Method for preparing water-soluble high-temperature corrosion inhibitor

A high-temperature corrosion inhibitor, water-soluble technology, applied in the field of preparation of water-soluble high-temperature corrosion inhibitor, can solve the problems of elimination, secondary addition device influence, poor dispersion performance, etc., to prevent erosion, simple method, water-soluble Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

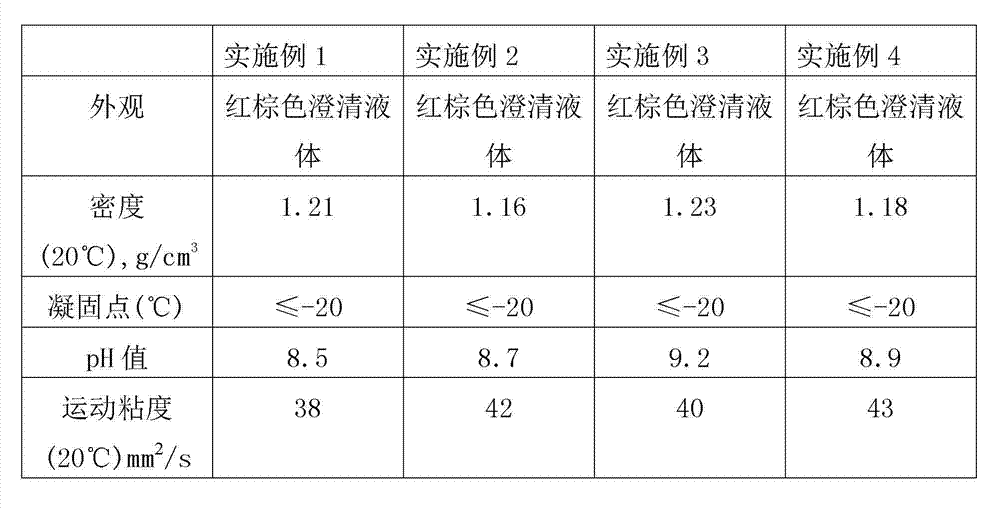

Examples

Embodiment 1

[0015] A water-soluble high-temperature corrosion inhibitor, composed of the following substances in mass percentage: 7.2% boric acid, 10.8% glycerin, 8.4% monoethanolamine, 30% sulfonated castor oil, and 43.6% water.

[0016] A kind of preparation method of water-soluble high-temperature corrosion inhibitor is:

[0017] (1) Preparation of anti-rust complex: Accurately weigh 120kg of water, 240kg of boric acid, and 360kg of glycerin in proportion to add to the reaction kettle, heat up to 50°C, add 280kg of monoethanolamine, then heat up to boiling, reflux for 2 hours, and then cool down to 46°C , Serve as anti-rust complex;

[0018] (2) Ingredients: pump 300kg of sulfonated castor oil and 300kg of the anti-rust complexing agent obtained in step (1) into the reactor, heat up to 100°C and stir for 30 minutes, cool down to 50°C, add 400kg of water, stir evenly to become water-soluble High temperature corrosion inhibitor.

Embodiment 2

[0020] A water-soluble high-temperature corrosion inhibitor, composed of the following substances in mass percentage: 6.5% boric acid, 10.3% glycerin, 7.9% monoethanolamine, 35% sulfonated castor oil, and 40.3% water.

[0021] A kind of preparation method of water-soluble high-temperature corrosion inhibitor is:

[0022] (1) Preparation of anti-rust complex: Accurately weigh 18kg of water, 65kg of boric acid, and 103kg of glycerin into the reactor, heat up to 50°C, add 79kg of monoethanolamine, then heat up to boiling, reflux for 2 hours, and then cool down to 48°C , Serve as anti-rust complex;

[0023] (2) Ingredients: pump 350kg sulfonated castor oil and 265kg anti-rust complexing agent obtained in step (1) into the reactor, heat up to 100°C and stir for 30 minutes, cool down to 50°C, add 385kg of water, stir evenly to become water-soluble High temperature corrosion inhibitor.

Embodiment 3

[0025] A water-soluble high-temperature corrosion inhibitor, consisting of the following substances in mass percentage: 7.5% boric acid, 11% glycerin, 8.1% monoethanolamine, 29% sulfonated castor oil, and 44.4% water.

[0026] A kind of preparation method of water-soluble high-temperature corrosion inhibitor is:

[0027] (1) Preparation of anti-rust complex: Accurately weigh 34kg of water, 75kg of boric acid, and 110kg of glycerin in proportion to add to the reaction kettle, heat up to 50°C, add 81kg of monoethanolamine, then heat up to boiling, reflux for 2 hours, and then cool down to 40°C , Serve as anti-rust complex;

[0028] (2) Ingredients: pump 290kg of sulfonated castor oil and 300kg of the anti-rust complexing agent obtained in step (1) into the reactor, heat up to 100°C and stir for 30 minutes, cool down to 50°C, add 410kg of water, stir evenly to become water-soluble High temperature corrosion inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com