Liquid crystal display device and backlight module

A technology of liquid crystal display device and liquid crystal display panel, applied in the direction of lighting device, fixed lighting device, lighting auxiliary device, etc., to achieve the effect of preventing excessive local stress and uniform supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

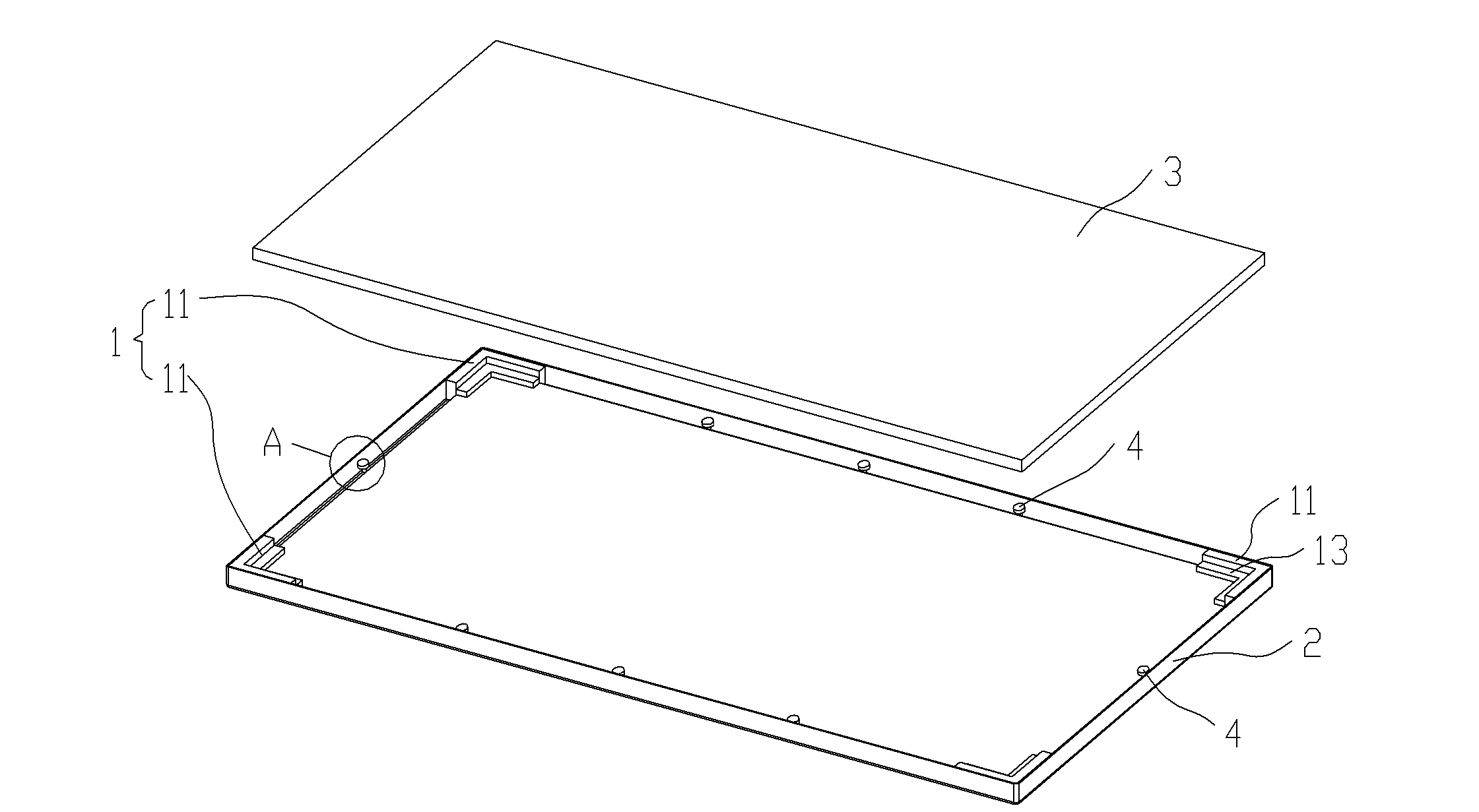

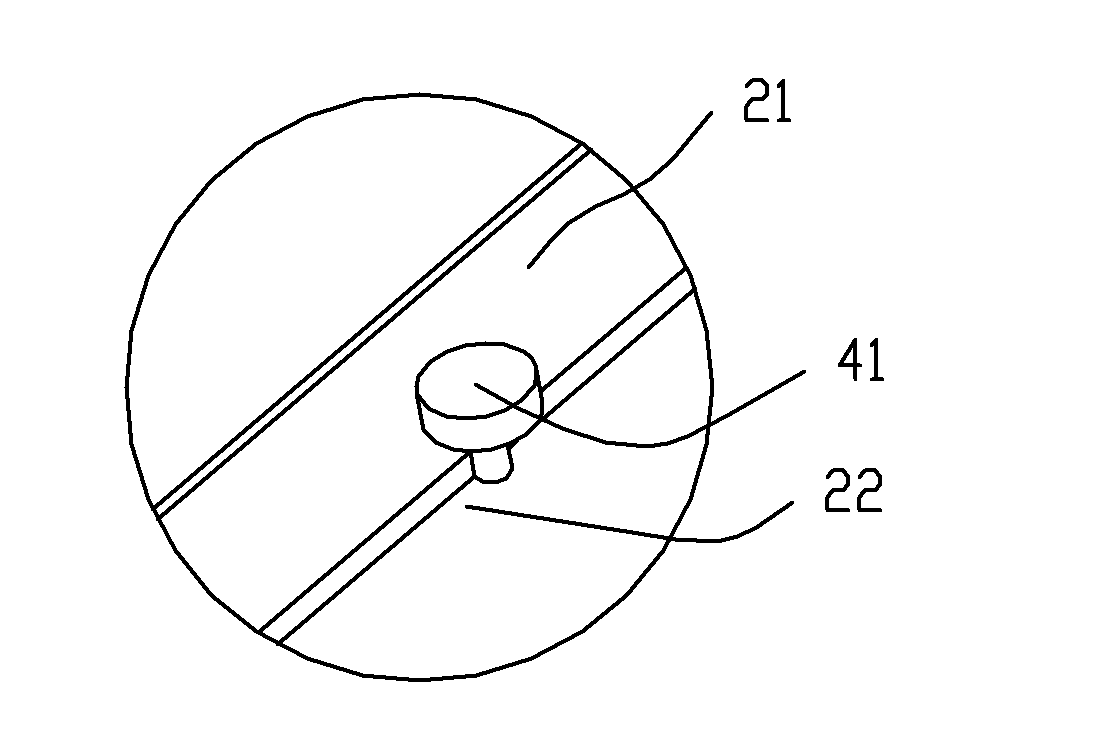

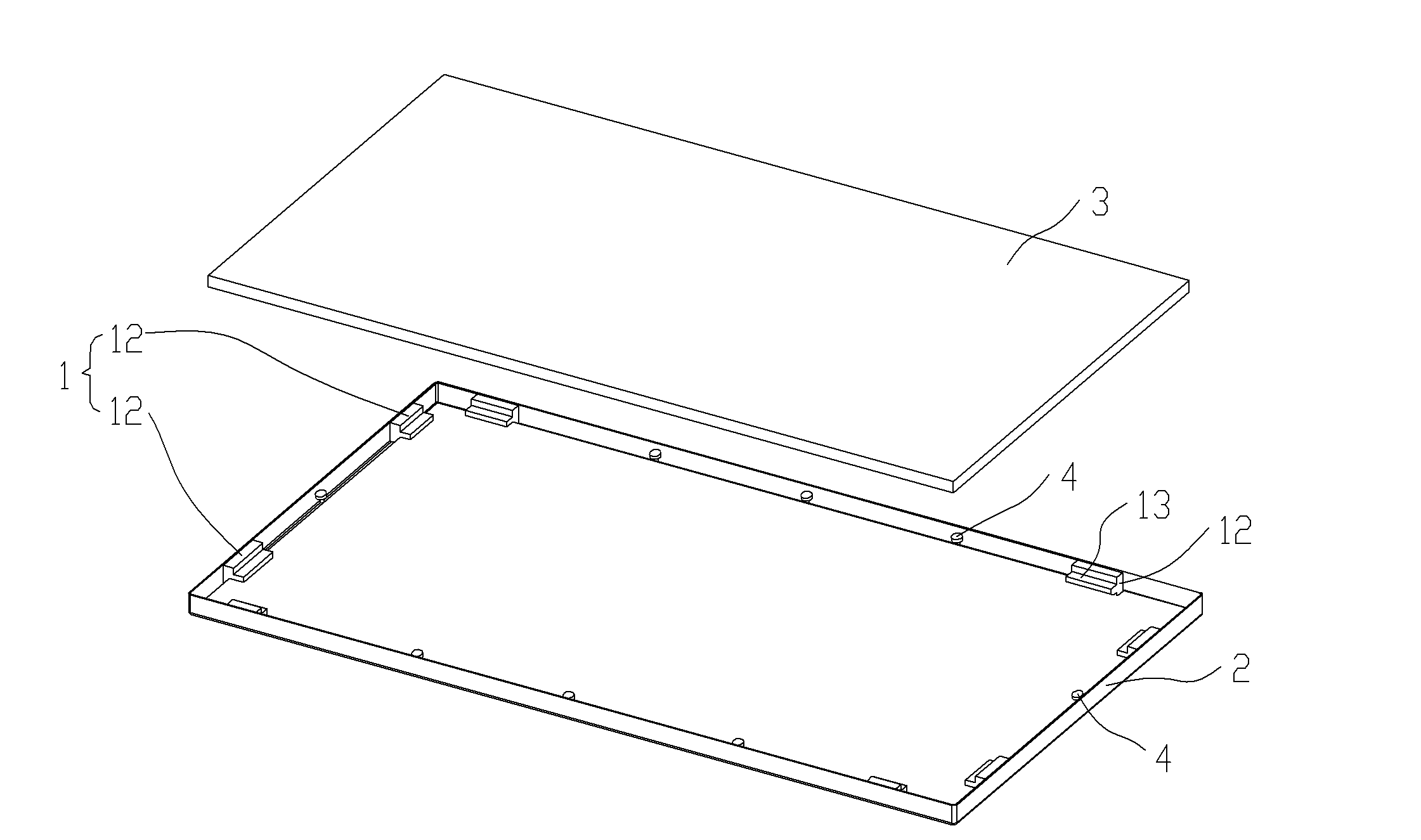

[0030] The present invention discloses a liquid crystal display device, including a backlight module, and the backlight module includes a middle frame 1 and a back plate 2, as Embodiment 1 of the liquid crystal display device, as shown in figure 1 and figure 2 As shown, it includes a middle frame 1, a back plate 2 and a liquid crystal display panel 3. The liquid crystal display panel 3 is arranged on the supporting surface 13 of the middle frame 1. The middle frame 1 includes a plurality of component units, and the adjacent component units There is a space between them, and the backlight module also includes a support 4 for assisting in supporting the liquid crystal display panel 3. The support 4 is fixedly arranged on the backplane 2, and the support 4 is located between two adjacent component units. The supporting surface 41 of the support member 4 is flush with the supporting surface 13 of the middle frame 1 .

[0031] The liquid crystal display device of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com