Gasifying chamber spray gun for granular magnesium desulfurization

A gasification chamber and granular magnesium technology, applied in the field of gasification chamber spray guns for granular magnesium desulfurization, can solve the problems of refractory gun skirt working lining damage, fast slag sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

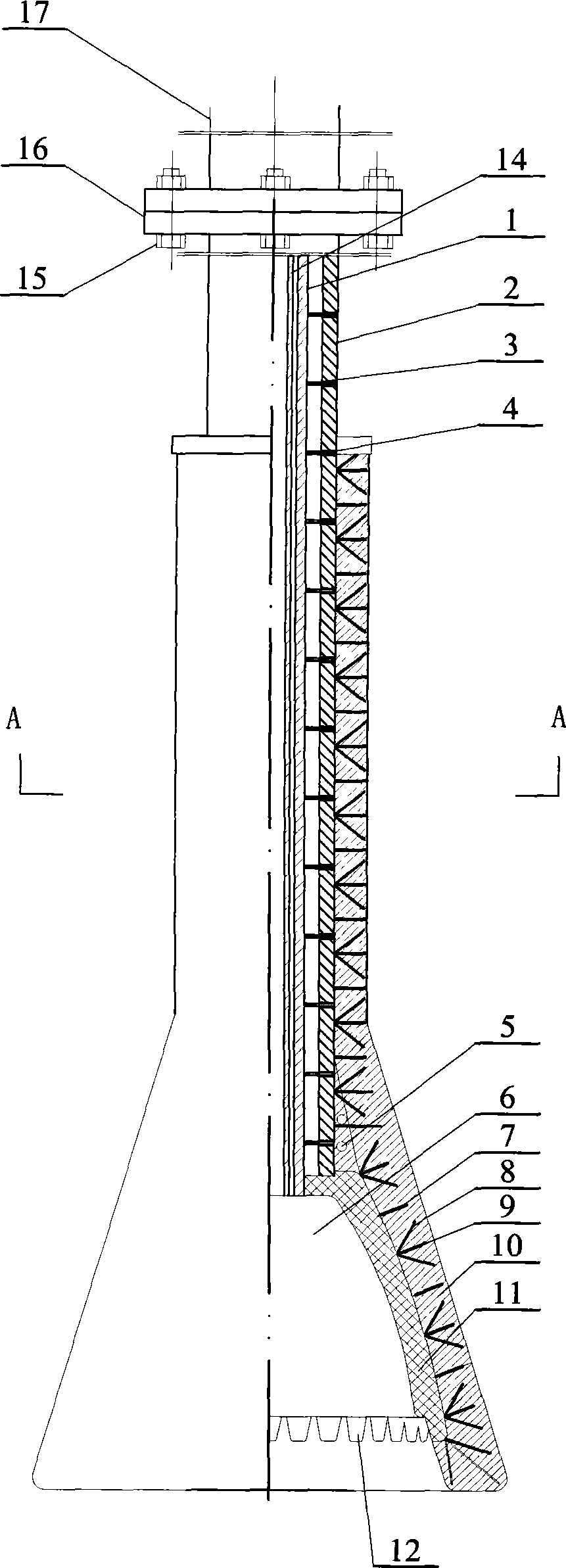

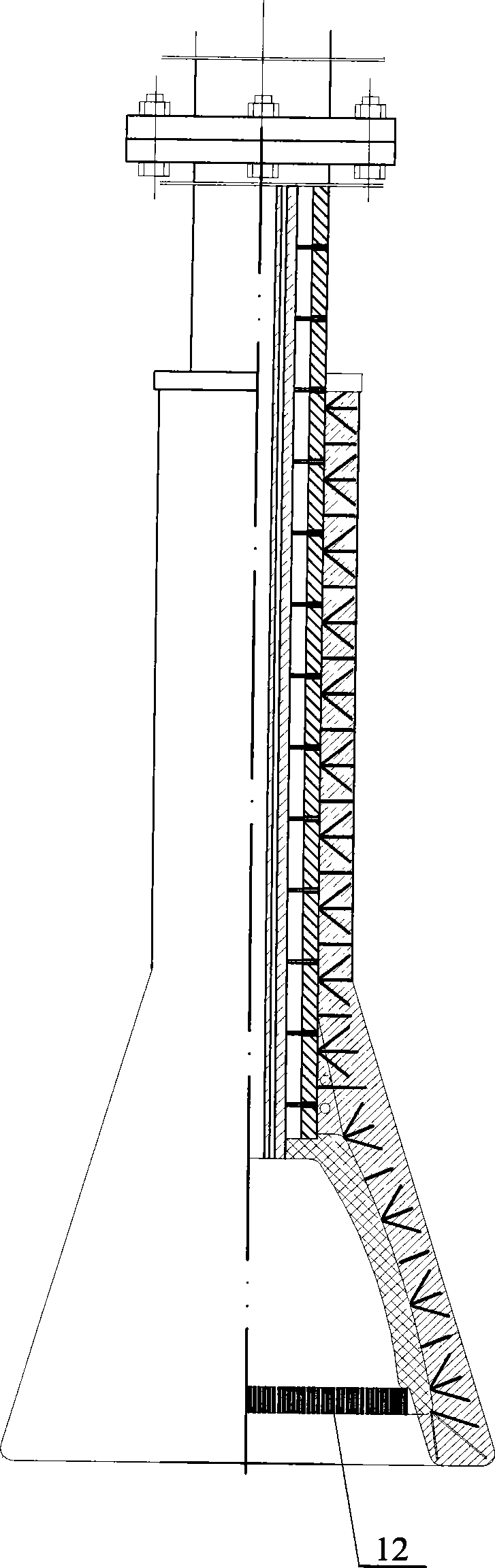

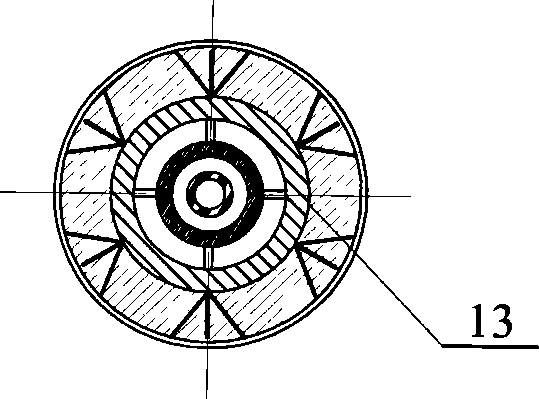

[0021] Such as figure 1 , figure 2As shown, the present invention comprises a metal gun core, and its upper end is provided with connecting flange 16, and spray gun is connected together with gun shaft 17 flanges by connecting bolt 15, and the lower end of metal gun core is provided with gasification chamber 6, and metal gun core The outer peripheral surface and the bottom surface of the steel pipe are covered with a refractory working lining 10, and the refractory working lining 10 is integrally casted with a refractory castable for a desulfurization spray gun with a patent number of ZL03118869.9; the metal gun core includes a main pipe 1, a reinforcing pipe 2 and several The bridging weldment 3, the main pipe 1 and the reinforcement pipe 2 are respectively made of ordinary carbon steel seamless steel pipes, the bridging weldment 3 is made of rebar, the reinforcement pipe 2 is set outside the main pipe 1, and a number of openings 4 are evenly arranged on its outer circumfere...

Embodiment 2

[0025] The difference between the present embodiment and the first embodiment is that several metal short cylinders are uniformly welded along the circumferential direction on the inner surface of the bottom skirt, and the metal short cylinders are rebars with a diameter of 18 mm.

[0026] The gasification chamber spray gun for granular magnesium desulfurization of the present invention has the following advantages:

[0027] 1. A gasification chamber spray gun for granular magnesium desulfurization of the present invention avoids direct contact between the slag washing water and the working lining of the refractory gun skirt, delaying the damage of the refractory gun skirt working lining and the burning of the bottom edge of the side wall of the gasification chamber 6 process.

[0028] 2. The present invention improves the anti-deformation ability of the side wall of the gasification chamber 6 by increasing the thickness of the bottom edge of the side wall of the gasification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com