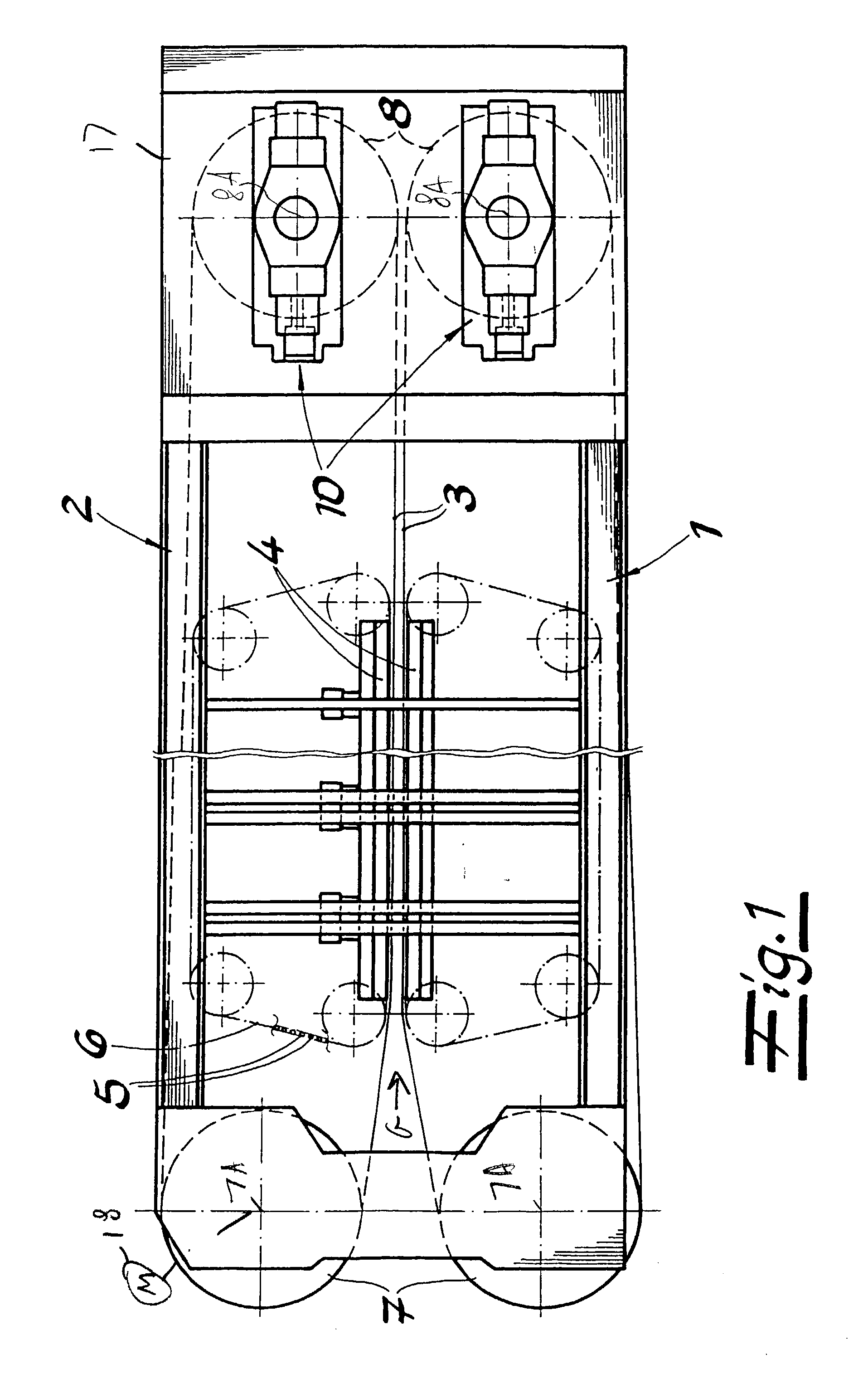

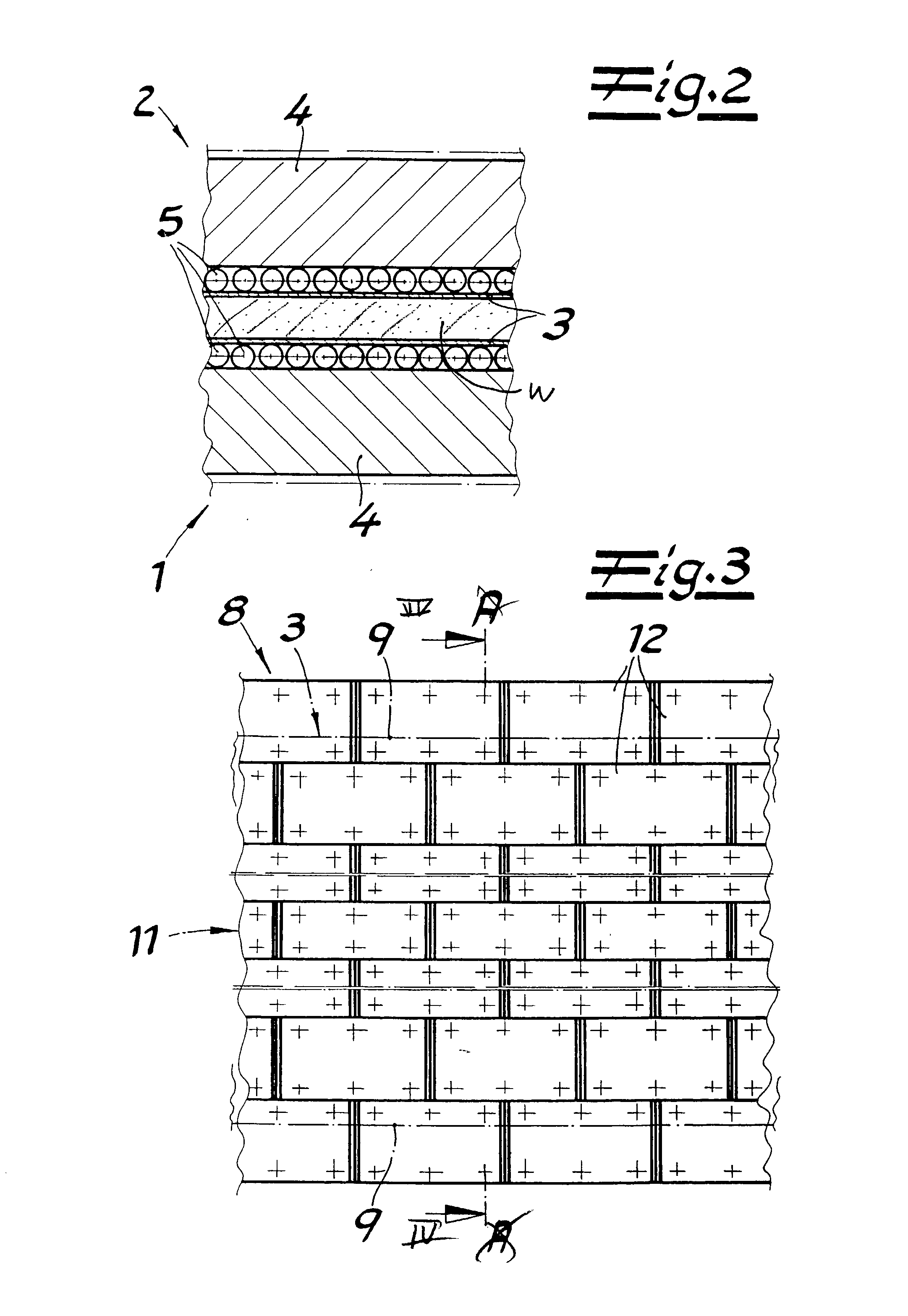

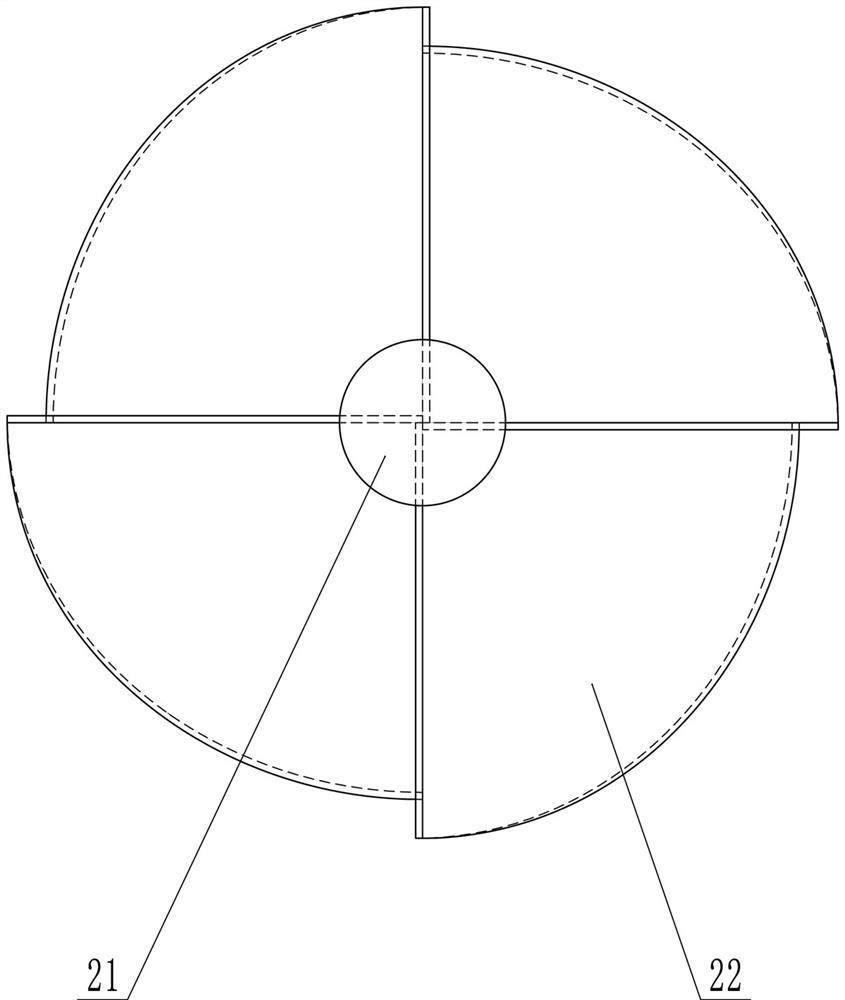

Belt-type particleboard press

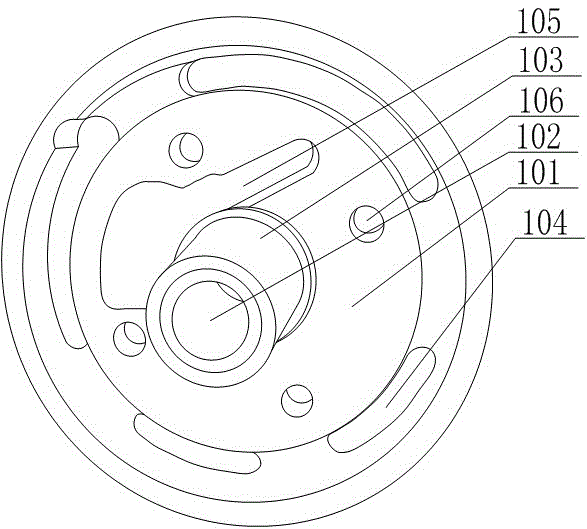

InactiveUS6829987B2Avoid excessive local stressSufficient protectionPlywood pressesPress rollersEngineeringSteel belt

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

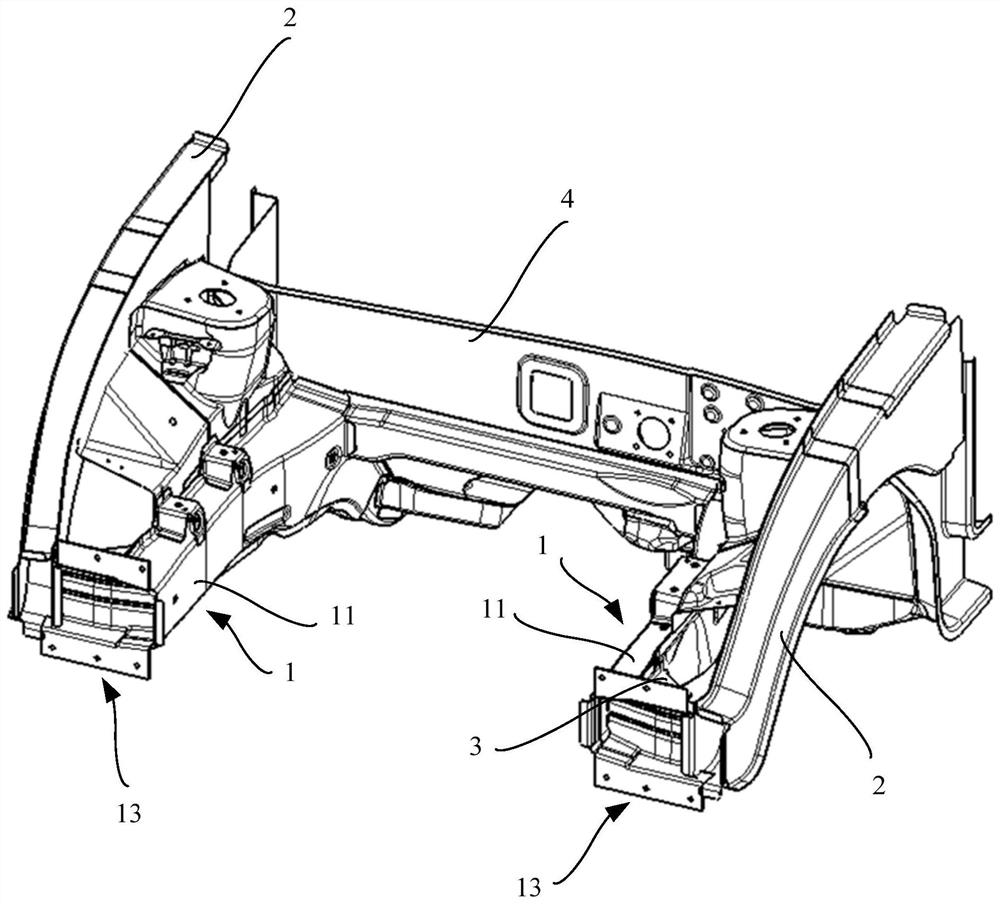

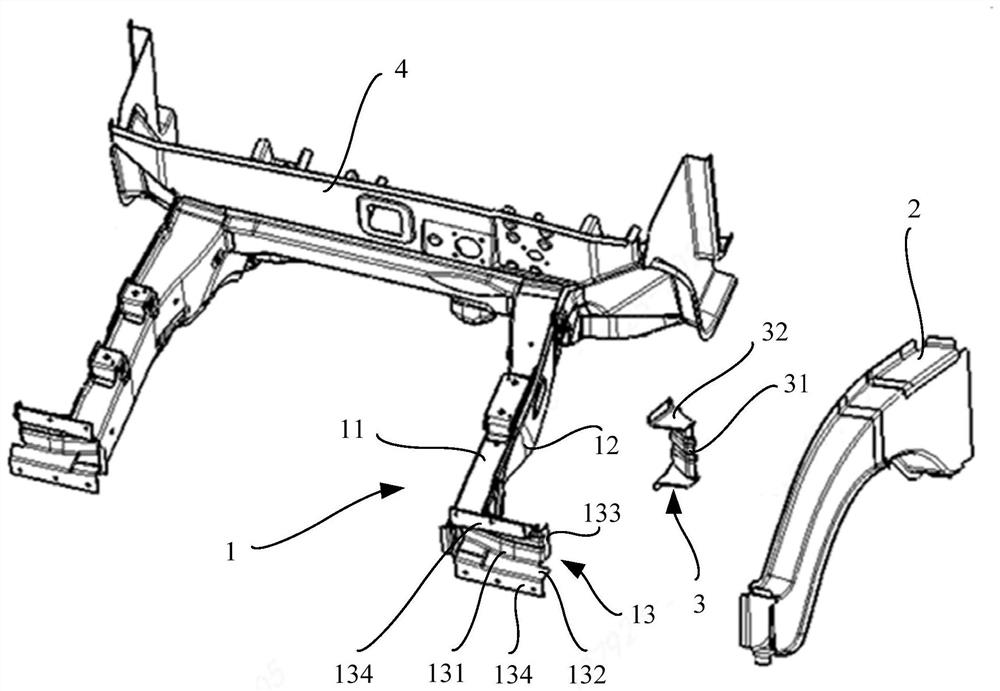

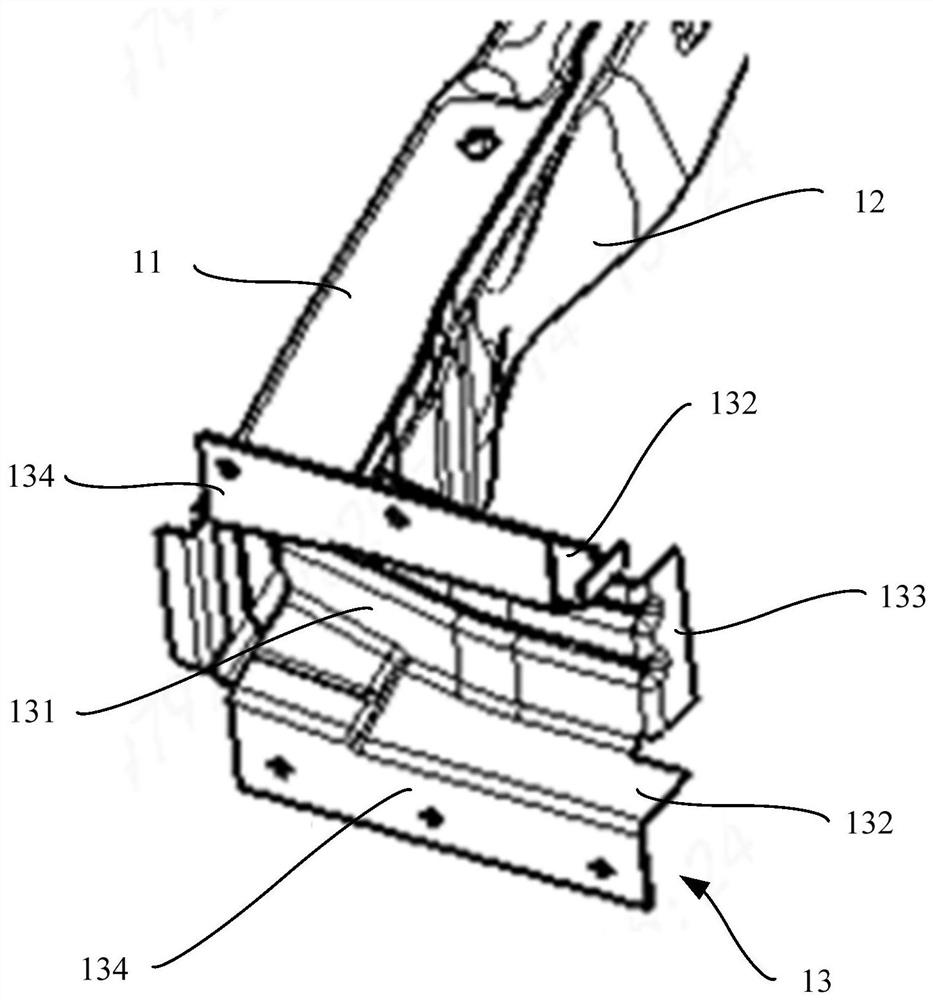

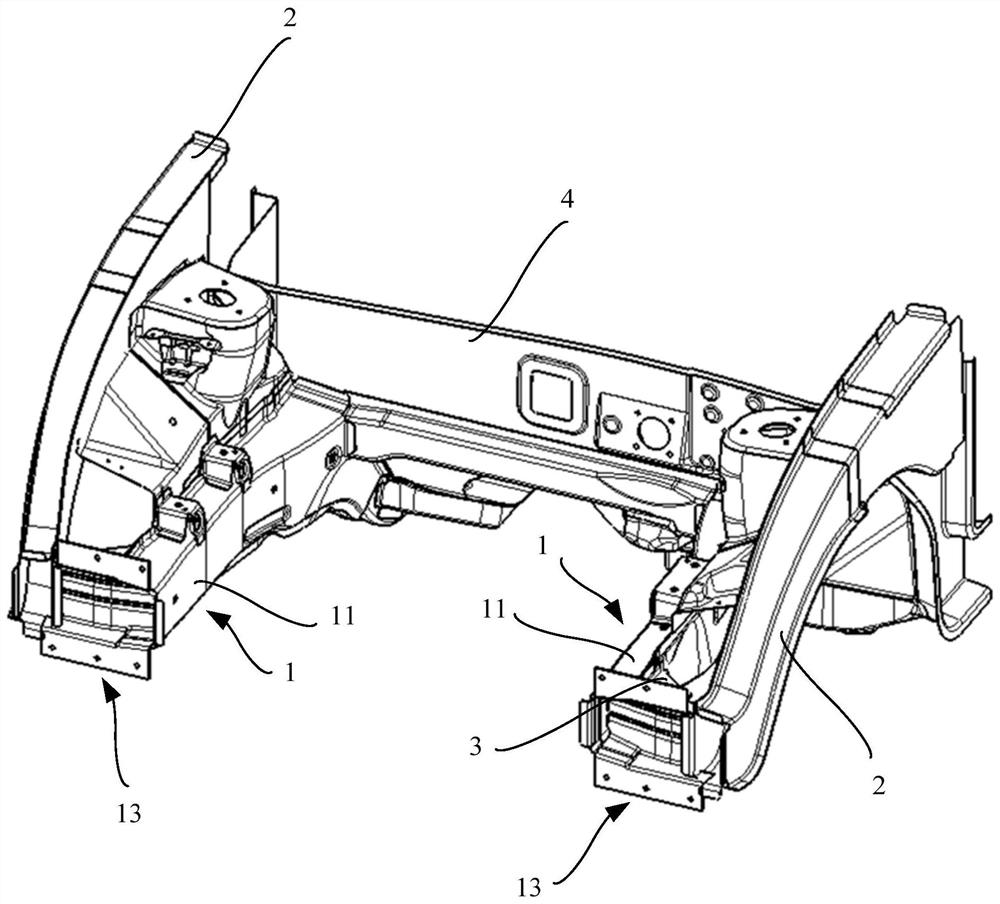

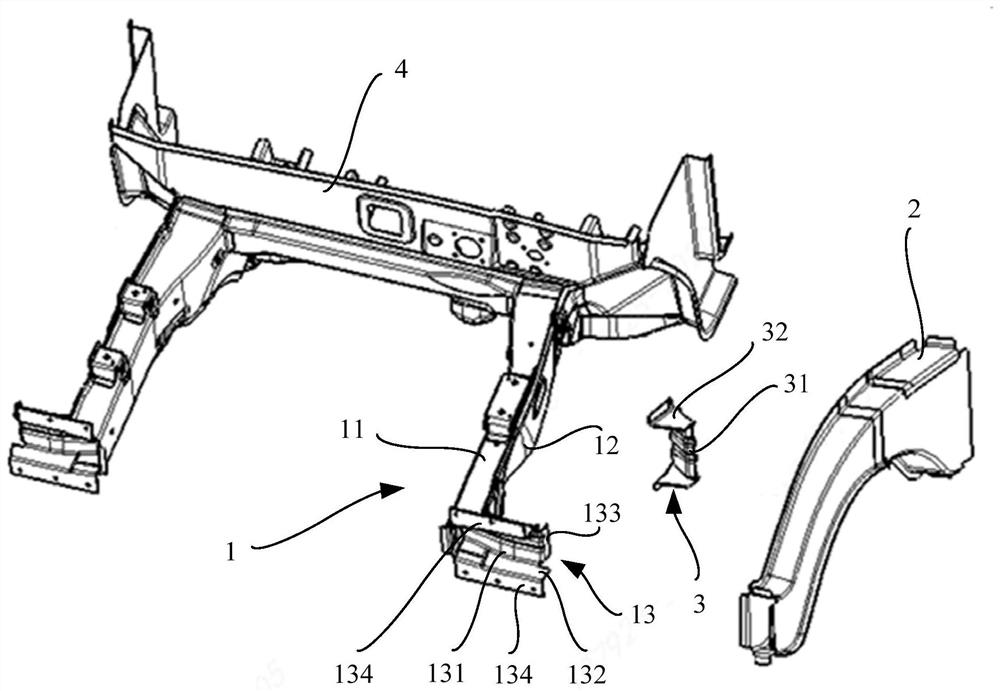

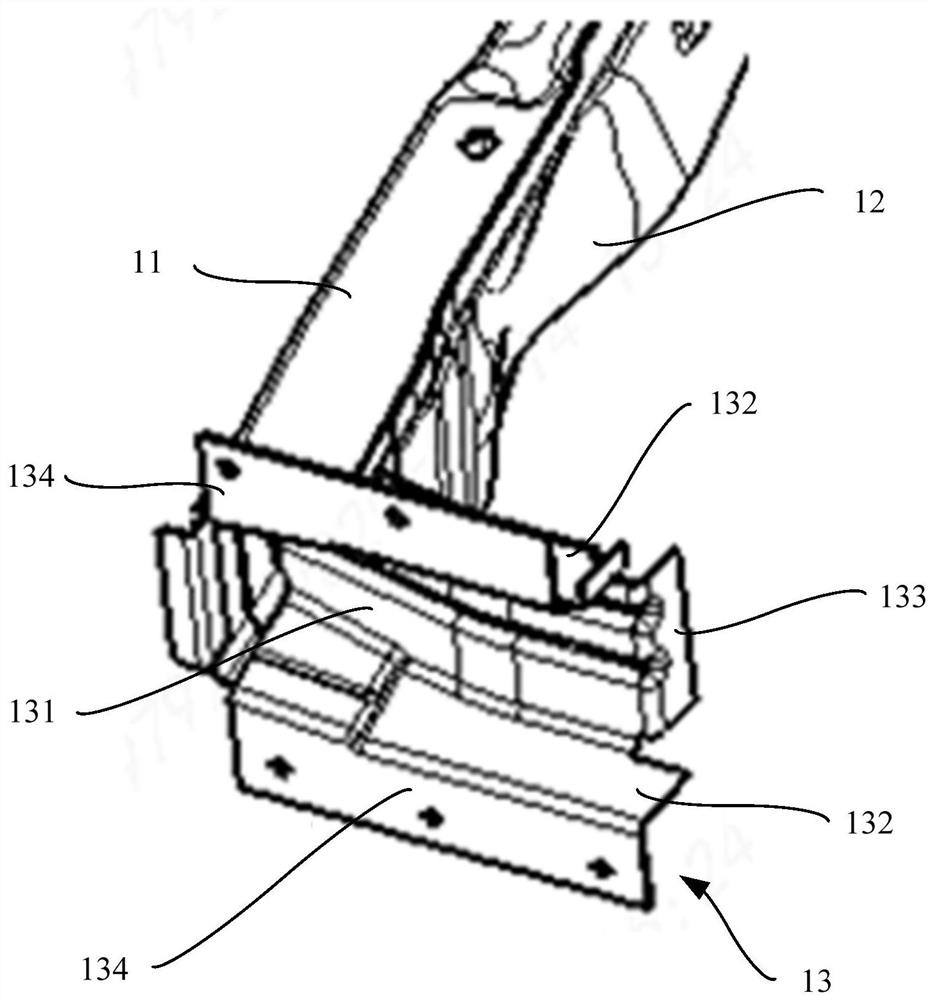

Automobile body front structure and automobile

ActiveCN112429088AImprove impact resistanceSmall amount of deformationUnderstructuresSuperstructure subunitsEnergy absorptionEngineering

The present invention provides an automobile body front structure which comprises a front longitudinal beam assembly and a front wheel cover side reinforcing beam. The front longitudinal beam assemblycomprises a front longitudinal beam inner plate, a front longitudinal beam cover plate and a front longitudinal beam supporting plate, wherein the front longitudinal beam inner plate comprises a longitudinal beam bottom plate and two longitudinal beam side plates located on the opposite two sides of the longitudinal beam bottom plate; the two longitudinal beam side plates are connected with the front longitudinal beam cover plate, and the front longitudinal beam cover plate is opposite to the longitudinal beam bottom plate; parts of the front longitudinal beam supporting plate is located in agroove defined by the longitudinal beam bottom plate and the longitudinal beam side plates; the part, located in the groove, of the front longitudinal beam supporting plate is connected with the longitudinal beam bottom plate and the longitudinal beam side plates; the plate face of the front longitudinal beam supporting plate is connected with the side edges of the front longitudinal beam cover plate; and the front wheel cover side reinforcing beam is connected with the part, located outside the groove, of the front longitudinal beam supporting plate. The energy absorption effect of the automobile body front structure can be improved, and the deformation amount of the passenger compartment is reduced.

Owner:CHERY AUTOMOBILE CO LTD

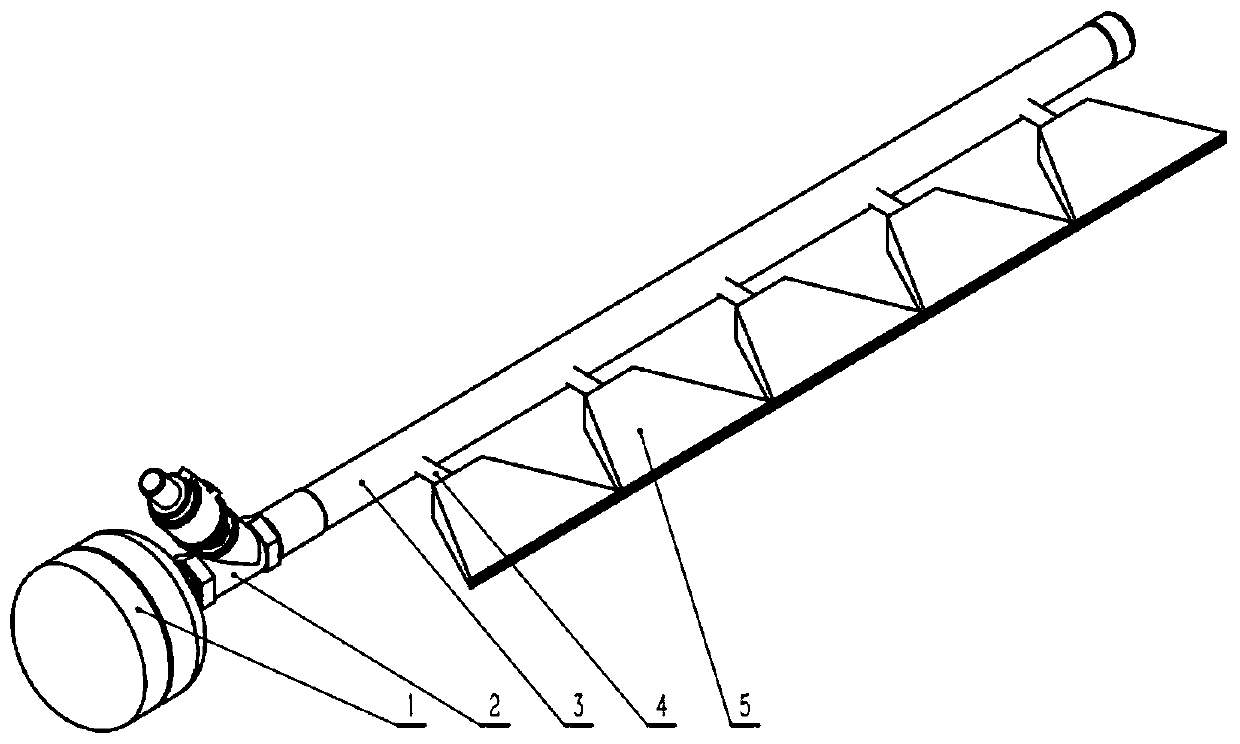

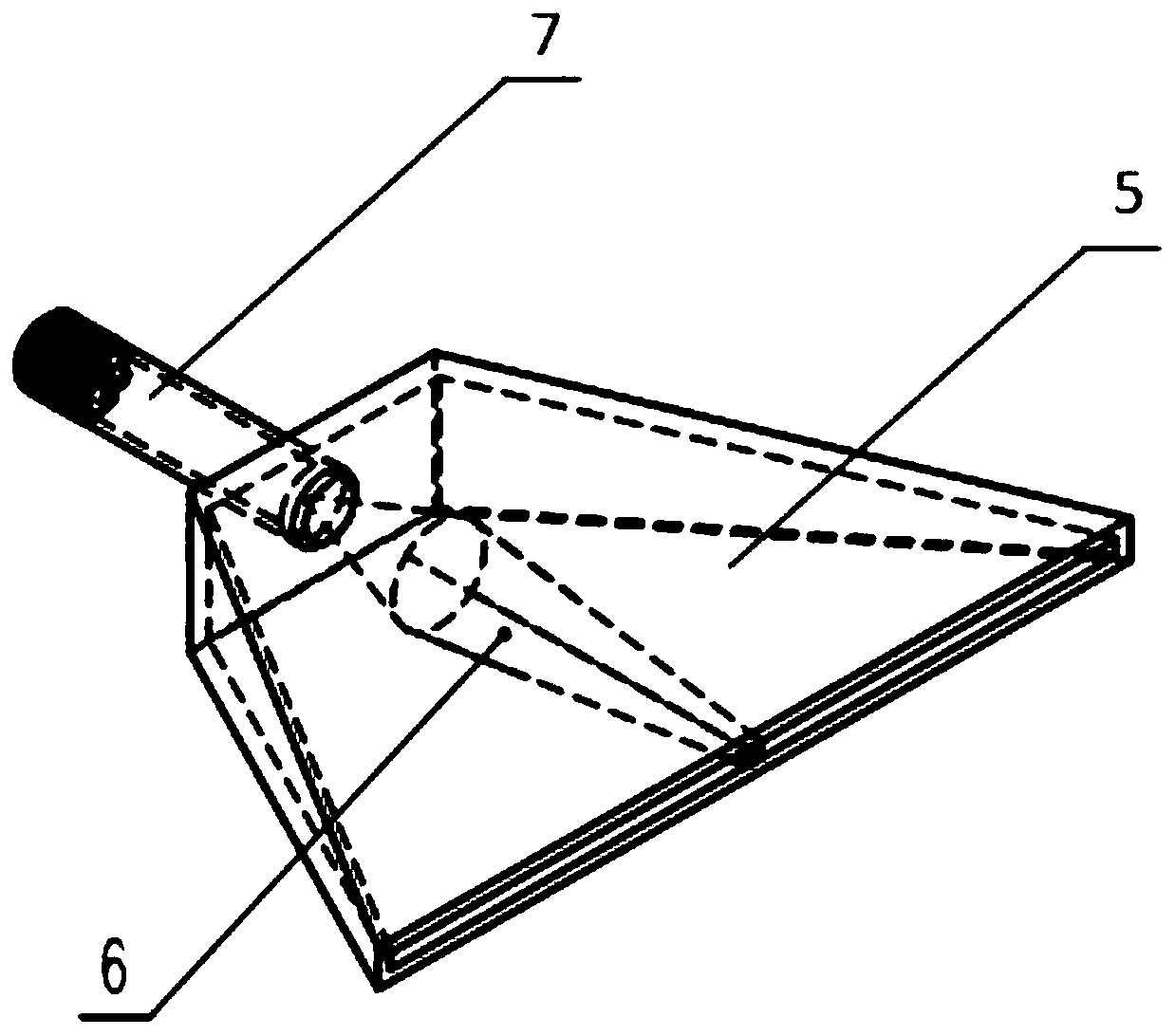

Soot blower suitable for SCR denitration of high-temperature and high-dust flue gas

PendingCN111408267AUniform blowing forceAvoid excessive local stressGas treatmentDispersed particle separationAutomotive engineeringSoot blower

The invention provides a soot blower suitable for SCR denitration of high-temperature and high-dust flue gas. The soot blower comprises an air supply unit, a control air valve unit, a gas transmissionheader pipe, and a nozzle unit, wherein the air supply unit is hermetically connected with one end of the air transmission header pipe through the control air valve unit; a gas transmission branch pipe is arranged on one side of the gas transmission header pipe; the nozzle unit is fixedly connected to the gas transmission branch pipe; wherein the nozzle unit is of a flat structure; according to the invention, the flat nozzle is adopted; the injection area and the effective effect are larger than those of the traditional circular injection hole; the soot blower is simple in structure and uniform in blowing force in a coverage area, can effectively prevent excessive local stress and damage to the surface layer of the catalyst, is mounted on the side of a certain distance above the surface layer of the catalyst, can effectively solve the problem of a blowing dead zone of a traditional soot blower, and solves the problems of local soot accumulation and blockage.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

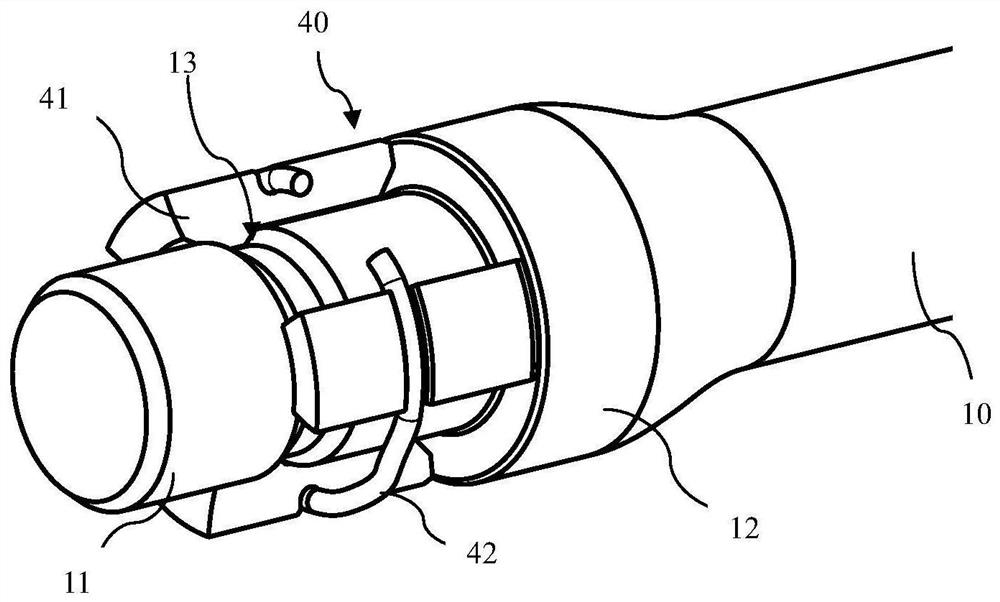

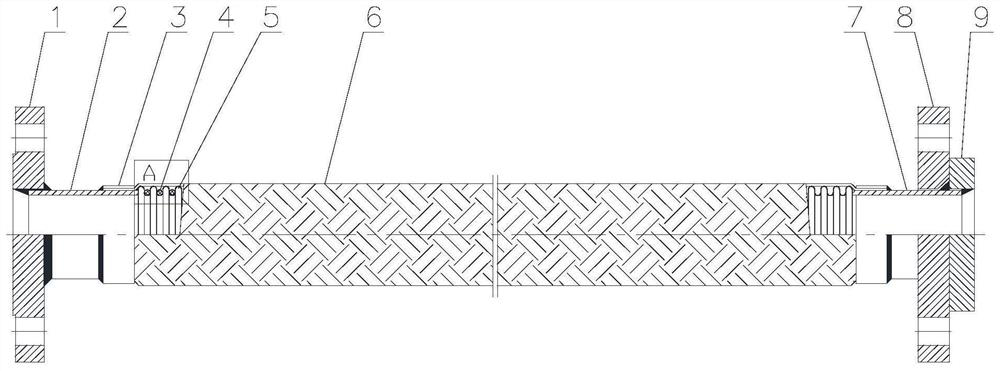

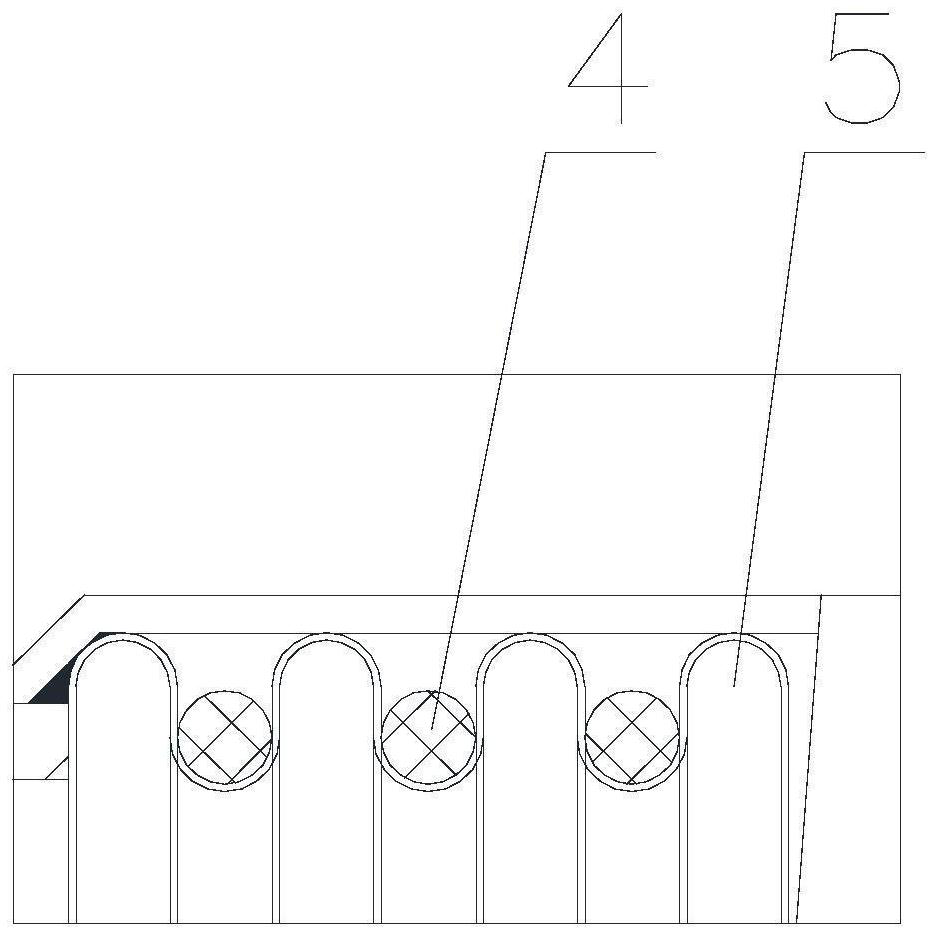

Bending-resistant metal hose with connector protection device

PendingCN113048310AEffective protectionExtended service lifeFlexible pipesHose connectionsStructural engineeringMetal hose

The invention relates to a bending-resistant metal hose with a connector protection device. The bending-resistant metal hose comprises a corrugated pipe, a net sleeve and connectors, wherein the net sleeve wraps the outer surface of the corrugated pipe, the connectors are arranged at the two ends of the corrugated pipe, each connector comprises a fixed flange and a loose flange, one end of the corrugated pipe is welded to the fixed flange through a short connecting pipe, and the other end of the corrugated pipe is connected with a welding ring through a long connecting pipe; and the bending-resistant flexible connector protection device is arranged at an end of the corrugated pipe, and the protection device comprises a flexible ring embedded in the wave trough of the corrugated pipe, a spring wound on the outer surface of the net sleeve, and a flexible sheath wrapping the outer surface of the net sleeve. According to the bending-resistant metal hose, the protection device is arranged at the connector of the metal hose, so that the circumstance that the hose is bent along the root is avoided, the stress condition of the root of the hose is dispersed, the local stress is prevented from being too large, and the metal hose is effectively protected; and meanwhile, the corrugated pipe has the bending resistance, the service life of the metal hose is prolonged, and potential safety hazards possibly occurring in the using process are eliminated.

Owner:JIANGSU HENGFENG BELLOWS

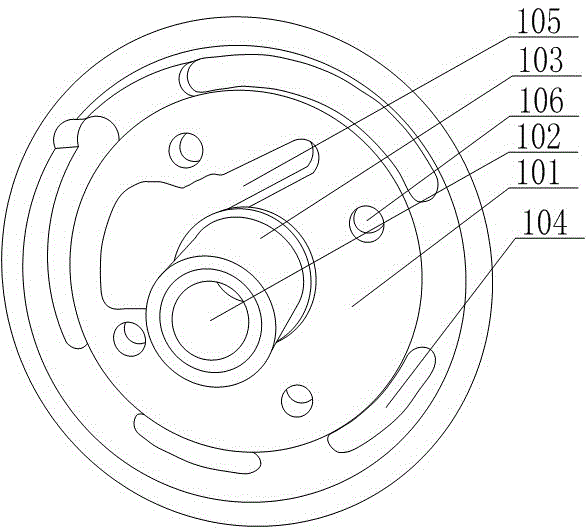

Quick hole-milling positioning tool for strong-sucking type eccentric upper seal flange

InactiveCN104148969AReduce generationSmall footprintWork clamping meansPositioning apparatusWear resistantEngineering

The invention discloses a quick hole-milling positioning tool for a strong-sucking type eccentric upper seal flange. The quick hole-milling positioning tool comprises positioning rings and a positioning disc. The positioning disc is provided with a group of arc-shaped side walls and eccentric positioning pin, the arc-shaped side walls form an excircle, the inner surface of each arc-shaped side wall and each end plane are connected through an inclined plane, and the two inclined planes constitute a conical surface. The quick hole-milling positioning tool further comprises air cylinders, an electromagnetic valve and pressure heads made of wear-resistant rubber, and the bottom of each pressure head is upwardly recessed to form a cavity. The inclined planes constitute the conical surface functioning in guiding placing of a seal plate, the seal plate can be quickly and conveniently placed in, and clamping speed is increased. By the aid of air pressure, the pressure heads and the seal plate can be fixed, lines on the surfaces of workpieces can be reduced due to large contact area, and cooling pipes are arranged in support columns in a concealed manner, so that space is not occupied, the structure is simplified, and the pursuit of simplicity and high efficiency is realized.

Owner:四川富临集团成都机床有限责任公司

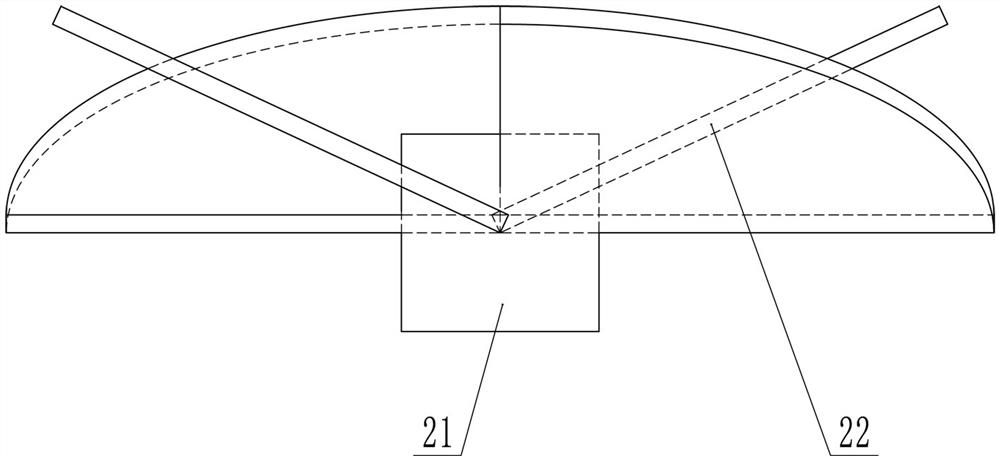

Belt-type particleboard press

A continuous belt press has upper and lower platens defining a horizontal gap. Upper and lower upstream drums and downstream are rotatable on the frame about respective horizontal drum axes at the upstream and downstream ends of the gap. Upper and lower endless steel belts spanned over the respective upper and lower drums each have a working stretch supported by respective upper and lower sets of rollers on the respective platens. Each belt has a pair of edges projecting transversely past the respective rollers and at least one of the drums of each of the belts has a substantially cylindrical central region of a predetermined central diameter bearing through the respective rollers on the working stretch of the respective belt and a pair of edge formations of smaller diameter than the central-region diameter lying outside the central region and in engagement with the edges of the respective belt.

Owner:SIEMPELKAMP MASCH & ANLAGENBAU GMBH & CO KG

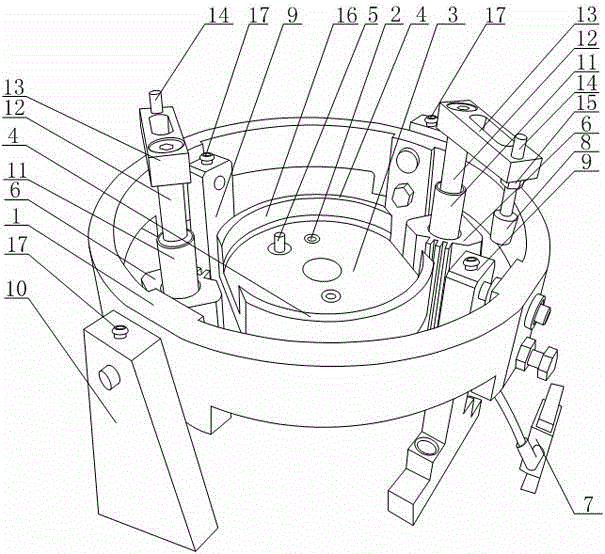

Multistation processing tool for strong-suction-type eccentric upper sealing head flange

InactiveCN104148970AReduce generationSmall footprintWork clamping meansPositioning apparatusWear resistantCooling effect

The invention discloses a multistation processing tool for a strong-suction-type eccentric upper sealing head flange. The multistation processing tool comprises a positioning ring, a positioning disc, circular-arc-shaped side walls, a positioning pin, a cushion block, air cylinders, electromagnetic valves and pressing heads, the middle portion of the cushion block is cut to form a diversion groove, the pressing heads are made by wear-resistant rubber, and the bottom of each pressing head upwards concaves to form a cavity. A conical face is formed through two bevels and plays a role in guiding putting-in of a sealing plate, and convenience is brought to quick putting-in of the sealing plate, so that clamping speed is increased; the pressing heads and the sealing plate can be fixed by only utilizing pressure of air, patterns generated on the surface of a workpiece can be reduced due to large contact area, and cooling liquid slips away from the diversion groove after flowing through a processing area, so that the phenomenon that the cooling liquid at the bottom locally accumulates and does not circulate due to the fact that the cooling liquid after cooling overflows from the upper side in the prior art is avoided, cooling can be realized better, and cooling effect is improved.

Owner:四川富临集团成都机床有限责任公司

Door window hinge

InactiveCN106320868AAvoid excessive local stressImprove reliabilityPin hingesElectrical and Electronics engineering

Owner:李思模

Biological tendon repair material and preparation method thereof

ActiveCN107854727BPromote growthEasy to climbTissue regenerationProsthesisCell-Extracellular MatrixCellular infiltration

The invention provides a biological tendon repairing material and a preparation method thereof. The biological tendon repairing material comprises an extracellular matrix body subjected to immunogen removal, wherein the extracellular matrix body consists of one or more layers and comprises a first surface and a second surface; the first surface comprises a first area and a second area; the mechanical strength of the first area is lower than that the second area. During preparation of an extracellular matrix subjected to immunogen removal, layering is avoided. As the biological tendon repairingmaterial is provided with the surface which consists of the first area and the second area, cellular infiltration of defective tissues is facilitated, tissue repairing is accomplished, stress born bythe repairing material can be uniformly distributed, and local stress cannot be excessively large. Besides, the surface has a high suture retention force and can serve as the second surface of a suture area of the repairing material, and the strength of the repairing material can be guaranteed while repairing of the defective tissues is facilitated.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

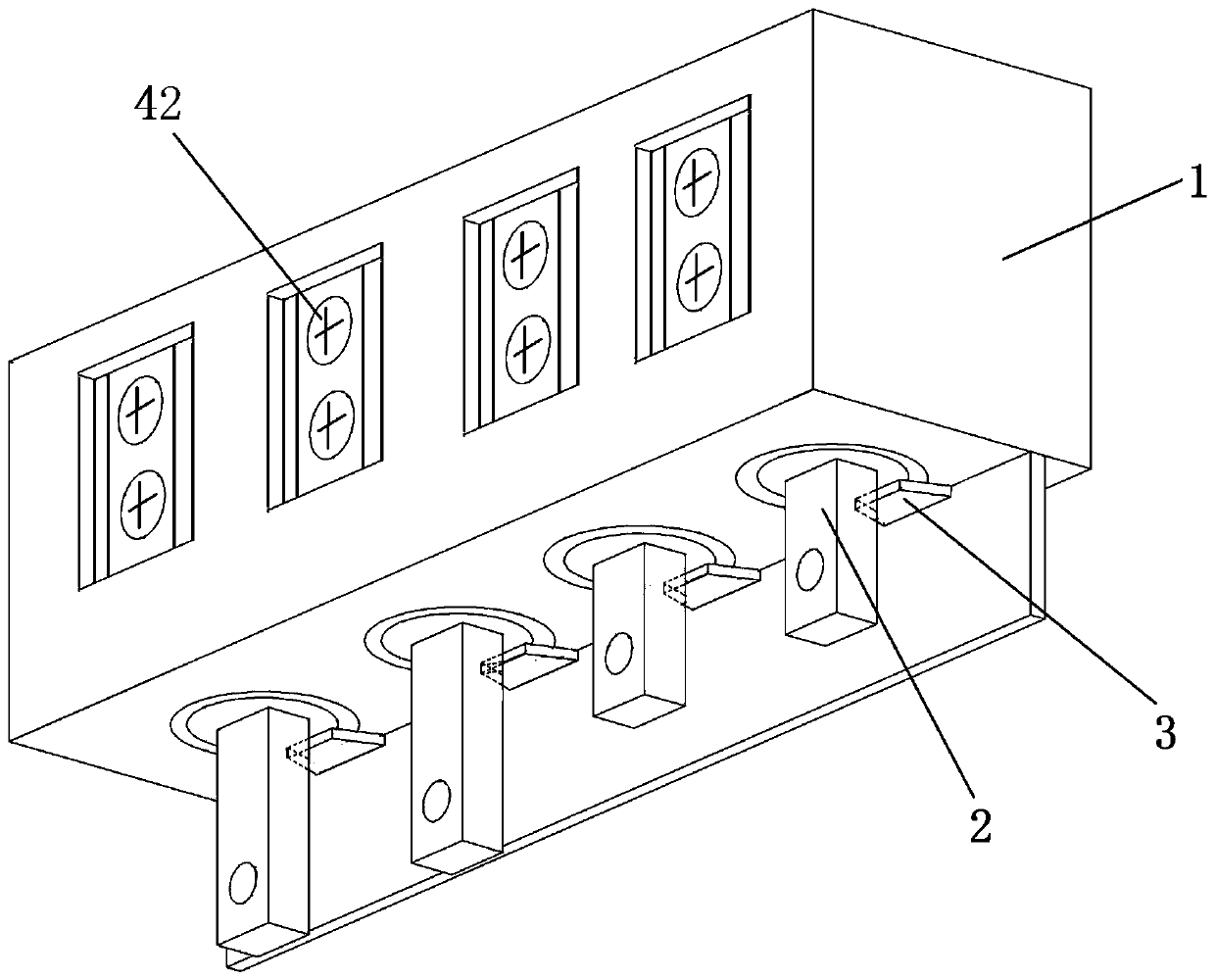

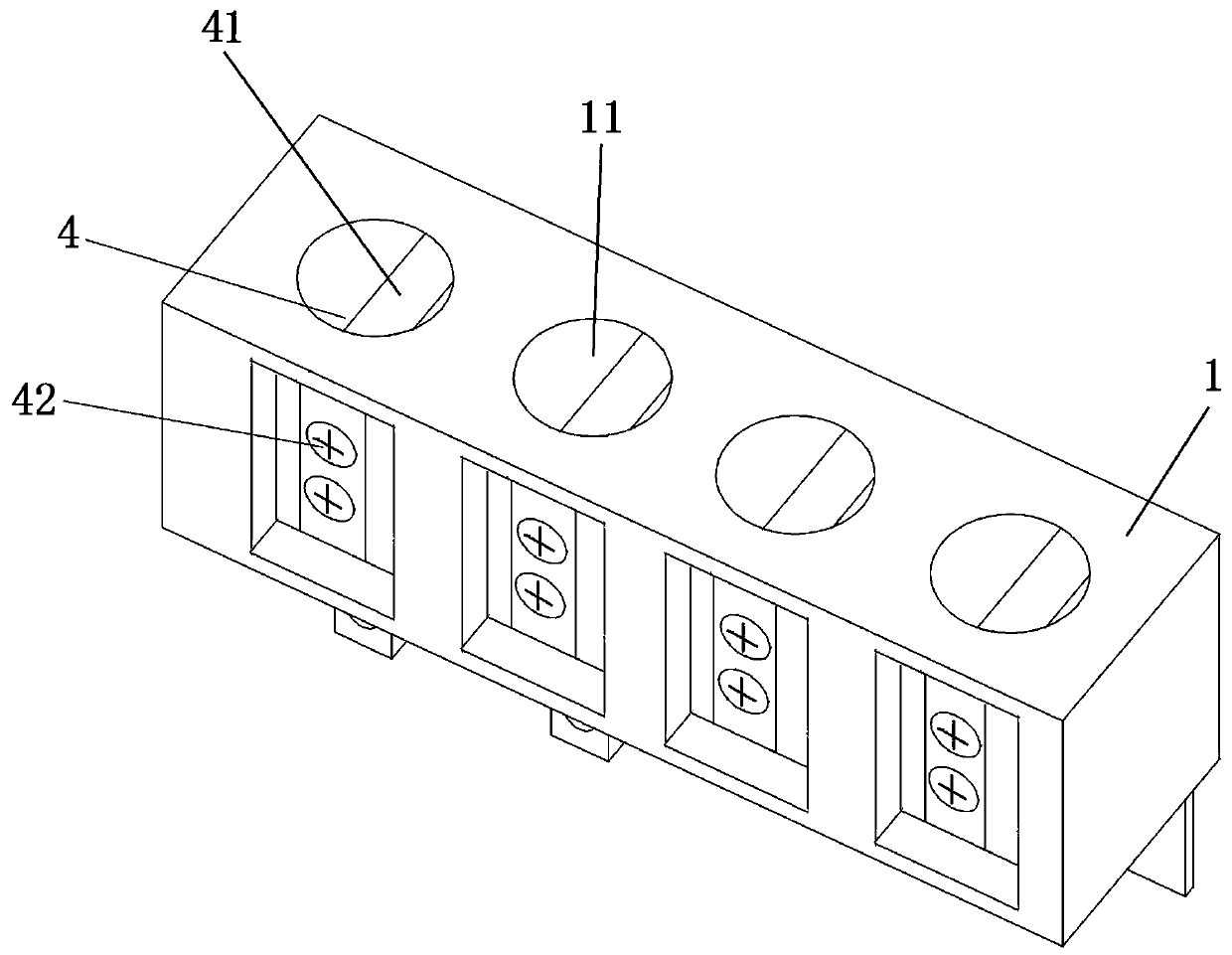

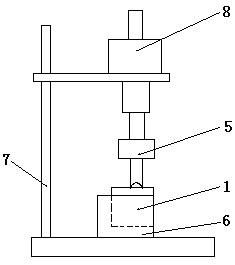

Electricity meter terminal seat intensity detecting device and method

InactiveCN110031318AReduce workloadImprove detection efficiencyMachine part testingMaterial strength using tensile/compressive forcesEngineeringWorkload

The invention provides an electricity meter terminal seat intensity detecting device and method. The electricity meter terminal seat intensity detecting device comprises a device frame, the device frame is provided with a telescopic drive mechanism and a base for supporting an electricity meter terminal seat, the base and the telescopic drive mechanism are arranged oppositely, a plurality of ejecting pushing heads are arranged at an output end of the telescopic drive mechanism, all the ejecting pushing heads are used for ejecting and pushing corresponding terminal assemblies on the electricitymeter terminal seat, thus the terminal assemblies eject and push corresponding terminal separation blades, and all the ejecting pushing heads are fixed to each other to evenly share acting force output by the telescopic drive mechanism. The ejecting pushing heads can detect multiple terminal separation blades simultaneously in the process of a single time action driven by the drive mechanism, theoutput acting force of the telescopic drive mechanism is evenly distributed to all the terminal assemblies and the terminal separation blades through all the ejecting pushing heads, and it is guaranteed that all the terminal assemblies and the terminal separation blades are subjected to the same detecting pressure. According to the electricity meter terminal seat intensity detecting device, the workload of technicians is reduced, and the detecting efficiency is improved.

Owner:HENAN XJ INSTR +1

Fixture special for sealing head

PendingCN109664318AEven by forceAvoid excessive local stressGripping headsEngineeringMechanical engineering

Owner:宜兴市联丰化工机械有限公司

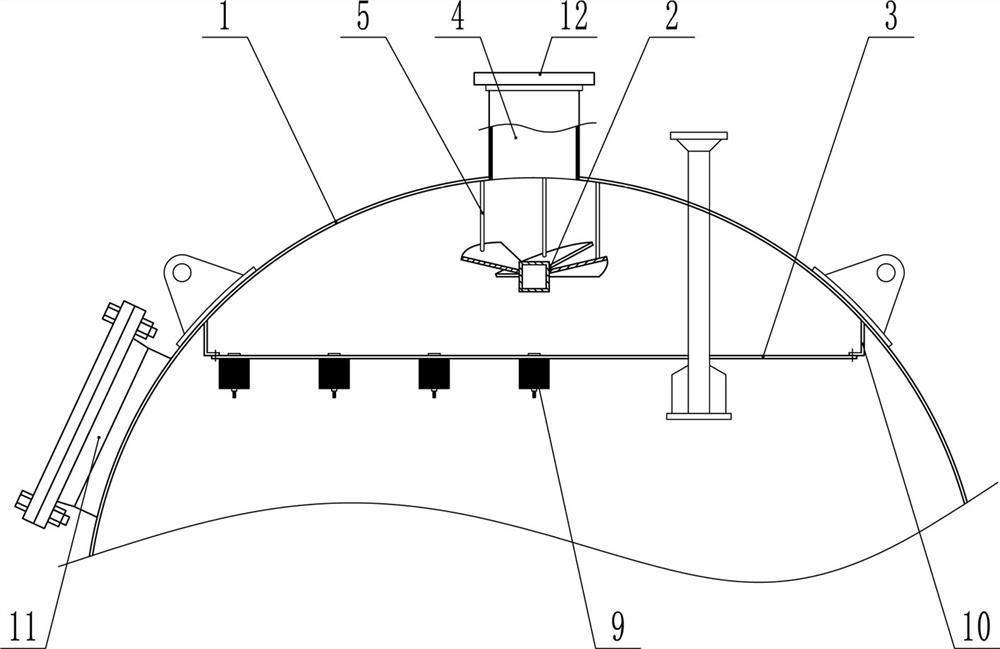

High-speed mixing bed adopting spiral fluid director water distribution plate and hexagonal unit perforated plate

ActiveCN113666454AImprove the uniformity of water distributionImprove uniformityWater/sewage treatment by ion-exchangeSustainable biological treatmentEngineeringFan blade

The invention provides a high-speed mixing bed adopting a spiral fluid director water distribution plate and a hexagonal unit perforated plate. The high-speed mixing bed comprises an arc-shaped top shell, a fan blade plate type water distribution plate and a water distribution perforated plate, wherein a water inlet is formed in the top end of the arc-shaped top shell, the fan blade plate type water distribution plate is arranged right below the water inlet, the water distribution perforated plate is arranged right below the fan blade plate type water distribution plate, the fan blade plate type water distribution plate comprises a central block and a plurality of upwarp fan blade plates which are uniformly connected to the central block, the water distribution perforated plate comprises a plurality of hexagonal unit plates and a plurality of arc-shaped plates, the hexagonal unit plates are spliced together, and the arc-shaped plates are spliced on the peripheries of the hexagonal unit plates. The high-speed mixing bed adopting the spiral fluid director water distribution plate and the hexagonal unit perforated plate has the advantages of scientific design, high water distribution uniformity, long service life and high purification efficiency.

Owner:国能荥阳热电有限公司 +1

A fast positioning tool for milling hole of eccentric upper head flange

InactiveCN104148968BHigh speedImprove processing efficiencyWork clamping meansPositioning apparatusElectromagnetic valveFlange

The invention discloses a hole-milling quick positioning tool for an eccentric upper sealing head flange. The hole-milling quick positioning tool comprises a positioning ring, a positioning disc, air cylinders, electromagnetic valves and pressing heads, a set of circular-arc-shaped side walls and an eccentric positioning pin are arranged on the positioning disc, the circular-arc-shaped side walls form a cylindrical excircle, the inner-side surface of each circular-arc-shaped side wall and an end-portion plane are connected through a bevel, two bevels form a conical face, the air cylinders extend and contract to drive the pressing heads to press or release a workpiece, a cooling liquid pipeline is arranged inside each of inner columns and outer columns, and a quick plug communicated with the corresponding cooling liquid pipeline is mounted on each of the inner columns and the outer columns. The conical face is formed by the two bevels and plays a role in guiding putting-in of a sealing plate, and convenience is brought to quick putting-in of the sealing plate, so that clamping speed is increased; by means of arranging cooling pipelines inside supporting columns, the cooling pipelines are contained in the supporting columns, so that no space is occupied, structure is simplified, and the objectives of compactness and high efficiency are achieved.

Owner:四川富临集团成都机床有限责任公司

An improved milling fixture for eccentric upper head flange

InactiveCN104148966BSmall footprintAvoid the phenomenon of accumulation and non-circulationWork clamping meansPositioning apparatusCooling effectEngineering

The invention discloses an improved hole milling clamp for an eccentric upper sealing head flange. The improved hole milling clamp comprises a positioning ring, a positioning disc, air cylinders, electromagnetic valves and pressing heads, a set of circular-arc-shaped side walls and an eccentric positioning pin are arranged on the positioning disc, the circular-arc-shaped side walls form a cylindrical excircle, the inner-side surface of each circular-arc-shaped side wall and an end-portion plane are connected through a bevel, two bevels form a conical face, a cushion block is arranged on the positioning disc, and the middle portion of the cushion block is cut to form a diversion groove; the air cylinders extend and contract to drive the pressing heads to press or release a workpiece, a cooling liquid pipeline is arranged inside each of inner columns and outer columns, and a quick plug communicated with the corresponding cooling liquid pipeline is mounted on each of the inner columns and the outer columns. Better cooling effect can be realized by utilizing the diversion groove, so that cooling effect is improved; by means of arranging cooling pipelines inside supporting columns, the cooling pipelines are contained in the supporting columns, so that no space is occupied, structure is simplified, and the objectives of compactness and high efficiency are achieved.

Owner:四川富临集团成都机床有限责任公司

Intermediate frequency simmering process for a335p92 material elbow

Owner:吉林昊宇电气股份有限公司

Front body structure and car

ActiveCN112429088BImprove impact resistanceSmall amount of deformationUnderstructuresSuperstructure subunitsEnergy absorptionMechanical engineering

Owner:CHERY AUTOMOBILE CO LTD

A fast positioning tool for milling hole of strong suction eccentric upper head flange

InactiveCN104148969BReduce generationSmall footprintWork clamping meansPositioning apparatusWear resistantEngineering

The invention discloses a quick hole-milling positioning tool for a strong-sucking type eccentric upper seal flange. The quick hole-milling positioning tool comprises positioning rings and a positioning disc. The positioning disc is provided with a group of arc-shaped side walls and eccentric positioning pin, the arc-shaped side walls form an excircle, the inner surface of each arc-shaped side wall and each end plane are connected through an inclined plane, and the two inclined planes constitute a conical surface. The quick hole-milling positioning tool further comprises air cylinders, an electromagnetic valve and pressure heads made of wear-resistant rubber, and the bottom of each pressure head is upwardly recessed to form a cavity. The inclined planes constitute the conical surface functioning in guiding placing of a seal plate, the seal plate can be quickly and conveniently placed in, and clamping speed is increased. By the aid of air pressure, the pressure heads and the seal plate can be fixed, lines on the surfaces of workpieces can be reduced due to large contact area, and cooling pipes are arranged in support columns in a concealed manner, so that space is not occupied, the structure is simplified, and the pursuit of simplicity and high efficiency is realized.

Owner:四川富临集团成都机床有限责任公司

Tow hook installation structure

ActiveCN111873730BAvoid mutual interferenceOccupy compressed spaceTowing devicesThreaded pipeEngineering

The invention provides a tow hook installation structure, which comprises a through hole formed at the bottom of the groove of the front anti-collision beam for the tow bar to pass through, a nut seat is arranged behind the through hole, and a threaded section of the tow bar in the vehicle length direction is provided. An expansion unit is arranged immediately in front of the unit. After the threaded section of the trailer rod is screwed into the nut seat, the rear end of the expansion unit and the nut seat are squeezed to drive the front end of the expansion unit to open, and the front end of the expansion unit is opened. The bottom of the groove constitutes a limit fit for restricting the forward displacement of the tow bar relative to the front crash beam. The common threaded pipe installation structure is cancelled, so as to prevent the excessively long rigid threaded pipe structure from occupying the compression space of the energy-absorbing box, and at the same time, a nut seat is reduced on the basis of the solution of the applicant's previous application, which makes the trailer When the hook is installed, only one nut seat is required to avoid mutual interference when multiple nut seats are installed together.

Owner:CHERY AUTOMOBILE CO LTD

Hole-milling assisting device for eccentric upper sealing head flange

InactiveCN104148972AImprove pass rateSmall footprintWork clamping meansPositioning apparatusEngineeringMachining process

The invention discloses a hole-milling assisting device for an eccentric upper sealing head flange. The hole-milling assisting device comprises a positioning ring, a positioning disc, air cylinders, electromagnetic valves and pressing heads, a set of circular-arc-shaped side walls and an eccentric positioning pin are arranged on the positioning disc, the circular-arc-shaped side walls form a cylindrical excircle, and the air cylinders extend and contract to drive the pressing heads to press or release a workpiece. By utilizing the hole-milling assisting device, processing of an axis hole, four through holes and a strip-shaped hole can be completed on a milling machine, and a sealing plate is clamped only once during processing, so that processing efficiency is improved; the sealing plate is fixed in position and quite easy to clamp, so that aligning difficulty is lowered, and inaccuracy in clamping is avoided; a reference is taken as a processing reference of the side walls, the four through holes and the strip-shaped hole, so that high uniformity is maintained, qualification rate of finished products is increased, and the finished product qualification rate is improved to be more than 97%.

Owner:四川富临集团成都机床有限责任公司

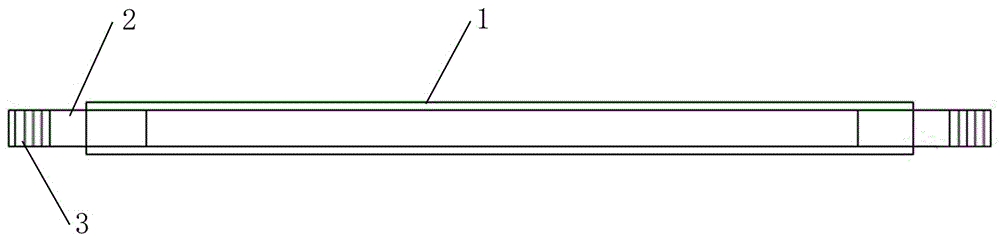

Connecting rod used for suction filtration machine dewatering system

The invention discloses a connecting rod used for a suction filtration machine dewatering system. The connecting rod comprises a middle connecting rod body and two end connecting rod bodies which are the same in structure. The middle connecting rod body is a hollow seamless steel pipe. The two end connecting rod bodies are symmetrically installed on the two sides of the middle connecting rod body in an inserted mode and are welded and fixed. Threads are arranged on the two end connecting rod bodies. The end connecting rod bodies are made of 0Cr19Ni9 steel. According to the connecting rod used for the suction filtration machine dewatering system, an original overall connecting rod design structure is changed into a segmented welding structure, the size of the middle connecting rod body is increased, so that the connecting rod is attached to a filter fan better; shaking in the production process is reduced, a whole fan plate is located in a compact integral structure, the integral structure strength is improved, and the situation that the stress borne locally is too large is avoided; and meanwhile, the force bearing point of the connecting rod is skillfully transferred to the welding position through the structure, the end connecting rod bodies are inserted into the middle connecting rod body by enough length, and the stress can be effectively dispersed, so that a stress concentration part is changed from a point to a surface, and the connecting rod stress bearing level is effectively improved.

Owner:韦海报

Milling and clamping device for eccentric upper head flange

InactiveCN104148971BPut in fastHigh speedWork clamping meansPositioning apparatusEngineeringElectromagnetic valve

Owner:四川富临集团成都机床有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com