Ferrous sulfate-antimony trisulfide composite liquid chromium removal agent as well as preparation method and application thereof

A technology of antimony trisulfide and ferrous sulfate, applied in the direction of improving process efficiency, etc., can solve problems such as unfavorable operator operation, unsatisfactory chromium reduction effect, unfavorable preservation and stability of chromium removal agent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

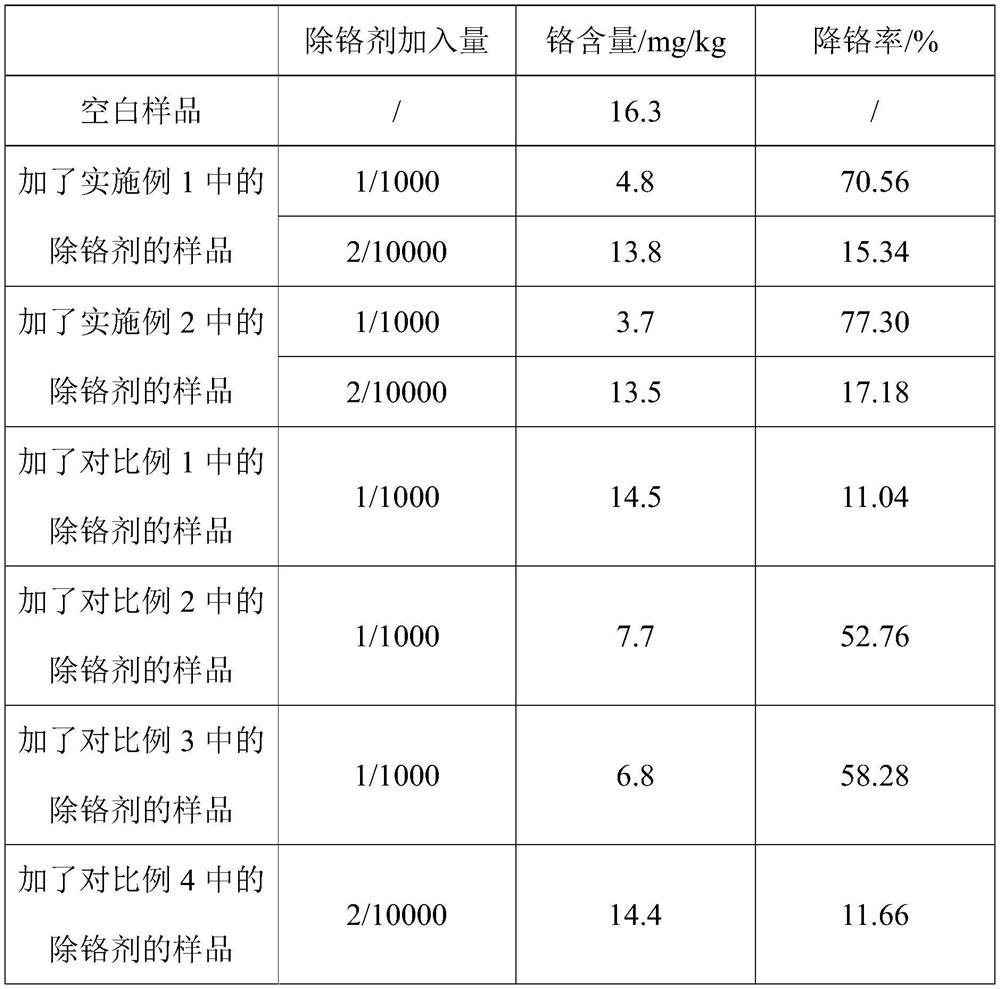

Examples

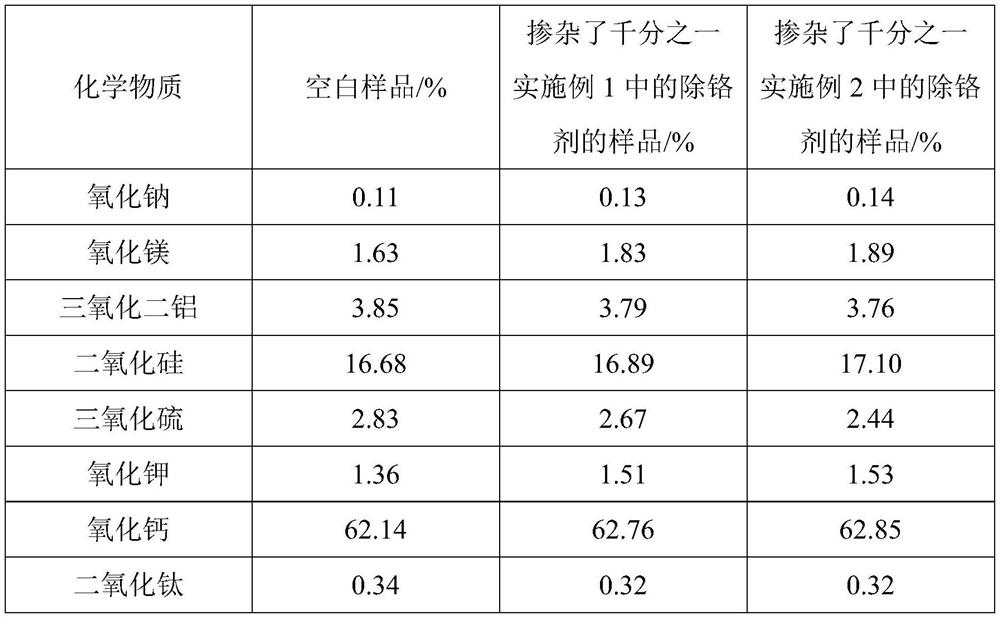

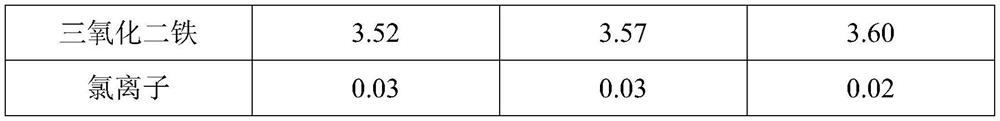

Embodiment 1

[0026] A ferrous sulfate-antimony trisulfide compound liquid chromium remover, which is composed of the following raw materials in mass percentage: 19% of ferrous sulfate heptahydrate, 13% of antimony trisulfide, 31% of water, and 5% of dimethyl sulfoxide , dextrin 32%.

[0027] The preparation method of described composite liquid chromium removal agent is:

[0028] A, formula quantity ferrous sulfate heptahydrate is dissolved in formula quantity water, obtains mixed solution one;

[0029] B, dissolving the antimony trisulfide of the formula quantity in the formula quantity dimethyl sulfoxide to obtain the mixed solution 2;

[0030] C. Add the mixed solution 2 into the mixed solution 1, stir evenly, then add the dextrin in the prescribed amount, and stir for 60 minutes to obtain the composite liquid chromium remover, which is a black pasty liquid.

Embodiment 2

[0032] A ferrous sulfate-antimony trisulfide composite liquid chromium remover, which is composed of the following raw materials in mass percentage: 18% of ferrous sulfate heptahydrate, 12% of antimony trisulfide, 31% of water, and 4% of dimethyl sulfoxide , dextrin 35%.

[0033] The preparation method of described composite liquid chromium removal agent is:

[0034] A, formula quantity ferrous sulfate heptahydrate is dissolved in formula quantity water, obtains mixed solution one;

[0035] B, dissolving the antimony trisulfide of the formula quantity in the formula quantity dimethyl sulfoxide to obtain the mixed solution 2;

[0036] C. Add the mixed solution 2 into the mixed solution 1, stir evenly, then add the dextrin in the prescribed amount, and stir for 60 minutes to obtain the composite liquid chromium remover, which is a black pasty liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com