Patents

Literature

52results about How to "There will be no stratification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

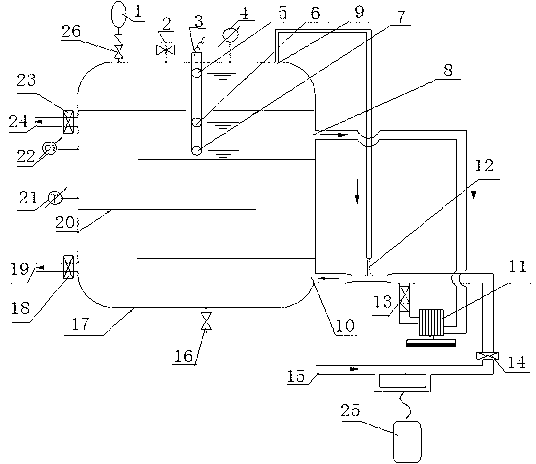

Water-fertilizer-gas integrated irrigation control system and control method

InactiveCN103314697AIntegrated Irrigation RealizationA wide range of incorporation ratiosClimate change adaptationWatering devicesAir cycleOxygen controller

The invention discloses a water-fertilizer-gas integrated irrigation control system and control method. The control system comprises a pressure-bearing water tank (17), wherein the pressure-bearing water tank (17) is provided with a pressure safety valve (2), a water level controller (3), a pressure controller (4), an inner circulating water gap (8), an air circulation port (9), a water inlet (10), a drain outlet (16), a low-post water outlet (19), a guide plate (20), a temperature transmitter (21), a dissolved oxygen controller (22) and a high-post water outlet (24), and a fertilization and air-entrapping device is arranged outside the pressure-bearing water tank (17); through the control of water inlet and outlet and aeration, a function of carrying out automatic aeration on liquid in the pressure-bearing water tank (17) can be achieved so as to achieve a preset water-gas mixing ratio. The system can realize water-fertilizer-gas integrated irrigation, thereby greatly increasing the water and fertilizer utilization efficiencies of crops.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

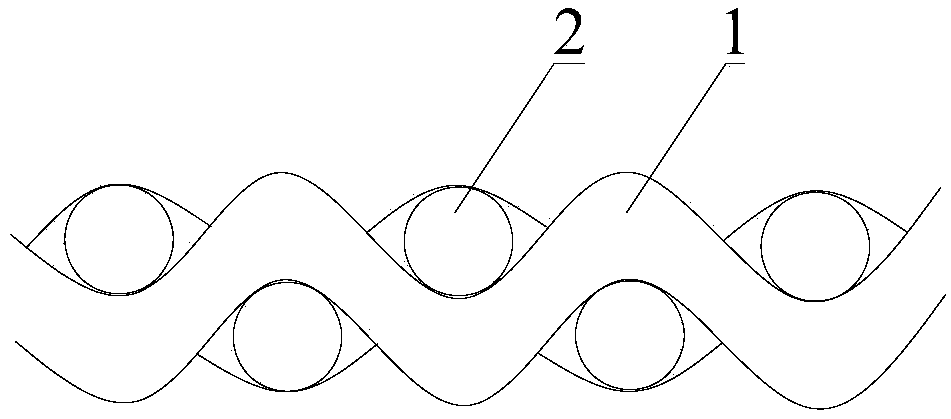

Biological tendon repairing material and preparation method thereof

ActiveCN107854727APromote growthEasy to climbTissue regenerationProsthesisCell-Extracellular MatrixCellular infiltration

The invention provides a biological tendon repairing material and a preparation method thereof. The biological tendon repairing material comprises an extracellular matrix body subjected to immunogen removal, wherein the extracellular matrix body consists of one or more layers and comprises a first surface and a second surface; the first surface comprises a first area and a second area; the mechanical strength of the first area is lower than that the second area. During preparation of an extracellular matrix subjected to immunogen removal, layering is avoided. As the biological tendon repairingmaterial is provided with the surface which consists of the first area and the second area, cellular infiltration of defective tissues is facilitated, tissue repairing is accomplished, stress born bythe repairing material can be uniformly distributed, and local stress cannot be excessively large. Besides, the surface has a high suture retention force and can serve as the second surface of a suture area of the repairing material, and the strength of the repairing material can be guaranteed while repairing of the defective tissues is facilitated.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

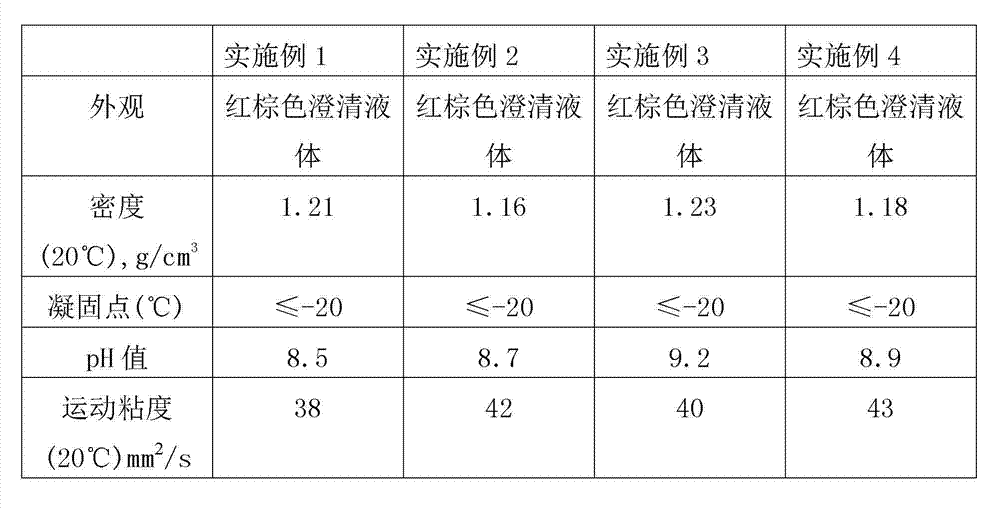

Method for preparing water-soluble high-temperature corrosion inhibitor

The invention discloses a method for preparing a water-soluble high-temperature corrosion inhibitor, which comprises the following steps: (1) antirust complex preparation: accurately weighting water, a boric acid and glycerin in proportion, adding the weighted water, boric acid and glycerin into a reaction kettle, heating the reaction kettle and adding monoethanolamine into the reaction kettle, heating the obtained mixture until the obtained mixture is boiled, flowing back and then cooling the obtained object so as to obtain an anti-rust complex; and (2) dosing: pumping sulfonated castor oil and the antirust complex obtained in the step (1) into a reaction kettle, heating and stirring the obtained mixture, cooling the obtained mixture and adding water into the obtained mixture, uniformly stirring the obtained product so as to obtain a water-soluble high-temperature corrosion inhibitor. The water-soluble high-temperature corrosion inhibitor prepared by using the method disclosed by the invention is good in water-solubility, no cosolvent is not required to be added when the corrosion inhibitor is used in a formula, and no laying phenomenon occurs when the corrosion inhibitor is compounded with any organic amine, thereby facilitating a neutralization reaction between the corrosion inhibitor and a naphthenic acid in raw oil; and the antirust complex of the corrosion inhibitor in the invention and the sulfonated castor oil can form a dense and firm protective film in a high-temperature tower, thereby effectively preventing the raw oil from eroding the inner wall of the tower.

Owner:江苏汉光实业股份有限公司 +1

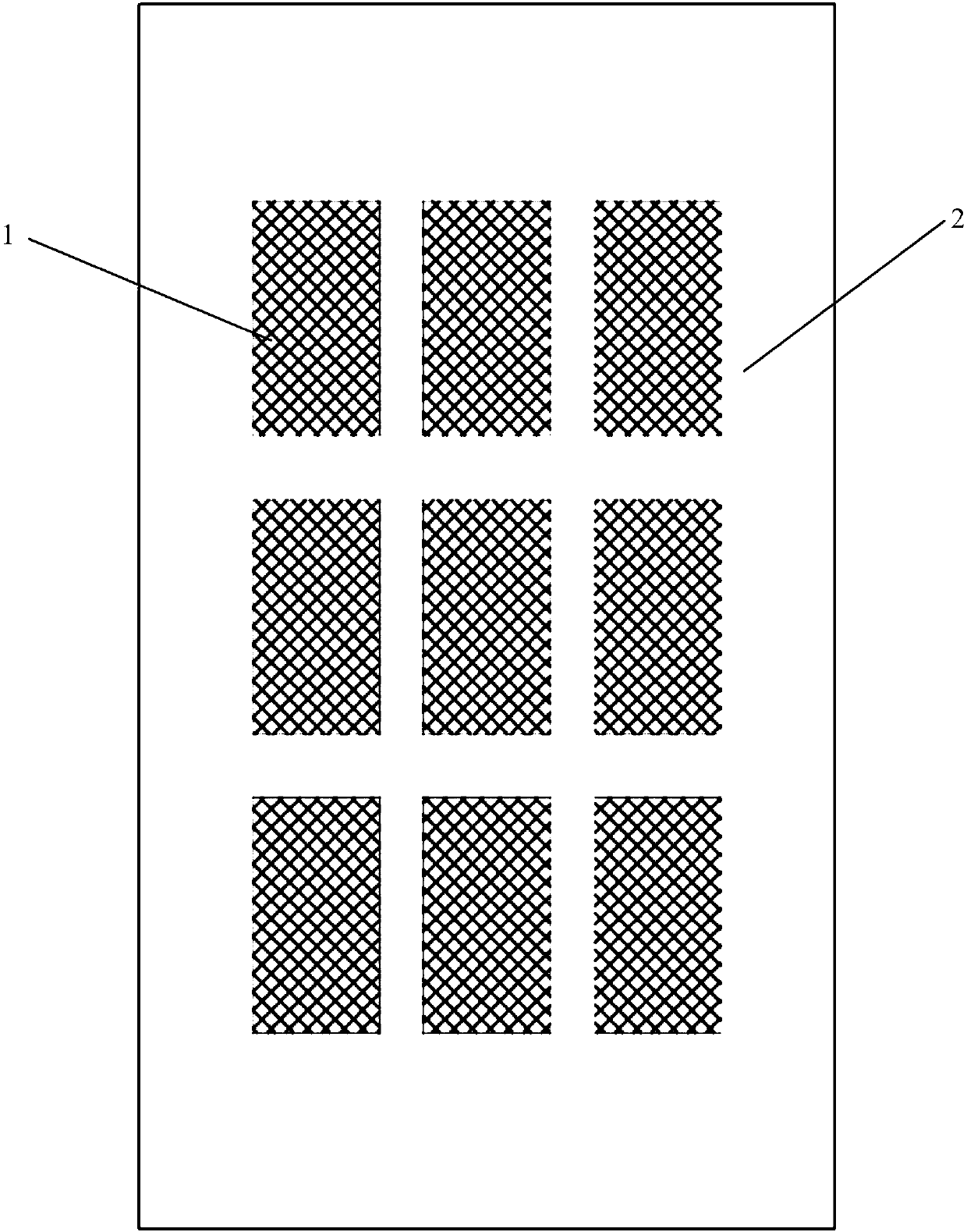

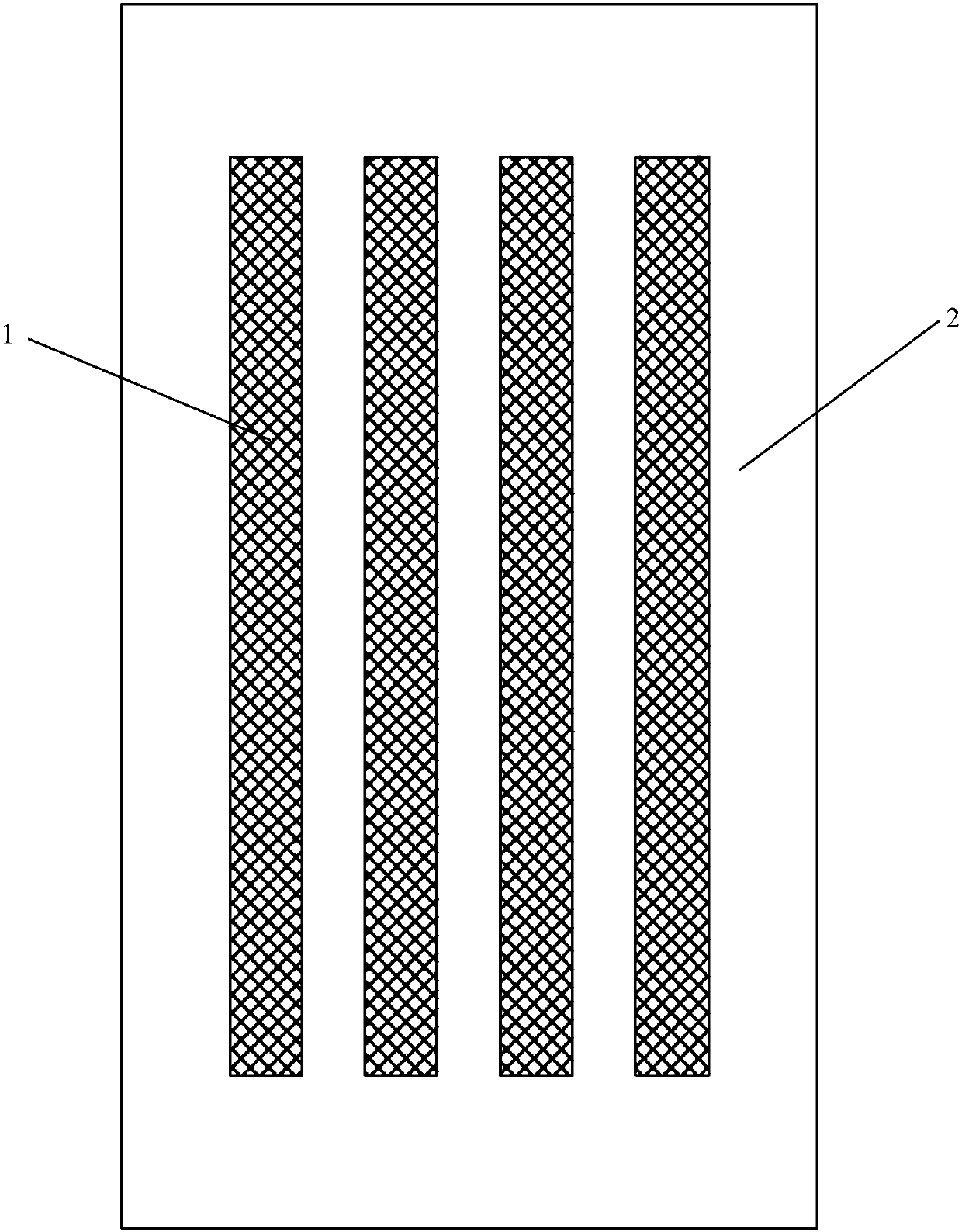

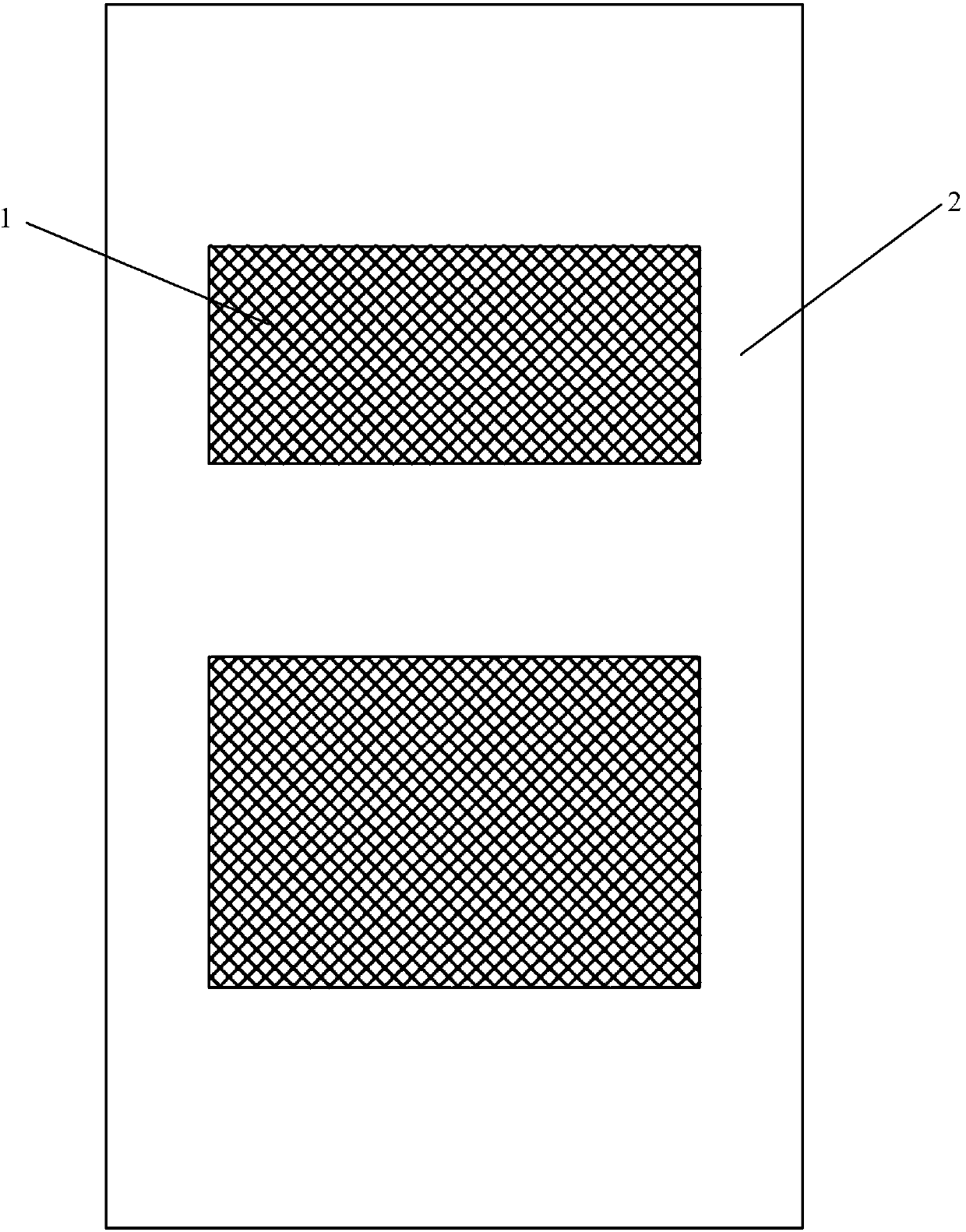

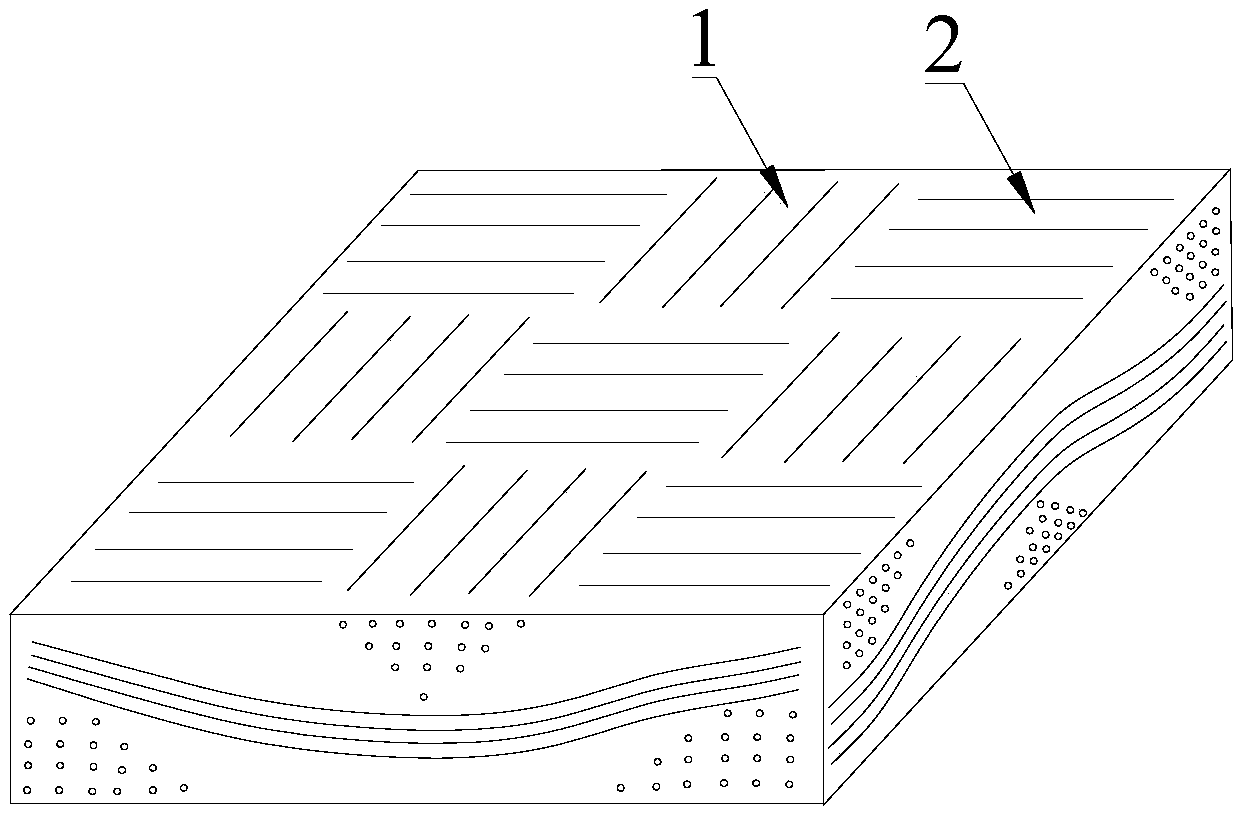

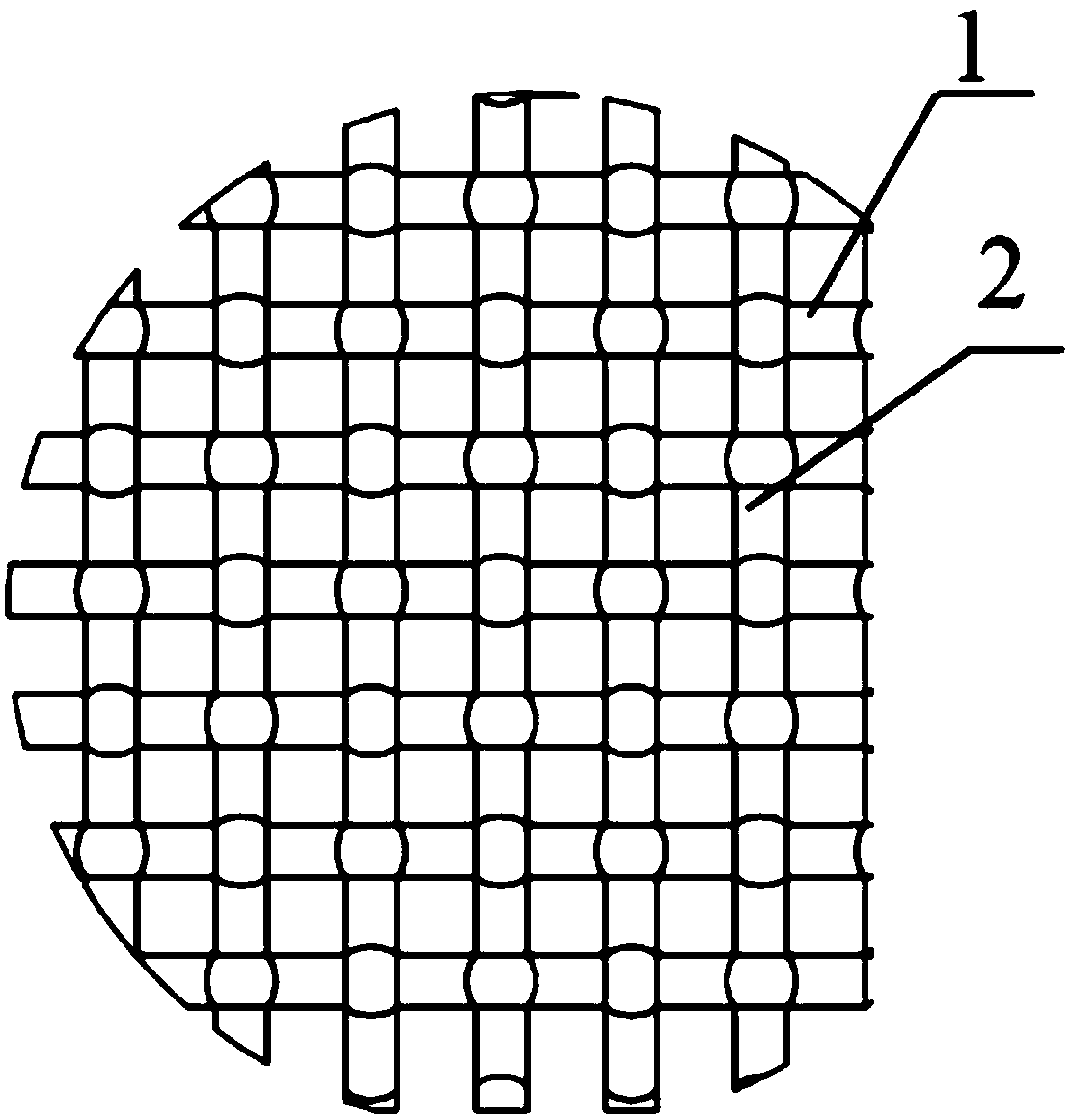

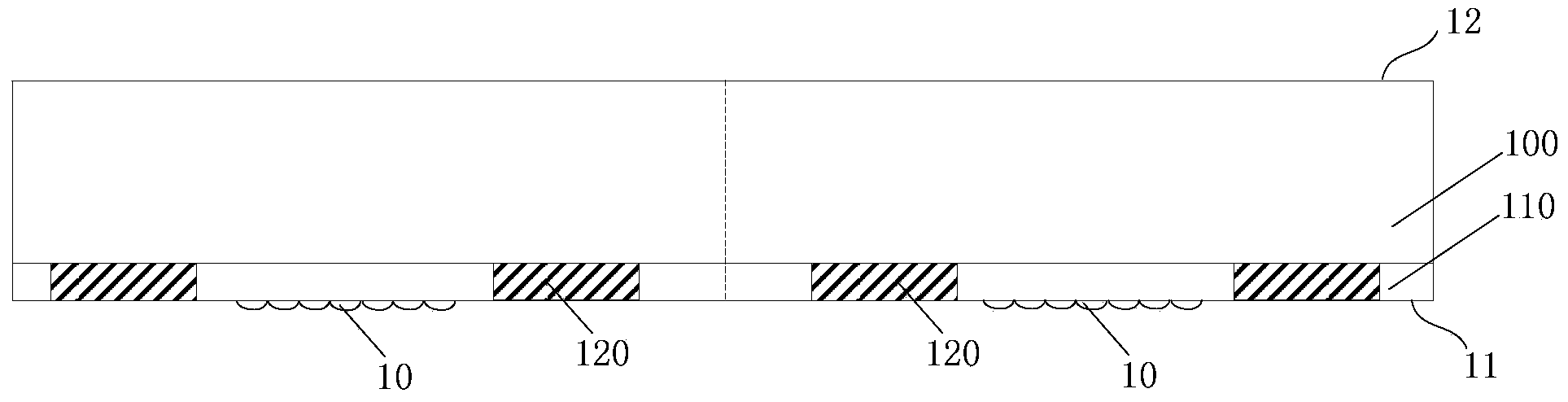

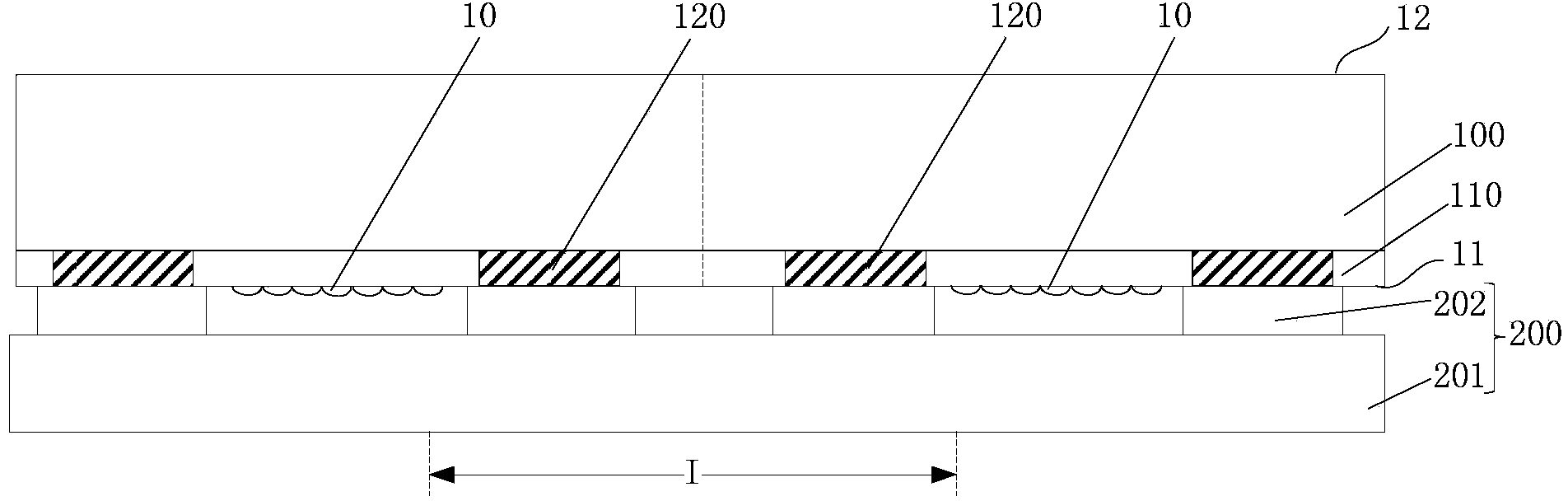

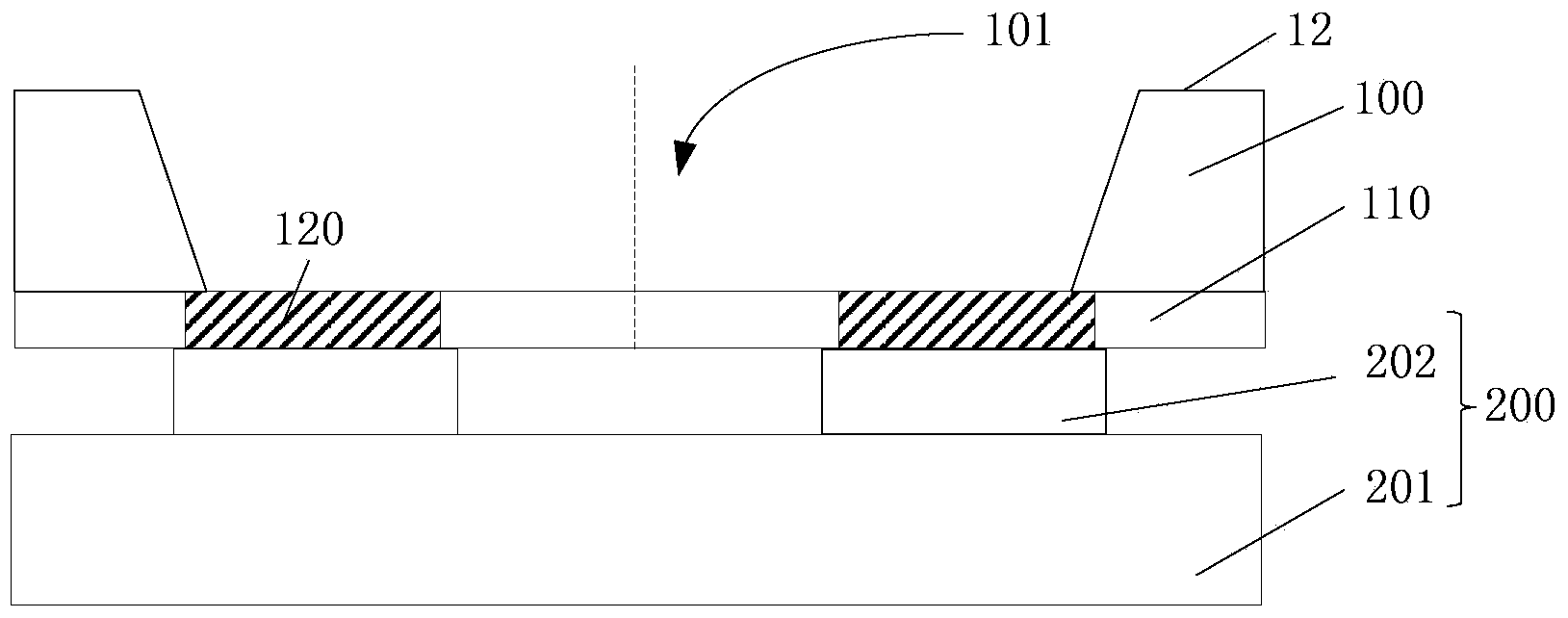

Liquid crystal polymer film and production method thereof

InactiveCN109651632AEquivalent mechanical propertiesThere will be no stratificationLiquid crystal compositionsPolymer scienceLiquid crystal

The invention discloses a liquid crystal polymer film and a production method thereof. The liquid crystal polymer film comprises at least two first orientation units and at least two second orientation units, the orientation directions of the first orientation units intersect with the orientation directions of the second orientations, the at least two first orientation units and the at least two second orientation units are arranged in a mesh woven structure, and the mesh woven structure is subjected to hot press molding to obtain the liquid crystal polymer film. The first orientation units and the second orientation units having different orientation directions are arranged in the mesh woven structure, the hot pressing molding is adopted to obtain the isotropic liquid crystal polymer filmwith same mechanical performances in an MD (machine direction) and in an TD (transverse direction), and the obtained film has no layering phenomenon in the thickness direction.

Owner:SHENZHEN SUNWAY COMM

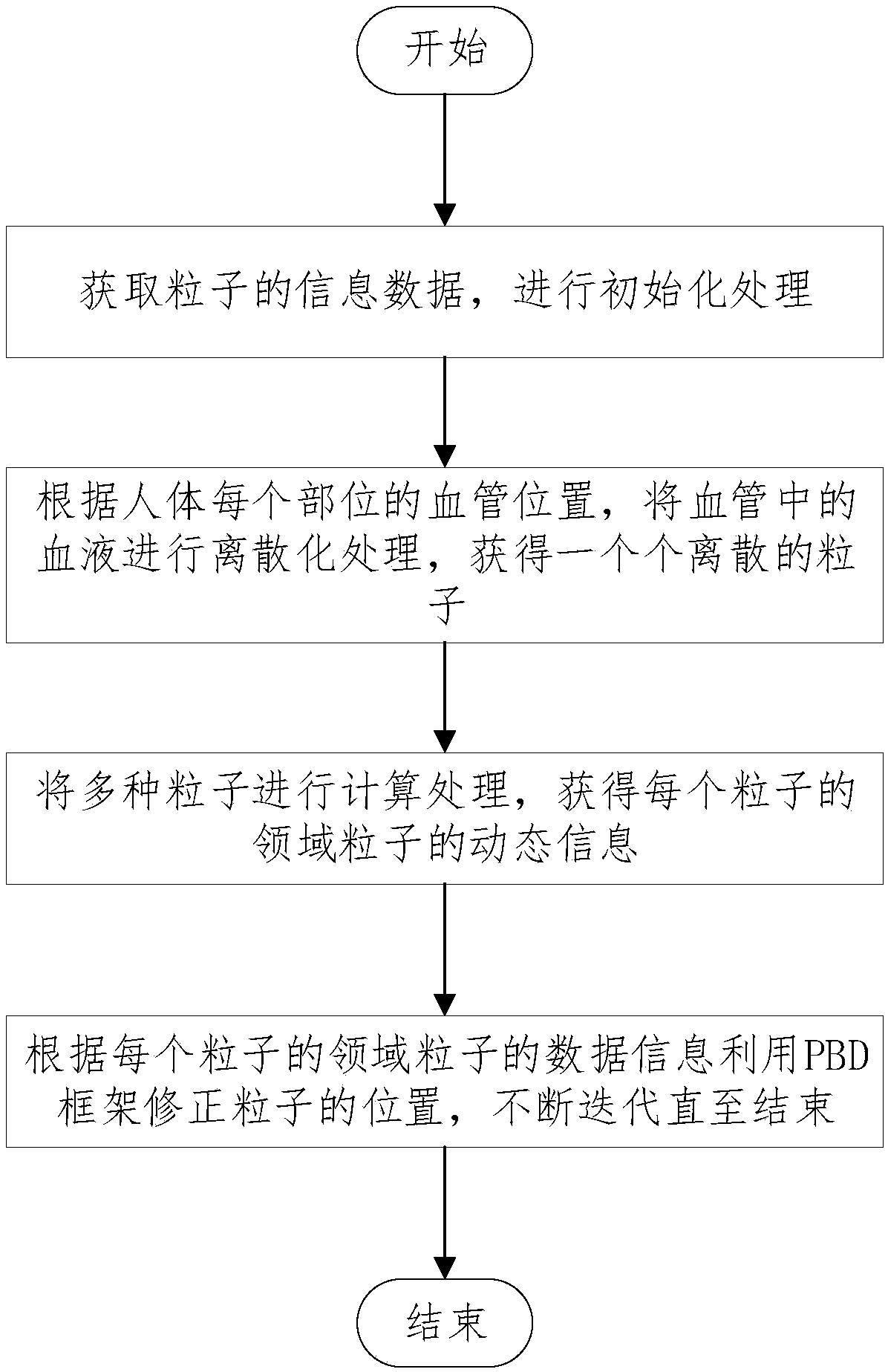

Blood simulation method based on PBF

InactiveCN108461149AGood real-time performanceDistribution guaranteeMedical simulationUnit volumeDiscretization

The embodiment of the invention discloses a blood simulation method based on PBF, wherein the method comprises the following steps of acquiring information data of particles and performing initialization processing; performing discretization on blood in the blood vessel according to the blood vessel position of each part of the human body, and obtaining discrete particles; conducting calculation processing on the multiple particles, and obtaining the dynamic information of the field particles of each particle; correcting the position of the particles through the PBD framework according to thedata information of the field particles of each particle, and carrying out iteration until the particles are finished. By implementing the embodiment of the invention, the limitation of a traditionalfluid simulation technology can be broken through, so that a larger time step is achieved in the simulation process, and has better real-time performance. The blood is simulated by combining multipleparticles, and appropriate modification can be carried out according to different application scenes by using the number of the particles, and meanwhile, the distribution conditions of the particles with different densities are constrained by using the density of the blood. The distribution condition of different types of particles in a unit volume is guaranteed, and the phenomenon of layering isavoided.

Owner:SUN YAT SEN UNIV

Moisturizing banishing essence containing beta-glucan and preparation method of moisturizing banishing essence

ActiveCN110075003AGood moisturizing effectImprove dullnessCosmetic preparationsToilet preparationsSaccharomycopsisBeta-glucan

The invention discloses moisturizing banishing essence containing beta-glucan and a preparation method of the moisturizing banishing essence, and belongs to the technical field of skin care products.The components of the moisturizing banishing essence containing the beta-glucan contain hematic acid, yeast peptide, saccharomycopsis ferment filtrate, rice ferment filtrate, saussurea involucrata fermentation liquor, nicotinamide, beta-glucan, a tremella fuciformis fruit body extract, and the like; natural organic efficient healthy and safe spot-fading components of the yeast peptide, the rice ferment filtrate and the saussurea involucrata fermentation liquor are added into a formula of the moisturizing banishing essence, the safety is high, and skin melanin and color spots can be effectivelyconfronted; the mass ratio of the beta-glucan to the tremella fuciformis fruit body extract is controlled in an implementation process, so that the prepared moisturizing banishing essence has excellent moisturizing property.

Owner:湖南美媛本草生物工程有限公司

Washable anti-counterfeiting hot stamping film and preparation method thereof

ActiveCN114407547AGood weather resistanceImprove acid and alkali corrosion resistancePackage recyclingPattern printingHot stampingStructural engineering

The washable anti-counterfeiting hot stamping film comprises a base material layer, a release layer, an imaging layer, a metal reflecting layer and an adhesive layer which are arranged in sequence, a wear-resistant protective layer is arranged between the release layer and the imaging layer; a wear-resistant protective layer is arranged between the imaging layer and the release layer, and a buffer layer is arranged between the wear-resistant protective layer and the imaging layer, so that the wear-resistant protective layer has good wear-resistant, waterproof, weather-resistant and acid and alkali corrosion-resistant effects, and can protect the imaging layer; according to the anti-counterfeiting hot stamping film, the anti-counterfeiting layer is arranged on the anti-counterfeiting hot stamping film, so that the imaging layer can effectively express patterns in a longer time, the buffer layer has good elasticity and plays a role in blocking and buffering, and the phenomenon that the anti-counterfeiting hot stamping film is subjected to negative influence on the release effect and the wear-resisting effect of the finished anti-counterfeiting hot stamping film due to deformation damage of the anti-counterfeiting hot stamping film and the release layer in the imaging process is avoided; and the imaging effect of the finished hot stamping film can be improved.

Owner:江苏泰佳新材料科技有限公司

Chip packaging method and packaging structure

ActiveCN103779245AAvoid disconnectionImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolder maskSolder ball

Provided are a chip packaging method and a packaging structure. The chip packaging method includes the steps of providing a substrate, wherein the substrate comprises a substrate body and a client layer on the surface of the substrate body, the surface of the client layer is a first surface, the surface, opposite to the first surface, of the substrate body is a second surface, and multiple welding pads are formed in the client layer; etching the second surface of the substrate to form a first groove, wherein the welding pads and a part of the surface of the client layer are exposed from the bottom of the first groove; forming an insulating layer on the surface of the inner wall of the first groove; forming a second groove which sequentially penetrates through the adjacent welding pads and the client layer between the adjacent welding pads in the arrangement direction of the welding pads; forming wiring metal layers on the surface of the first groove, the surface of the second groove and the surface of the insulating layer; forming solder mask layers on the surfaces of the wiring metal layers, wherein openings are formed in the solder mask layers, and partial surfaces of the wiring metal layers are exposed from the openings; forming solder balls located on the surfaces of the wiring metal layers in the openings. The chip packaging method can improve reliability of the packaging structure.

Owner:CHINA WAFER LEVEL CSP

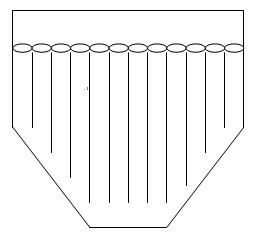

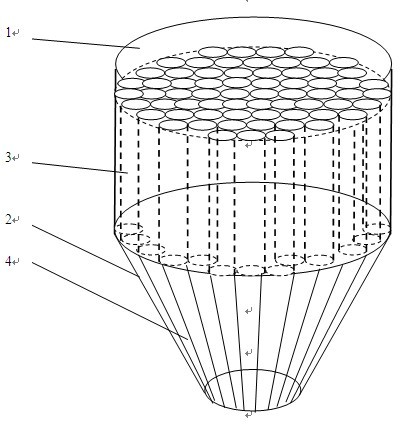

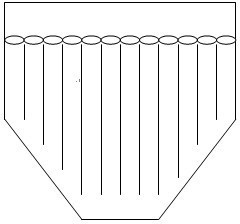

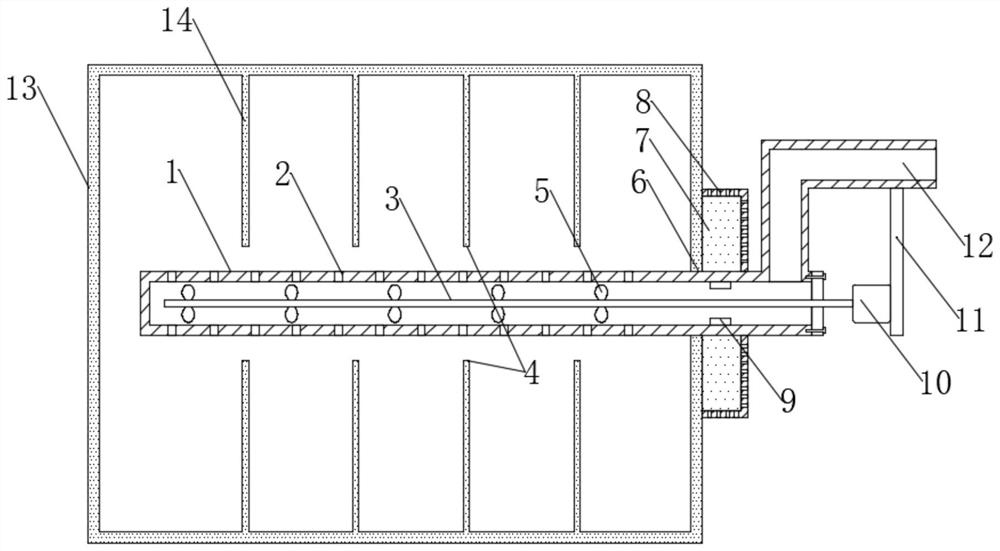

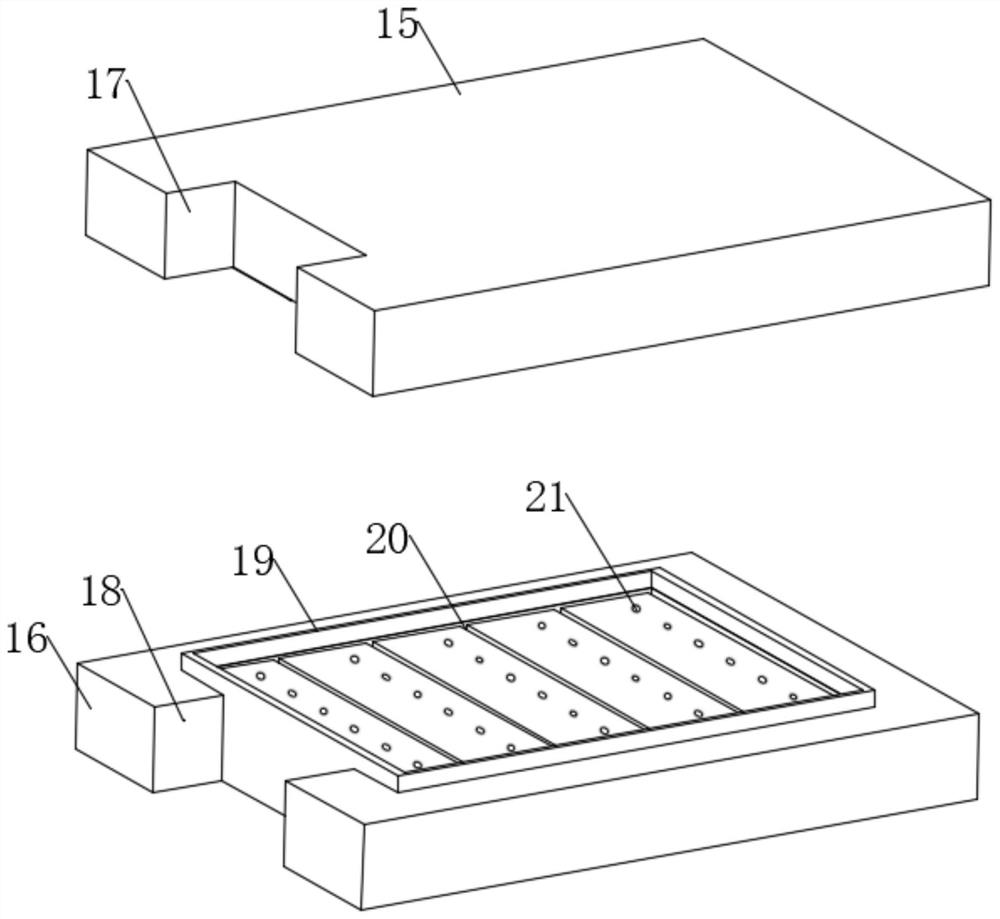

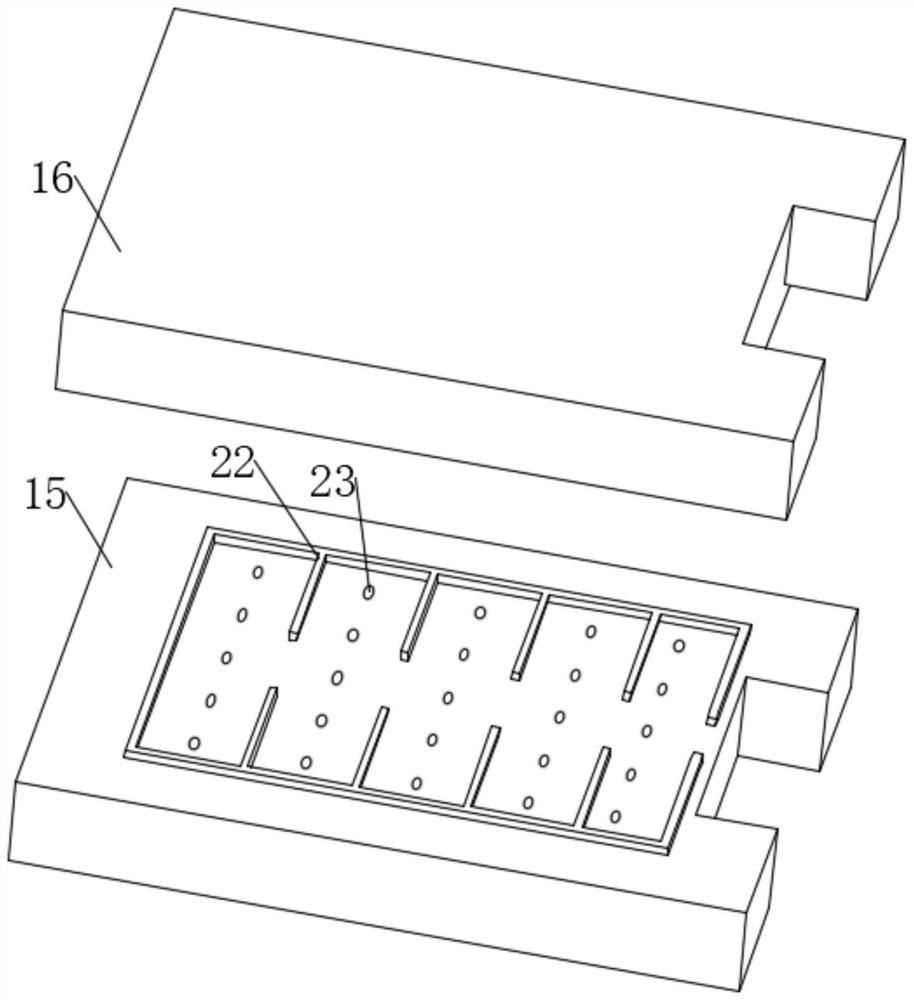

Novel storage bin

ActiveCN102211697AThere will be no stratificationSave spaceLarge containersEngineeringMechanical engineering

The invention relates to a storage bin. The novel storage bin comprises a bin body and is characterized in that: a material unloading passage is formed in the storage bin; and the material unloading passage is extended from an upper port of the storage bin to the lower part of the storage bin. When various particle materials with different specific gravities and shapes are mixed according to different proportions, the phenomenon that the running line speed of particles is different due to different resistances of particles with different densities and particle sizes in the throwing process, so the grading and secondary layering of products are caused by drop point difference of the particles in the conventional process is avoided, and the quality of the product and the stability of fertilizer efficiency are guaranteed.

Owner:SHANDONG AGRI UNIV FERTILIZER TECH CO LTD

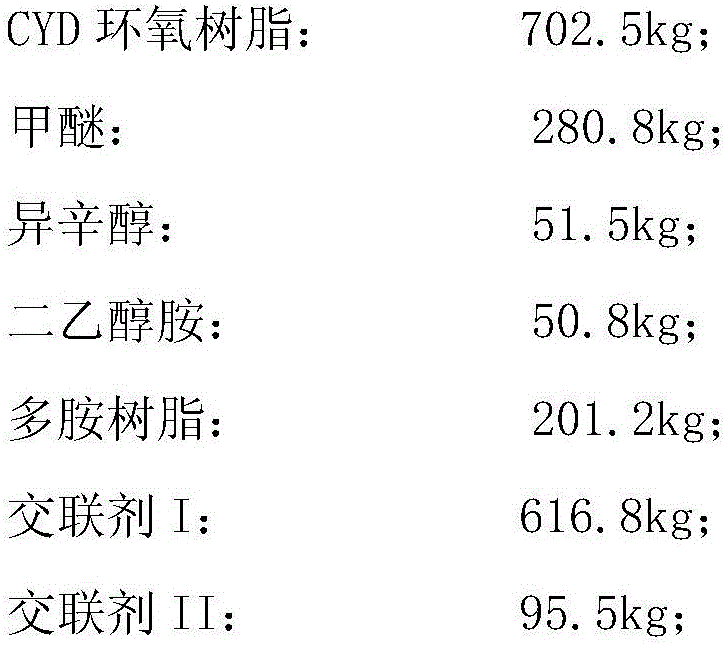

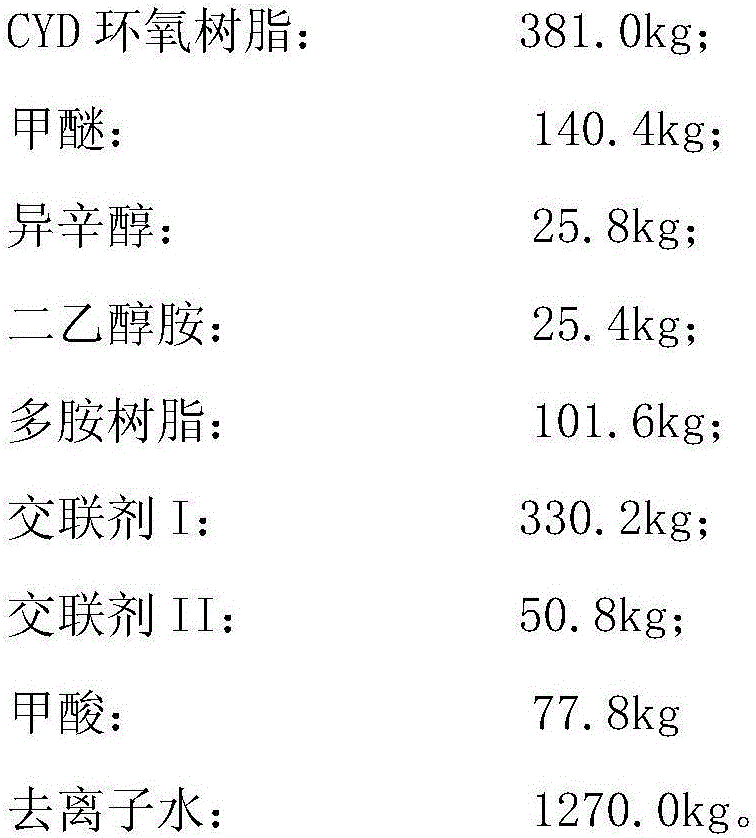

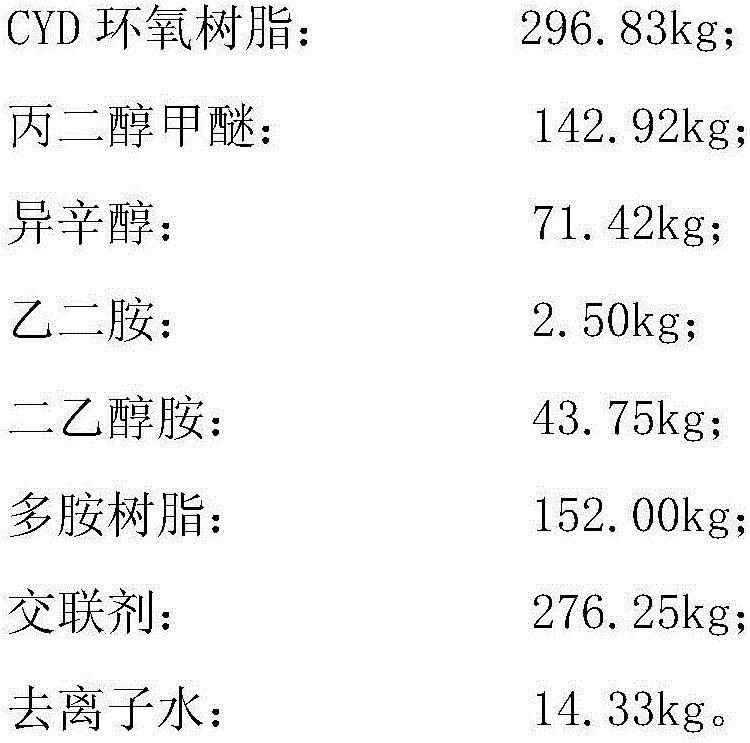

Negative waterborne coating emulsion and production process thereof

ActiveCN105778724ANot volatileAntisepticAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyIsooctyl alcohol

The invention discloses negative waterborne coating emulsion and a production process thereof, belonging to the technical field of anticorrosive coatings. The emulsion comprises 13-21 parts of epoxy resin, 5-9 parts of methyl ether, 1-1.5 parts of isooctyl alcohol, 1-1.5 parts of diethanol amine and 3-6 parts of polyamine resin by weight and is prepared by carrying out chemical reaction and mixing on the components, then carrying out neutralization with 1.5-3 parts by weight of carboxylic acid and then carrying out dispersion in 38-60 parts by weight of deionized water. The emulsion and the production process have the beneficial effects that the loss is low in the emulsion production process, thus reducing the production cost; the emulsion has high throwing power and good levelling property and ductility; and the production process is high in production efficiency and has the effect of improving the product quality.

Owner:WEIFANG HELI WATER BASED PAINT MAKING CO LTD

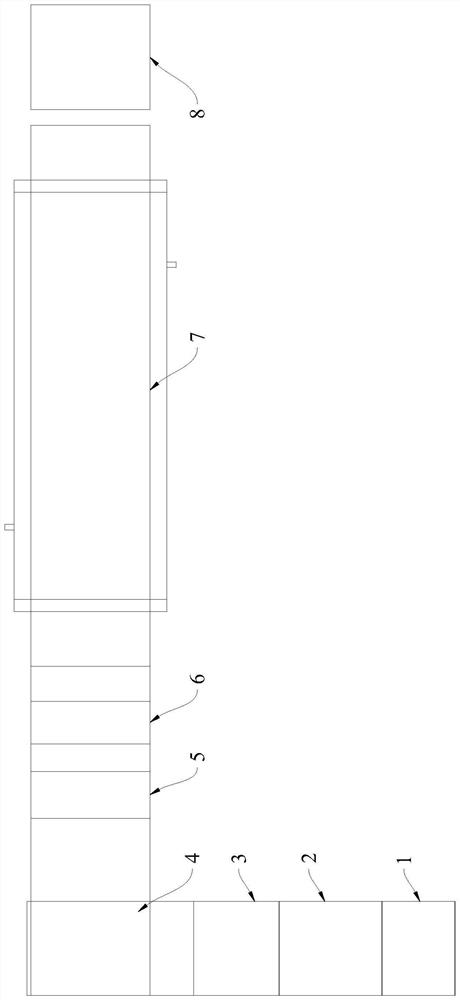

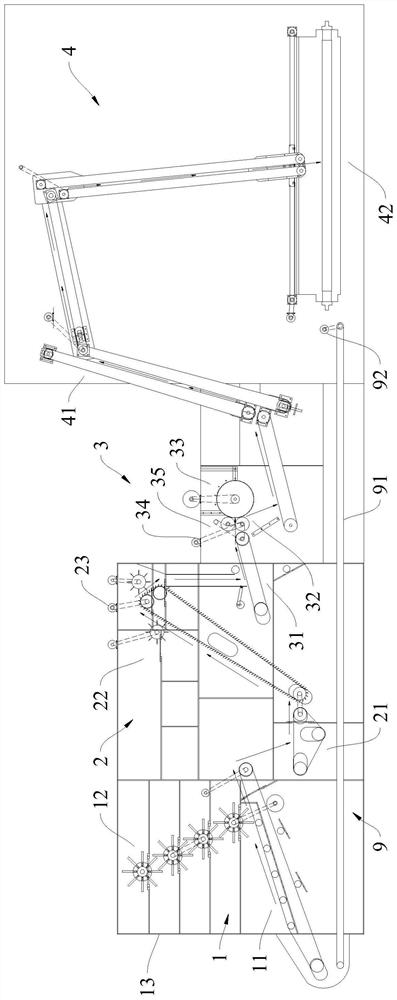

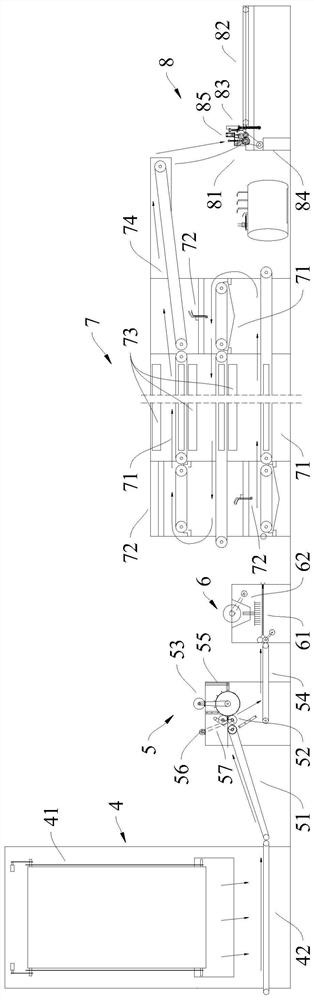

Production line of ultrathin flat coir mat and manufacturing method of flat coir mat

ActiveCN112831912AInto the uniformReduce dosageFibre cleaning/openingSevering textilesProduction lineAdhesive glue

The invention discloses a production line of an ultrathin flat coir mat and a manufacturing method of the flat coir mat. The production line comprises an unpacking device, a material fixing device, a first opening device, a lapping device, a second opening device, a needling device, a rubber spraying and drying device and a cutting device, wherein the unpacking device, the material fixing device, the first opening device, the lapping device, the second opening device, the needling device, the rubber spraying and drying device and the cutting device are sequentially arranged. According to the production line of the ultrathin flat coir mat, the second opening device is additionally arranged on a lapping conveying path to open and scatter a coir web, so that the coir web becomes particularly fluffy, glue can uniformly enter the middle layer of the coir web in a glue spraying process, the usage amount of coir can be reduced, the manufactured coir web is thinner than an existing coir web, the produced flat coir mat is thinner, the phenomenon of breakage is avoided, the product quality is improved, and more purposes can be achieved.

Owner:刘超

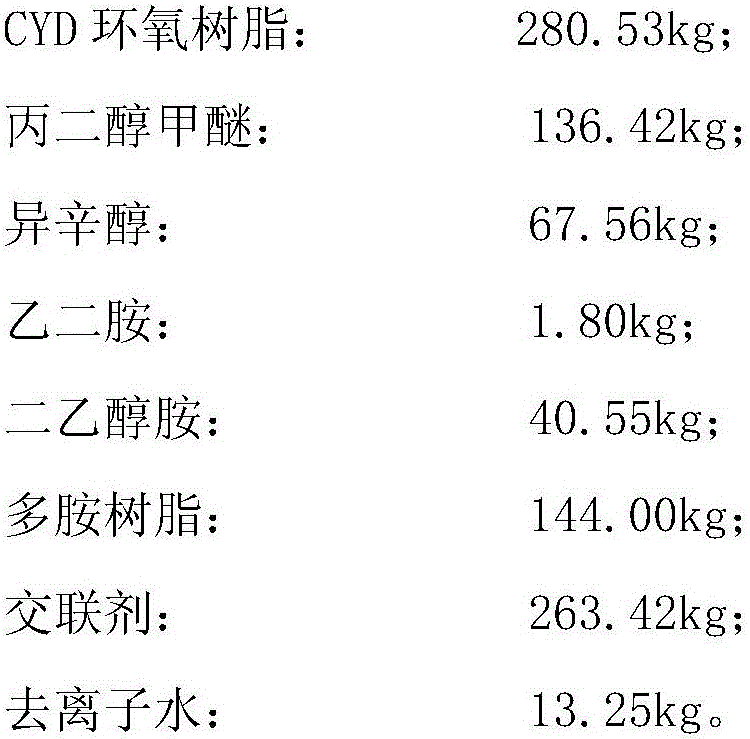

Resin color paste and production process thereof

The invention discloses resin color paste and a production process thereof, and belongs to the technical field of anticorrosive paint. The resin color paste is prepared by performing chemical reaction and mixing on 260 to 330 parts of epoxy resin, 130 to 160 parts of ether alcohol solvents, 60 to 80 parts of isooctanol, 35 to 50 parts of diethanolameineb and 100 to 200 parts of polyamine resin and dispersing the obtained material in 10 to 20 parts of de-ionized water through being metered in parts by weight. The production process comprises epoxy resin melting, raw material addition and heat insulation reaction. In the resin color paste production process, the loss is little; the production cost is reduced; the hole shrinkage resistance effect is good; the product quality is improved; the hydrophilicity is high. Through the production process, the ring opening of epoxy resin is proper; the raw material waste is avoided; meanwhile, the water solubility of the epoxy resin is improved; the hole shrinkage of products is eliminated; the product quality is improved.

Owner:WEIFANG HELI WATER BASED PAINT MAKING CO LTD

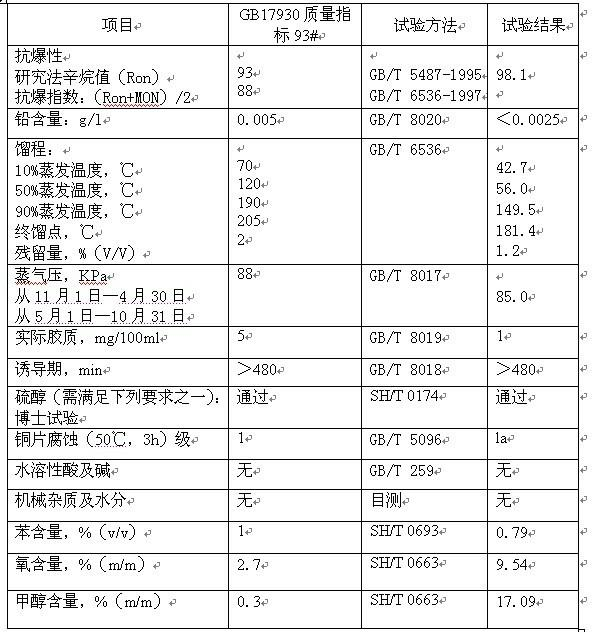

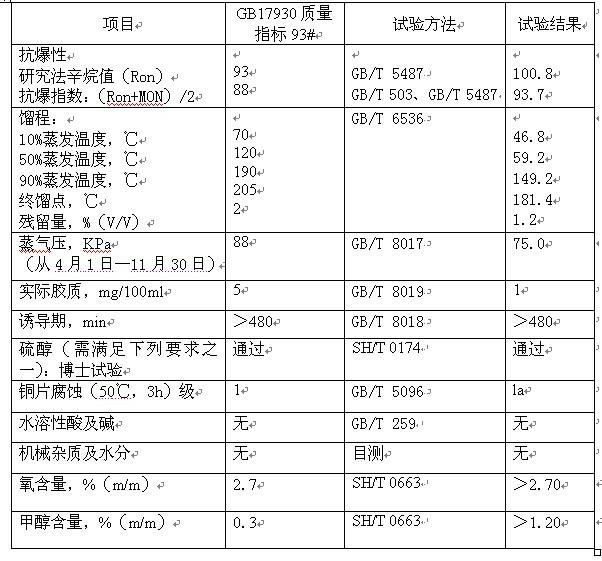

Motor fuel additive and motor high-cleanness gasoline containing same

InactiveCN102304400AImprove antiknock performanceImprove low temperature performanceLiquid carbonaceous fuelsIsobutanolNaphtha

The invention discloses a motor fuel additive and motor high-cleanness gasoline containing the same. The motor fuel additive comprises the following components in percentage by weight: 0.03 to 0.05 percent of ferrocene, 2 to 5 percent of acetone, 3 to 8 percent of isobutanol, 6 to 8 percent of toluene, 2 to 6 percent of isobutylene and the balance of methanol. The motor high-clearness gasoline comprises the following components in percentage by weight: 60 to 80 percent of naphtha and 20 to 40 percent of motor fuel additive. The addition of ferrocene into the motor fuel additive improves the anti-detonating quality of motor vehicles, and conducts functions of reducing carbon accumulation in spray nozzle and assisting combustion; the organic materials including acetone, isobutanol, toluene and isobutylene can improve the swelling performance and intersolubility between methanol and gasoline, improve the low-temperature performance of gasoline, and enhance the cold startup performance of the motor high-clearness gasoline; and isobutanol can lower the sulfur content in fuel and reduce emission of harmful materials. The motor high-cleanness gasoline has the advantages of low corrosion performance, high cold startup performance and uniform quality.

Owner:彭爱国

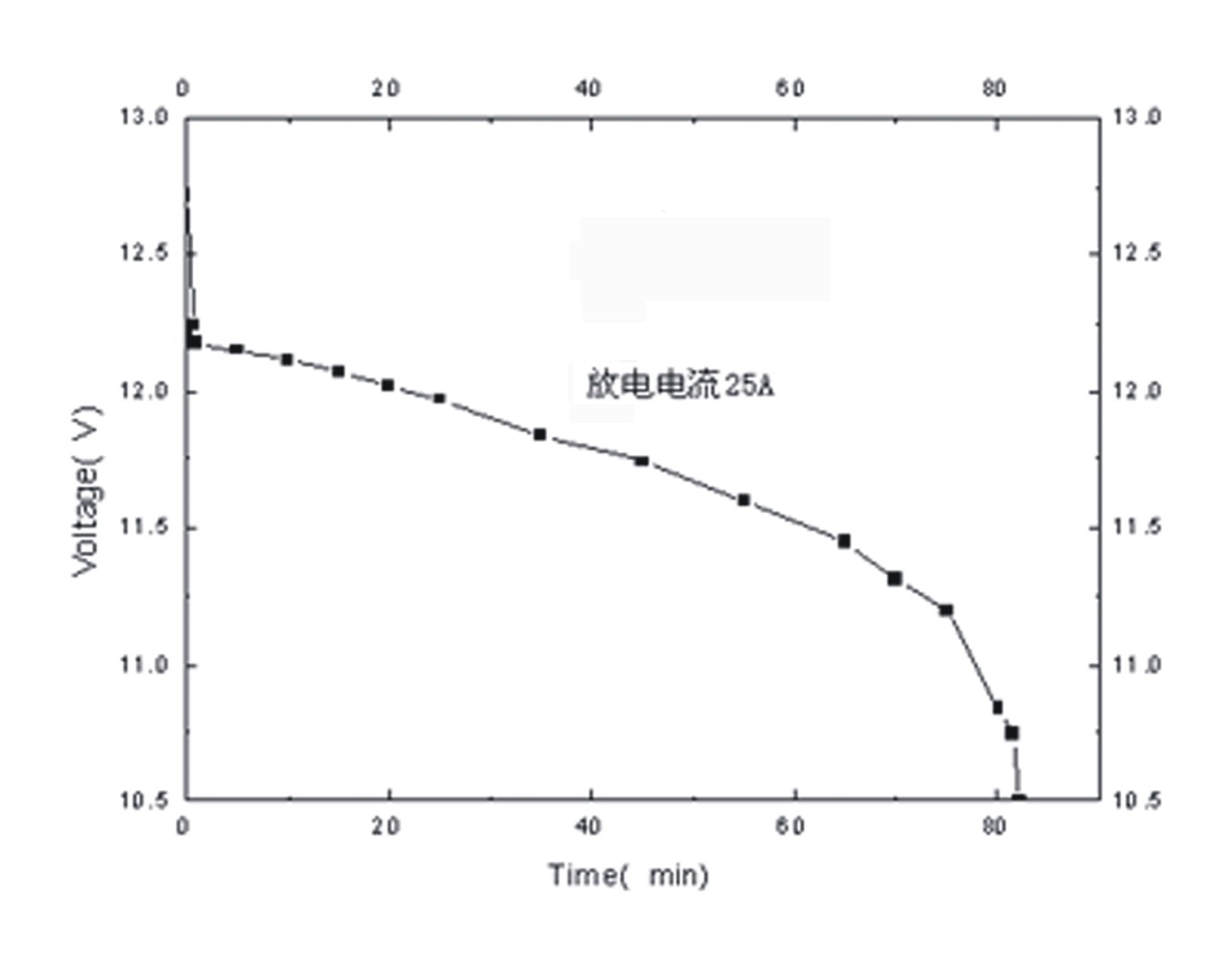

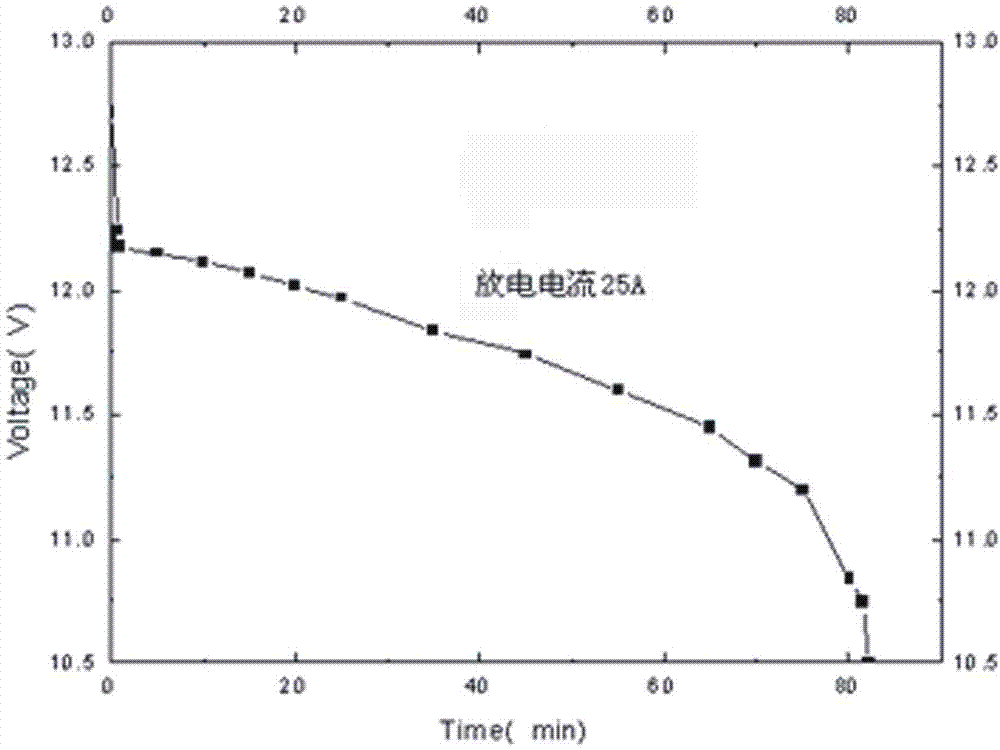

Solid electrolyte for lead-acid storage battery

InactiveCN102646853APrevent leakageSolve dehydrationLead-acid accumulatorsTetrafluoroethyleneColloid

The invention discloses a solid electrolyte for a lead-acid storage battery, which comprises sulfuric acid and a modified tetrafluoroethylene-vinylidene fluoride copolymer with a microporous structure, the quality content of the sulfuric acid in the solid electrolyte ranges between 35% and 65%, and the sulfuric acid is absorbed inside hole passages of the modified tetrafluoroethylene-vinylidene fluoride copolymer with the microporous structure through a capillary action. The solid electrolyte solves the problems of liquid leakage and water loss in lead-acid storage batteries, stratification of a colloidal electrolyte is avoided, and after the lead-acid storage battery of the solid electrolyte is charged and discharge repeatedly for 200 times, voltage and discharge capacity are still good.

Owner:四川久远环通电源有限责任公司

Discharging and packaging mechanism capable of uniformizing material components in food material bags

ActiveCN114180142AEvenly distributedGuaranteed uniformityWrapper twisting/gatheringPackaging foodstuffsMouthfeelEngineering

The discharging and packaging mechanism comprises a discharging mechanism and a packaging mechanism, the discharging mechanism comprises a feeding pipeline, a transmission shaft is arranged in the feeding pipeline, a rotating plate is fixedly arranged on the transmission shaft, one end of the feeding pipeline extends into a plastic packaging bag, and the other end of the feeding pipeline extends into the packaging bag. The feeding pipeline is provided with a plurality of sets of feeding outlets penetrating through the interior and the exterior, the side face of the end, located outside the plastic packaging bag, of the feeding pipeline communicates with an external feeding pipe, the discharging mechanism can evenly convey and store materials into the plastic packaging bag, and the phenomena that the materials in the plastic packaging bag are layered and separated from one another are avoided; the phenomenon that in the prior art, even utilization of ingredients in the sauce cannot be guaranteed when people eat part of the sauce in a plastic packaging bag is solved, the sauce in the plastic packaging bag is evenly distributed after the discharging mechanism is used, even distribution of the ingredients can be guaranteed when people eat part of the sauce in the plastic packaging bag, and the taste is not affected.

Owner:HUAINAN YISHENG FOOD

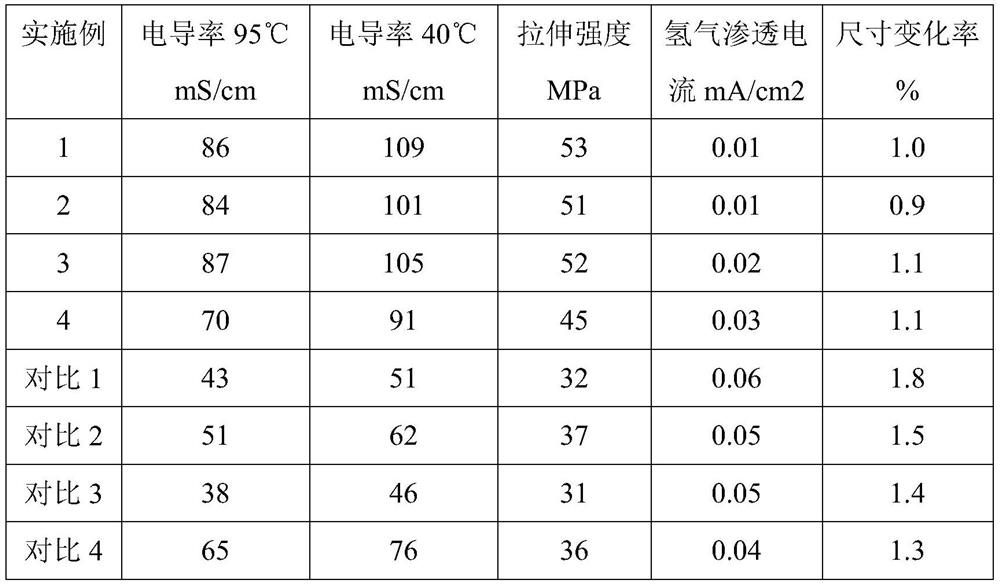

Multilayer proton exchange membrane for water electrolysis and preparation method thereof

The invention discloses a multi-layer proton exchange membrane for water electrolysis, the multi-layer proton exchange membrane comprises a five-layer structure which sequentially comprises a long side chain perfluorinated sulfonic acid resin layer, a short side chain perfluorinated sulfonic acid resin layer, a microporous layer, a short side chain perfluorinated sulfonic acid resin layer and a long side chain perfluorinated sulfonic acid resin layer, and the preparation method comprises the following steps: firstly, dissolving long side chain resin and short side chain resin to prepare a membrane casting solution; secondly, filling the long-side-chain perfluorinated sulfonic acid resin solution and the short-side-chain perfluorinated sulfonic acid resin solution into a coating die head for layered coating and film forming; laying a polytetrafluoroethylene microporous membrane again, and carrying out layered coating on the long and short side chain perfluorinated sulfonic acid resin solution to obtain a composite structure; and rolling and laminating the prepared composite layer II to obtain the multi-layer proton exchange membrane for water electrolysis. The proton exchange membrane disclosed by the invention is better in uniformity; the long side chain resin and the short side chain resin are alternated, so that high conductivity under low IEC can be realized, the proton exchange composite membrane has relatively good chemical stability, dimensional stability and relatively high conductivity, and the problems of poor proton conductivity and short service life in the operation process are solved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

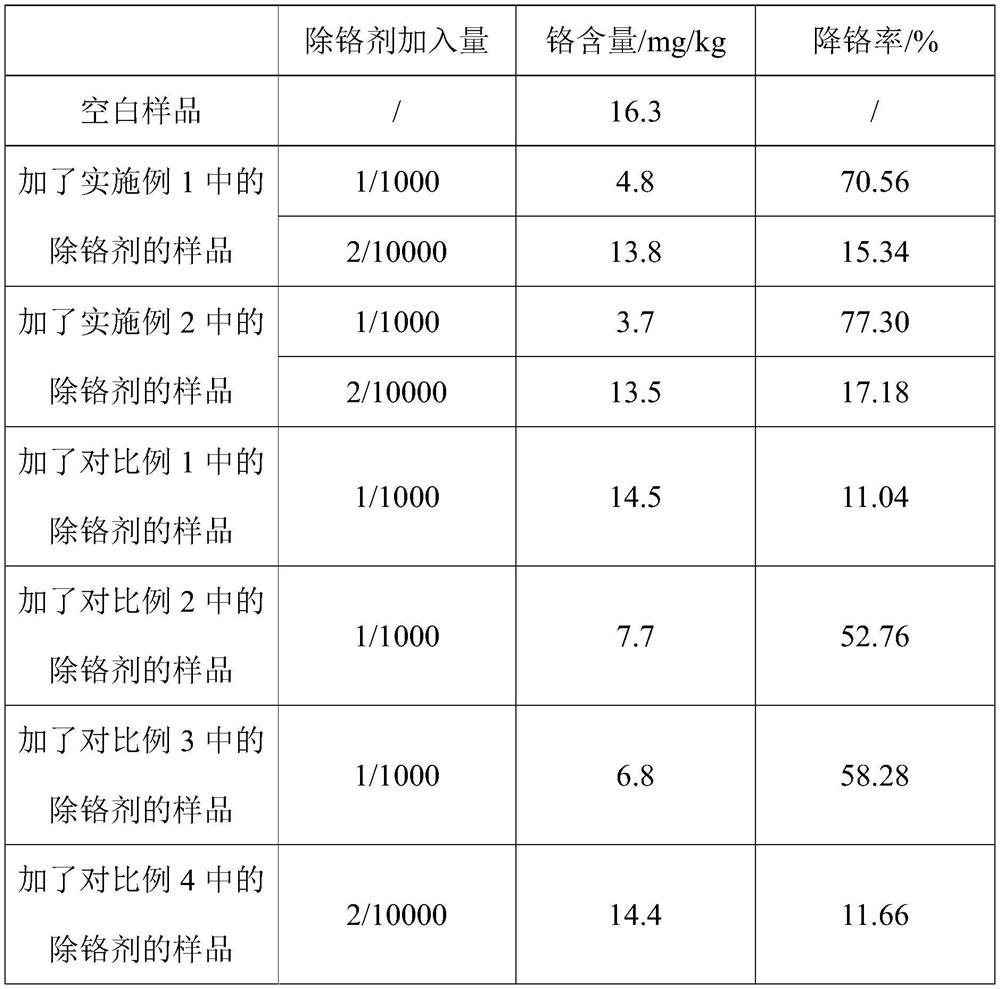

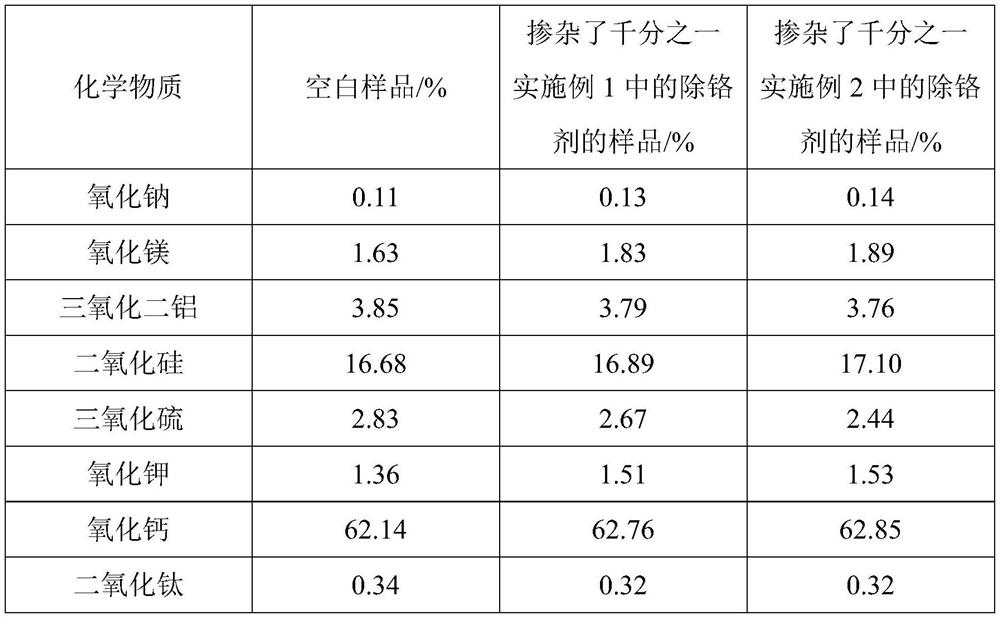

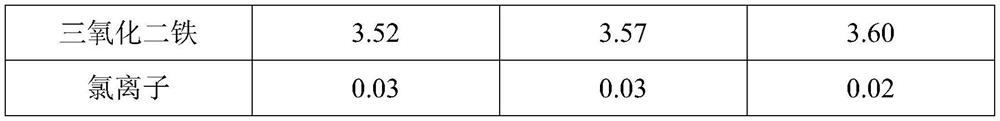

Ferrous sulfate-antimony trisulfide composite liquid chromium removal agent as well as preparation method and application thereof

ActiveCN114213056AReductiveImprove the effect of chromium removalProcess efficiency improvementFerrous sulfate heptahydrateOrganosolv

The invention discloses a ferrous sulfate-antimony trisulfide composite liquid chromium removal agent as well as a preparation method and application thereof. The composite liquid chromium removal agent comprises the following raw materials in percentage by mass: 18%-19% of ferrous sulfate heptahydrate, 12%-13% of antimony trisulfide, 31%-32% of water, 4%-5% of an organic solvent and 32%-35% of dextrin. The ferrous sulfate-antimony trisulfide composite liquid chromium removal agent with high stability and good chromium removal effect is prepared by taking ferrous sulfate heptahydrate and antimony trisulfide as reducing agents, water and an organic solvent as solvents and dextrin as a stabilizer. And adverse effects on chemical components, standard consistency, setting time, stability and fineness of the cement are avoided.

Owner:安徽精公检测检验中心有限公司

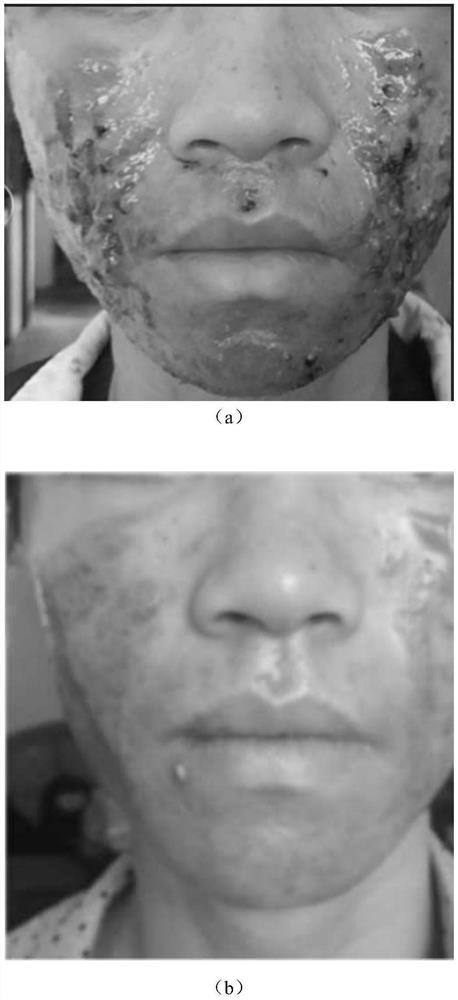

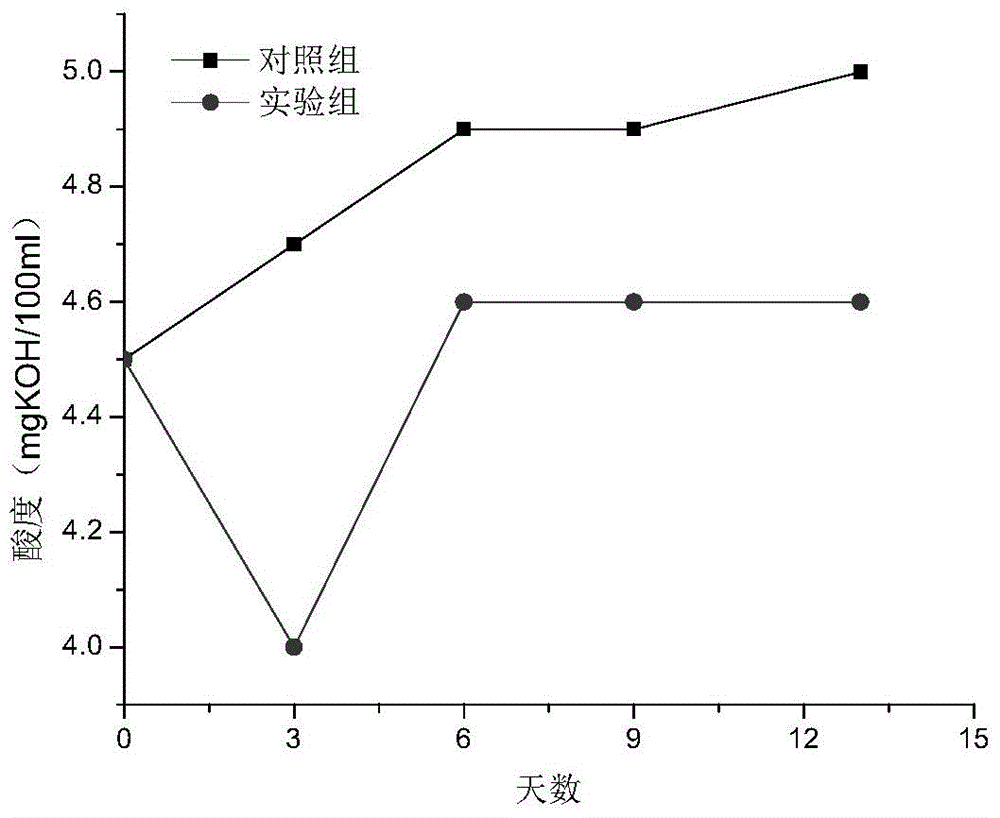

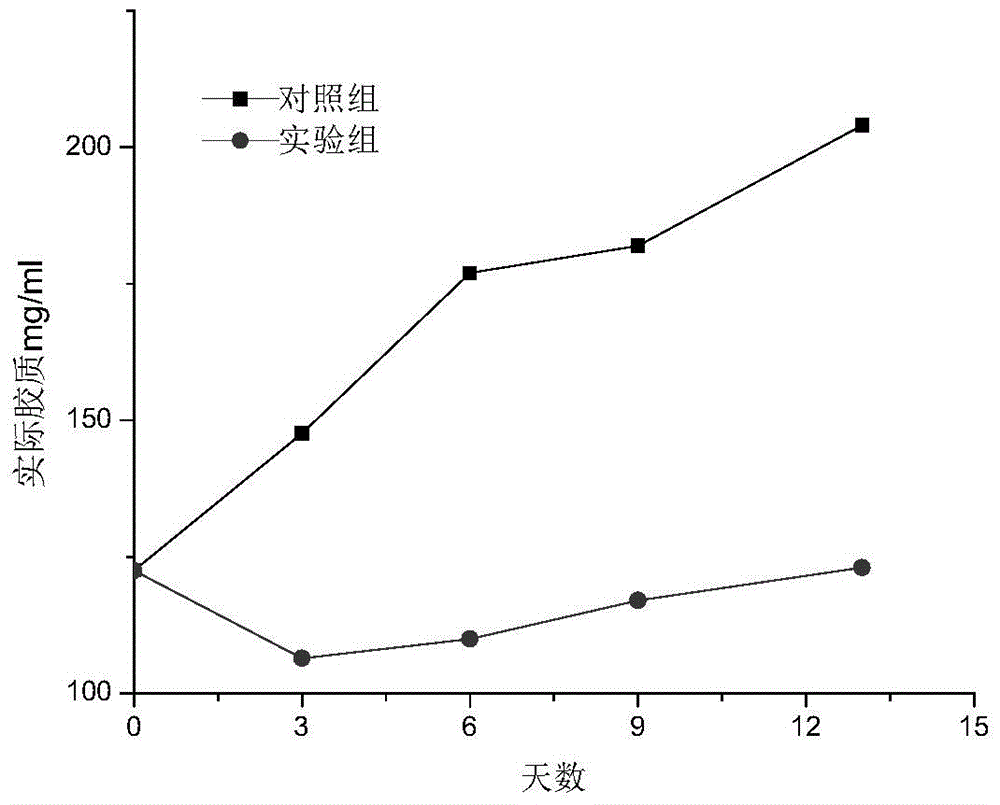

Ozone liquid dressing applied to skin diseases and preparation method thereof

PendingCN113769149AGood emulsifying effectEasy to operateAntibacterial agentsAntipyreticGlycerolAcrylic acid

The invention discloses an ozone liquid dressing applied to skin diseases and a preparation method thereof. The ozone liquid dressing is prepared from ozone oil, water, glycerol, maltitol, betaine, propylene glycol, trehalose, 1, 2-hexanediol, hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, isoprene glycol, ammonium acryloyldimethyl taurate / VP copolymer, methylparaben, dipotassium glycyrrhizinate, polyacrylate cross-linked polymer-6, EDTA (ethylene diamine tetraacetic acid) disodium, an oat kernel extract, p-hydroxyacetophenone, butanediol and a Chinese herbaceous peony root extract. The prepared ozone liquid dressing is good in emulsification effect, uniform in ozone distribution and free of layering phenomenon after being placed for a long time.

Owner:彭彬

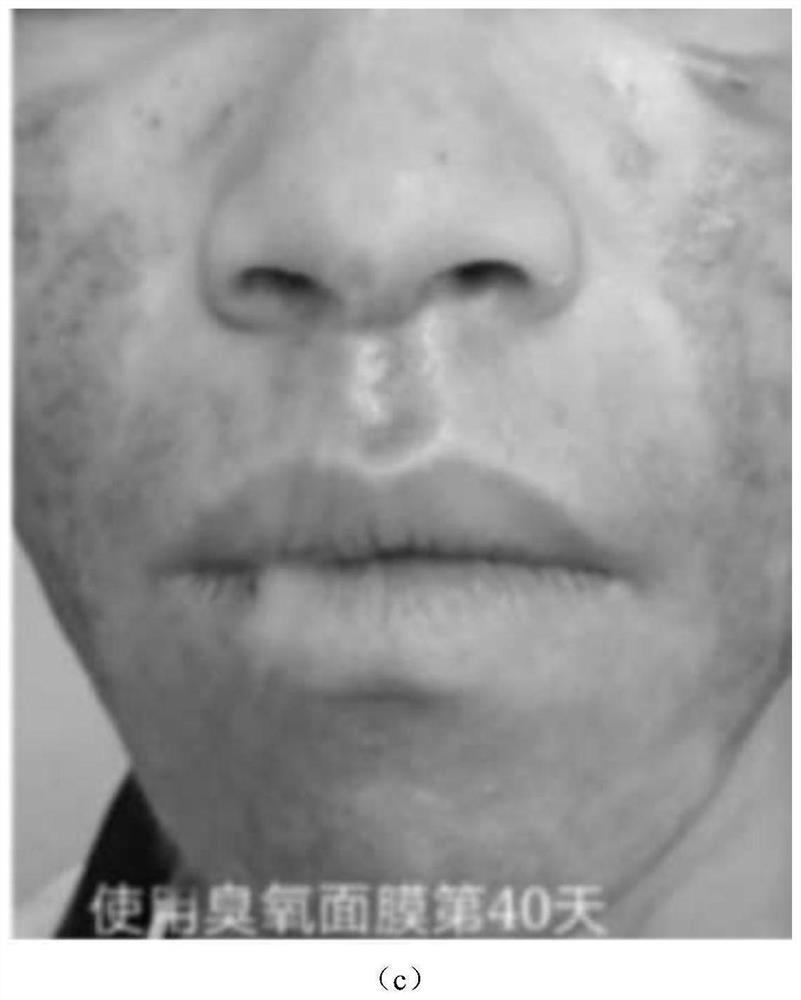

High surface tension polypropylene composite material and preparation method thereof

The invention discloses a high surface tension polypropylene composite material and a preparation method thereof, the composite material is prepared from the following components by weight: 43-83 parts of polypropylene, 2-6 parts of polyethylene, 5-15 parts of nylon 6, 3-15 parts of a flexibilizer, 5-15 parts of an inorganic filler, 2-6 parts of a polar modifier, 0.5-1.0 part of an antioxidant, 0.1-0.5 part of a processing aid, and 0.8-1.5 parts of stearic acid ethoxyamide. The polar modifier is at least one of a methyl methacrylate grafted ethylene-1-octylene copolymer and a glycidyl methacrylate grafted ethylene-1-octylene copolymer. The added polar modifier has better compatibility with the nylon 6, increases the phase interface thickness, and has more significant toughening effect on the nylon 6; by adding a weak-polarity assistant stearic acid ethoxy amide, the polarity of the modified polypropylene material is improved in an auxiliary manner, and the surface tension of the material is improved.

Owner:HEFEI GENIUS NEW MATERIALS

Decorative gypsum terrace and decorative gypsum board and preparation method thereof

The invention discloses a decorative gypsum terrace and a decorative gypsum board and a preparation method thereof. The method comprises the following steps of (1) designing a pattern gypsum layer manufacturing mold according to the required pattern, casting the colorful gypsum slurry into the pattern gypsum layer manufacturing mold, and drying to obtain a colorful pattern gypsum block; (2) putting the colorful pattern gypsum block obtained in the step 1 into a ground or a plate mold, casting a main gypsum casting material into the ground or the plate mold, solidifying to form a main gypsum layer, so as to obtain a decorative gypsum terrace or a decorative gypsum board crude product; and (3) after standing for 2-6 hours at room temperature, carrying out water grinding, so that washing themain gypsum casting material covered on the colorful pattern gypsum block away by water; or standing until the main gypsum casting material is completely dried, grinding into powder through a grindingmachine, and blowing or sucking the powder to remove the powder. The main gypsum layer and the colorful pattern gypsum block in the decorative gypsum terrace or the decorative gypsum board are integrated, and the phenomenon of layering is avoided.

Owner:JINGMEN QIAN NIAN JIAN HEALTH CARE TECH

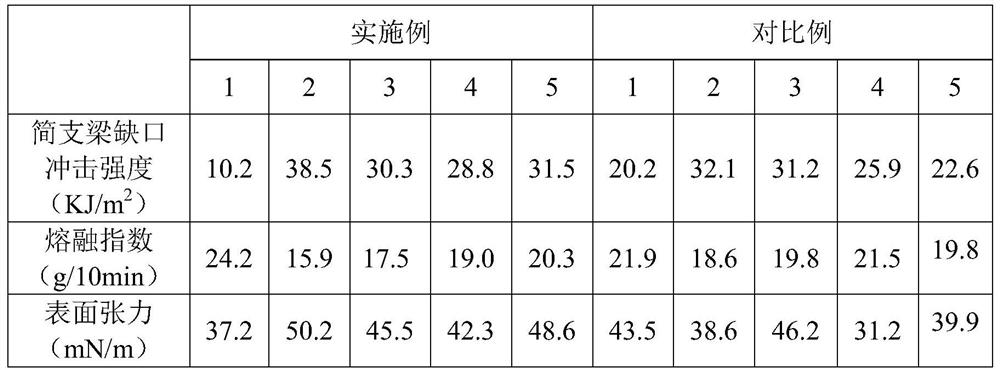

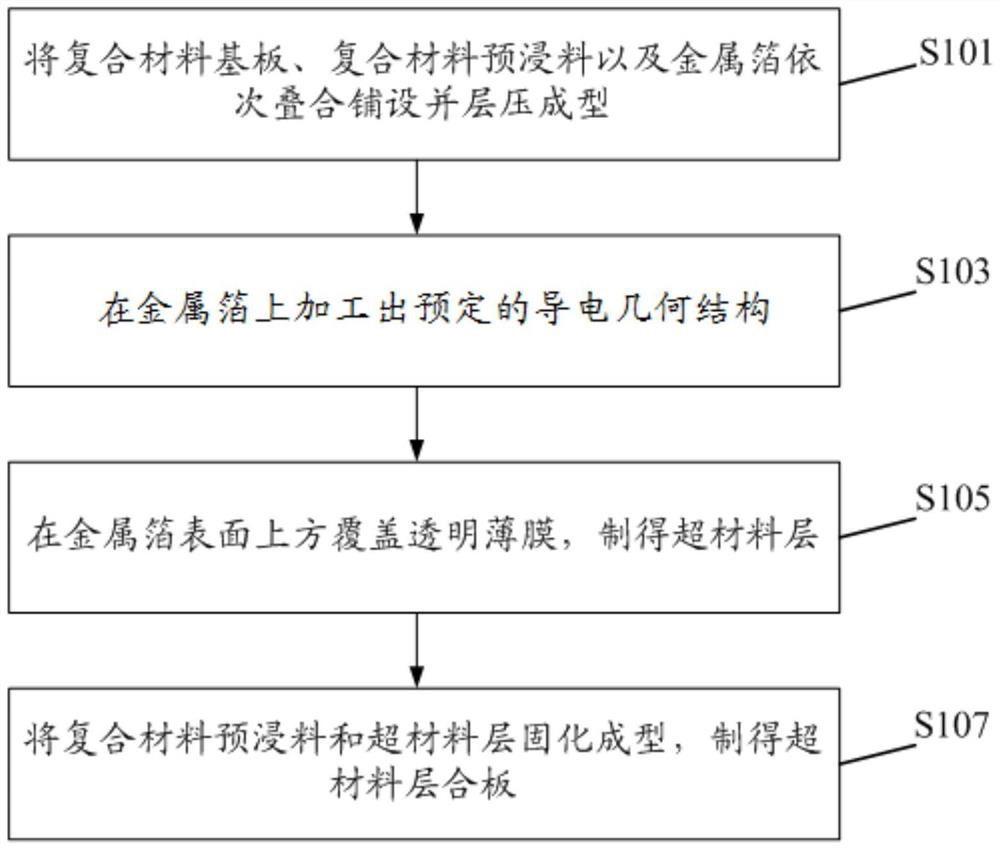

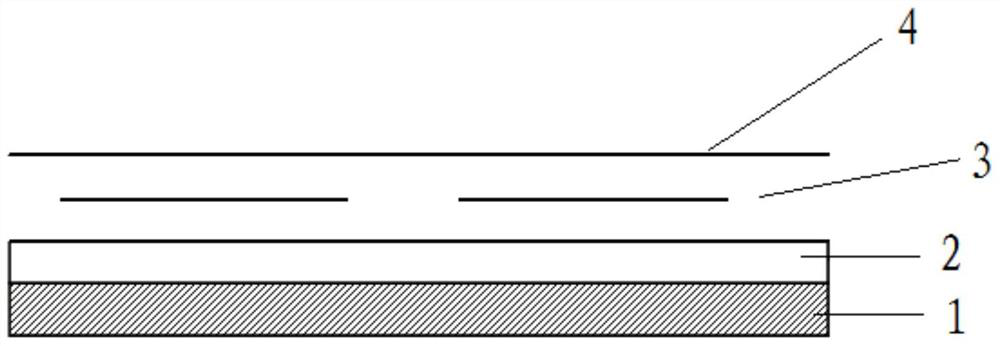

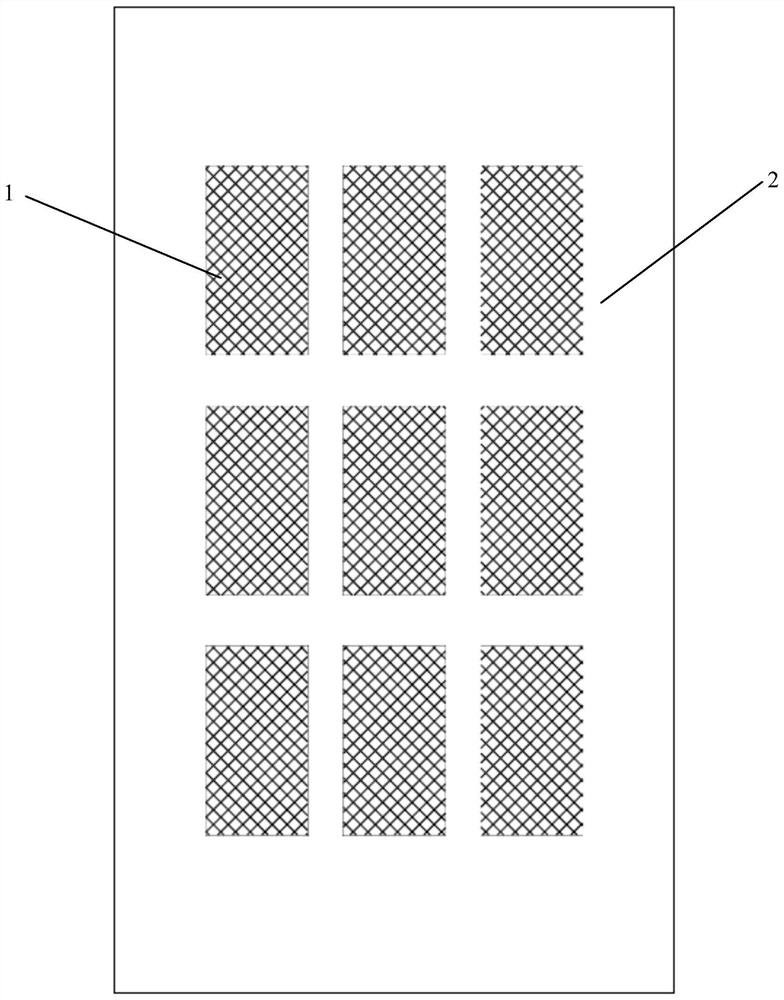

A kind of metamaterial laminated board and preparation method thereof

ActiveCN107089050BIncrease binding areaThere will be no stratificationLaminationLamination apparatusThermal dilatationMetallic foil

The invention provides a metamaterial laminate and a preparing method thereof. The method comprises the steps of conducting lamination, laying and laminating forming on a composite material substrate, a composite material prepreg and tinsel in sequence; machining a predetermined conductive geometric structure on tinsel; covering the upper portion of the surface of tinsel with transparent thin film to prepare a metamaterial layer; conducting curing molding on the composite material prepreg and the metamaterial layer to prepare the metamaterial laminate. In the metamaterial laminate prepared through the method, the binding areas among different layers of the metamaterial laminate are broadened, the thermal expansion stress among different materials is reduced, the structural stability of the metamaterial laminate is strengthened, and thus the situation that the laminate is layered cannot occur; meanwhile, metal material carriers are reduced, and the strength of the laminate is drastically improved on the condition that important performance of electrical performance, stealth performance and the like is not changed.

Owner:KUANG CHI INST OF ADVANCED TECH +1

Solid electrolyte for lead-acid storage battery

The invention discloses a solid electrolyte for a lead-acid storage battery, which comprises sulfuric acid and a modified tetrafluoroethylene-vinylidene fluoride copolymer with a microporous structure, the quality content of the sulfuric acid in the solid electrolyte ranges between 35% and 65%, and the sulfuric acid is absorbed inside hole passages of the modified tetrafluoroethylene-vinylidene fluoride copolymer with the microporous structure through a capillary action. The solid electrolyte solves the problems of liquid leakage and water loss in lead-acid storage batteries, stratification of a colloidal electrolyte is avoided, and after the lead-acid storage battery of the solid electrolyte is charged and discharge repeatedly for 200 times, voltage and discharge capacity are still good.

Owner:四川久远环通电源有限责任公司

Biological tendon repair material and preparation method thereof

ActiveCN107854727BPromote growthEasy to climbTissue regenerationProsthesisCell-Extracellular MatrixCellular infiltration

The invention provides a biological tendon repairing material and a preparation method thereof. The biological tendon repairing material comprises an extracellular matrix body subjected to immunogen removal, wherein the extracellular matrix body consists of one or more layers and comprises a first surface and a second surface; the first surface comprises a first area and a second area; the mechanical strength of the first area is lower than that the second area. During preparation of an extracellular matrix subjected to immunogen removal, layering is avoided. As the biological tendon repairingmaterial is provided with the surface which consists of the first area and the second area, cellular infiltration of defective tissues is facilitated, tissue repairing is accomplished, stress born bythe repairing material can be uniformly distributed, and local stress cannot be excessively large. Besides, the surface has a high suture retention force and can serve as the second surface of a suture area of the repairing material, and the strength of the repairing material can be guaranteed while repairing of the defective tissues is facilitated.

Owner:BEIJING BIOSIS HEALING BIOLOGICAL TECH

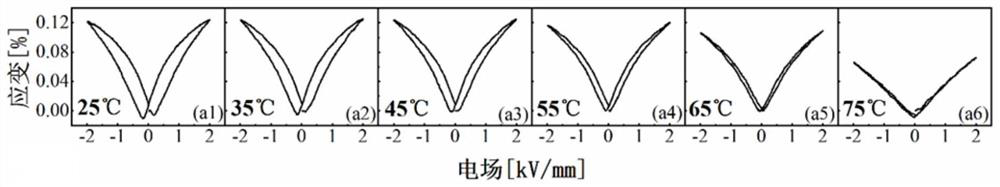

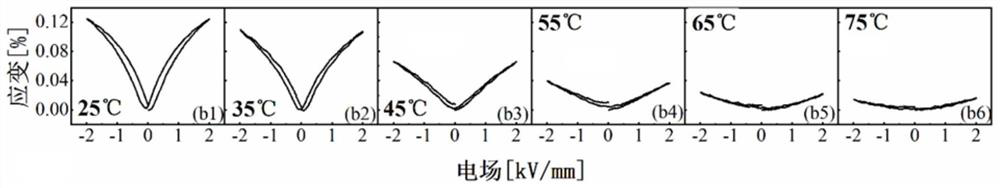

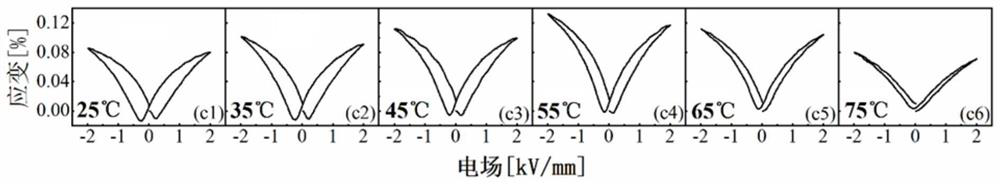

Piezoelectric ceramic with laminated structure and preparation method and application thereof

ActiveCN114149258AImproving temperature stability of electrostrainHigh electrostrainPiezoelectric/electrostrictive/magnetostrictive devicesCeramicCeramic materials

The invention discloses piezoelectric ceramic with a laminated structure as well as a preparation method and application of the piezoelectric ceramic. The preparation method of the piezoelectric ceramic with the laminated structure comprises the following steps: obtaining raw material powder: obtaining piezoelectric ceramic powder of at least two systems with different Curie temperature points, taking corresponding components of multiphase coexistence points of the respective systems as cores, and respectively selecting the cores and components floating within 15% on the two sides of the cores as the piezoelectric ceramic powder; and preparing a finished product: superposing the piezoelectric ceramic powder layer by layer to form a semi-finished product with a laminated structure, sintering, cleaning, cutting and sputtering to prepare the finished product. The electrostrictive strain of the piezoelectric ceramic with the laminated structure prepared by the invention almost expresses relatively high electrostrictive strain in a single component at different temperatures, that is, the peak value of the piezoelectric ceramic with the laminated structure in the temperature range interval is equal to or even higher than the peak values of BTS0.105 piezoelectric ceramic and BTH0.11 piezoelectric ceramic, and the piezoelectric ceramic has a comprehensive effect.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

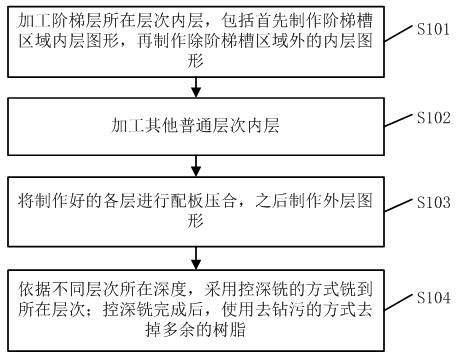

Multilayer step PCB manufacturing method, PCB and electronic equipment

PendingCN114286528AGood reliabilityShort processConductive pattern formationConductive material chemical/electrolytical removalManufacturing engineeringIndustrial engineering

The invention relates to the field of PCB manufacturing, and particularly discloses a multi-layer step PCB manufacturing method, a PCB and electronic equipment, the inner layer of the layer where a step layer is located is machined, and the method comprises the steps that firstly, an inner layer pattern of a step groove area is manufactured, and then an inner layer pattern except the step groove area is manufactured; inner layers of other common layers are processed; the manufactured layers are subjected to board matching and pressing, and then an outer layer pattern is manufactured; according to the depths of different layers, the layers are milled in a depth-controlled milling mode; and after depth-controlled milling is completed, redundant resin is removed in a drilling dirt removing mode. In the manufacturing process, the inner layer of the layer where the step layer is located is manufactured firstly, the depth is controlled during outer side depth-controlled milling, it is guaranteed that no adhesive residue exists, then redundant resin is removed in a drilling dirt removing mode, finally, the PCB is manufactured in a one-time pressing mode, machining of the step PCB of any layer can be achieved, the layering situation is avoided, and reliability is good; the process is short, the cost is low, and any manual operation is not needed; and gummosis at the step can be completely avoided.

Owner:SUZHOU LANGCHAO INTELLIGENT TECH CO LTD

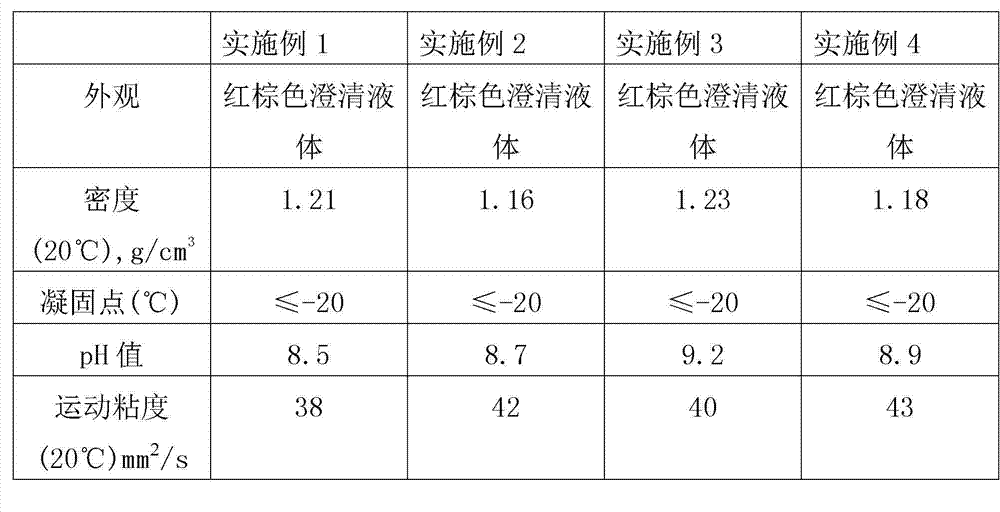

Water-soluble high-temperature corrosion inhibitor

ActiveCN102965148AGood water solubilityAvoid erosionTreatment apparatus corrosion/fouling inhibitionSolventSolubility

The invention discloses a water-soluble high-temperature corrosion inhibitor, which belongs to the technical field of metal corrosion and protection. The corrosion inhibitor disclosed by the invention is composed of the following components in percentage by mass: 6.5-7.6% of a boracic acid, 10-11.3% of glycerin, 7.9-9.2% of monoethanolamine, 20-40% of sulfonated castor oil, and the balance of water. The raw materials used in the invention are non-toxic, and have no side effects on products and the subsequent processing of products; the water-soluble high-temperature corrosion inhibitor disclosed by the invention is good in water-solubility, no cosolvent is not required to be added when the corrosion inhibitor is used in a formula, and no laying phenomenon occurs when the corrosion inhibitor is compounded with any organic amine, thereby facilitating a neutralization reaction between the corrosion inhibitor and a naphthenic acid in raw oil; and a rust-proof complex of the corrosion inhibitor in the invention and sulfonated castor oil can form a dense and firm protective film in a high-temperature tower, thereby effectively preventing the raw oil from eroding the inner wall of the tower.

Owner:江苏汉光实业股份有限公司

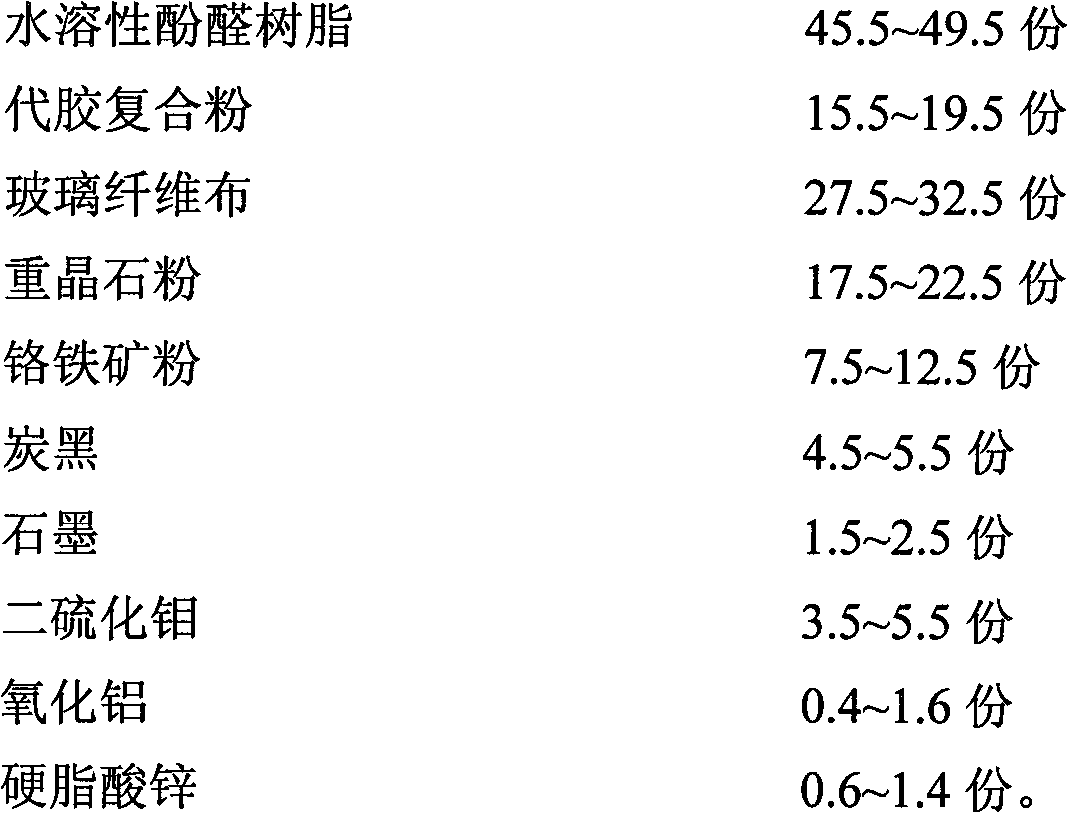

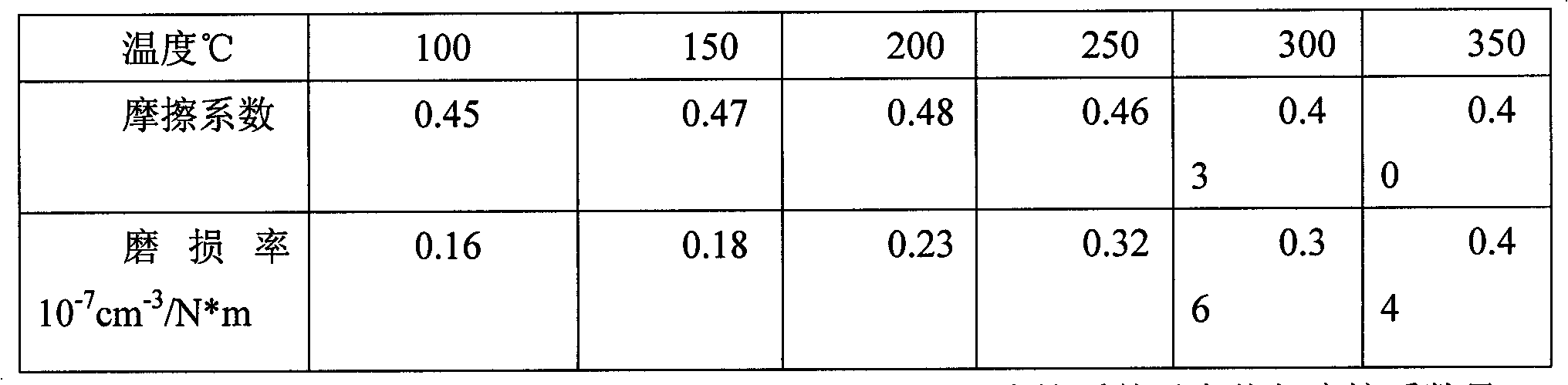

Clutch facing without rubber winding and preparation method thereof

The present invention provides a clutch facing without rubber winding and a preparation method thereof. The abrasion resistance and heat resistance of the product are poor, because rubber is used as a binder for the conventional clutch facing. Large amount of organic solvents are used in the preparation process, resulting in large environmental pollution and high production cost. The water-soluble phenolic resin and the rubber-substituting composite powder are used as a binder in the present invention. The clutch facing includes components by weight: 45.5-49.5 parts of the water-soluble phenolic resin, 15.5-19.5 parts of the rubber-substituting composite powder, 27.5-32.5 parts of glass fiber cloth, 17.5-22.5 parts of barite powder, 7.5-12.5 parts of chromite powder, 4.5-5.5 parts of carbon black, 1.5-2.5 parts of graphite, 3.5-5.5 parts of molybdenum disulfide, 0.4-1.6 parts of alumina, and 0.6-1.4 parts of zinc stearate. The use of the rubber and the organic solvent are prevented in the preparation. The products are good in heat resistance, high and stable in friction coefficient, low in wear rate, and high in rotation burst strength, and can fully meet the requirement of vehicles at high-speed running.

Owner:浙江科马摩擦材料股份有限公司

A kind of diesel oil cleaning life extension material and preparation method thereof

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA

Water-soluble high-temperature corrosion inhibitor

ActiveCN102965148BGood water solubilityConducive to neutralizationTreatment apparatus corrosion/fouling inhibitionSolubilityGlycerol

The invention discloses a water-soluble high-temperature corrosion inhibitor, which belongs to the technical field of metal corrosion and protection. The corrosion inhibitor disclosed by the invention is composed of the following components in percentage by mass: 6.5-7.6% of a boracic acid, 10-11.3% of glycerin, 7.9-9.2% of monoethanolamine, 20-40% of sulfonated castor oil, and the balance of water. The raw materials used in the invention are non-toxic, and have no side effects on products and the subsequent processing of products; the water-soluble high-temperature corrosion inhibitor disclosed by the invention is good in water-solubility, no cosolvent is not required to be added when the corrosion inhibitor is used in a formula, and no laying phenomenon occurs when the corrosion inhibitor is compounded with any organic amine, thereby facilitating a neutralization reaction between the corrosion inhibitor and a naphthenic acid in raw oil; and a rust-proof complex of the corrosion inhibitor in the invention and sulfonated castor oil can form a dense and firm protective film in a high-temperature tower, thereby effectively preventing the raw oil from eroding the inner wall of the tower.

Owner:江苏汉光实业股份有限公司

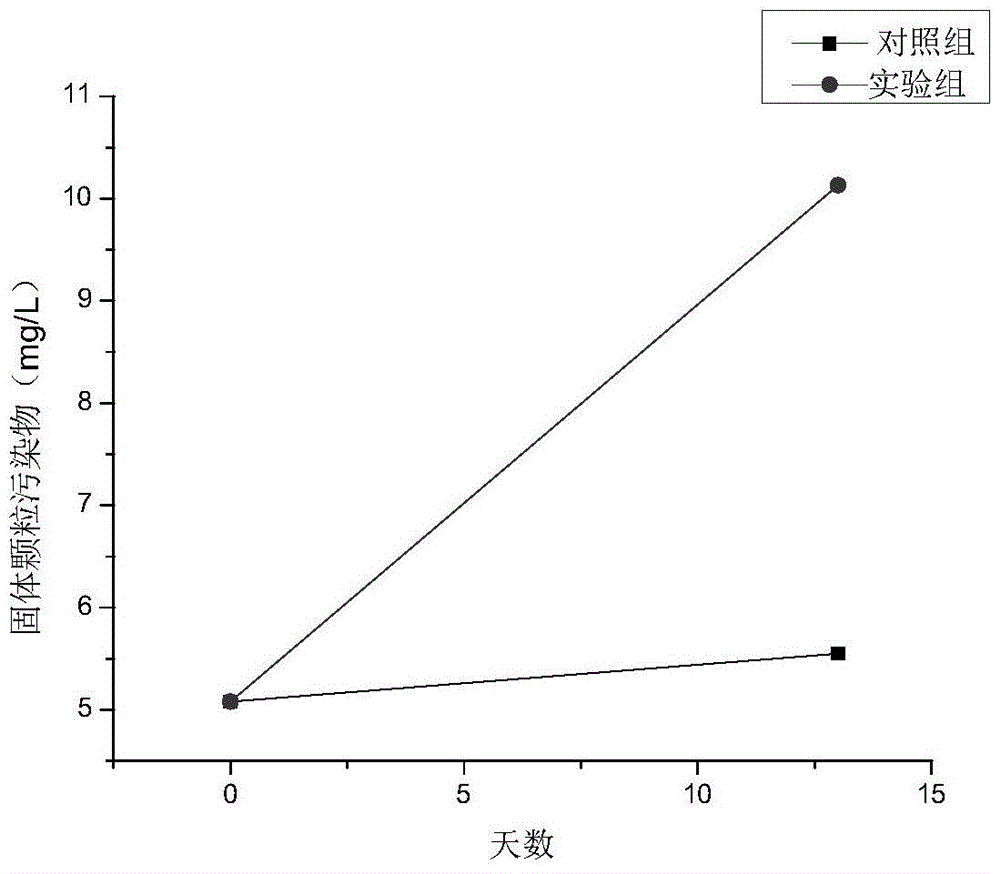

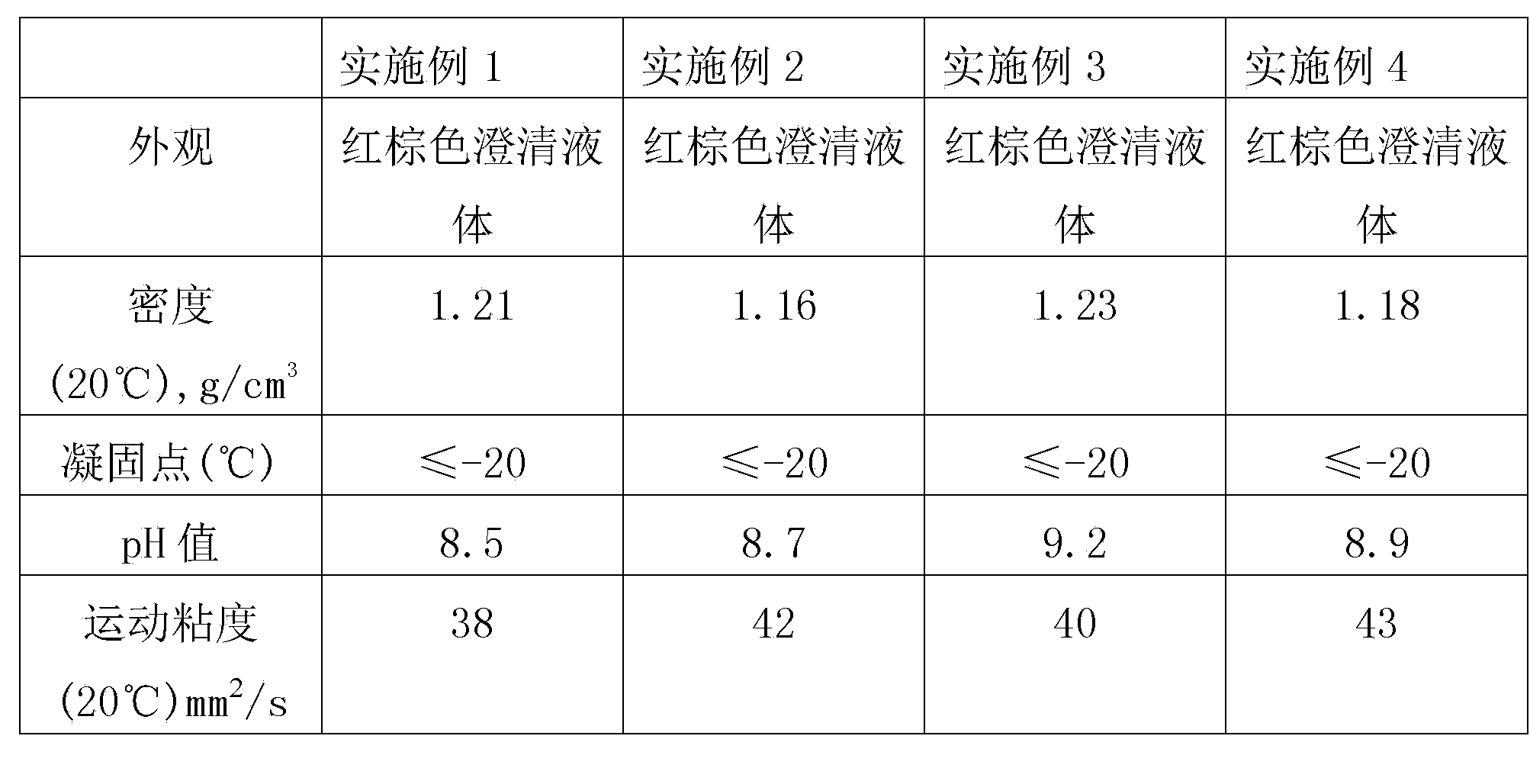

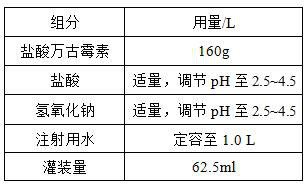

Preparation method of vancomycin hydrochloride freeze-dried powder injection for high-concentration injection

InactiveCN113101361AProtect from oxygenShorten the dissolution timeAntibacterial agentsPowder deliveryVancomycinumHigh concentration

The invention provides a preparation method of a vancomycin hydrochloride freeze-dried powder injection for high-concentration injection, which comprises the following steps: A, under a dark condition and at the temperature of 15-25 DEG C, adding a part of water for injection in a prescription dosage into a liquid preparation tank, and introducing N2 into water to dissolve oxygen which is less than 2 ppm; B, adding 150-180 parts by weight of vancomycin hydrochloride, and stirring until vancomycin hydrochloride is dissolved; C, adjusting the pH value to 2.5-4.5, reducing the temperature of the liquid medicine to 2-8 DEG C, and adding the remaining prescription dosage of water for injection to make the volume constant to 1000 parts by weight; and D, carrying out secondary sterilization and filtration by adopting a filter, filling, feeding and freeze-drying to obtain a finished product. The freeze-dried finished product is a large-specification product of 10g / bottle, has no layering problem and is high in stability.

Owner:KINDOS PHARM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com