Connecting rod used for suction filtration machine dewatering system

A suction filter and connecting rod technology, applied in the field of feeding system, can solve the problems affecting production output and quality, the suction filter stuck, heat loss, etc., to avoid excessive local stress, increase the overall structural strength, The effect of raising the level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

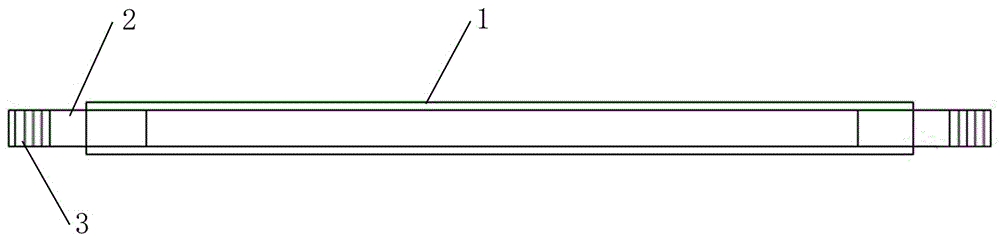

[0011] Such as figure 1 As shown, the connecting rod for the dehydration system of a suction filter according to the embodiment of the present invention includes a middle connecting rod 1 and two end connecting rods 2 with the same structure, and the middle connecting rod 1 is a hollow seamless steel pipe. The connecting rods 2 at both ends are symmetrically plugged and installed on both sides of the middle connecting rod 1 and fixed by welding, and the connecting rods 2 at both ends are provided with threads 3 .

[0012] In the present invention, the design structure of the original whole connecting rod is changed to a segmented welding structure, and the size of the middle connecting rod is enlarged, so that the connecting rod fits the filter fan better, reduces shaking during the production process, and makes the whole fan plate in a relatively tight position. In the overall structure, the strength of the overall structure is increased to avoid excessive local stress; at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com