A kind of metamaterial laminated board and preparation method thereof

A technology of metamaterials and laminates, applied in chemical instruments and methods, lamination, layered products, etc., can solve problems affecting the performance of laminates, layer failure, etc., to enhance stability, reduce thermal expansion stress, reduce metal The effect of the material carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

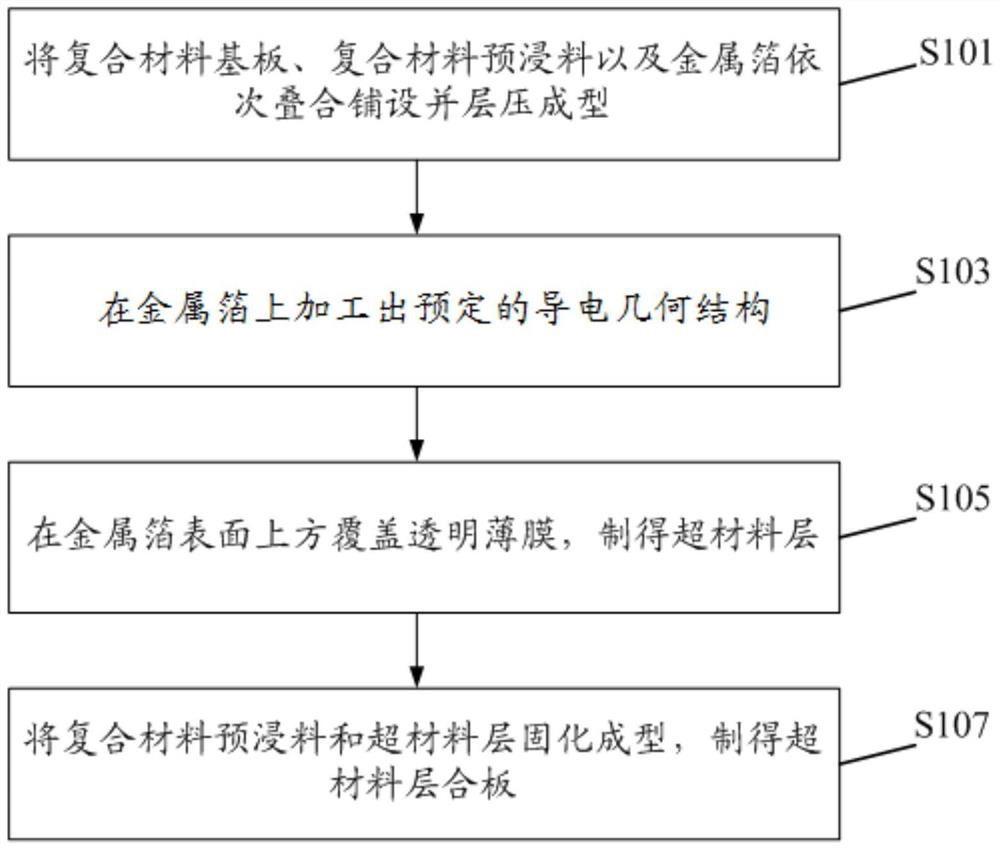

[0023] Fabrication method of metamaterial laminate

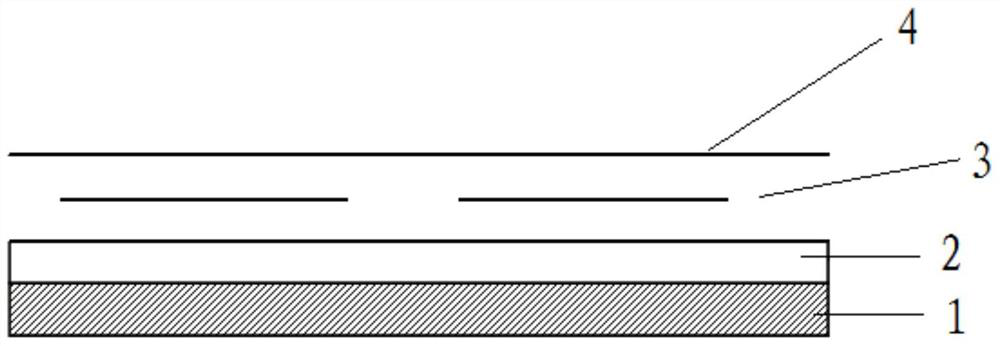

[0024] Such as figure 1 As shown in step S101 of , the composite material substrate, composite material prepreg and metal foil are laminated and laminated in sequence. In step S101 , lamination molding is performed at a temperature between 60° C. and 100° C., preferably, lamination molding is performed at a temperature between 80° C. and 100° C., which improves the efficiency of lamination molding. In step S101, use a hot roller press to implement lamination molding, and the pressure of the roller press is 2 to 30 kg / cm 2 , the rolling speed is 1-10m / min. In step S101 , the composite material substrate has a thickness of 0.5mm˜2mm. In step S101, the thickness of the composite material prepreg is 0.1mm-1mm.

[0025] Such as figure 1 As shown in step S103 of , a predetermined conductive geometric structure is processed on the metal foil. In step S103, a predetermined conductive geometric structure is processed on the met...

Embodiment 1

[0030] A composite material substrate with a thickness of 0.5 mm, a composite material prepreg with a thickness of 0.1 mm, and a silver foil with a thickness of 10 μm are laminated in sequence and laminated with a hot roller press at 80 ° C. 30kg / cm for roll pressure 2 , the rolling speed is 10m / min; laser engraving is used to process a predetermined conductive geometric structure on the silver foil; the surface of the silver foil is covered with transparent polyethylene terephthalate ( PET) release film to obtain a supermaterial layer; the composite material prepreg and the supermaterial layer are cured for 8 hours under the conditions of a pressure of -0.1MPa and a temperature of 260°C to obtain a supermaterial laminate.

Embodiment 2

[0032] A composite material substrate with a thickness of 2 mm, a composite material prepreg with a thickness of 1 mm, and a copper foil with a thickness of 200 μm are stacked in sequence and laminated with a hot roll press at 60 ° C. The roll pressure is The pressure is 18kg / cm 2 , the rolling speed is 5m / min; the predetermined conductive geometric structure is processed on the copper foil by micro-etching technology; the polyethylene terephthalate ( PET) release film to obtain a metamaterial layer, and the composite material prepreg and the metamaterial layer are cured for 5 hours under the conditions of a pressure of -0.6MPa and a temperature of 200°C to obtain a supermaterial laminate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com