Dust removing mechanism of side wall type plate placing machine

A technology for placing boards and sticking dust, which is applied in the direction of cleaning methods using gas flow, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult removal of foreign matter on the surface of boards and weakening of the effect of sticky dust sheets, and achieve Improve cleanliness and uniform blowing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

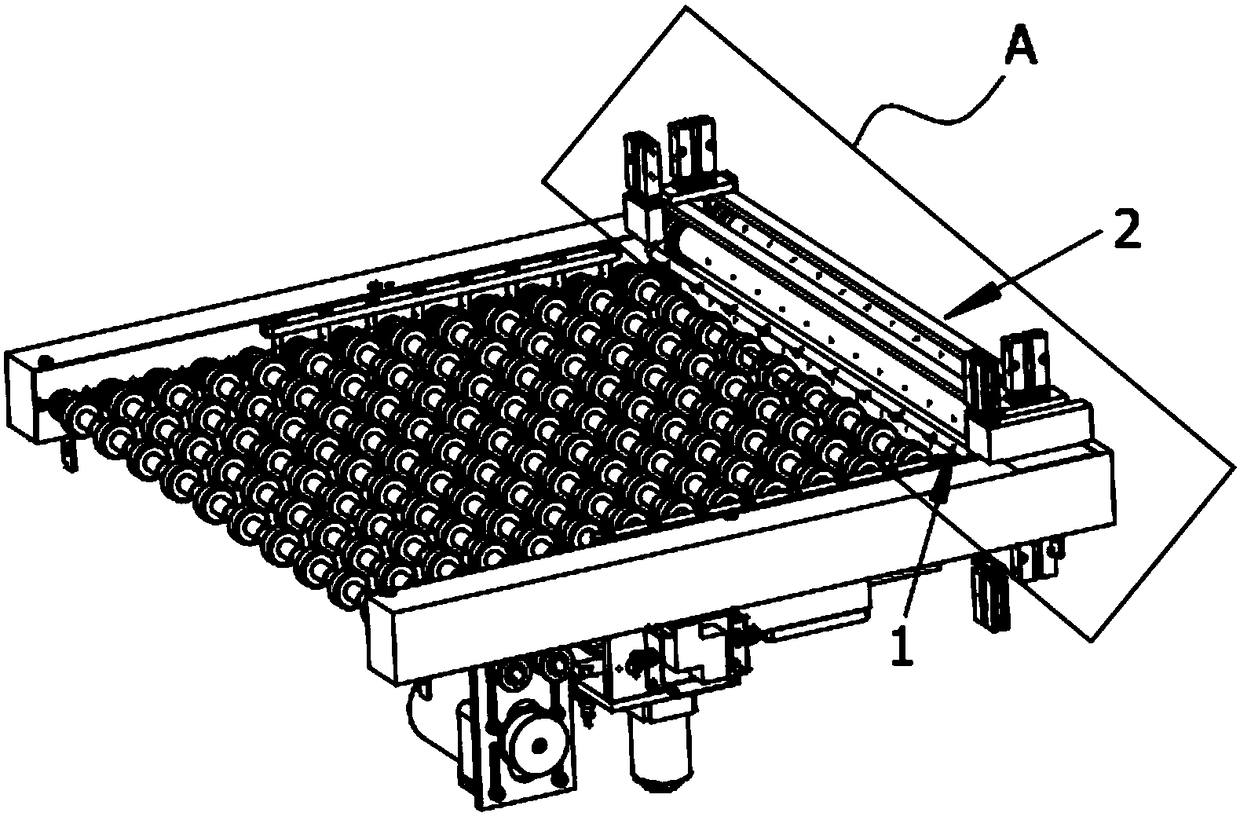

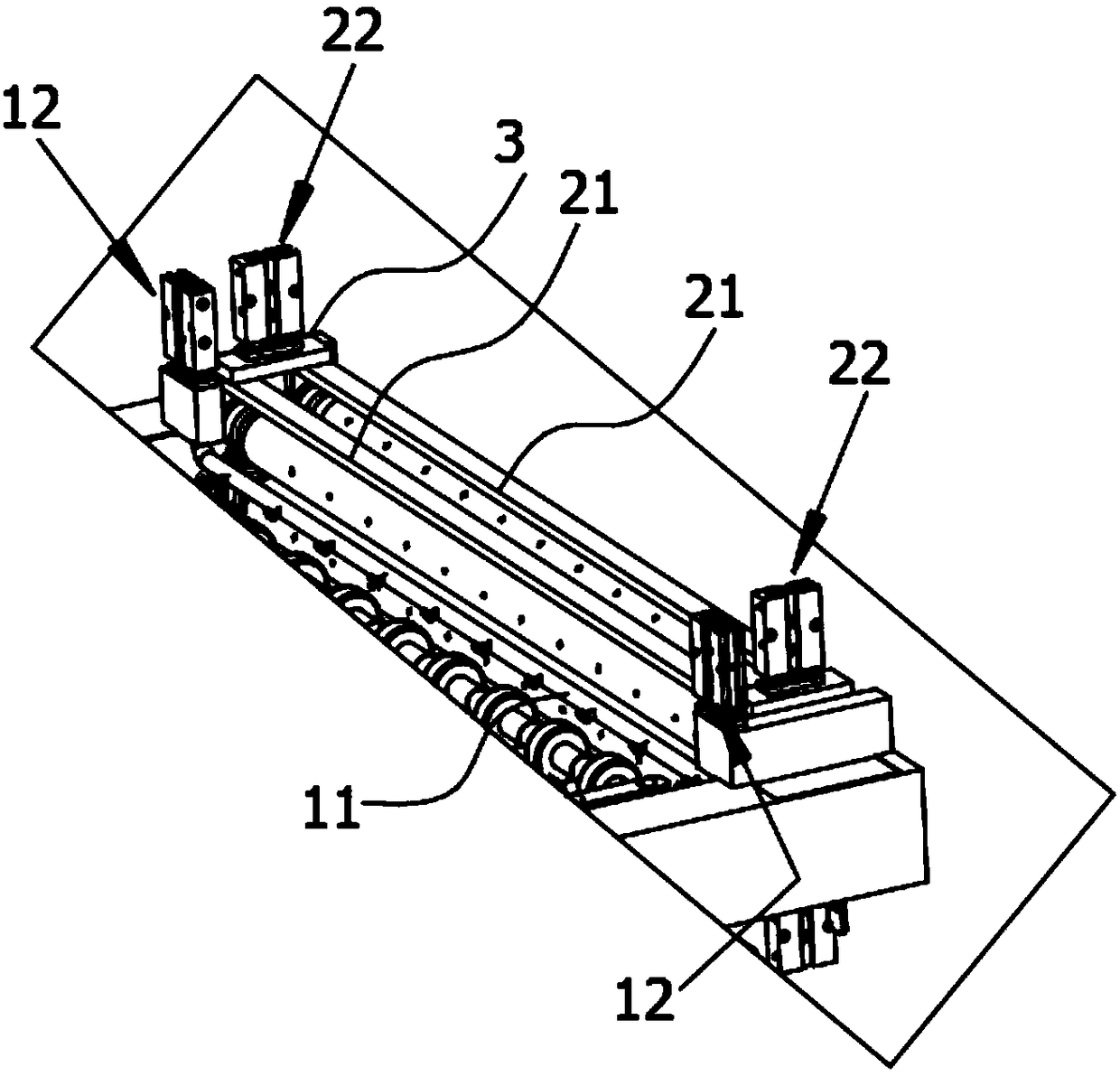

[0040] Embodiment: a kind of dust removal mechanism of side wall type board machine, such as Figure 1-Figure 7 As shown, it includes a dust removal mechanism fixed on the frame, and the dust removal mechanism includes a primary dust blowing structure 1 and a secondary dust sticking structure 2 symmetrically located downstream of the conveying section, and the primary dust blowing structure 1 is located at the second Upstream of Class Sticky Structure 2;

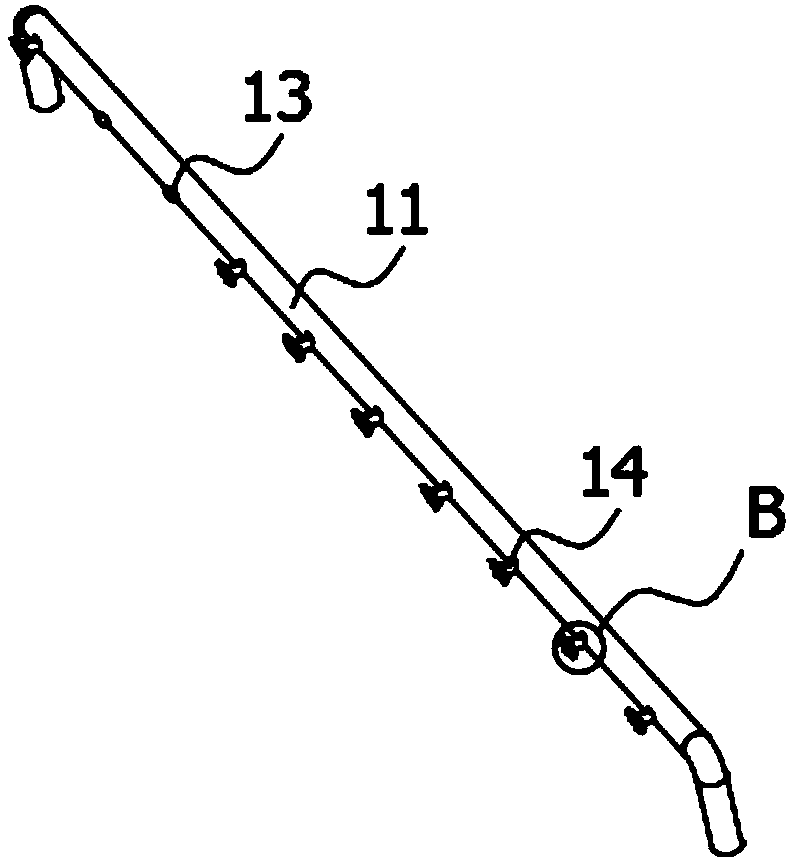

[0041] Each of the first-stage dust blowing structures 1 includes a hollow tube 11 and a first lifting structure 12 that drives the hollow tube close to and away from the conveying section, and the space between the two hollow tubes that are symmetrical up and down is the gap through which the material passes; One end of the hollow tube 12 is closed and the other end is connected to the gas source through a trachea. The side of the hollow tube 12 opposite to the material conveying direction is evenly distributed with through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com