Soot blower suitable for SCR denitration of high-temperature and high-dust flue gas

A technology of sootblower and flue gas, which is applied in the direction of cleaning method using gas flow, gas treatment, cleaning method and utensils, etc. It can solve the problems of amazing compressed air consumption, limited coverage area, unstable operation, etc., and achieve local solution Dust accumulation and clogging, prevention of local excessive force, uniform blowing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

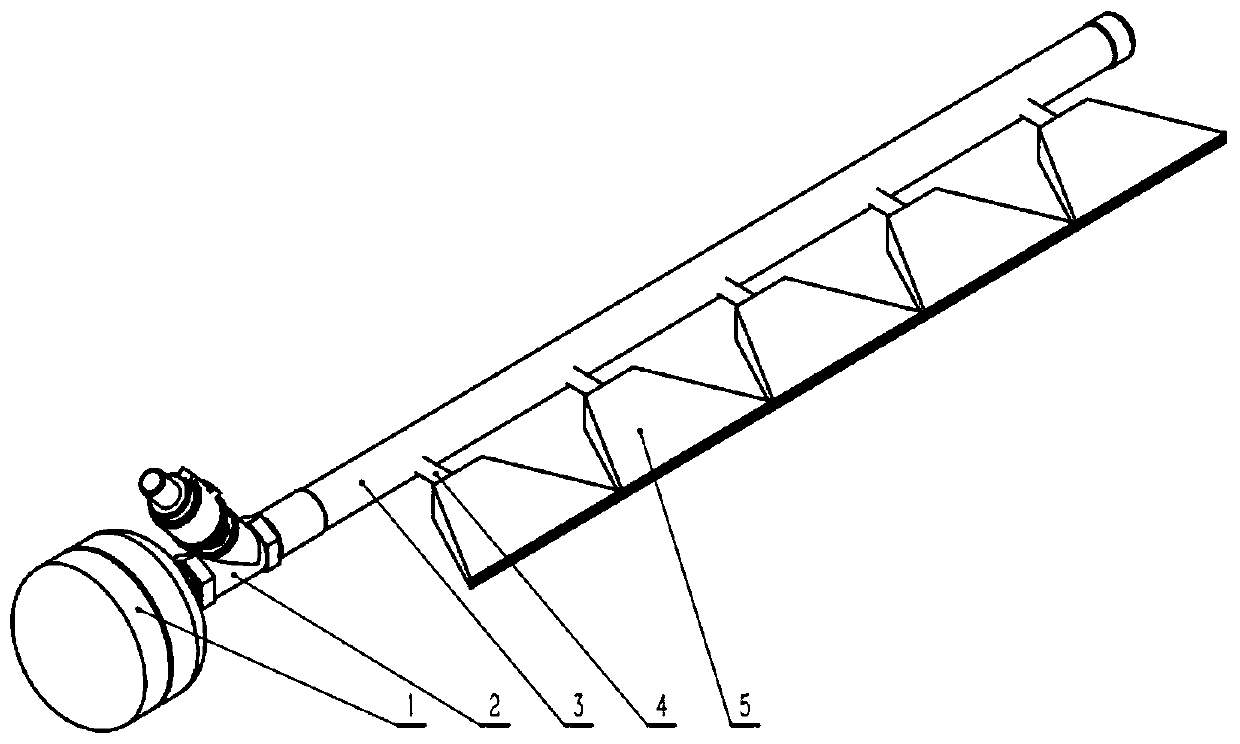

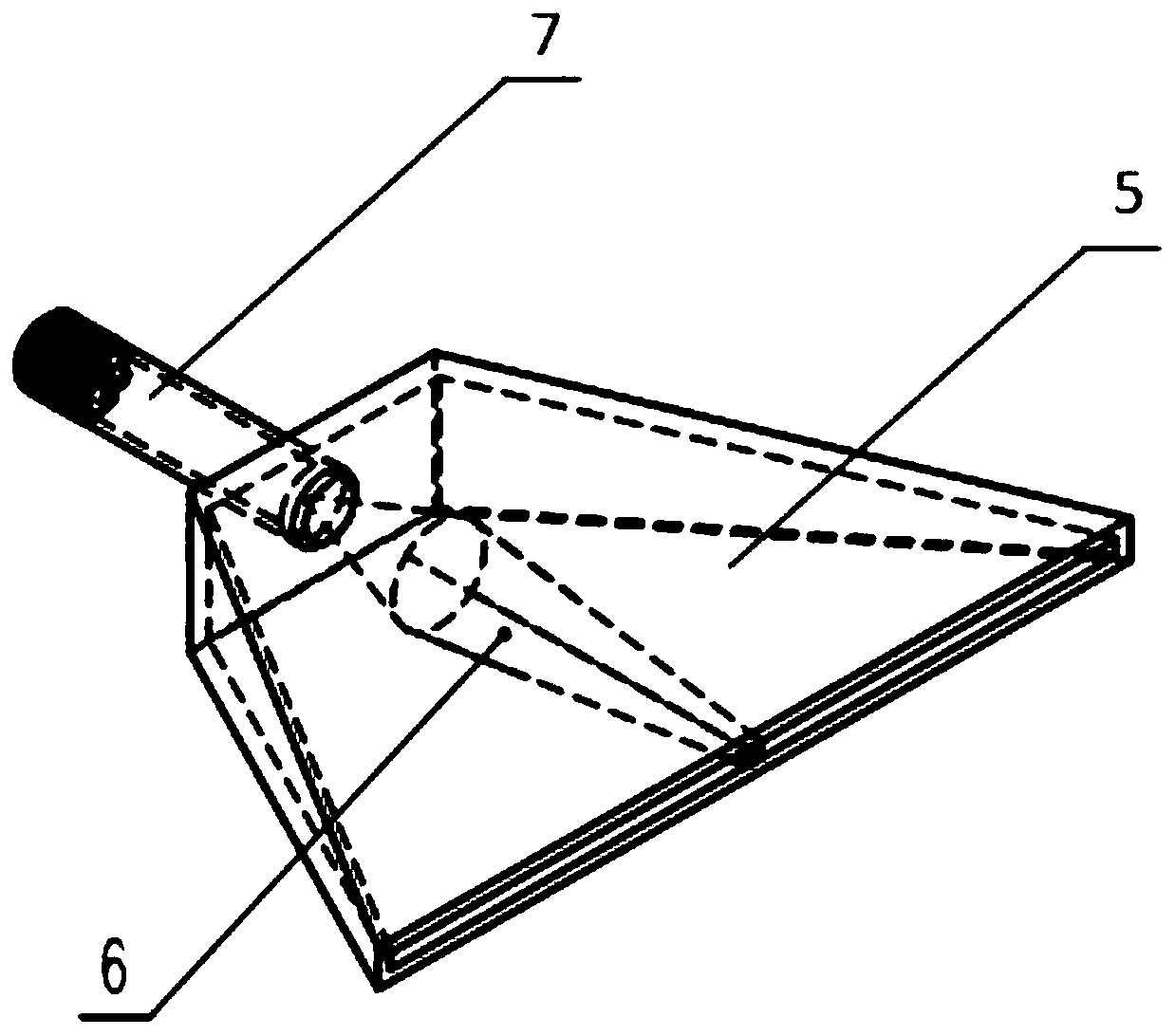

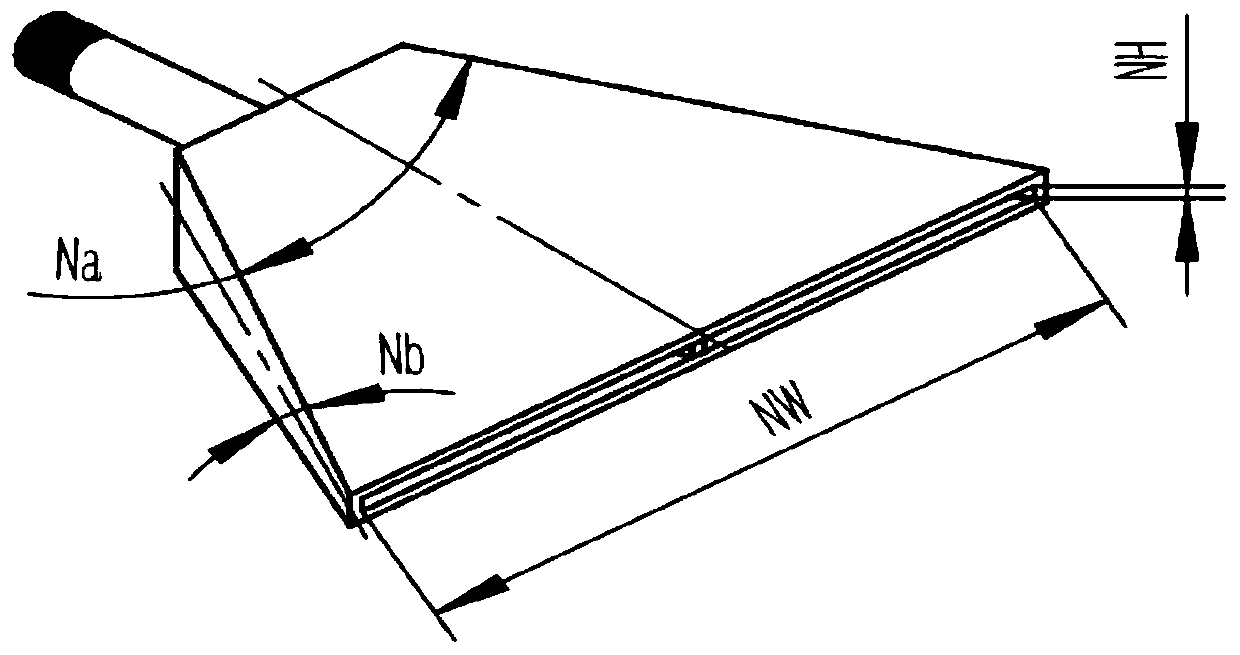

[0036] The invention is applied to a cement kiln tail high-temperature flue gas SCR denitrification side line pilot test, the treated flue gas volume is 76530m3 / hr, the flue gas temperature is 300-350°C, and the flue gas dust content is 115g / m3. The arrangement of soot blowers in SCR denitrification is as follows: Figure 7 As shown, the value of Dh is 75mm, and the value of Da is 7 degrees. Install on the main gas pipe 3 of the soot blower as figure 1 Five flat spouts 5 are shown. The compressed air bag 1 has a storage volume of 500L, the size of the main gas pipeline 3 is DN50, the size of the gas pipeline 4 is DN15, and the interval is 255mm. Such as Figure 3-Figure 4 The dimensions of the flat nozzle 5 shown are as follows: the length ND is 154 mm, the opening thickness NH is 5 mm, the flat opening angle Nb is 9.5°, and the opening width NW is 253 mm. Such as Figure 5-Figure 6 The size of the air separation inner core 6 shown is as follows: the length CL1 is 45mm, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com