Water-soluble high-temperature corrosion inhibitor

A high-temperature corrosion inhibitor and water-soluble technology, which is applied in the direction of corrosion/scaling inhibition of processing equipment, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problems of poor dispersion performance, elimination, unfavorable neutralization reaction, etc., and achieve good water solubility , the effect of preventing erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

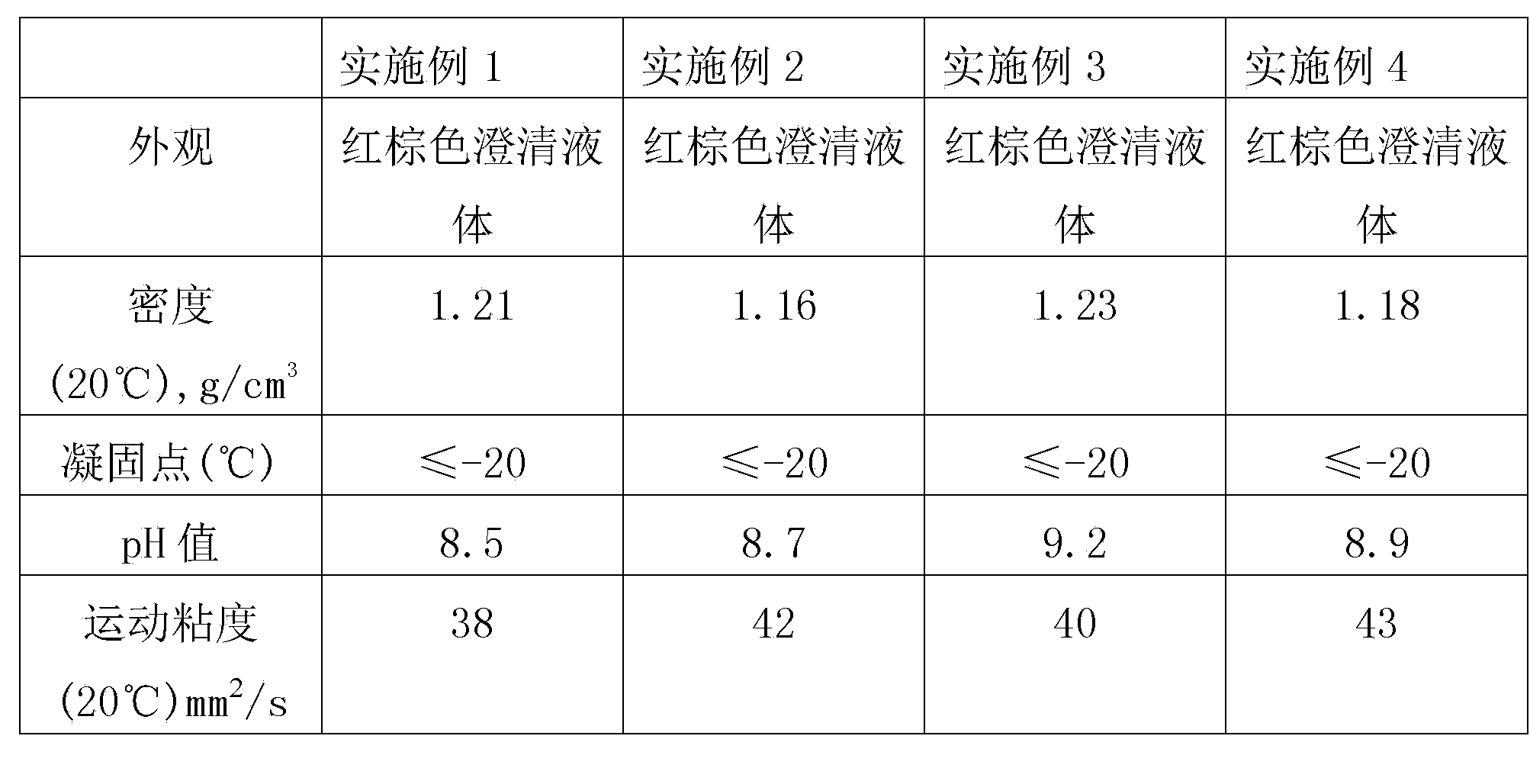

Examples

Embodiment 1

[0015] A water-soluble high-temperature corrosion inhibitor, composed of the following substances in mass percentage: 7.2% boric acid, 10.8% glycerin, 8.4% monoethanolamine, 30% sulfonated castor oil, and 43.6% water.

[0016] A kind of preparation method of water-soluble high-temperature corrosion inhibitor is:

[0017] (1) Preparation of anti-rust complex: Accurately weigh 120kg of water, 240kg of boric acid, and 360kg of glycerin in proportion to add to the reaction kettle, heat up to 50°C, add 280kg of monoethanolamine, then heat up to boiling, reflux for 2 hours, and then cool down to 46°C , Serve as anti-rust complex;

[0018] (2) Ingredients: pump 300kg of sulfonated castor oil and 300kg of the anti-rust complexing agent obtained in step (1) into the reactor, heat up to 100°C and stir for 30 minutes, cool down to 50°C, add 400kg of water, stir evenly to become water-soluble High temperature corrosion inhibitor.

Embodiment 2

[0020] A water-soluble high-temperature corrosion inhibitor, composed of the following substances in mass percentage: 6.5% boric acid, 10.3% glycerin, 7.9% monoethanolamine, 35% sulfonated castor oil, and 40.3% water.

[0021] A kind of preparation method of water-soluble high-temperature corrosion inhibitor is:

[0022] (1) Preparation of anti-rust complex: Accurately weigh 18kg of water, 65kg of boric acid, and 103kg of glycerin into the reactor, heat up to 50°C, add 79kg of monoethanolamine, then heat up to boiling, reflux for 2 hours, and then cool down to 48°C , Serve as anti-rust complex;

[0023] (2) Ingredients: pump 350kg sulfonated castor oil and 265kg anti-rust complexing agent obtained in step (1) into the reactor, heat up to 100°C and stir for 30 minutes, cool down to 50°C, add 385kg of water, stir evenly to become water-soluble High temperature corrosion inhibitor.

Embodiment 3

[0025] A water-soluble high-temperature corrosion inhibitor, consisting of the following substances in mass percentage: 7.5% boric acid, 11% glycerin, 8.1% monoethanolamine, 29% sulfonated castor oil, and 44.4% water.

[0026] A kind of preparation method of water-soluble high-temperature corrosion inhibitor is:

[0027] (1) Preparation of anti-rust complex: Accurately weigh 34kg of water, 75kg of boric acid, and 110kg of glycerin in proportion to add to the reaction kettle, heat up to 50°C, add 81kg of monoethanolamine, then heat up to boiling, reflux for 2 hours, and then cool down to 40°C , Serve as anti-rust complex;

[0028] (2) Ingredients: pump 290kg of sulfonated castor oil and 300kg of the anti-rust complexing agent obtained in step (1) into the reactor, heat up to 100°C and stir for 30 minutes, cool down to 50°C, add 410kg of water, stir evenly to become water-soluble High temperature corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com