Process for preparing strontium aluminate series luminescence material by self-spreading synthesis method

A technology of luminescent materials and synthesis methods, which can be used in luminescent materials, chemical instruments and methods, etc., and can solve the problems of high hardness of substances, limited application fields and application scope, and poor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

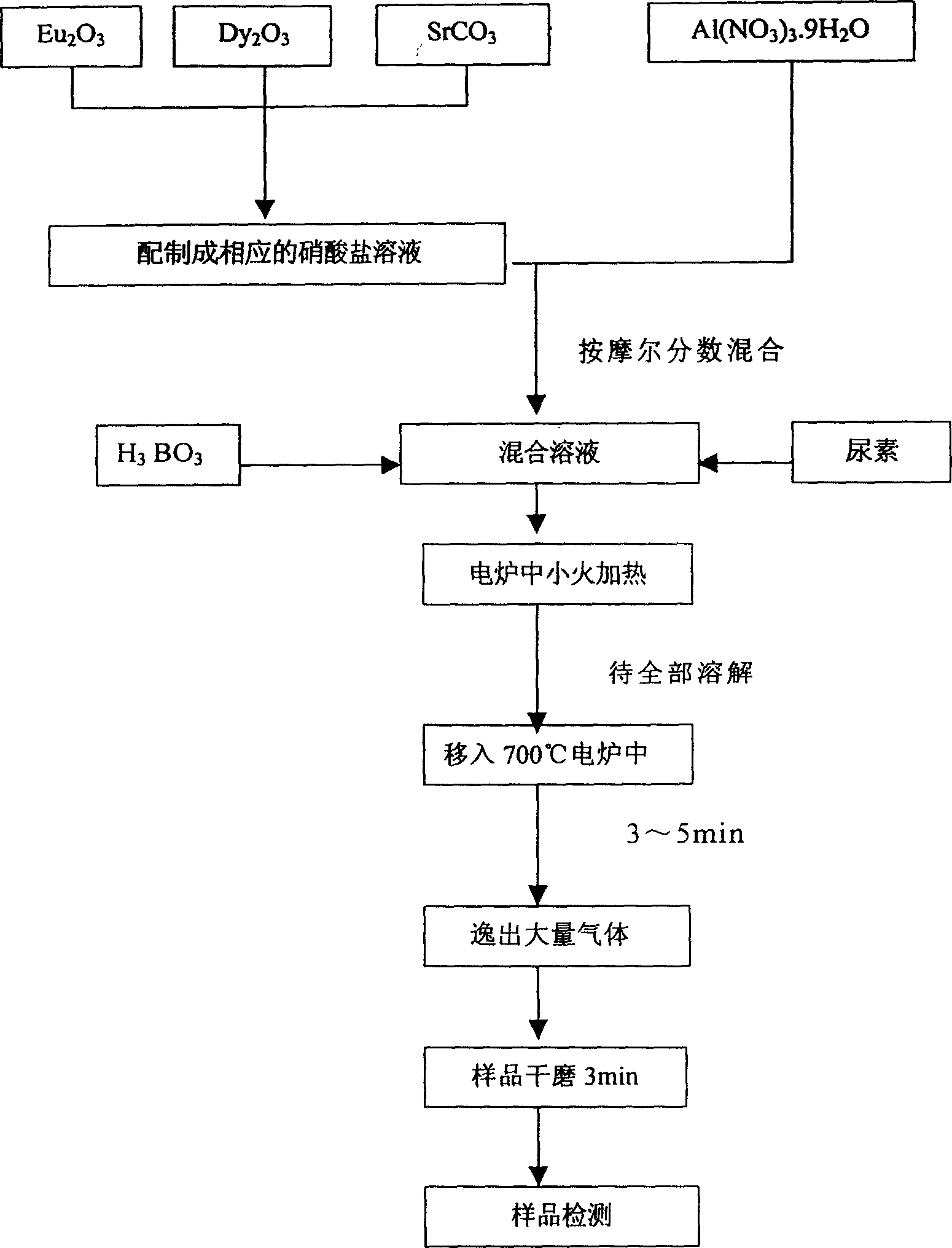

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0012] The process steps of preparing strontium aluminate-based luminescent materials by the self-propagating synthesis method of the present invention are as follows:

[0013] a. Add Eu 2 o 3 、Dy 2 o 3 , SrCO 3 Prepare a certain concentration of nitrate solution.

[0014] b. Mix the nitrate solution with Al(NO 3 ) 3 9H 2 O is mixed according to the ratio of Al / Sr=1.8-2.1 and 3.6-4.2, Eu and Dy ions are added in a ratio of 0.1-0.15 mol%, and then a certain amount of additive solution and urea are added to make a mixed solution. The additive solution can be boric acid (H 3 BO 3 ), borax, phosphorus pentoxide, phosphoric acid, its addition: boric acid (H 3 BO 3 ) or borax is 1-2mol%, phosphorus pentoxide (P 2 o 5 ) or phosphoric acid is 2-3mol%; the addition of this urea is 2.5-3.5W rationale.

[0015] c. Put the container containing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com