Metal-supported porous carbon film, fuel cell electrode and fuel cell employing the electrode

a porous carbon film and fuel cell technology, applied in the direction of metal/metal-oxide/metal-hydroxide catalysts, cell components, physical/chemical process catalysts, etc., can solve the problems of poor in-plane uniformity of reaction, increased internal resistance of electrodes, inferior battery properties, etc., to achieve simple fabrication steps and effective utilization of metal-based catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

reference example 1

Production of Porous Polyimide Film

[0073]After polymerizing 3,3′,4,4′-biphenyltetracarboxylic dianhydride and paraphenylenediamine in N-methyl-2-pyrrolidone, the obtained polyamic acid solution was cast to a prescribed thickness onto a mirror-polished stainless steel sheet, and then a doctor knife was used to uniformly coat NMP thereover, after which it was allowed to stand for 1 minute and was subsequently immersed in methanol for precipitation of a polyamic acid film. It was then immersed in an ion-exchanged water bath to release the film from the stainless steel sheet and dried, and finally heat treated at 400° C. for 20 minutes to obtain a porous polyimide film.

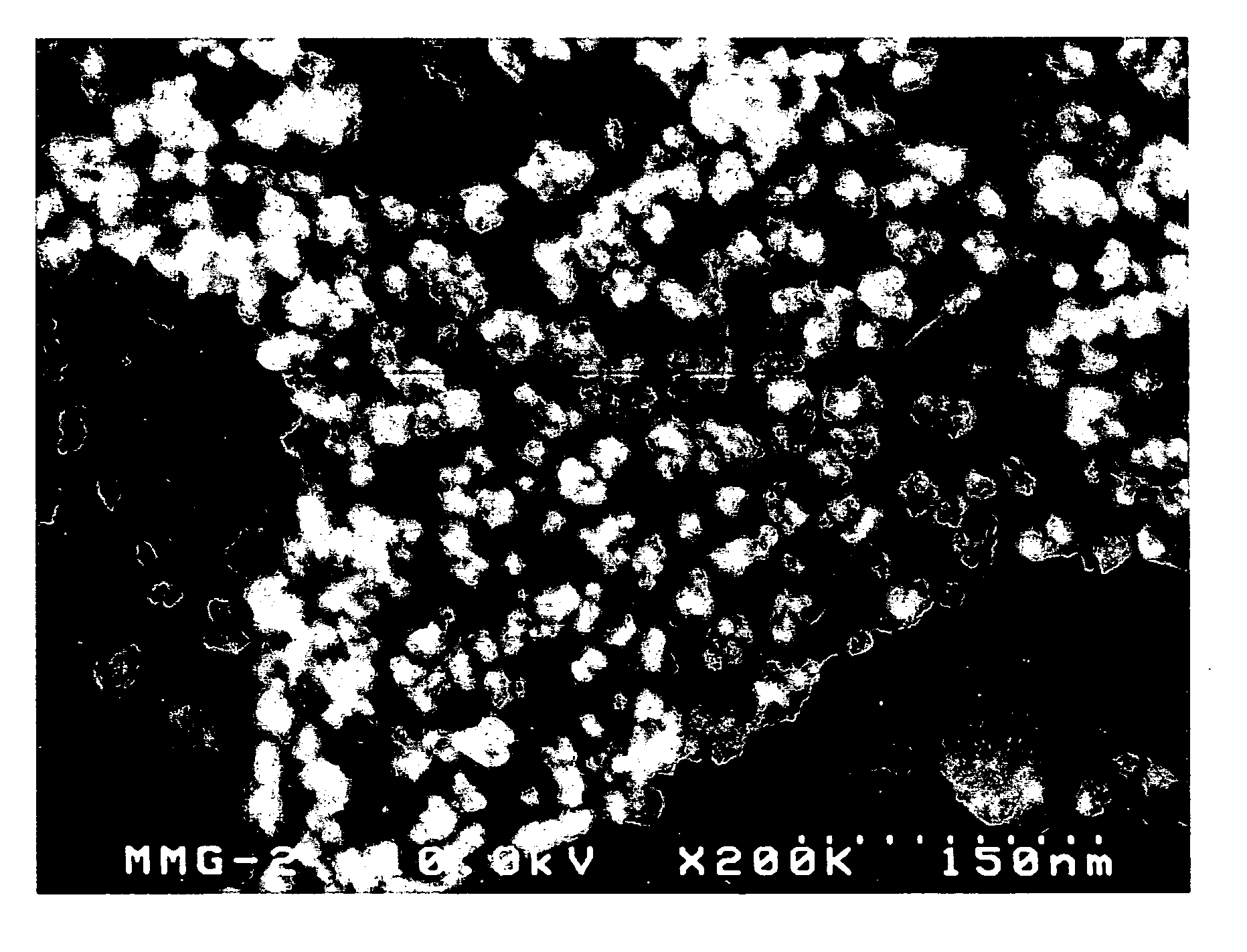

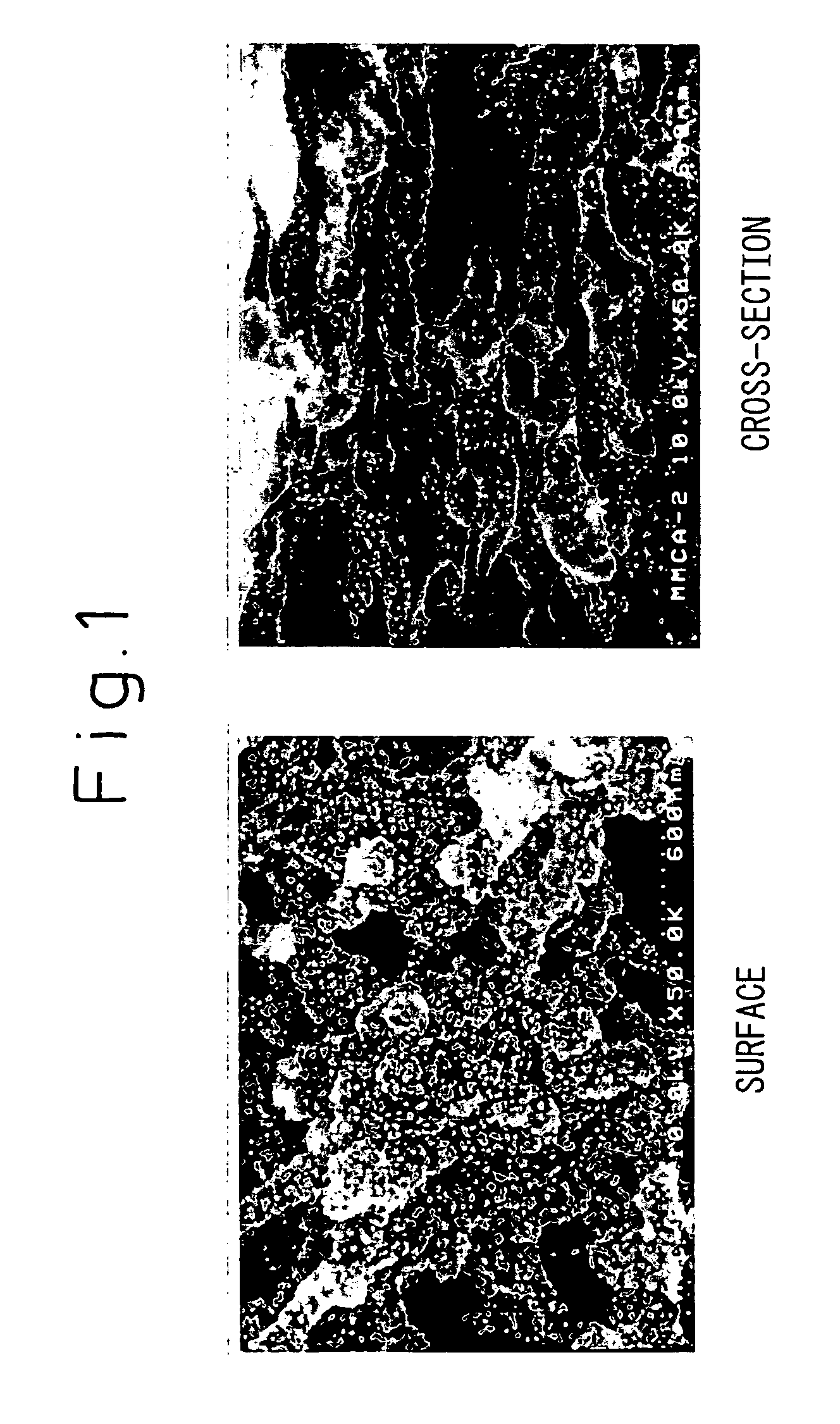

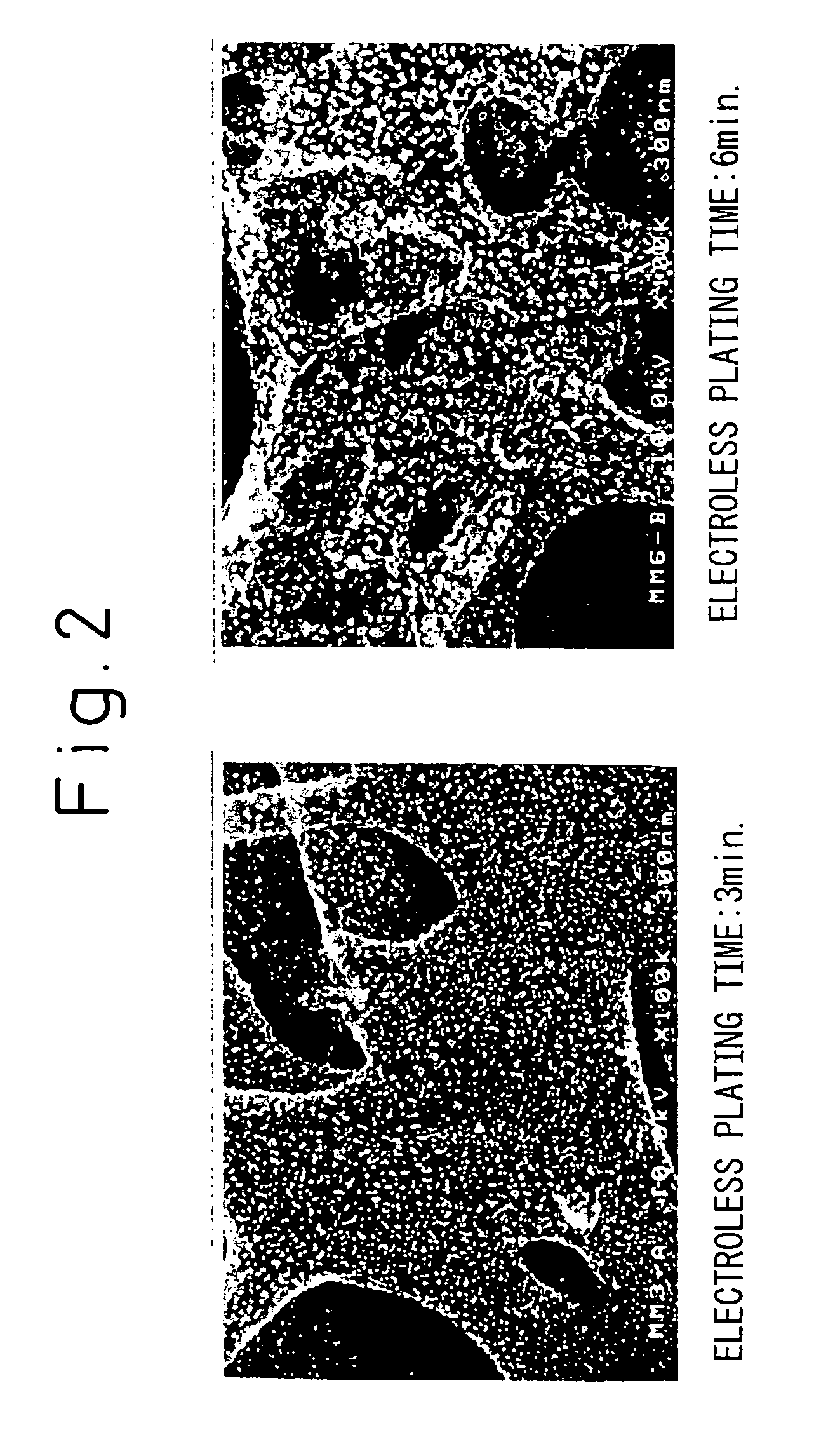

[0074]The film had an imidation of 90%, a film thickness of 32 μm, a gas permeability of 20 sec / 100 ml, a void percentage of 45% and a film surface mean pore size of 0.15 μm. This film was confirmed to have a three-dimensional network structure composed of polyimide through SEM observation.

reference example 2

Production of Porous Carbon Film

[0075]The porous polyimide film was carbonized at a temperature of 2100° C. for 120 minutes under a nitrogen gas stream to obtain a porous carbon film with a graphitization of 40%, a film thickness of 27 μm, a gas permeability of 26 sec / 100 ml, a void percentage of 40% and a mean pore size of 0.13 μm. This film was confirmed to have a three-dimensional network structure composed of carbon through SEM observation.

reference example 3

Production of Porous Graphite Film

[0076]The porous carbon film was held at 3000° C. for 120 minutes in an argon gas atmosphere to obtain a porous graphite film having a crystallization (graphitization) of 90% or greater, a mean pore size of 0.11 μm, 24 μm of membrane thickness, a lattice constant of 2.53 Å on the a axis and 6.68 Å on the c axis and a crystallite size of 180 Å on the (002) face and 90 Å on the (101) face. Penetration of methanol, dropped onto the film surface, through to the back confirmed the presence of fine connected pores in the film interior.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com